Rapport - November 2009 - Unipart Rail

Rapport - November 2009 - Unipart Rail

Rapport - November 2009 - Unipart Rail

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

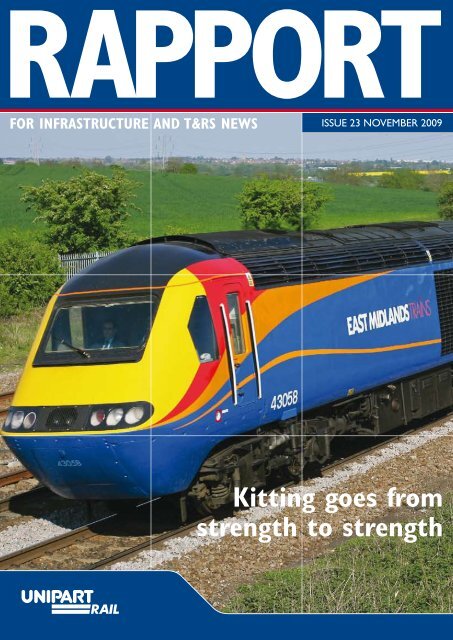

RAPPORT<br />

for Infrastructure and T&RS News<br />

ISSUE 23 NOVEMBER <strong>2009</strong><br />

Kitting goes from<br />

strength to strength

2 Traction and Rolling Stock Traction and Rolling Stock 3<br />

Inside this<br />

Issue…<br />

Traction and Rolling Stock<br />

<strong>Unipart</strong> <strong>Rail</strong> becomes OEM<br />

supplier to Siemens 2<br />

A move from spare parts<br />

provider to OEM supplier<br />

Improved Lighting sticks 3<br />

Dependable light when you need it most<br />

Value Added Service – Kitting 4<br />

East Midlands Trains improves<br />

productivity with kitting<br />

A Partnership for the Supply of<br />

150 Bogies 5<br />

<strong>Unipart</strong> <strong>Rail</strong> and LH Group enter<br />

a new relationship for Class 150<br />

C4 bogie overhaul work<br />

<strong>Unipart</strong> Expert Practices in Australia 6<br />

<strong>Unipart</strong> <strong>Rail</strong> Expert Practices supports<br />

<strong>Rail</strong>Corp’s CI programme<br />

<strong>Unipart</strong> <strong>Rail</strong> and 3M 6<br />

A new partnership offering the<br />

full range of 3M rail products<br />

Product & Service Solutions 8 & 9<br />

CCTV bespoke design DVR<br />

replacement and Vehicle Movers<br />

New Directors for <strong>Unipart</strong> <strong>Rail</strong> 10<br />

Welcome to our new T&RS<br />

Engineering Director and Business<br />

Development Director (DACH)<br />

Infrastructure<br />

Kitting Services for Balfour Beatty 11<br />

A remote warehouse kitting service<br />

to support electrification work<br />

New Framework Contracts with<br />

Network <strong>Rail</strong> 12<br />

New contracts for the supply of<br />

Cables, Relay’s, LED Signal Heads<br />

and Banner Heads<br />

Consultants to the Crossrail Project 13<br />

<strong>Unipart</strong> <strong>Rail</strong> provides logistics consultancy<br />

Let building Commence 13<br />

New 4-REB control centre<br />

for London Underground<br />

More New Products 14<br />

New innovations for the railway system,<br />

latest developments in Point Heating<br />

Electrification Improvements 15<br />

Expanding the range of products &<br />

services for Overhead Line Equipment<br />

& Third <strong>Rail</strong> Electrification<br />

<strong>Unipart</strong> Group<br />

Ambassador Role for<br />

Chief Executive 16<br />

John Neill is appointed as HRH The Prince<br />

of Wales’Ambassador for the South East<br />

Hat Trick of Gold Awards 16<br />

<strong>Unipart</strong> awarded ‘Gold Status’ in BITC’s<br />

Corporate Responsibility Index<br />

<strong>Unipart</strong> <strong>Rail</strong> becomes OEM to Siemens<br />

For many years, <strong>Unipart</strong> <strong>Rail</strong> has been one of Britain’s most important logistic<br />

service providers for the rail aftermarket, and has more recently been actively<br />

establishing itself within the world-wide rail aftermarket as both a spare<br />

parts provider and an OEM supplier.<br />

This move towards becoming an OEM The success of these projects led to both<br />

supplier was started by <strong>Unipart</strong> <strong>Rail</strong> companies discussing more long-term<br />

manufacturing ‘niche’ products to provide partnerships, which has culminated in<br />

the rail industry with reliable, high quality <strong>Unipart</strong> <strong>Rail</strong> and Siemens jointly entering<br />

products at competitive prices. Against a framework agreement to provide ‘niche’<br />

fierce competition, <strong>Unipart</strong> <strong>Rail</strong> won products such as E-APC Receivers AWS/<br />

orders from Siemens Germany to provide TPWS and DRA units to Siemens’ entire<br />

E-APC Receivers to Siemens’ West UK fleet. The <strong>Unipart</strong> <strong>Rail</strong> team was led by<br />

Midlands Franchise and Mumbai projects. Sven Busche, Paul Jolly and Tom Monk.<br />

The first 350/2 comes off the production line. Photo courtesy of London Midland ©<strong>2009</strong>.<br />

To check product quality and safety<br />

standards, Siemens audited <strong>Unipart</strong> <strong>Rail</strong>’s<br />

site in Crewe twice. The first audit in<br />

2008 focused on general manufacturing<br />

skills, project management capabilities and<br />

logistical expertise. In June <strong>2009</strong> Siemens<br />

returned to Crewe for the first article<br />

inspection concentrating on the quality<br />

of the first batch of ‘niche’ products.<br />

Siemens was delighted to see such a good<br />

combination of technical rail know-how,<br />

logistical capabilities, project management<br />

skills and product quality. <strong>Unipart</strong> <strong>Rail</strong><br />

started delivering its first ‘niche’ products<br />

in July <strong>2009</strong> for Siemens’ Scot<strong>Rail</strong> project.<br />

This framework agreement represents<br />

a major step change, from spare parts<br />

provider to OEM supplier demonstrating<br />

<strong>Unipart</strong> <strong>Rail</strong>’s commitment to improved<br />

safety and enhanced quality in the rail<br />

industry over many years.<br />

...a major step<br />

change, from<br />

spare parts<br />

provider<br />

to OEM<br />

supplier...<br />

Emergency<br />

Lighting<br />

Sticks<br />

POWERFUL, PORTABLE,<br />

RELIABLE light that<br />

produces no heat,<br />

flames or sparks.<br />

Working in partnership with Cyalume<br />

Technologies, <strong>Unipart</strong> <strong>Rail</strong> is now<br />

distributing a range of evacuation lighting<br />

products.<br />

Order the New 10” system which<br />

replaces the 6” one NOW!<br />

4 Provides safety and reassurance<br />

4 360º light for four hours<br />

4 Easy to install and maintain<br />

4 GM/RT2130<br />

4 Reach compliant EC N° 1907/2006<br />

4 EN ISO 9001: 2000<br />

EvacLight and EvacStations provide<br />

passengers with a feeling of safety and<br />

comfort as a visible aid in the event of<br />

lighting failure. Typically situated near the<br />

train exit, when the housing is opened, all<br />

the EvacLights within will be illuminated.<br />

Evacuees can remove the EvacLight and<br />

proceed with the evacuation process.<br />

Contact: trsenquiries@unipartrail.com<br />

to PLACE YOUR ORDER NOW or<br />

request an onsite demonstration, or view<br />

a video at www.unipartrail.com/cyalume<br />

Dependable<br />

light when<br />

you need it<br />

the most.<br />

...for Infrastructure and T&RS News from

4 Traction and Rolling Stock Traction and Rolling Stock 5<br />

Value added<br />

service for<br />

east midlands<br />

trains<br />

C6 kitting for HST<br />

fleet refurbishment<br />

At <strong>Unipart</strong> <strong>Rail</strong> we are constantly developing<br />

propositions that provide our customers with<br />

innovative product solutions and improvements in<br />

material supply that save them both time and money, adding<br />

considerable value to the service we offer.<br />

For many years, <strong>Unipart</strong> <strong>Rail</strong> has supplied complex kits of parts<br />

to our customers. Using robust material forecasting and planning<br />

ensures that all components involved in a kit are purchased and<br />

tailored to individual customer’s specification.<br />

Kitting offers train operators many benefits including:<br />

4 Reducing procurement activity (one catalogue number only!)<br />

4 Optimisation of storage and subsequent decanting of<br />

individual components<br />

4 Significant reductions in time and cost associated with the<br />

management of various components, often from several<br />

suppliers e.g. expediting.<br />

The result - much improved productivity at the depot<br />

<strong>Unipart</strong> <strong>Rail</strong>’s rigorous quality system ensures that the kits are<br />

produced correctly and in accordance with the customer’s bill<br />

of material with every stage of the kitting process being quality<br />

controlled to ensure 100% conformity.<br />

In order to support the refurbishment of their fleet of HST<br />

vehicles, East Midlands Trains (EMT) has chosen to use a “onestop-shop”<br />

strategy for the supply of the C6 materials and<br />

has contracted <strong>Unipart</strong> <strong>Rail</strong> to supply this in kit form. Project<br />

Manager for EMT, Chris Elliott says, “We have chosen <strong>Unipart</strong> <strong>Rail</strong><br />

because we believe that they can deliver a good service at a very<br />

competitive price.”<br />

The project will see a total of 94 vehicle kits delivered by <strong>Unipart</strong><br />

<strong>Rail</strong> over the next 12 months, each kit being delivered on a “justin-time”<br />

basis.<br />

Photography by Richard Gennis<br />

“We have<br />

chosen<br />

<strong>Unipart</strong> <strong>Rail</strong><br />

because we<br />

believe that<br />

they can deliver<br />

a good service<br />

at a very<br />

competitive<br />

price”.<br />

Chris Elliott,<br />

Project Manager for EMT<br />

New Bogie partnership<br />

<strong>Unipart</strong> <strong>Rail</strong> and LH Group<br />

Services have been furthering<br />

their relationship to win bogie<br />

overhaul work, and in July <strong>2009</strong> they<br />

were awarded a contract for Class 150,<br />

C4 Overhaul work. The contract was for<br />

a quantity of 150 bogies over a period of<br />

two years starting at the end of July.<br />

Both companies had strengths and<br />

capabilities in different areas; <strong>Unipart</strong> <strong>Rail</strong><br />

had the expertise in the disassembly and<br />

reassembly of the bogies and in producing<br />

a high quality product, and LH Group<br />

Services (LHGS) were experts in producing<br />

quality and competitive DMU wheelsets.<br />

Both companies agreed that to link the two<br />

areas of capability together would make a<br />

very competitive quality proposition.<br />

Michael Isaac, Group Commercial and<br />

Financial Director of LH Group Services,<br />

said, “I was very impressed with the<br />

process that <strong>Unipart</strong> <strong>Rail</strong> offered, for<br />

LH it was almost the first time perfect<br />

solution, in that they had a float of bogies<br />

available so we were able to offer clean,<br />

quality product to the customer’s delivery<br />

requirements, with little risk of late delivery.<br />

I was very impressed with the bogie unit.<br />

Clearly the unit is set up to deliver large<br />

quantities of bogies very quickly. This is<br />

a relationship and a style of working we<br />

can look to take forward, we have already<br />

submitted a second bid in partnership with<br />

<strong>Unipart</strong> <strong>Rail</strong>, and we hope to submit more<br />

bids in the future.”<br />

Since the <strong>Unipart</strong> <strong>Rail</strong> Production Bogie<br />

Unit (PBU) was opened in 2007, the team<br />

has worked very hard to standardise<br />

the method of introducing new bogie<br />

work into the unit. When the PBU was<br />

established, the process took two weeks to<br />

service bogies from rolling stock. By using<br />

key metrics of Quality, Cost and Delivery<br />

(QCD) alongside the methodology of the<br />

<strong>Unipart</strong> Way tools, the PBU team has been<br />

able to come up with a new process which<br />

enables them to achieve the overhaul of<br />

bogies in a much leaner time-scale. Within<br />

the process it highlights any risks and<br />

opportunities associated with the order,<br />

thus ensuring the end deliverables of QCD.<br />

Les Hobson, Manufacturing Director,<br />

<strong>Unipart</strong> <strong>Rail</strong>, summarised the Continuous<br />

Improvement initiatives of the bogie<br />

overhaul facility, “Through using the tools<br />

and techniques of the <strong>Unipart</strong> Way and<br />

the development of our people, we have<br />

been able to create new processes to not<br />

only overhaul bogies to new specifications,<br />

but within hugely reduced time frames.<br />

This means we can be confident of<br />

offering a consistent, high quality bogie<br />

overhaul service to meet varying customer<br />

requirements.”<br />

<strong>Unipart</strong> <strong>Rail</strong> and LHGS are confident<br />

that by continuously improving and<br />

working through a joint partnership,<br />

further bogie contracts can be won,<br />

and would welcome any enquiries via<br />

trsenquiries@unipartrail.com.<br />

...for Infrastructure and T&RS News from

6 Traction and Rolling Stock Traction and Rolling Stock 7<br />

Expert Practices in Sydney<br />

<strong>Unipart</strong> Expert Practices in<br />

Sydney is pleased to announce<br />

a major contract secured to<br />

support <strong>Rail</strong>Corp NSW.<br />

<strong>Rail</strong>Corp is responsible for delivering,<br />

maintaining and providing a safe and<br />

reliable rail service throughout the Sydney<br />

metropolitan area and rural New South<br />

Wales.<br />

The contract is to support <strong>Rail</strong>Corp’s<br />

Continuous Improvement programme.<br />

David Fillipetto, <strong>Rail</strong>Corp Director of Lean<br />

Six Sigma, explains what they were aiming<br />

to achieve and why <strong>Unipart</strong> was the<br />

Complete rail solutions from <strong>Unipart</strong> <strong>Rail</strong> and 3M<br />

<strong>Unipart</strong> <strong>Rail</strong> and 3M <strong>Rail</strong> Solutions<br />

have forged a partnership that<br />

will make it quicker and easier<br />

for train operating companies to order<br />

the full range of 3M products for the<br />

rail industry.<br />

3M has been producing products for<br />

the UK rail industry for over 80 years,<br />

providing innovative, cost effective<br />

solutions for virtually every aspect<br />

of rolling stock refurbishment and<br />

maintenance. Now, with this new<br />

partnership with <strong>Unipart</strong> <strong>Rail</strong>, customers<br />

can access 3M’s wide range of solutions<br />

and capabilities for rail refurbishment,<br />

maintenance and operations under one<br />

point of contact.<br />

successful bidder. “<strong>Rail</strong>Corp is embracing<br />

the Lean and Six Sigma philosophies as key<br />

drivers of organisational change. The goal<br />

is to improve asset reliability and make<br />

processes more efficient. The rolling stock<br />

division is at the forefront of implementing<br />

these tools to drive workplace reform and<br />

ensure that it can meet the challenges of<br />

maintaining assets to the highest standard.<br />

He went on: The review of the Supply<br />

Chain, utilising the expertise of <strong>Unipart</strong><br />

will go a long way to satisfying these goals.<br />

It is intended to make the process of<br />

providing parts flow better to the right<br />

Using <strong>Unipart</strong> <strong>Rail</strong> as a single supplier<br />

for all 3M rail products will significantly<br />

reduce and simplify your supply chain. You<br />

will no longer have to deal with multiple<br />

deliveries from different suppliers at<br />

different times. This will be replaced with<br />

one contact for all deliveries. Materials<br />

and supplies for each job can be delivered<br />

in one batch with no waiting around for<br />

individual items. With next day delivery<br />

available on most items, you can minimise<br />

downtime and cut the cost of your<br />

refurbishment programmes.<br />

3M <strong>Rail</strong> Solutions and <strong>Unipart</strong> <strong>Rail</strong> now<br />

have the joint capability to provide a<br />

solution for almost any problem; from<br />

absorbing to abrading, bonding to buffing,<br />

place at the right time, making peoples’<br />

jobs easier and getting trains back into<br />

service quicker. We are looking forward to<br />

the outcomes of this review.”<br />

After an extensive interview process<br />

<strong>Rail</strong>Corp selected Tony Metcalfe from<br />

<strong>Unipart</strong> to support delivery of the<br />

improvement activities. He was chosen for<br />

his extensive knowledge in Lean, his track<br />

record in Lean implementation and his 22<br />

years experience in the rail industry.<br />

“My role within the contract is to deliver<br />

process improvements and knowledge<br />

transfer, utilising the tools and techniques<br />

of the <strong>Unipart</strong> Way and Lean.”<br />

The first project was to improve a<br />

logistics process at Hornsby Maintenance<br />

Depot. Using a number of Lean tools a<br />

baseline was agreed and waste identified<br />

within the current process. The <strong>Unipart</strong><br />

Way tools used included:<br />

4 Value Stream Mapping<br />

4 Process Trials<br />

4 Layout and Work Sequence<br />

4 7 Wastes<br />

4 Insight Stars<br />

levelling to lighting, matting to moisture<br />

blocking, securing to signage and weight<br />

reduction to wrapping; responding to<br />

issues such as branding, protection, energy<br />

management, total cost of ownership,<br />

passenger experience and vandalism. One<br />

stop to keep you on track!<br />

With <strong>Unipart</strong> <strong>Rail</strong> and 3M you can feel<br />

confident that you’re dealing with a<br />

partnership with an unrivalled track<br />

record of supporting the UK rail industry.<br />

To obtain further details of the 3M<br />

proposition please contact Carl Agar,<br />

Head of Product Marketing, 01302 731419<br />

or email trsenquiries@unipartrail.com<br />

Future State workshops were then held<br />

to establish a new way of working. The<br />

members of the workshop all worked<br />

within the current process and had over<br />

200 years of rail experience. After training,<br />

the team established a future state that<br />

was then trialed and later implemented.<br />

To ensure the future state was sustained<br />

the team used Standard Operating<br />

Procedures and adopted <strong>Unipart</strong>’s<br />

Workplace Audit process.<br />

Stop Press:<br />

Contract Extension<br />

It has just been announced that <strong>Unipart</strong><br />

has secured an extension to the current<br />

contract that will see Tony working with<br />

<strong>Rail</strong>Corp well into 2010. As part of the<br />

extension, Tony will be engaging two<br />

additional <strong>Rail</strong>Corp depots and numerous<br />

depot staff.<br />

For further information on any of the<br />

<strong>Unipart</strong> Way tools mentioned in this<br />

article, or to discuss how <strong>Unipart</strong> can play<br />

part in your future success, please contact<br />

Karen Beardsley on 01302 731507.<br />

Exhibiting<br />

Stateside<br />

<strong>Rail</strong>way Systems Suppliers<br />

Inc (RSSI) – Nashville,<br />

Tennessee, May <strong>2009</strong><br />

In May, <strong>Unipart</strong> <strong>Rail</strong> participated<br />

at RSSI in Nashville, Tennessee,<br />

a specialist show which is only<br />

open to RSSI members. As a result,<br />

everyone who attends has a very<br />

specific interest in <strong>Rail</strong>way Signalling<br />

– one of <strong>Unipart</strong> <strong>Rail</strong>’s core skills<br />

operated through Dorman. The<br />

opening reception and gala dinner<br />

were attended by over 900 people and<br />

Dorman was welcomed as the only<br />

overseas exhibitor.<br />

...for Infrastructure and T&RS News from

8 Traction and Rolling Stock Traction and Rolling Stock 9<br />

Back-off!<br />

Reduce the risk of back injuries<br />

with <strong>Unipart</strong> <strong>Rail</strong>’s Vehicle Movers<br />

<strong>Unipart</strong> <strong>Rail</strong>’s Vehicle-Movers offer a simple but effective<br />

solution for the safe movement of loose wheelsets,<br />

bogies and vehicles up to 60t in weight. Ideal for<br />

use in depots, workshops and sidings, the Vehicle-Movers are<br />

simple to use and can be operated by a single person.<br />

4 Safely moves vehicles of up to 60 tonne (t) in weight<br />

4 Suitable for wheel diameters between 600mm – 1000mm<br />

diameter<br />

4 Excellent for moving bogies and loose wheelsets<br />

4 Great for moving vehicles small distances to jacking points or<br />

over pits without the need to power-up the vehicle<br />

4 Reduces the risk of injury from manual handling issues and<br />

industrial accident claims<br />

4 Simple to use and store<br />

The Vehicle-Movers effectively reduce the risk from manual<br />

handling issues – more than a third of all over-three-day injuries<br />

reported to the HSE and local authorities are caused by manual<br />

handing issues, i.e. the transporting or supporting of loads by<br />

hand or by bodily force. *<br />

*source http://www.hse.gov.uk/pubns/indg143.pdf<br />

To obtain further details or a site visit and demonstration please<br />

contact Kevin Orton, <strong>Unipart</strong> <strong>Rail</strong>’s Business Development<br />

Manager on 07801 798988 or trsenquiries@unipartrail.com<br />

UK’s leading disc pad supplier - latest quality approval success<br />

<strong>Unipart</strong> <strong>Rail</strong>’s partner in the supply<br />

of disc brake pads, Becorit GmbH,<br />

has recently become the first<br />

friction material supplier to be accredited<br />

according to the International <strong>Rail</strong>way<br />

Industry Standard (IRIS).<br />

IRIS is unique to the railway industry<br />

and intends to extend the ISO 9001<br />

quality standard. Promoted by UNIFE and<br />

supported by both system integrators<br />

and equipment manufacturers, this<br />

initiative is modelled on similar quality<br />

standards already in place in the aerospace,<br />

automotive and food industries.<br />

IRIS intends to develop and establish an<br />

internationally recognised standard that<br />

encompasses the actual evaluation process,<br />

as well as an audit and scoring methodology.<br />

Having been the first supplier to gain<br />

accreditation to the <strong>Unipart</strong> <strong>Rail</strong> Technical<br />

Dossier (UTD) five years ago, this latest<br />

award coincides with Becorit’s successful<br />

audit against UTD version 2, and reinforces<br />

Becorit’s position within the UK rail friction<br />

market.<br />

Steve Morris, Becorit’s UK Business Manager<br />

says, “The amount of work associated with<br />

achieving the IRIS certification should not<br />

be underestimated. Similar to the RISAS<br />

scheme adopted by a number of UK<br />

manufacturers, IRIS is focused on the railway<br />

industry and therefore much more relevant<br />

to suppliers such as ourselves.<br />

He added, “The Becorit team headed by<br />

our Quality Manager Dr Jurgen Lehr, should<br />

be congratulated in this achievement. I am<br />

confident that this will lead to benefits for<br />

our worldwide customer base including<br />

our key UK customer, <strong>Unipart</strong> <strong>Rail</strong>,<br />

going forward.”<br />

This approval complements Becorit’s<br />

success in introducing a new disc pad<br />

material, 922-1U, into the market. The<br />

project has been running for a number of<br />

years and this material now covers the<br />

majority of pad demand in the UK. As a<br />

result of moving to 922-1U material, a<br />

large number of train operating companies<br />

have reduced the Life Cycle Cost (LCC) of<br />

braking and benefitted from using a more<br />

environmentally friendly material due to<br />

Antinomy Trisulphide not being used in its<br />

formulation. George Tillier, <strong>Unipart</strong> <strong>Rail</strong>’s<br />

Sales & Customer Service Director said,<br />

“Becorit’s success in obtaining the IRIS<br />

accreditation is a further recognition for this<br />

innovative and highly environmentally aware<br />

partner supplier. Over the past few years,<br />

together we have introduced a new material<br />

which not only significantly reduces train<br />

operator’s Life Cycle Costs, but ensures<br />

maintenance staff are working in a safe<br />

environment.”<br />

winning solutions<br />

for CCTV on Trains<br />

<strong>Unipart</strong> <strong>Rail</strong> and DVRX, a leading CCTV manufacturer, have joined forces to<br />

launch a bespoke design DVR replacement to train operators, ROSCOs and<br />

train manufacturing companies.<br />

<strong>Unipart</strong> <strong>Rail</strong> has recognised that a large<br />

number of rail vehicle CCTV systems have<br />

service and reliability problems. Some<br />

original suppliers are no longer in business<br />

or have been acquired by larger and more<br />

diverse companies. This in turn has led<br />

to constraints on parts supply, lead-time<br />

availability and high replacement costs.<br />

<strong>Unipart</strong> <strong>Rail</strong>’s proposition solves these<br />

inherent problems.<br />

The rail environment is as harsh and as<br />

hostile as it can get for CCTV:-<br />

4 Extreme temperatures<br />

4 High vibration<br />

4 Volatile and wide ranging DC<br />

power sources<br />

4 Volatile Electrical Earth conditions<br />

4 Electro Magnetic Compatability<br />

(EMC) and (RFI) emissions<br />

4 Extreme wet / dry conditions.<br />

It’s no surprise that developing and<br />

producing a robust CCTV proposition<br />

that can deal with these conditions is<br />

a challenge for any company. <strong>Unipart</strong><br />

<strong>Rail</strong> has however found a solution. By<br />

partnering with DVRX, (our UK design,<br />

manufacturing and systems integration<br />

company with a great reputation for<br />

quality and reliability, and who exclusively<br />

specialise in CCTV solutions for the<br />

transport industry) we have developed an<br />

exceptional product and service offering<br />

that addresses the current problems faced<br />

in a very cost effective way.<br />

DVRX is one of only a few product<br />

providers worldwide that have the<br />

expertise and global certifications to meet<br />

the demanding standards of both rail and<br />

automotive regulators.<br />

<strong>Rail</strong><br />

4 EMC - EN 50121-2-3:2006<br />

4 EN 50155:2006 Class A & B<br />

Automotive<br />

4 EMC EC 95/54<br />

4 >Sept 2007 (Directive 2004/108/EC)<br />

The <strong>Unipart</strong> <strong>Rail</strong> / DVRX solution has<br />

been developed to deliver to customers:<br />

4 Simple change-over solutions,<br />

eliminating the need for re-wiring and<br />

extensive installations<br />

4 Bespoke design and plug ‘n’ play<br />

functionality to match existing<br />

footprints and meet or exceed<br />

current performance<br />

4 Extreme cost effectiveness.<br />

The solution will provide customers with<br />

the lowest total cost of ownership over<br />

the life of their CCTV investment, and<br />

therefore deliver a very strong business<br />

case to support a good return on their<br />

investment.<br />

Initially this launch will focus on UK <strong>Rail</strong><br />

operators and ROSCOs but it is expected<br />

to expand rapidly into Europe and other<br />

international territories.<br />

For further details on this exciting new<br />

and innovative CCTV proposition contact:<br />

Carl Agar, Head of Product Marketing,<br />

01302 731419, or email trsenquiries@<br />

unipartrail.com<br />

...for Infrastructure and T&RS News from

10 Traction and Rolling Stock Infrastructure 11<br />

New T&RS Engineering Director Business<br />

Following the recent retirement of David Astill, <strong>Unipart</strong><br />

<strong>Rail</strong> has appointed Mike Roe as Traction and Rolling<br />

Stock (T&RS) Engineering Director based in Doncaster.<br />

Mike is a Chartered Engineer with over 30 of the team and<br />

years’ experience in the field of traction we are currently<br />

& rolling stock and in his new role he will working on some<br />

be responsible for leading engineering key projects: -<br />

strategy and product development for 4 Development of<br />

<strong>Unipart</strong> <strong>Rail</strong>’s large portfolio of T&RS technical forums<br />

parts and services.<br />

with key TOC’s & ROSCO’s, including<br />

Mike, a practitioner of Kaizen and Lean obsolescence management<br />

manufacturing, has held senior positions 4 Working with major Suppliers in<br />

in the rail industry including relevant defect root cause analysis, and product<br />

train operations and vehicle overhaul and reliability improvements<br />

refurbishment. He joins <strong>Unipart</strong> <strong>Rail</strong> from<br />

4 Leading <strong>Unipart</strong> <strong>Rail</strong>’s next stage of<br />

Wabtec <strong>Rail</strong> where he was Engineering<br />

RISAS level 2 approvals”<br />

Director.<br />

Mike shall be writing in future editions<br />

Mike commented, “I am delighted to have<br />

of <strong>Rapport</strong> to update on the progress of<br />

joined <strong>Unipart</strong> <strong>Rail</strong> at this important time<br />

these projects.<br />

in the rail industry. I have been impressed<br />

by the professionalism and commitment<br />

DIFFICULT ECONOMIC TIMES FOR SUPPLIERS<br />

In the last edition of <strong>Rapport</strong><br />

Steve Tonks, <strong>Unipart</strong> <strong>Rail</strong>’s T&RS<br />

Procurement Director, wrote an<br />

article showing how the economic<br />

downturn was impacting on suppliers to<br />

<strong>Unipart</strong> <strong>Rail</strong>. Six months further on Steve<br />

updates <strong>Rapport</strong> on the latest position.<br />

Well, it certainly has not got better!!!<br />

Since the last article we have experienced<br />

a further three suppliers going into<br />

administration. As a result of our<br />

management of the situation there was<br />

no interruption of material supply. We<br />

need to ensure continuity of supply to<br />

our customers, and recognise the need to<br />

safeguard the supply chain, we are closely<br />

monitoring all of our suppliers. To assist this<br />

monitoring process we have developed a<br />

‘watch list’ of suppliers who we believe are<br />

vulnerable in the current economic climate.<br />

Currently we have 13 suppliers on this<br />

‘watch list’ who have been included for a<br />

number of reasons:<br />

4 Shortage of work due to cancellations of<br />

orders from customers in markets other<br />

than <strong>Rail</strong><br />

4 Looking to pull orders forward from<br />

<strong>Unipart</strong> <strong>Rail</strong> due to a general lack of work<br />

4 Chasing early payments<br />

4 Delivering material at least a few weeks<br />

early hoping <strong>Unipart</strong> <strong>Rail</strong> pay them early<br />

We have identified individual strategies<br />

for each of these 13 suppliers, including<br />

contingency plans should they not be able<br />

to supply at some stage in the future.<br />

There are increasing numbers of suppliers<br />

who are experiencing difficulties due to<br />

the current economic recession and we at<br />

<strong>Unipart</strong> <strong>Rail</strong> continue to face more demands<br />

upon us to ensure continuity of supply to our<br />

customers. Wherever possible, we are assisting<br />

suppliers in difficulty and we recognise we<br />

have a valuable role to play in managing these<br />

issues for the foreseeable future.<br />

Development<br />

Director<br />

(DACH Region)<br />

<strong>Unipart</strong><br />

<strong>Rail</strong> is<br />

pleased<br />

to announce the<br />

appointment<br />

of Business<br />

Development<br />

Director, Neil<br />

Tinworth for<br />

Germany, Austria and Switzerland<br />

(DACH) Region.<br />

Neil was formerly Technical Services<br />

Director with the European rail vehicle<br />

lessor, Angel Trains International, where he<br />

had responsibility for the management of<br />

over 400 locomotives and multiple units.<br />

Previously working in Western Europe with<br />

Roland Berger, Booz Allen Hamilton, and<br />

Siemens Transportation in Germany, Neil<br />

has an MBA, is a qualified engineer and a<br />

fluent German speaker.<br />

George Tillier, Sales and Customer Service<br />

Director of <strong>Unipart</strong> <strong>Rail</strong>, said, “We are<br />

delighted Neil has joined the <strong>Unipart</strong> <strong>Rail</strong><br />

team. His market knowledge, engineering<br />

and language skills will support and<br />

strengthen our presence in these key<br />

European rail markets. Neil’s personal<br />

commitment and enthusiasm will be<br />

invaluable in developing and delivering our<br />

propositions for the DACH region.”<br />

Neil commented, “I am delighted to be<br />

joining <strong>Unipart</strong> <strong>Rail</strong> at an important stage<br />

in its development. <strong>Unipart</strong> <strong>Rail</strong> has been<br />

providing quality goods and services to the<br />

rail industry in the United Kingdom for<br />

many years and I am sure that customers<br />

in Germany, Austria and Switzerland will<br />

be able to benefit from the experience and<br />

expertise that <strong>Unipart</strong> <strong>Rail</strong> possesses.”<br />

Kitting Services for Balfour Beatty<br />

Following the successful implementation of Remote Warehouse Supply Chain Management at the Ashford Signalling Stores<br />

for Balfour Beatty, <strong>Unipart</strong> <strong>Rail</strong> has now introduced a remote warehouse kitting service to support Balfour Beatty’s<br />

electrification work.<br />

The success of the signalling stores - He added, “As the pallets are transferred are now seeing the benefits.”<br />

covering around 1370 line items – led directly into our own vehicle at our <strong>Unipart</strong> <strong>Rail</strong>’s Service Covers:<br />

Balfour Beatty to ask <strong>Unipart</strong> <strong>Rail</strong> to depot, there is no need for unpacking and 4 Advance planning<br />

develop a new service to deliver full kits storage, eliminating potential errors which 4 Supplier management<br />

of palletised materials to each of their might occur through double-handling.” 4 Palletising and labelling to<br />

possessions in a ‘just-in-time-format’. Balfour Beatty’s Paul Martin, Acting<br />

customer requirement<br />

Dave Gibbs, <strong>Unipart</strong> <strong>Rail</strong>’s SCM Project ETM Manager, observed, “We previously 4 Just-in-time delivery<br />

Manager, said, “This kind of service is had supervisors identifying and picking 4 100% on-time delivery.<br />

perfect for <strong>Unipart</strong> <strong>Rail</strong>. Our position materials from our stocks for each piece<br />

in the supply chain means that we can of work. Now they can concentrate<br />

What is a possession?<br />

co-ordinate the materials precisely to the on the project itself, confident that the<br />

A possession is when a section of track is<br />

customers requirements and iron-out any materials will arrive precisely to meet<br />

taken out of service for trains to enable<br />

potential problems well in advance. With their needs. We have also been able to<br />

works to be completed. These usually<br />

just-in-time, we have to achieve 100% on significantly reduce our materials<br />

happen over-night, at weekends and<br />

time delivery, every time.”<br />

inventory.”<br />

on holidays. Possessions are limited in<br />

Working at least 12 weeks in advance of He finished by saying, “There is still some<br />

time, so need to run to a tight timetable<br />

each weekend possession, Steve Edwards, nervousness at handing the complete<br />

to ensure trains can resume running<br />

<strong>Unipart</strong> <strong>Rail</strong>’s Project Manager, attends a materials supply to <strong>Unipart</strong> <strong>Rail</strong>, but their<br />

on schedule.<br />

Balfour Beatty weekly planning meeting response so far has been positive and we<br />

where the schedule of materials are<br />

agreed. This enables Steve to identify any<br />

potential supply issues with key equipment<br />

and put resolutions in place before they<br />

become a problem.<br />

Working closely with <strong>Unipart</strong> <strong>Rail</strong>’s<br />

Inventory Management Team, the materials<br />

for the possessions are palletised in<br />

precisely the right way for the installation<br />

engineers to direct the pallets to the<br />

right part of the possession and, with<br />

everything being supplied for each element<br />

of the work being palletised together, the<br />

work of installation can progress smoothly<br />

and quickly.<br />

Mike Vaz, Territory Electrification Manager<br />

for Balfour Beatty, said, “This new service<br />

has been running since June and has<br />

enabled us to move from multi-supplier,<br />

multi-requisition and multi-deliveries<br />

to a single relationship and a single<br />

delivery each week. It has streamlined the<br />

materials supply process considerably.”<br />

...for Infrastructure and T&RS News from

12 Infrastructure<br />

<strong>Unipart</strong> <strong>Rail</strong> wins framework<br />

contracts with Network <strong>Rail</strong><br />

<strong>Unipart</strong> <strong>Rail</strong> has been awarded three Framework Contracts with Network <strong>Rail</strong> for the supply<br />

of <strong>Rail</strong>way Cables, LED Signal Heads and Relays.<br />

<strong>Rail</strong>way Cables<br />

<strong>Unipart</strong> <strong>Rail</strong> and Eland Cables are to play an important role in the<br />

development of Britain’s rail infrastructure, after <strong>Unipart</strong> <strong>Rail</strong> secured a<br />

three-year contract with Network <strong>Rail</strong> for the supply of cable.<br />

The contract to supply electrical cables and related services to Network <strong>Rail</strong>, awarded<br />

in June, involves a collaboration between the two leading suppliers in the rail industry.<br />

The decision follows more than a decade of successful joint working between Eland<br />

Cables and <strong>Unipart</strong> <strong>Rail</strong> – most notably on the West Coast Route Modernisation<br />

(WCRM) project. With Network <strong>Rail</strong> Framework Supplier status, rail customers can<br />

benefit from competitive pricing, guaranteed stockholding and immediate availability<br />

on a huge range of rail cables and accessories – including <strong>Rail</strong> Signalling Cables and <strong>Rail</strong><br />

Telecoms Cables.<br />

Eland Cables and <strong>Unipart</strong> <strong>Rail</strong>’s latest move serves to reinforce what is already a<br />

strong working relationship between the two companies. In a joint statement, Managing<br />

Directors Philip Brown and Graham Jackson said, “The decision to collaborate over the<br />

Network <strong>Rail</strong> bid was not a difficult one to make.<br />

By combining Eland Cables’ supplier relationships,<br />

technical knowledge and sourcing expertise with<br />

<strong>Unipart</strong> <strong>Rail</strong>’s logistics and materials management<br />

experience, we can give rail customers more choice<br />

and even more competitive prices – while continuing<br />

to deliver fast turnaround times and a consistently<br />

high level of service.”<br />

Relays<br />

A new Cable Handbook has been published<br />

and is now available – find out more at<br />

www.unipartrail.com/elandcable<br />

where you can order your personal copy.<br />

<strong>Unipart</strong> <strong>Rail</strong>’s experience in supplying relays<br />

is second to none, and the new Network <strong>Rail</strong><br />

Framework Contract for the supply of BR930 relays<br />

recognises our central role in the supply chain supporting<br />

their projects and maintenance work.<br />

Under the three year contract, Network <strong>Rail</strong> and its Contractors<br />

are able to call-off their requirements under the Framework.<br />

The handy <strong>Unipart</strong> <strong>Rail</strong> ‘PinCode Look-up Charts can be<br />

found at www.unipartrail.com/catalogue.aspx<br />

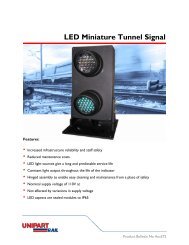

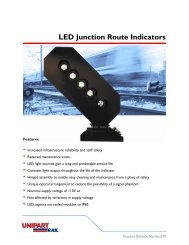

LED Signal Heads and<br />

Banner Signals<br />

<strong>Unipart</strong> <strong>Rail</strong> (Dorman) has been<br />

awarded a Framework Contract<br />

from Network <strong>Rail</strong> to supply<br />

Colour Light Signals and Banner Signals<br />

to the UK rail industry. Dorman,<br />

with its wide range of LED signalling<br />

products, is the market leader for<br />

LED signals.<br />

Innovation and the continued<br />

development of new technology has<br />

enabled Dorman to gain their market<br />

position and will enable the company to<br />

continue to be a significant player the UK<br />

rail industry.<br />

Mark Morse, Dorman Managing Director<br />

said, “The award of this contract<br />

recognises that the Dorman range of<br />

signal heads – of which over 20,000 have<br />

been installed – is key to ensure that the<br />

UK infrastructure continues to meet the<br />

needs of our modern world.”<br />

The current LED handbook can be<br />

downloaded from www.unipartrail.com/<br />

productinformation.aspx<br />

Consultants to the Crossrail Project<br />

Earlier in the year, <strong>Unipart</strong> <strong>Rail</strong><br />

was appointed to provide logistics<br />

consultancy to the Crossrail Project,<br />

as part of the Transcend Consortium. In<br />

this article we explain what this means.<br />

What is Crossrail?: Improving the cross<br />

London rail system was first suggested<br />

in the 1989 ‘Central London <strong>Rail</strong> Study’.<br />

Parliamentary approval was finally achieved in<br />

2008 when the Crossrail Act received Royal<br />

Assent giving Crossrail Ltd the permission for<br />

the £15.9 bn railway to be built.<br />

It will be the largest single addition to the<br />

London transport network for 50 years and<br />

the largest engineering project in Europe<br />

covering:<br />

4 The modification of about 119km of railway<br />

from Maidenhead in Berkshire to Shenfield<br />

and Abbey Wood in Essex<br />

4 The building of 23km of sub surface railway<br />

via two new six metre tunnels under<br />

London, connecting the City to Canary<br />

Wharf, the West End, Heathrow Airport<br />

and commuter areas east and west of<br />

London<br />

4 The building of seven new stations<br />

4 The transportation of 200 million people<br />

each year, relieving pressure on the<br />

underground system.<br />

Crossrail Ltd is a wholly owned subsidiary of<br />

Transport for London (TfL). The Secretary of<br />

State for Transport and the Mayor of London<br />

are joint sponsors of the Crossrail project.<br />

To manage this project, tenders were issued<br />

for a ‘Programme Partner’ and a ‘Project<br />

Delivery<br />

Partner’ in late<br />

2008. It was<br />

through this<br />

process that<br />

<strong>Unipart</strong> was<br />

offered the<br />

opportunity to<br />

become active in supporting a Joint Venture<br />

(JV) known as ‘Transcend’ which was one of<br />

a number of parties bidding for the role of<br />

Programme Partner. The key members of<br />

the Transcend JV were the AECOM multidisciplinary<br />

engineering consultancy and<br />

CH2M Hill with the Nichols Group.<br />

Why we are involved: It was the Nichols<br />

Group Chairman who invited <strong>Unipart</strong><br />

Let building commence!<br />

<strong>Unipart</strong> <strong>Rail</strong> is highly experienced<br />

in delivering fully kitted<br />

Relocatable Equipment Buildings<br />

(REBs), but as a development of this<br />

experience, York Service Centre is<br />

building a new 4-REB control centre<br />

for London Underground’s Neasden<br />

improvement works, being undertaken<br />

by Thales Signalling Solutions.<br />

Ordinarily, the REBs would be delivered<br />

into the York facility and wired there.<br />

However, due to the volume of work<br />

currently in-progress, an innovative<br />

approach for this work was created, which<br />

means that the REBs have been delivered<br />

into our Doncaster site, and the work will<br />

be undertaken there instead.<br />

The four REBs arrived in August and were<br />

off-loaded using a specialist crane. The<br />

fitting out will take place throughout the<br />

autumn and is due to be completed by the<br />

end of October in time for delivery to site<br />

Infrastructure 13<br />

to participate, given our track record<br />

in excellent supply chain expertise and<br />

experience coupled to that of deep<br />

knowledge of the rail industry. <strong>Unipart</strong>’s initial<br />

focus was to design and develop a proposal<br />

for the logistics function with the other<br />

Transcend team members to offer a superior<br />

package of services and expertise essential<br />

for the new Crossrail team to tackle this<br />

complex project. A joint team was formed to<br />

support the Transcend bid team from <strong>Unipart</strong><br />

Expert Practices and <strong>Unipart</strong> which was<br />

successful in being awarded the contract by<br />

Crossrail with a rapid mobilisation in March<br />

<strong>2009</strong>.<br />

The future: We are now developing<br />

the logistics plan for Crossrail and will<br />

increasingly be working with Crossrail<br />

Central (a team comprising Bechtel, Halcrow<br />

and Systra), the Programme Delivery Partner<br />

to ensure the project starts on schedule.<br />

Preparatory works will continue throughout<br />

<strong>2009</strong> with the main Crossrail construction<br />

starting in 2010. Crossrail is scheduled to<br />

open for service in 2017.<br />

in December.<br />

In addition, 53 track-side control cabinets<br />

will be manufactured at <strong>Unipart</strong> <strong>Rail</strong><br />

Crewe for the Neasden project.<br />

...for Infrastructure and T&RS News from

14 Infrastructure<br />

Infrastructure 15<br />

More new product<br />

introductions!<br />

preparing for Winter<br />

Bringing new innovations into the market is key to ensuring the railway<br />

system is as safe and efficient as possible.<br />

There has been a great deal of activity in the Infrastructure Procurement and<br />

The variances of the UK winter<br />

(and in particular the effect<br />

this can have on the smooth<br />

Expanded Portfolio and Kitting<br />

Options<br />

<strong>Unipart</strong> <strong>Rail</strong> has now expanded its range<br />

New Point Heating Handbook<br />

The new <strong>Unipart</strong> <strong>Rail</strong> Point Heating<br />

Handbook is now available and offers<br />

Engineering departments, identifying new materials for our infrastructure customers.<br />

operation of the rail network) make it<br />

of products relating to Point Heating and<br />

at a glance, listings of every component<br />

Below is a sample of some of these new products, as well as links to more information<br />

essential that systems are in place to<br />

offers a “one-stop-shop” option for all<br />

used in fitting point layouts - including<br />

on the website.<br />

ensure that ice and snow do not disrupt<br />

products required to carry out a complete<br />

the option of selecting a kit of parts for<br />

TPWS Multi-Meter<br />

The Fluke 287 TPWS Multi-Meter is the ONLY Network<br />

<strong>Rail</strong> approved meter with the necessary functionality for<br />

taking safety-critical measurements on track-side TPWS<br />

systems. This supersedes the Fluke 187 TPWS Meter.<br />

http://www.unipartrail.com/WebPDF/ProductBulletins/<br />

D221.pdf<br />

the movement of the point switches<br />

that are critical to train movements.<br />

The UK rail network is therefore being<br />

progressively fitted or updated with the<br />

latest developments in Point Heating and<br />

<strong>Unipart</strong> <strong>Rail</strong> is well positioned to support<br />

this initiative.<br />

Point Heating installation. To further<br />

assist customers, kits of parts have been<br />

introduced as an option so complete<br />

packages of equipment arrive on-site<br />

ready for installation. This has the added<br />

bonus of simplifying the ordering process<br />

for our customers.<br />

OHLE Height and Stagger Gauge<br />

The new Height and Stagger Gauge for UK track gauge is fabricated from lightweight<br />

aluminium making it easily transportable as well as being robust enough to withstand<br />

trackside use.<br />

http://www.unipartrail.com/WebPDF/ProductBulletins/363.pdf<br />

TrakRat Trolleys<br />

A new range of manually operated rail<br />

maintenance trolleys, complete with disc<br />

brakes for greater control.<br />

http://www.unipartrail.com/WebPDF/<br />

ProductBulletins/351.pdf<br />

Polymer Cable Trough<br />

Less than a quarter the weight of the concrete<br />

equivalent, this new range of troughing is<br />

designed to connect seamlessly with existing<br />

concrete troughs.<br />

http://www.unipartrail.com/WebPDF/<br />

ProductBulletins/354.pdf<br />

Electrification Improvements<br />

any particular length of switch or type of<br />

rail. The handbook also provides both<br />

options of self regulating or constant<br />

wattage installations.<br />

The service available also guarantees<br />

that all components available are<br />

from up to date approved sources of<br />

manufacture. Customers requiring their<br />

own particular kitting of parts for their<br />

specific project needs can also have<br />

bespoke kits provided.<br />

For a personal copy of the Point Heating<br />

Handbook, please e-mail your name and<br />

address to enquiries@unipartrail.com.<br />

<strong>Unipart</strong> <strong>Rail</strong> is extending its<br />

support and services to<br />

customers in respect of both<br />

Overhead Line Equipment and Third <strong>Rail</strong><br />

Electrification.<br />

A Project Team set up at the start of <strong>2009</strong><br />

and involving customers, manufacturers<br />

and suppliers has progressively expanded<br />

the range of products and services<br />

available.<br />

An already comprehensive database of<br />

electrification part numbers and the cross<br />

matches between Network <strong>Rail</strong> PADS<br />

catalogue numbers, Overhead Line part<br />

numbers and Assembly Drawings has been<br />

built upon and is now providing customers<br />

with information that allows them to be<br />

supported by speedy and detailed pricing<br />

and availability data either by spreadsheet<br />

or traditional quotation methods.<br />

Improved stockholdings<br />

Project Team discussions with customers<br />

have already led to the significant growth<br />

of the product range offered along<br />

with investment in stockholding of the<br />

electrification range of materials to<br />

specifically ensure that the key materials<br />

are available when required.<br />

Just in time deliveries<br />

Further development has seen the<br />

introduction of ‘work packages’ where the<br />

materials for specific sites are packaged<br />

together and delivered as a complete<br />

inventory of all materials for the individual<br />

area of work. This aids customers through<br />

single drop deliveries of all materials at<br />

pre-agreed dates and times that minimise<br />

local storage and lessens the risk of<br />

losses at site. <strong>Unipart</strong> <strong>Rail</strong> understands<br />

that space on site can be limited and the<br />

package option can be significant in best<br />

usage of this space.<br />

The Electrification Project Team is made<br />

up of Procurement Experts, Technical<br />

Support, Commercial Manager and Stock<br />

Controllers and further development of<br />

the support and services continues.<br />

...for Infrastructure and T&RS News from

16 <strong>Unipart</strong> Group<br />

<strong>Unipart</strong> Scores Hat trick of gold awards<br />

For the third time, Business in the<br />

Community has awarded <strong>Unipart</strong><br />

“gold status” in its Corporate<br />

Responsibility Index, the UK’s leading<br />

benchmark for responsible business. This<br />

places <strong>Unipart</strong> amongst some of the top<br />

companies in the world.<br />

According to BiTC, top companies<br />

demonstrate clear commitments to<br />

improve continually in four key areas:<br />

Environment, Community, Workplace,<br />

Marketplace.<br />

<strong>Unipart</strong> had to be assessed and score<br />

highly in each of the categories, showing<br />

its maintenance of the balance between<br />

environmental, workplace and social<br />

performance.<br />

Stop Press:<br />

<strong>Rapport</strong> going Greener!<br />

If you would prefer to read a greener copy<br />

of <strong>Rapport</strong> in 2010, then please send your<br />

details to: trsenquiries@unipartrail.com<br />

Our contribution counts!<br />

Contact us…<br />

For further information about any of<br />

the services or products described in<br />

this edition of <strong>Rapport</strong> please contact<br />

<strong>Unipart</strong> <strong>Rail</strong> on 01302 731400 or<br />

trsenquiries@unipartrail.com<br />

<strong>Unipart</strong> <strong>Rail</strong> Ltd, Jupiter Building,<br />

First Point, Balby Carr Bank,<br />

Doncaster DN4 5JQ<br />

www.unipartrail.com<br />

<strong>Rapport</strong> is produced for <strong>Unipart</strong> <strong>Rail</strong> by:<br />

Verve Creative Solutions, <strong>Unipart</strong> House<br />

Garsington Road, Cowley, Oxford OX4 2NG.<br />

Developing our People<br />

“It is really a story of how a company can<br />

create a set of values and then bring them<br />

to life through the day-to-day actions of<br />

our employees. From our earliest days of<br />

opening the <strong>Unipart</strong> U to our current<br />

training programmes that enable our<br />

people to become qualified as ‘expert<br />

practitioners’, <strong>Unipart</strong> has put great store<br />

in the belief that learning and problem<br />

solving are fundamental to engaging<br />

people. Our corporate responsibility<br />

programmes reflect that philosophy and<br />

extend it to our key stakeholders.”<br />

Waste Recycling and Energy Savings<br />

<strong>Unipart</strong> have more than 70 problem<br />

solving teams focused on reducing the<br />

company’s environmental impact, with one<br />

site aiming to completely eliminate landfill<br />

waste through recycling programmes.<br />

Another site has implemented so many<br />

energy saving solutions that it has become<br />

a showcase for energy saving<br />

technologies.<br />

“Across our group of companies, there<br />

are many <strong>Unipart</strong> people pursuing our<br />

corporate responsibility goals in the<br />

community, in our marketplaces and in<br />

environmental programmes,” said John<br />

Neill. “This third gold award is a great<br />

tribute to their efforts and our shared<br />

commitment to developing people within<br />

our company to excel in everything they<br />

do through training, coaching and a strong<br />

philosophy of continuous improvement<br />

that our people bring to life everyday.”<br />

Ambassador role for <strong>Unipart</strong><br />

Group Chief Executive<br />

John Neill, Chief Executive, <strong>Unipart</strong><br />

Group, has been appointed as<br />

HRH The Prince of Wales’ <strong>2009</strong><br />

Ambassador for the South East<br />

in recognition of his leadership and<br />

commitment to responsible business<br />

The Prince’s Ambassador Award is part<br />

of Business in the Community’s (BITC)<br />

Awards for Excellence <strong>2009</strong>, which<br />

recognises businesses for the positive<br />

impact they have on society.<br />

Andy Finch, Regional Director South East<br />

from BITC said: “In the current climate it’s<br />

never been more important for businesses<br />

to show their leadership when it comes to<br />

responsible business issues. I am delighted<br />

that John has been recognised by HRH<br />

The Prince of Wales, for the positive social<br />

impact that businesses and their leaders<br />

can bring to their communities.”<br />

At the BITC South East awards event,<br />

HRH The Prince of Wales said in a prerecorded<br />

message, “I am delighted that<br />

John Neill, Chief Executive <strong>Unipart</strong> Group,<br />

is my Ambassador for the South East this<br />

year. <strong>Unipart</strong>, under John’s stewardship,<br />

is a longstanding member of Business<br />

in the Community. John encourages<br />

his management team across the UK<br />

to participate in my Prince’s Seeing is<br />

Believing programme and he encourages<br />

<strong>Unipart</strong> graduates to participate in the<br />

CARES programme* to enhance their<br />

learning and skills.<br />

“John also frees his staff to work directly<br />

with local partners to enable economic<br />

development in schools and communities’<br />

organisations. John joined my BITC Board<br />

in 1992 and has been enthusiastic in his<br />

advice to inspire business. He will always<br />

challenge established thinking and believes<br />

that there is no substitute for seeing for<br />

yourself rather than reading reports.”<br />

(*a network of partner companies that<br />

address social issues in communities)