download - Radio Frequency Systems

download - Radio Frequency Systems

download - Radio Frequency Systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

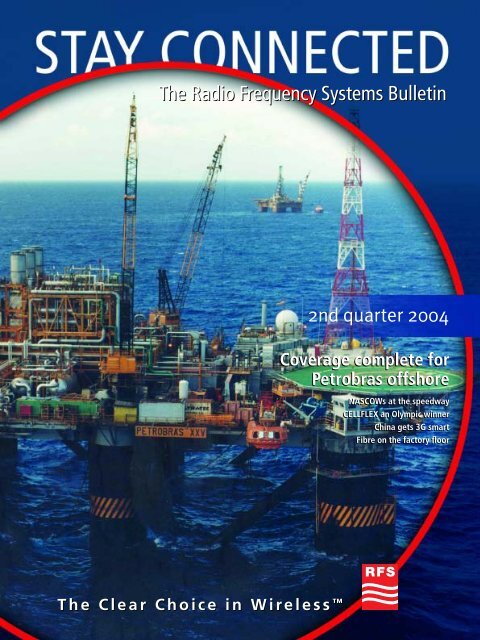

The <strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong> Bulletin<br />

2nd quarter 2004<br />

Coverage complete for<br />

Petrobras offshore<br />

NASCOWs at the speedway<br />

CELLFLEX an Olympic winner<br />

China gets 3G smart<br />

Fibre on the factory floor<br />

The Clear Choice in Wireless

2<br />

03 Editorial<br />

The new ‘killer app’: the family phone<br />

04 What’s New<br />

RADIAFLEX ‘A’ enhances<br />

confined coverage<br />

Optimizer cellular/PCS wins<br />

over 90 degrees<br />

RFS CompactLine suite complete<br />

at three-foot<br />

RFS Superturnstile turns heads<br />

06 Cover Story<br />

Coverage complete for<br />

Petrobras offshore<br />

09 Confined Coverage<br />

Fiber forms the factory floor<br />

cutting edge<br />

10 Feeder <strong>Systems</strong><br />

America applauds CELLFLEX ‘A’<br />

RFS reels off rural success in Sweden<br />

INDEX<br />

12 Regional Focus<br />

China gets 3G smart<br />

15 Microwave<br />

US public safety radio contract<br />

awarded to RFS<br />

16 Cellular<br />

NASCOWs at the speedway<br />

18 In Touch<br />

New RFS software tool aids<br />

microwave link design<br />

RFS backbone for Nigerian operator<br />

Focus on Asia in June 2004<br />

PLURAL and CELLFLEX a winner<br />

at Athens Olympics<br />

PREVIEW: Connections, corrugations<br />

and costs—the feeder cable debate<br />

<strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong><br />

WorldWideWeb:<br />

http://www.rfsworld.com<br />

Publisher: Jörg Springer<br />

Executive Editor/Editor Asia Pacific:<br />

Peter Walters<br />

Editor EMAI: Paul Newsome<br />

Editor Americas: Ann Polanski<br />

Managing Editor: Allan Alderson<br />

Production Editor: Christian Michatsch<br />

Art Director: Matthias Schwedt<br />

Authors: Allan Alderson, Dr Ellen Gregory<br />

Photos: RFS archives; Chris Adams; Blickpunkt<br />

Photodesign; Getty images; Thomas Kähler;<br />

C. Mayhew & R. Simmon (NASA/GSFC),<br />

(NOAA/NGDC), DSMP Digital Archive; Shelton<br />

Muller; Petrobras archives; Ann Polanski, Chloe Yao<br />

Cover images: Petrobras archives<br />

Cover art: Matthias Schwedt<br />

Print: Print Design, Minden<br />

Layout and Graphics:<br />

inform Advertising, Hannover<br />

Editorial Services:<br />

Relate Technical Communications, Melbourne<br />

Trademarks: CELLFLEX ® , BDA ® , FLEXWELL ® ,<br />

MicroTenna, Optimizer ® , RADIAFLEX ® ,<br />

<strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong> ® , RFS ® , RFS CompactLine ® ,<br />

SlimLine ® and The Clear Choice in Wireless are<br />

trademarks, service marks or registered trademarks<br />

of <strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong>.<br />

On the cover:<br />

One of 96 offshore oil production platforms owned<br />

and operated by oil and gas giant Petrobras,<br />

platform P25 is a semi-submersible oil platform located<br />

off Brazil’s north coast, in the deep waters<br />

of the Campos Basin.<br />

China gets 3G smart<br />

As the world’s largest mobile market<br />

enjoys healthy growth—and increasing competition—RFS<br />

provides 3G technology for<br />

extensive trials of W-CDMA, CDMA2000 and<br />

TD-SCDMA in three major cities.<br />

12<br />

6<br />

Coverage complete for Petrobras offshore<br />

Hundreds of kilometres from the Brazilian<br />

coastline, RFS helps oil and gas giant Petrobras<br />

realize a new industry standard in offshore<br />

platform deck-to-deck RF communications.<br />

16<br />

NASCOWs at the speedway<br />

New NASCAR series sponsor, Nextel Communications,<br />

deploys a groundbreaking mobile<br />

cellular coverage solution founded on RFS’s<br />

unique Optimizer RT remote tilt technology.<br />

Fibre forms the factory floor cutting edge<br />

A major saw blade manufacturer in Massachusetts<br />

enjoys the benefits of plantwide PCS<br />

reception, courtesy of a hybrid passive/active<br />

confined coverage solution from RFS.<br />

9<br />

PLURAL and CELLFLEX a winner<br />

at Athens Olympics<br />

<strong>Radio</strong> <strong>Frequency</strong> System’s Greek distribution<br />

partner, PLURAL, has been awarded the<br />

contract to provide the RF distribution system<br />

for mobile telephony coverage of the Athens<br />

Olympic Stadium—RFS’s CELLFLEX feeder<br />

cable will play a vital role.<br />

19

IMPRINT<br />

The new ‘killer app’:<br />

the family phone<br />

When, in the closing days of 2003, industry<br />

and media pundits began predicting high<br />

levels of churn in the US cellular market,<br />

the global cellular industry took a deep<br />

breath. The central issue was the ruling<br />

by the country’s Federal Communications<br />

Commission (FCC) to introduce local<br />

number portability (LNP), particularly from<br />

mobile-to-mobile. It was predicted that,<br />

when the legislation was passed in<br />

November 2003, there would follow<br />

huge waves of subscriber churn.<br />

As it turned out, these worries were<br />

unfounded. The country’s cellular<br />

operators, in the large, retained their loyal<br />

subscriber bases, and the resulting levels<br />

of churn were unexceptional.<br />

infrastructure offers enormous coverage<br />

reach at low cost, while delivering greater<br />

flexibility and functionality to the way<br />

people communicate.<br />

In the wake of the FCC’s limited fixedto-mobile<br />

LNP ruling, numerous market<br />

research groups have reported on the<br />

potential cellular subscriber growth this has<br />

unleashed, as consumers freely migrate to<br />

wireless as their primary connection. Digital<br />

communications market research group,<br />

In-Stat MDR, has reported that while US<br />

consumers using wireless as their primary<br />

connection currently only account for<br />

around 15 per cent of connections, around<br />

Yet the reality is that to-date, the newly<br />

liberated US subscriber hasn’t rushed to<br />

‘cut the cord’ to his or her landline. In<br />

essence, this is because the wireless market<br />

is not yet ready. Consumers today believe—<br />

perhaps justifiably in some markets—that<br />

landline still provides some intangible sense<br />

of ‘reliability’.<br />

Herein lies both opportunity and challenge<br />

for the wireless sector in all parts of the<br />

world. Almost all the market research<br />

shows that—while consumers are willing<br />

and in many cases keen to rationalize their<br />

communications to a wireless platform—<br />

price, network coverage and QoS are still<br />

viewed as reasons to retain the landline.<br />

<strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong> is committed to<br />

addressing the latter two, by providing the<br />

advanced RF solutions needed to achieve<br />

the advanced levels of coverage and QoS<br />

to support the progressive migration to<br />

‘wireless-only’. The secret to unleashing<br />

this next wave in subscription growth<br />

is network RF optimization. As a result,<br />

Dr Klaus-Dieter Mischerikow<br />

<strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong> President<br />

EDITORIAL<br />

3<br />

At the same time that the FCC ruled on<br />

mobile-to-mobile LNP, it also permitted<br />

restricted fixed-to-mobile LNP. From a<br />

global perspective, this is a far more<br />

interesting development, and one that<br />

regulators and industry groups around the<br />

world are watching very closely. While the<br />

FCC is the first to make such a landmark<br />

ruling (albeit in a limited sense), it is a clear<br />

indicator that other regulators and markets<br />

will eventually follow. Why? Because<br />

wireless technology can provide superior<br />

performance, convenience and services to<br />

those offered by legacy wireline—the<br />

future is wireless.<br />

The substitution of fixed communications<br />

with mobile is a real and growing<br />

phenomenon around the world. The<br />

number of mobile subscriptions in each<br />

country is increasing at a much faster rate<br />

than that of fixed lines. Economics and<br />

convenience are behind this trend: cellular<br />

one-quarter of the remainder have<br />

signalled a readiness to move from wireline<br />

to wireless.<br />

By 2008, it is predicted that close to<br />

one-third of US wireless subscribers will no<br />

longer have a landline connection. This<br />

represents a massive potential for wireless<br />

market growth, both in terms of raw<br />

subscriptions and ARPU.<br />

While the phenomenon of wireless subscriptions<br />

outstripping wireline connections<br />

is ‘old news’ for emerging markets such as<br />

China, Africa and India, it is a completely<br />

new concept in more established wirelinedominated<br />

markets such as Europe and<br />

North America. Clearly, the wireless<br />

markets in these areas are ripe for a new<br />

wave of growth, when legislators and<br />

regulators eventually permit similar<br />

subscriber number portability.<br />

operators are turning to RFS for a<br />

host of ‘smart’ filter, cable and antenna<br />

technologies, which boost the capabilities<br />

of existing systems while imparting<br />

flexibility to system design and operation.<br />

Adaptability of the network is also<br />

of paramount importance—networks increasingly<br />

need dynamic RF optimization<br />

tools that allow them to respond to<br />

surges in demand and variable subscriber<br />

load conditions.<br />

Since this optimizing methodology extends<br />

to every part of the RF chain, the days of<br />

just being an antenna vendor are over. Now<br />

operators are looking to partner with<br />

highly competent ‘engineering in RF’<br />

organizations, such as RFS. In this way, they<br />

are able to send an increasingly clear signal<br />

into people’s homes: the future will be<br />

wireless, and its ‘killer application’ will be<br />

the family phone line.<br />

Klaus-Dieter Mischerikow

RADIAFLEX ‘A’ enhances<br />

confined coverage<br />

In-building and in-tunnel wireless coverage<br />

is set to gain from the latest radiating cable<br />

series enhancement from <strong>Radio</strong> <strong>Frequency</strong><br />

<strong>Systems</strong>. Offering enhanced performance<br />

and reduced longitudinal attenuation,<br />

RFS’s new RADIAFLEX ‘A’ is the successor<br />

to its popular RADIAFLEX range of foamdielectric<br />

radiating cable and connectors.<br />

With RFS low-density foam technology at its<br />

core, the new ‘A’ series offers crucial RF<br />

performance improvements for all smooth<br />

wall and corrugated RADIAFLEX cable<br />

series products. Significantly, at the same<br />

cost-per-length as its predecessor, the<br />

RADIAFLEX ‘A’ series features a reduction<br />

of typically six per cent in longitudinal<br />

attenuation across the entire frequency range.<br />

According to Peter Raabe, RFS Global<br />

Product Manager for Wireless Distributed<br />

Communication <strong>Systems</strong>, the introduction<br />

of higher frequency services in confined<br />

areas—including the universal mobile<br />

telecommunications system (UMTS) and<br />

wireless local area networks (WLAN)—<br />

has been the key driver behind the<br />

development of the new low-loss radiating<br />

cable technology. “The system designer is<br />

always fighting for every decibel (dB) loss,”<br />

he said. “Saving insertion loss on the<br />

radiating cable makes the system much<br />

more future-proof, and very well-suited<br />

for the high-frequency range, especially<br />

3G applications.”<br />

The ‘A’ series will be available in smooth<br />

wall RADIAFLEX diameters (1/2, 7/8, 1-1/4<br />

and 1-5/8 inch) and corrugated RADIAFLEX<br />

diameters (7/8, 1-1/4 and 1-5/8 inch). To<br />

accommodate the enhanced cable core,<br />

RFS is also providing new connectors for<br />

the 7/8, 1-1/4 and 1-5/8 inch diameter<br />

RADIAFLEX ‘A’ cables, with the last two<br />

being retrofittable to previous generation<br />

RADIAFLEX cable. No new tooling is<br />

required. And since the jacket diameters of<br />

RADIAFLEX ‘A’ cable remain unchanged, all<br />

existing installation accessories fit to the<br />

new series as well.<br />

4 WHAT’S NEW<br />

Optimizer cellular/PCS<br />

wins over 90 degrees<br />

The ongoing demand in North America for<br />

90-degree aperture cellular antennas,<br />

coupled with an increasing need for<br />

dualband solutions, has spawned an<br />

important new addition to the RFS Optimizer<br />

family—the new Optimizer cellular/PCS<br />

dualband antenna.<br />

Unveiled at CTIA 2004 in March this year, the<br />

new additions to Optimizer antenna family<br />

support both US cellular and personal<br />

communications systems (PCS) bands under<br />

one radome, with independent variable<br />

electrical tilt in each band. Importantly, the<br />

new antennas are available in beam width<br />

variants of either 65 degrees or 90 degrees,<br />

with effective polarization diversity retained<br />

across the entire aperture.<br />

“Until now, no-one has really been able to realize<br />

an effective 90-degree polarization<br />

diversity dualband antenna,” said David<br />

Kiesling, Director of Marketing, RFS<br />

Americas. “Other manufacturers have<br />

struggled to realize effective cross-polar<br />

discrimination over the entire 90 degrees.<br />

Our new models boast 20 dB cross-polar<br />

discrimination at bore site, and better than<br />

7 dB across the entire aperture, guaranteeing<br />

effecting polarization diversity over the<br />

entire 90-degree beam.”<br />

Both the 65 and 90-degree beam width<br />

dualband Optimizer antennas boast an<br />

electrical tilt range of 0 to 10 degrees. As<br />

with all RFS Optimizer antennas, the new<br />

Optimizer dualband antennas provide<br />

superior upper side lobe suppression (better<br />

than 18 dB across the entire tilt range) and<br />

enhanced gain (nominal gain of 15 dB in<br />

each band). At first release both antennas will<br />

be available in two-metre long versions, with<br />

1.3-metre versions to follow later in 2004.

RFS CompactLine suite<br />

complete at three-foot<br />

<strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong> has recently<br />

completed two important additions to its<br />

range of cost-effective CompactLine<br />

microwave antennas: the new three-foot<br />

diameter CompactLine SB3 series, plus<br />

a new two-foot diameter CompactLine<br />

that meets the US Federal Communications<br />

Commission’s (FCC’s) category A performance<br />

requirements in the emerging<br />

10-GHz band.<br />

The RFS CompactLine family is a<br />

comprehensive suite of solid reflector,<br />

low-profile, high-performance microwave<br />

antennas. Standard features of the<br />

CompactLine suite include a short shroud<br />

for low visual impact, and a modified<br />

Cassegrain feed system with shaped<br />

subreflector for optimum gain and<br />

pattern performance.<br />

The new SB3 antenna completes the RFS<br />

CompactLine suite in the two- to four-foot<br />

diameter area. Ideal for point-to-point<br />

applications, the CompactLine SB3<br />

provides a practical alternative to oneand<br />

two-foot antennas, for high-capacity<br />

applications that demand a greater system<br />

gain. The three-foot CompactLine antenna<br />

offers the necessary system gains without<br />

concession, while dramatically reducing<br />

tower load when compared to the<br />

four-foot variants.<br />

First release CompactLine SB3 antennas<br />

were launched to the market during the<br />

second quarter of 2004, with the complete<br />

SB3 product portfolio ultimately providing<br />

three-foot diameter microwave antenna<br />

solutions for the 10- to 32-GHz frequency<br />

bands.<br />

Also launched during this period is the<br />

new two-foot diameter CompactLine<br />

SB2-105—a microwave antenna specifically<br />

developed to meet the FCC’s recently<br />

revamped Category A performance<br />

requirements in the emerging 10-GHz<br />

band. Earlier FCC Category A gain<br />

requirement in the 10-GHz band effectively<br />

had customers locked into a four-foot<br />

antenna solution, which was often oversized<br />

from a gain perspective. The new<br />

CompactLine SB2-105 solution helps<br />

open up this underutilized band, by<br />

providing a truly economic and low-profile<br />

solution for point-to-point and backbone<br />

applications.<br />

RFS superturnstile<br />

turns heads<br />

5<br />

<strong>Radio</strong> <strong>Frequency</strong> System’s new ultra-slim and<br />

lightweight superturnstile UHF broadcast<br />

antenna turned many a head at the NAB<br />

2004 broadcast industry exhibition, held in<br />

Las Vegas earlier this year. Supporting the<br />

entire US and European UHF bands<br />

(470 to 862 MHz), the new RFS superturnstile<br />

antenna exhibits pattern circularity<br />

that competing, higher price point<br />

broadband antennas struggle to achieve.<br />

“The profile of our new superturnstile is less<br />

than that of competing UHF broadband<br />

antennas,” said RFS Broadcast Engineering<br />

Manager Dale Davenport. “This has resulted<br />

in a significant reduction in wind loading and<br />

weight when compared with competing<br />

products, providing broadcasters with<br />

enormous flexibility when considering<br />

installation on existing laden towers.”<br />

The result of rigorous computer modelling<br />

and ingenious materials selection, the RFS<br />

superturnstile exhibits pattern ripple of<br />

better than ±1.5 dB across the entire UHF<br />

band. Its low drag profile underpins the<br />

antenna’s high wind speed rating and low<br />

wind load characteristics.<br />

Uniquely cost-effective, the RFS superturnstile<br />

antenna family provides the ideal<br />

reduced-power digital television (DTV)<br />

broadcast solution for broadcasters who<br />

plan to take advantage of the Federal<br />

Communications Commission’s (FCC’s)<br />

waiver on the end-2004 full-power DTV<br />

deadline. The RFS superturnstile is also ideal<br />

for many other low and medium power<br />

broadcast applications, such as coverage<br />

of small to medium-sized cities, and<br />

translator applications. Mounting options<br />

include top mount and side mount.<br />

The new superturnstile is available in<br />

array sizes of up to 16 wavelengths for<br />

the top-mounted antenna, and up to 32<br />

wavelengths for the side-mounted version.<br />

The family features a low drag fibreglass<br />

radome that provides excellent protection<br />

from the environment and acts as the<br />

main structural element of the antenna<br />

assembly. The antennas range in average<br />

input power rating from 4 kW through to<br />

16 kW, and up to 32 kW for the sidemounted<br />

version. Gains from 7.2 dBd to<br />

15.4 dBd are available.

Coverage complete for<br />

Petrobras offshore<br />

Hundreds of kilometres from the Brazilian coastline, RFS helps oil and<br />

gas giant Petrobras realize a new industry standard in offshore platform<br />

deck-to-deck RF communications.<br />

6<br />

COVER STORY<br />

Offshore oil explor ation and drilling—most<br />

particularly deepwater and ultra-deepwater<br />

wells—is a relatively young and fast<br />

changing industry. While the earliest<br />

offshore platforms were established in<br />

the late-1940s, offshore oil production<br />

really only reached global significance<br />

two decades later. Over the past ten years,<br />

drilling operations have moved into areas<br />

well beyond the continental shelf<br />

and water depths exceeding 1,000<br />

metres—the so-called ultra-deepwater<br />

drilling. This is a very new industry<br />

that demands entirely new approaches<br />

to offshore exploration, drilling and<br />

production. One company leading in this<br />

important area of resource development is<br />

the Brazilian oil and gas group, Petrobras.<br />

Petrobras is a name synonymous with<br />

deepwater and ultra-deepwater drilling,<br />

and is renowned for its innovation in<br />

this sector. An integrated international<br />

oil and gas company engaged in<br />

exploration, development and production<br />

of hydro-carbons, oil and a wide range of<br />

petroleum products and derivatives,<br />

Petrobras is Brazil’s largest company in<br />

terms of revenue and one of the world’s<br />

top 20 oil and gas groups. The company<br />

holds the world ‘water depth’ record<br />

for offshore oil drilling—the 7-RO-8 well<br />

in Roncador field, in the far reaches of<br />

the massive Campos Basin oil and gas<br />

reserve, off the northern coast of Rio<br />

de Janeiro state.<br />

Deepwater innovation<br />

The company has played a vital role in the<br />

development of new technologies that<br />

are now the mainstays of such deep and<br />

ultra-deepwater exploration and drilling.<br />

These include 3D seismic exploration<br />

programs, innovative drilling and production<br />

structures such as the ‘floating<br />

production storage and offloading’<br />

(FPSO) and tension leg platform (TLP),<br />

and horizontal and multibranch well<br />

development.<br />

According to the company’s Supervisor of<br />

Offshore Maintenance and Operations—<br />

Telecommunications, Acir Cumin, onplatform<br />

communications have also<br />

undergone change, as the company<br />

moves into deeper waters of exploration.<br />

Any offshore drilling platform, Cumin<br />

explains, presents a demanding environment<br />

from a communications perspective.<br />

Two imperatives underscore all offshore<br />

operations: ensuring premium operational<br />

safety, due to the remoteness of the<br />

platform and the volatile nature of the<br />

materials being handled; and optimizing<br />

uptime and efficiency, due to the enormous<br />

costs of establishing and manning a rig.<br />

Seamless on-platform communications are<br />

essential to realizing these two goals.<br />

An important 2001 initiative by the<br />

company—known as the ‘Operational &<br />

Excellence Plan’—set out a number of<br />

performance benchmarks for its platform<br />

systems and development. One of these<br />

was on-platform communications coverage.<br />

On most offshore platforms throughout the<br />

world, deck-to-deck communications is<br />

achieved via a combination of UHF ‘lineof-sight’<br />

communications and hardwired<br />

paging intercoms. Given the dense-packed<br />

nature of the machinery and men on the<br />

platform deck areas, achieving immediate<br />

operational access to clear communications<br />

can often prove a challenge. “I’ve been<br />

using UHF communications for platform<br />

operations and maintenance crews for<br />

more than 15 years. Using such<br />

conventional radio systems we’ve often<br />

experienced RF ‘shadows’,” Cumin says.<br />

The Petrobras 2001 ‘Operational &<br />

Excellence Plan’ demanded a raising of

the industry bar in on-platform radio<br />

communications, by specifying 100 per<br />

cent RF coverage of all platform operations<br />

and maintenance areas.<br />

Up to 2001, Petrobras had used a<br />

‘passive repeater’ system to distribute<br />

the 450 MHz production and maintenance<br />

communications band about the platforms.<br />

This involved a network of antennas<br />

located across each of its platforms to<br />

distribute and re-distribute the signal. “It<br />

was a success in some areas, but not in<br />

others,” Cumin explains. “So we<br />

approached <strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong> for a<br />

system guaranteed to achieve 100 per cent<br />

coverage.”<br />

group in its Sao Paulo centre, Amauri Soares,<br />

concurs with Dorst’s view, and cites the<br />

dense-packed nature of RF reflection and<br />

attenuation objects on each platform as a<br />

further challenge. “The platforms are all<br />

unique—they are all different,” he says.<br />

“Each deck area can measure as much as 120<br />

metres by 100 metres in area, with the deck<br />

crammed with metal machinery and rooms.<br />

There are many people moving about on the<br />

platform as well—often up to 110 personnel.<br />

The combination of the RF reflections caused<br />

by the metal objects, coupled with the<br />

prospect of RF ‘fades’ (caused by personnel<br />

as they move about the decks) makes for a<br />

challenging design environment!”<br />

Unique structures<br />

The project entailed innumerable<br />

challenges, not the least being the wide<br />

variety of platform structures that RFS<br />

had to address. In addition to Petrobras’s<br />

more conventional fixed platforms, it also<br />

requested RFS address RF communications<br />

on its two deepwater structural innovations:<br />

the ‘floating production storage and offloading’<br />

(FPSO) and the ‘semi-submersible’<br />

platforms. The FPSO is essentially a ship fitted<br />

out for drilling and product storage, and<br />

long-term at-sea location at the well site. The<br />

‘semi-submersible’, on the other hand, is a<br />

floating drilling unit fitted with pontoons and<br />

columns that, when flooded with<br />

seawater, cause the structure to submerge to<br />

a predetermined depth. Both the FPSO and<br />

the semi-submersible are moored to the<br />

seabed at the drilling location, and<br />

connected to the well by flexible risers.<br />

“What was interesting here, is that these<br />

structures really demanded a hybrid<br />

approach to the RF design,” explains RFS’s<br />

Vice President of Americas Wireless<br />

Distributed Communications <strong>Systems</strong> (WDCS),<br />

Ron Dorst. “The buildings on the multideck<br />

platforms are essentially similar to<br />

high-rise building structures. The columns<br />

and pontoons of the semi-submersibles, on<br />

the other hand, have much more in common<br />

with the many rail and road tunnels and<br />

metros that RFS has worked on throughout<br />

the world. So what we’ve had to do is<br />

combine our know-how from the road and<br />

rail sector with that of in-building, to come<br />

up with the optimal oil platform solution.”<br />

Chief designer with the RFS WDCS design<br />

From prototype to project<br />

The solution proposed by Soares and his<br />

team was based on realizing ‘contoured’<br />

RF coverage, tailored to achieve 100<br />

per cent coverage of the operations and<br />

maintenance points on each of the<br />

Petrobras platforms. RFS’s Stationmaster II<br />

omnidirectional antennas were proposed to<br />

achieve RF coverage in the open outdoor<br />

deck areas, while a network of RFS<br />

point-source omnidirectional indoor<br />

antennas were suggested for the platform’s<br />

closed deck areas. In these areas, the RF<br />

signal would be distributed via power<br />

dividers and directional couplers to ensure<br />

balanced coverage to all points.<br />

Feeder connections to each RF device<br />

would be achieved via RFS’s CELLFLEX<br />

foam-dielectric coaxial feeder cable. For<br />

the more tunnel-like areas of the<br />

platforms, such as the semi-submersible’s<br />

columns, pontoons and submarine deck,<br />

RFS proposed using its world-renowned<br />

RADIAFLEX RCF series broadband radiating<br />

cable to provide homogeneous RF<br />

distribution.<br />

On the basis of this proposal, Petrobras<br />

commissioned RFS in 2002 to develop a<br />

prototype system for the first of these<br />

platforms, an exploration drilling rig known<br />

at P23. “This was the first to use RFS’s<br />

distributed RF approach,” explains<br />

Petrobras’s Cumin. “The P23 prototype<br />

proved a success. The main gains [on<br />

this platform] related to the speed of<br />

communications and the assurance that<br />

every part of the platform was covered.<br />

For example, if you have to close a valve for<br />

Petrobras’s platform P25 is a semisubmersible<br />

platform located in the<br />

deep waters surrounding the<br />

Campos Basin’s Albacora oil field.<br />

7

emergency reasons, it can be performed<br />

quickly. This derives the safety and security<br />

that Petrobras targets.”<br />

As a result of the P23 trial success, RFS was<br />

commissioned in late-2003 to fit out a<br />

further twenty offshore structures: seven<br />

FPSOs, ten semi-submersibles and three fixed<br />

platforms.<br />

Soares and his team immediately surveyed<br />

all twenty structures and assigned an<br />

installation and commissioning crew for the<br />

project. “An important element of this<br />

project was that Petrobras required a total<br />

turnkey approach,” explains RFS Key Account<br />

Manager for Petrobras, Marcus Gama. “This<br />

meant we were not only responsible for<br />

the total RF design and technology supply,<br />

but also for the supply and installation of<br />

the radio basestations, the on-platform<br />

distribution systems and all associated<br />

peripherals. We also took responsibility for the<br />

mobile radio programming, site commissioning<br />

and system performance tests.”<br />

Design of all 20 platform systems was<br />

The installation demanded ‘intrinsically<br />

safe’ radio systems be used—these ensure<br />

that ‘emitted’ electrical energy is kept<br />

below a maximum level, and prevents the<br />

occurrence of any potential spark ignition<br />

sources. Suitable lightning protection was<br />

also essential in the exposed open waters of<br />

the Atlantic. A ten-hour rated UPS backup<br />

was included for the radio system, to<br />

provide support in the event of a platform<br />

power failure. While the initial design scope<br />

was to support a five channel, 450 MHz<br />

analogue system, for reasons of<br />

futureproofing, Petrobras demanded that<br />

the entire system be broadband to 2.4 GHz.<br />

The RFS design team had also to take special<br />

heed of on-platform ‘hazardous area<br />

zoning’ requirements, and particularly the<br />

transition of cable between these zones.<br />

To this end, many room-to-room cable<br />

transitions had to be specially sealed and<br />

fireproofed, using appropriate synthetic<br />

sealing blocks and sealant. The entire<br />

Plan’—achieving 100 per cent RF coverage<br />

of all operations and maintenance points<br />

across the platform.<br />

This was put to the test in late March 2004,<br />

when the first of the twenty upgraded<br />

platforms—an FPSO called P47—was<br />

subjected to System Assessment Testing by<br />

the Petrobras team in its dry dock facility in<br />

the city of Rio de Janeiro. The RF signal<br />

levels easily met the Petrobras-specified<br />

minimum requirement of -70 dBm across<br />

the entire platform, and often clearly<br />

exceeded this level. “This is a 100 per cent<br />

improvement [over the previous system],”<br />

Cumin says. “The operations and maintenance<br />

crews will now have the guarantee<br />

that they will find a well-established<br />

signal to start and receive the communications—quality<br />

communications can now be<br />

achieved anywhere on the platform.”<br />

With the P47 soon destined to leave Rio de<br />

Janeiro and make its way out to the deep<br />

waters of Campos Basin’s Marlim field, the<br />

8 C OVER STORY<br />

An FPSO is a ship fitted out<br />

for drilling, product storage and<br />

long-term at-sea location—pictured<br />

is Petrobras’s P37 in the Marlim oil field.<br />

completed by the RFS Sao Paulo team<br />

during September/October 2003, with<br />

Petrobras-witnessed factory acceptance<br />

testing completed at RFS Sao Paulo.<br />

Installation commenced in November of<br />

the same year, with commissioning of<br />

the systems completed during the first<br />

half of 2004.<br />

Offshore challenges<br />

The project presented the RFS WDCS<br />

design team with a number of technical<br />

challenges—many of them unique to<br />

the offshore platform environment. For<br />

obvious safety reasons, the entire<br />

installation—including feeder cables<br />

and radiating cables—had to be both<br />

flame and fire retardant, and low<br />

smoke producing. This specification was<br />

easily met by RFS RADIAFLEX and<br />

CELLFLEX, as its ‘JFL’ jacket is flame and<br />

fire retardant to IEC 60 332, and<br />

classified ‘low smoke’ in accordance<br />

with IEC 61 034.<br />

installation had to be both corrosion and<br />

vibration resistant, to ensure it survived<br />

the salt-laden atmosphere and platform<br />

vibrations.<br />

System redundancy was also essential.<br />

“The system had to be designed to ensure<br />

optimal reliability,” explains Cumin. “On<br />

the platform there are operationally hazardous<br />

areas—such as the production<br />

deck—where a feeder cable passing over<br />

the area might be at risk from machinery.”<br />

A complete system redundancy plan was<br />

undertaken by RFS in conjunction with<br />

Petrobras. In areas where it was deemed<br />

necessary, RFS deployed redundant feeders,<br />

alternative low-gain back-up antenna<br />

systems, and so on.<br />

New industry standard<br />

But the most important objective of all,<br />

according to Cumin, was realizing<br />

the new industry standard specified in<br />

Petrobras’s ‘Operational & Excellence<br />

remaining 19 platforms in this project are<br />

scheduled for System Assessment Testing<br />

by Petrobras through to mid-2004. In the<br />

latter half of 2004, RFS is scheduled to<br />

commence fitting out a further nine<br />

Petrobras platforms. Once again, this will<br />

be a total turnkey project, with guaranteed<br />

RF coverage on each of the platforms.<br />

The Petrobras 2001 ‘Operational &<br />

Excellence Plan’ set out to realize a new<br />

global standard for deck-to-deck RF<br />

coverage on offshore platforms. As a<br />

renowned leader and innovator in the<br />

sector, this is no new terrain for the oil and<br />

gas giant. “RFS is proud to have played<br />

such a significant role in helping Petrobras<br />

achieve this new standard,” says RFS’s Ron<br />

Dorst. “It’s been an undeniable challenge,<br />

but the success of this project exemplifies<br />

the breadth of our company’s confined<br />

coverage know-how and experience—and<br />

the almost limitless nature of a truly<br />

tailored RF solution”.

Fiber forms the factory<br />

floor cutting edge<br />

A major saw blade manufacturer in Massachusetts enjoys the benefits<br />

of plantwide PCS reception, courtesy of a hybrid passive/active confined<br />

coverage solution from RFS.<br />

Lenox Saw in East Longmeadow, Massachusetts,<br />

USA is a company on the cutting<br />

edge—in every respect. Manufacturing a<br />

wide range of bandsaw, hacksaw, and<br />

reciprocating saw blades, plus hole saws<br />

and other cutting tools, its LENOX brand<br />

enjoys an enviable reputation for premium<br />

quality in over 70 countries around the<br />

world.<br />

The company uses the most advanced<br />

manufacturing techniques, and relies on a<br />

plantwide personal communications<br />

service (PCS) wireless communications<br />

system as a means of communicating<br />

with many of its key staff, as<br />

they move about its massive<br />

525,000 square foot<br />

(52,500 square metre)<br />

facility. “Our senior<br />

management, supervisors<br />

and support<br />

people use it,” explained<br />

Lenox Saw’s plant engineer<br />

Ed Lagoy. “It has definite<br />

advantages for us. For example, if you’re<br />

a maintenance fellow and you’re<br />

trouble-shooting a problem, it’s kinda nice<br />

to talk to the manufacturer while you’re<br />

looking at the machine.”<br />

Hybrid solution<br />

While the mobility of PCS wireless<br />

communications provides convenience,<br />

the company had struggled with a number<br />

of ‘dead spots’ or poor reception areas<br />

about its large facility. A detailed site survey<br />

initiated and overseen by Lenox’s Director<br />

of Information <strong>Systems</strong>, Wes Crouch,<br />

quantified the extent of the problem and<br />

the possible solutions. <strong>Radio</strong> <strong>Frequency</strong><br />

<strong>Systems</strong> was approached in late 2003 to<br />

explore these solutions further. “Due to the<br />

scale of this facility, we knew that<br />

a conventional passive RF solution<br />

would not be practical,” said Jerry Black,<br />

RFS’s Director Wireless Distributed Communications<br />

System (WDCS) Products<br />

Technical Sales. “As a result, we explored<br />

our library of hybrid passive/active<br />

systems.”<br />

Working in conjunction with US fiber optic<br />

technology group Mobile Access, RFS came<br />

up with the optimal solution—one that<br />

provides both premium performance and<br />

cost-efficiency. The solution proposed was<br />

based on a backbone of single-mode<br />

optical fiber, routed about the entire<br />

manufacturing facility. At the donor site, or<br />

front end, was an RFS I-BDA 48000 series<br />

bi-directional amplifier (BDA). This<br />

provided the important uplink and<br />

downlink gain required across the<br />

installation. The I-BDA 48000, in turn,<br />

fed into a main hub, which provided the<br />

RF-to-optical (E/O) transition and optical<br />

fiber marshalling point.<br />

Three remote hubs were located along the<br />

fiber backbone, supporting the optical-to-<br />

RF (O/E) transition, and marshalling to around<br />

20 strategically located point source<br />

antennas. The nominated antennas were<br />

RFS’s renowned A088 series broadband<br />

MicroTenna indoor antennas, which were<br />

connected to the hubs using RFS’s low<br />

attenuation CELLFLEX foam dielectric coaxial<br />

cable.<br />

Fiber turnkey<br />

The entire hybrid solution was provided<br />

by RFS on a total turnkey basis. “This<br />

was a complete engineering/furnish/install<br />

project—it was our responsibility from<br />

end-to-end,” said Black. “The design was<br />

completed by our engineering team in<br />

Meriden, Connecticut, then the site<br />

installation, commissioning and testing<br />

completed by our nominated installation<br />

sub-contractor.”<br />

According to Lenox Saw’s Ed Lagoy, the<br />

installation went very smoothly indeed. “It<br />

was completed over a couple of weeks and<br />

they worked during the off-shift. Frankly,<br />

they were pretty invisible to us—and that’s a<br />

good thing for me, ‘cause it means the job’s<br />

getting done!”<br />

The hybrid solution deployed at Lenox Saw<br />

offers a number of key advantages over<br />

conventional fiber-based confined coverage<br />

solutions—most notably, its broadband<br />

nature. “The RFS/Mobile Access solution is<br />

broadband from end-to-end,” Black said.<br />

“While the Lenox Saw system currently supports<br />

only code division multiple access<br />

(CDMA) 1900 multi-carrier service, it could<br />

CONFINED COVERAGE 9<br />

easily accommodate an overlaid WiFi,<br />

paging, or other cellular based services in the<br />

future—all on the same fiber!”<br />

Dead spots out<br />

At the completion of the project the results<br />

were very positive indeed, with the ‘dead<br />

spots’ essentially eradicated. “Our subcontractor<br />

took levels throughout the building<br />

and compared it to our design predictions,”<br />

Black said. “We were 95 to 98 per cent of<br />

predicted—Lenox Saw could not have been<br />

more pleased!”<br />

With its proven strength and capability in<br />

the large-campus confined coverage sector,<br />

Black is enthusiastic about RFS’s future.<br />

“We come to the market with proven wireless<br />

know-how, total turnkey capability, and<br />

the richest library of passive, active and<br />

hybrid solutions and technologies from which<br />

to draw,” he said. “It’s an unbeatable combination—we<br />

bring the best of both the passive<br />

and active worlds to our customers.”

America applauds CELLFLEX ‘A’<br />

From coast to coast, US cellular OEMs and installation crews are enthusiastically<br />

embracing RFS’s enhanced base station feeder cable.<br />

In the quest for improved wireless coverage<br />

and services, operators across the United<br />

States are embarking on a broad program<br />

of infrastructure upgrades, and this has<br />

created an ever-increasing demand for high<br />

quality feeder systems. Increasingly, many<br />

operators and OEMs are turning to <strong>Radio</strong><br />

<strong>Frequency</strong> <strong>Systems</strong>. Just under a year after<br />

its July 2003 global launch, the ‘A’ series of<br />

CELLFLEX feeder cable is proving itself<br />

well suited to meet the range of<br />

RF performance and field installation<br />

requirements of modern American cell<br />

sites. And the word is fast spreading.<br />

Corridor to performance<br />

The CELLFLEX ‘A’ series is winning over new<br />

and existing RFS customers across the<br />

US, says Chris Adams, RFS Area Product<br />

“The needs of the project were simple.<br />

They wanted the best possible material for<br />

RF transmission, without compromising<br />

mechanical performance. They also wanted<br />

a product that they were comfortable<br />

using,” explains Adams. In CELLFLEX ‘A’,<br />

the companies found an optimal feeder cable<br />

solution, offering reduced transmission<br />

losses, while having enough similarities to<br />

the more familiar CELLFLEX products to<br />

minimize further training.<br />

Preferred approach<br />

In the last few years, the US RF market has<br />

demonstrated a substantial shift in attitude<br />

towards feeder systems. The previous focus<br />

was largely on the performance of<br />

antennas and, to some extent, the filtering<br />

and combining equipment. “In the minds<br />

10 FEEDER SYSTEMS<br />

Manager for Transmission Lines. The<br />

success is attributable to the fact that<br />

the cable has achieved an improved<br />

attenuation profile without sacrificing<br />

mechanical properties, while maintaining<br />

tooling and connector compatibility with<br />

the popular preceding technology—the<br />

RFS standard CELLFLEX series. Adams adds,<br />

“We’re finding that many of those who<br />

have had a chance to review the product<br />

are now opting to make the ‘A’ series their<br />

preferred cable product. In Central America<br />

too, a number of customers are assigning it<br />

a ‘priority’ status.”<br />

Recently, the ‘A’ series feeder cable was<br />

selected for a large-scale project in the<br />

Boston area where two major personal<br />

communication service (PCS) operators<br />

have formed a joint venture to fill in<br />

coverage gaps or ‘holes’, particularly along<br />

highways. In the early stages of the project,<br />

it was necessary for both companies<br />

to fundamentally agree on a feeder cable<br />

product, which could accommodate<br />

immediate and future capacity improvements.<br />

of many, cable was cable, and there really<br />

were no differences,” Adams remarks. By<br />

contrast, today there is a clear imperative to<br />

look closely at the performance of the<br />

transmission line system. “If you don’t<br />

minimize losses in the feeder cable, then<br />

the best overall performance for the<br />

transmission system won’t be realized.”<br />

All components of RFS’s CELLFLEX ‘A’ series<br />

have been designed with a view to ensuring<br />

the best possible performance for the entire<br />

transmission line. Adams points out that<br />

this is a new approach, a change from the<br />

days in which, “cable people only focus on<br />

cable, and connector people only focus on<br />

connectors.” He adds that RFS is now going<br />

beyond cables and connectors, and is<br />

looking, for example, at optimizing the<br />

performance of the jumpers at the<br />

cable ends, cable related accessories and<br />

installation tooling.<br />

Beyond performance metrics, however,<br />

there is another factor behind the<br />

growing appeal of the ‘A’ series—<br />

the often-overlooked impact on site<br />

installation. In the US, the fact that<br />

CELLFLEX ‘A’ connectors are backwards<br />

compatible with the original CELLFLEX<br />

connectors is a very attractive feature of the<br />

RFS system. Adams says, “It is important to<br />

cater to the needs of the guys in the field—<br />

they’re the ones who have to deal with any<br />

problems. So, we’re doing a lot of different<br />

things to make them happy.”

RFS reels off rural<br />

success in Sweden<br />

Quality, service and innovative cable reel solutions are behind the<br />

selection of RFS as a key feeder supplier to Sweden’s UMTS roll-out.<br />

The last thing that Torbjörn Zadig wants<br />

is for those building Sweden’s third<br />

generation (3G) cellular infrastructure to<br />

be left out in the cold. Zadig is Contract<br />

Manager for the 3G Infrastructure Services<br />

(3GIS) group, responsible for implementing<br />

universal mobile telecommunication system<br />

(UMTS) services in Sweden’s non-metropolitan<br />

areas. With several thousand base<br />

stations to be constructed in a narrow<br />

time-frame, the fast and efficient delivery<br />

of equipment to site is a priority. “We have<br />

thousands of people building the<br />

network for us. We don’t have a minute<br />

to spare,” he says.<br />

The challenges for the suppliers of base<br />

station feeder systems are particularly<br />

Zadig says that the need for 3GIS to keep<br />

costs down means that there is much<br />

pressure placed on logistic support.<br />

“We require that suppliers take full<br />

responsibility for the logistic processes:<br />

from confirming the order with the<br />

contractors, cutting the cable, and making<br />

sure that the cable arrives at the site in due<br />

time,” he explains.<br />

Speed is also a major factor; deliveries are<br />

based on a five-day lead time and the<br />

cables have to arrive at each site pre-cut.<br />

“We don’t want the contractor to purchase<br />

a cable drum of 500 metres, then<br />

take it to a local storage and cut the cable<br />

to the dimension that they want—we<br />

don’t have time to do that,” says Zadig.<br />

has been supplying 3GIS with feeder<br />

systems (mostly 1-5/8 inch CELLFLEX<br />

feeder cable and jumpers) over the last<br />

year, and in November 2003, 3GIS<br />

extended the agreement and selected RFS<br />

to supply these products for its roll-out in<br />

the southern half of Sweden.<br />

Martin Buhl, Senior Sales Manager for<br />

RFS Denmark, attributes this decision<br />

to RFS’s approach to service, and the<br />

development of a unique cable supply<br />

solution. Buhl explains that RFS and its<br />

local distributor, Elproman, raised the<br />

issue of how best to supply feeder<br />

cable with a number of Swedish antenna<br />

installation companies: “They explained<br />

that they had waste cable and empty<br />

FEEDER SYSTEMS 11<br />

significant. The higher frequency<br />

(2100 MHz) signal used for UMTS means<br />

greater diameter feeder cables are<br />

required to minimize attenuation. For<br />

3GIS, quality is important, but overall<br />

service is critical: the cable needs to arrive<br />

at site in a way that is convenient for<br />

contractors to handle, and which also<br />

minimizes waste. As a result, <strong>Radio</strong><br />

<strong>Frequency</strong> <strong>Systems</strong> was recently selected<br />

as a key feeder systems supplier to the<br />

3GIS project.<br />

Rapid roll-out<br />

3GIS is a joint venture between Vodafone<br />

Sweden, Orange Sweden and 3 Sweden.<br />

While the rival operators have separate<br />

UMTS network infrastructure in the main<br />

cities, Sweden’s very stringent 3G license<br />

requirements (almost 99.8 per cent population<br />

coverage once the rollout is completed)<br />

compelled them to cooperate in rural areas.<br />

Even so, the scale of the task ahead is<br />

impressive: the roll-out constitutes one of<br />

Sweden’s largest ever industrial projects.<br />

To ensure the fastest turnaround, the<br />

feeder cables arrive at each 3GIS site,<br />

in lengths pre-cut for the site. These are<br />

provided on purpose-built cable drums<br />

that can be strapped to a pallet for easy<br />

transportation, then easily dismantled<br />

afterwards.<br />

Unique service<br />

As it turns out, RFS is able to meet 3GIS’s<br />

requirements of taking full logistic<br />

responsibility for deliveries, while<br />

providing cable pre-cut to length. RFS<br />

drums that they couldn’t get rid of, so<br />

we asked the factory to engineer an<br />

alternative solution.”<br />

Buhl points out that now RFS can not only<br />

provide pre-cut cable lengths, but it also<br />

has developed a cable drum that can<br />

be strapped to a pallet (and thus<br />

lifted by a normal truck lift) for easy<br />

transportation, and which can also be<br />

easily dismantled afterwards. “Nobody<br />

thought about these easy-to-dismantle<br />

drums beforehand—it has proved to be a<br />

real advantage,” he says.<br />

Finally, according to Buhl, the specific<br />

design of RFS’s feeder cable makes it<br />

eminently suitable for use in Sweden’s<br />

harsh climate. “There are very low<br />

temperatures in the winter time, and most<br />

cables become quite stiff and difficult to<br />

bend,” he says. “The advantage of the<br />

CELLFLEX cable jacket is that it is well<br />

suited for these conditions and easy to<br />

install even in the extreme cold.”

China gets<br />

3G smart<br />

As the world’s largest mobile market enjoys healthy growth—and<br />

increasing competition—RFS provides 3G technology for extensive<br />

trials of W-CDMA, CDMA2000 and TD-SCDMA in three major cities.<br />

A few months before the billionth global<br />

subscriber was acquired by the global<br />

system for mobile communications (GSM)<br />

digital cellular technology, the People’s<br />

Republic of China achieved its own wireless<br />

milestone: in November 2003, the number<br />

of mobile phone users in China exceeded<br />

the number of landlines.<br />

With an estimated 260 million landline<br />

connections in China, surpassing this has<br />

been no mean feat; and certainly GSM has<br />

played a large part, contributing more than<br />

90 per cent of the 270 million Chinese<br />

cellular subscriptions. Yet this figure<br />

represents less than 25 per cent cellular<br />

least, capacity for more than 10 million<br />

subscribers will be added across Beijing<br />

and at least 13 major provinces. As the<br />

network also deploys improved general<br />

packet radio service (GPRS) offerings,<br />

the upgrades will not only provide<br />

enhanced data services for China Mobile<br />

subscribers, but are likely to propel their<br />

number past the 200 million mark.<br />

“Yet despite these projects, the main<br />

emphasis for China Mobile this year<br />

will be network optimization,” says<br />

Zhu Du-qing, Product Manager for<br />

<strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong> China. “After<br />

10 years in operation, China Mobile’s<br />

12 REGIONAL FOCUS<br />

The Chinese government<br />

is supporting widespread<br />

trials of 3G technology<br />

during 2004.<br />

penetration, highlighting the still-enormous<br />

growth potential in China, and justifying<br />

the current emphasis of many global telcos<br />

on this, the world’s largest market.<br />

The rate of cellular uptake in China<br />

continues to be staggering. In 2003, over<br />

50 million mobile subscriptions were added<br />

by the nation’s two existing wireless<br />

operators, China Mobile and China<br />

Unicom. To support this level of growth,<br />

both operators are confronted by an almost<br />

perpetual need to expand and upgrade<br />

their networks, with performance a rising<br />

issue in the face of competition from the<br />

‘Little Smart’ limited mobility networks of<br />

the fixed line operators. The healthy<br />

market has also encouraged the Chinese<br />

government to support widespread trials<br />

of third generation (3G) technology<br />

during 2004.<br />

Optimization expansion<br />

The world’s single largest cellular network,<br />

China Mobile GSM, is continuing to expand<br />

capacity in 2004. In one series of projects at<br />

GSM network is approaching maturity.<br />

Capital investment in the network will<br />

be reduced by about a quarter in 2004,<br />

and China Mobile will be seeking to<br />

wring maximum returns out of its<br />

existing assets.”<br />

China Unicom’s GSM network is less than<br />

half the size of China Mobile’s, but Zhu<br />

says it is likely the network will remain<br />

static, as the operator instead focuses on<br />

the expansion of its two-year-old code<br />

division multiple access (CDMA) network.<br />

“The third phase of its expansion was<br />

launched late last year, and the fourth<br />

phase will commence towards the end<br />

of this year,” he says. “With just 19 million<br />

subscribers, there is still plenty of room<br />

for growth of the network.”<br />

In support of the CDMA phase III<br />

network expansion, RFS is supplying<br />

antenna and feeder systems to at least<br />

eight of the provincial Unicom operators.<br />

The range supplied by RFS encompasses<br />

fixed and variable electrical tilt antennas<br />

(AP, Optimizer APX and Optimizer

APXV series), along with CELLFLEX feeder<br />

cable and accessories, plus RF conditioning<br />

components.<br />

RFS was similarly involved in the phase II<br />

China Unicom CDMA expansion during<br />

2002-2003, and significantly expanded the<br />

area of its Shanghai manufacturing facility<br />

last year to accommodate the demand.<br />

Since then, the range of products locally<br />

manufactured continues to increase, with<br />

14 antenna models added in 2003, and<br />

plans to introduce more this year—<br />

particularly the Optimizer cross-polarized<br />

variable electrical tilt antennas (APXV series).<br />

“More and more of our customers are in<br />

need of these high performance antennas<br />

to meet demanding network expansion<br />

and optimization requirements,” Zhu says.<br />

“Features such as side lobe suppression and<br />

null fill are becoming very important as the<br />

networks mature.”<br />

Little Smart<br />

According to Zhu, the emergence of the<br />

1900-MHz ‘Little Smart’—or Xiaolingtong—<br />

limited mobility networks as major players<br />

in China’s wireless market has challenged<br />

the cellular operators and shifted the<br />

balance.<br />

Originally introduced into rural areas in<br />

1998 by China’s two fixed line operators,<br />

China Telecom and China Netcom, Little<br />

Smart is based on a wireless local<br />

loop (WLL) technology called personal<br />

handyphone system (PHS), reconfigured<br />

and renamed the personal access system<br />

(PAS). It is technically a citywide extension<br />

of the fixed line phone service, offering all<br />

the functionality of cellular technology—<br />

including text messaging—for around a<br />

quarter of the price.<br />

Owing to high user demand, in 2003<br />

China’s Ministry for Information Industry<br />

(MII) eventually relented on the ruling that<br />

banned Little Smart from metropolitan<br />

areas. “Last year, the Little Smart service<br />

was launched in cities around the country,<br />

including Beijing, Guangzhou and Shanghai,”<br />

says Zhu. “Both China Mobile and China<br />

Unicom are facing stiff competition, and<br />

have had to drop their tariffs significantly.”<br />

Now claiming 38 million subscribers<br />

throughout China, the Little Smart service<br />

has found its niche in China’s vast ‘budget’<br />

subscriber market, but its lack of true<br />

mobility means that the cellular networks<br />

are likely to retain and continue growing<br />

their subscriber bases, particularly with the<br />

dawn of next generation technologies.<br />

3G trials<br />

Although the Chinese government might<br />

be some way off issuing licenses for<br />

3G cellular services, 2004 is seeing<br />

comprehensive trials by all likely operators<br />

of all likely 3G technologies.<br />

In a series of outdoor base station trials<br />

taking place mainly in Beijing, Shanghai<br />

and Guangzhou, China Mobile and China<br />

Unicom, plus potential 3G license-holders<br />

Beijing<br />

Shanghai<br />

Guangzhou<br />

RFS’s Shanghai manufacturing centre<br />

continues to expand its product range,<br />

with manufacture of RADIAFLEX RLKU<br />

to be introduced in July 2004.

The Chenghua Mobile Building in<br />

Guangzhou features a camouflage<br />

antenna solution from RFS.<br />

tilt antennas, remote control units, feeders<br />

and accessories to Nortel, Alcatel, Fujitsu<br />

and UTStarcom for their trial 3G sites.<br />

“High performance RFS Optimizer<br />

broadband antennas (APXV18-206515L),<br />

manufactured in Shanghai, are being<br />

used at many of the trial sites—both<br />

W-CDMA and CDMA2000,” says Zhu.<br />

“The Optimizer RT remote tilt functionality<br />

has also been deployed. This enables the<br />

antenna footprint to be adjusted through<br />

tilting the beam via computer instructions<br />

from the bottom of the mast or the<br />

network control centre.” The trials will<br />

focus on performance, stability, and<br />

wide-area RF testing.<br />

Poised to explode<br />

RFS’s significant involvement in the<br />

nationwide 3G trials is indicative of its<br />

status as a valued supplier of cellular<br />

antenna technology in China. Its three sales<br />

offices and distributor network are well<br />

positioned to support the massive market,<br />

14 REGIONAL FOCUS<br />

China Telecom, China Netcom, China<br />

Satcom and China Railcom, are each<br />

testing a selection of wideband CDMA<br />

(W-CDMA), CDMA2000, and the Chinadeveloped<br />

technology, time division<br />

synchronous CDMA (TD-SCDMA).<br />

According to Zhu, the year-long trials<br />

are largely to allow time for the<br />

fledgling TD-SCDMA technology to<br />

mature. “The government is really<br />

encouraging TD-SCDMA,” says Zhu. “It has<br />

been allocated the widest UMTS [universal<br />

mobile telecommunications system]<br />

bandwidth of 155 MHz, and the MII has<br />

made it mandatory for all six operators to<br />

test the technology during 2004.”<br />

TD-SCDMA is a 3G radio access technology<br />

that combines the unique spectrum<br />

efficiency of CDMA with the possibility of<br />

asymmetric data transfer provided by the<br />

time division multiple access (TDMA) frame<br />

structure of GSM. “Carriers such as China<br />

Mobile will probably use a combination of<br />

TD-SCDMA in metropolitan areas—since it<br />

provides better bandwidth utilization—and<br />

High performance RFS Optimizer antennas<br />

are manufactured and tested in Shanghai.<br />

W-CDMA in provincial regions,” says Zhu.<br />

Also extensively trialled by five of the six<br />

carriers will be W-CDMA, the natural<br />

evolution of GSM, with 200 trial base<br />

stations deployed across the three cities.<br />

CDMA2000, as the progression of CDMA,<br />

is being tested by China Unicom, China<br />

Telecom and China Satcom. Most of<br />

the prominent OEMs in China are also<br />

participating in various partnerships, and<br />

RFS has supplied high performance variable<br />

particularly as the company’s Shanghai<br />

manufacturing centre expands in capability.<br />

In July this year, RFS will commence<br />

production of its leading RADIAFLEX RLKU<br />

radiating cable in the 1-5/8 inch size, which<br />

is proving a popular solution for metro<br />

coverage—as evidenced by deployments in<br />

the Shenzhen, Shanghai and Guangzhou<br />

Metros. The company is also involved with<br />

a number of provincial cellular operators,<br />

trialling cluster antennas, remote tilt<br />

control, and environmentally-friendly (low<br />

visual impact) solutions.<br />

The feeling in China at the moment is one<br />

of baited breath. Although the second<br />

generation networks will continue to<br />

expand and optimize, and Little Smart<br />

gain momentum, a great deal of attention<br />

will be focused on the 3G trials in<br />

Shanghai, Beijing and Guangzhou. At the<br />

end of the year that breath will be<br />

released; and once 3G technologies are<br />

proven and licenses issued, the world’s<br />

largest market, thus poised, is set once<br />

again to explode.

RFS: a world of<br />

microwave<br />

communications<br />

The equipment specified in the WSCA<br />

purchasing agreement represent a small<br />

part of the complete RFS microwave<br />

product suite. The full range of RFS<br />

microwave antennas is the most<br />

comprehensive in the industry, available in<br />

all common frequency bands up to 40 GHz.<br />

The microwave product range includes:<br />

Solid parabolic microwave antennas—<br />

point-to-point antennas in four performance<br />

classes—Standard, Improved,<br />

High and Ultra High—offering complete<br />

flexibility when designing a network.<br />

This range includes the popular RFS<br />

SlimLine and CompactLine series antennas.<br />

RFS SlimLine and CompactLine antennas—<br />

cost-effective microwave solutions for<br />

mobile operators and private microwave<br />

users. The SlimLine series antennas utilize<br />

a conventional feed system and are<br />

available in Standard, High and Ultra High<br />

performance versions. The CompactLine<br />

series antennas use a special feed system,<br />

which results in a reduced shroud length<br />

and consequently a lower antenna profile.<br />

This CompactLine range is extending with<br />

the release of the three-foot diameter<br />

SB3 series, the new two-foot diameter,<br />

10-GHz SB2-105 antenna (see What’s New<br />

pages), and the new four-foot diameter,<br />

7.1-GHz SB4-W71 antenna products.<br />

Microwave grid antennas—heavy-duty<br />

antennas in four basic types for<br />

low capacity rural telephony, Spread<br />

Spectrum/ISM band and wireless local loop<br />

(WLL) applications.<br />

Broadband wireless antennas—a wide<br />

variety of point to multipoint antennas for<br />

WLL, local multipoint distribution system<br />

(LMDS) and multipoint microwave<br />

distribution system (MMDS) applications.<br />

RFS FLEXWELL waveguides and accessories—in<br />

support of the microwave<br />

antenna, the corrugated elliptical waveguide<br />

provides the highest quality<br />

transmission medium for the radio-toantenna<br />

microwave link.<br />

US public safety radio<br />

contract awarded to RFS<br />

The signing of a new purchasing agreement for RFS microwave equipment<br />

provides a number of US states with a cost-effective means of improving<br />

public safety infrastructure.<br />

The Western States Contracting Alliance<br />

(WSCA) has finalized its contract for the<br />

purchase of public safety communications<br />

equipment. The development enables<br />

government agencies, sub-agencies and<br />

political non-profit organizations, within<br />

the WSCA member states, to purchase<br />

microwave antennas, waveguide, and<br />

related accessories directly from the<br />

competitively awarded contract. Wireless<br />

technology group <strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong><br />

was the sole awardee for the two phases of<br />

the US$10 million contract, signed in<br />

November 2003, which pertain to existing<br />

and new microwave networks respectively.<br />

According to RFS District Sales Manager<br />

Tim Twiford, the purchasing agreement<br />

comes at a time of major investment in<br />

public safety radio networks in the US. The<br />

need for greater infrastructure to support<br />

more communities and roads is one factor<br />

behind this. The federal government’s drive<br />

for a reliable communications backbone<br />

across the country—especially in the wake<br />

of national security threats—is another.<br />

“They don’t want the equipment to fail.<br />

So, while every state has these networks in<br />

place already, many of them need to be<br />

upgraded to newer digital systems,”<br />

said Twiford.<br />

One of the key issues that the WSCA<br />

contract will, in part, address is the issue of<br />

interoperability. The public safety radio<br />

networks, be they for police, fire-fighting or<br />

transport, have traditionally used a variety<br />

of vendor systems, supporting different<br />

communications formats and frequencies<br />

from VHF 150 MHz to PCS 1900 MHz.<br />

By enabling the states to obtain highperformance<br />

microwave components<br />

directly from RFS, without the administrative<br />

burden of having to manage multiple<br />

MICROWAVE<br />

bids, the contract takes a step towards<br />

equipment standardization. Twiford believes<br />

that the impact will be<br />

increasing inter-working between public<br />

safety radio systems across the region, “By<br />

using equipment that is standardized,<br />

or that can work together and talk to<br />

each other, they will be able to handle<br />

emergencies that go across counties<br />

or jurisdictions.”<br />

15

NASCOWs at<br />

the speedway<br />

New NASCAR series sponsor, Nextel Communications, deploys a groundbreaking<br />

mobile cellular coverage solution founded on RFS’s unique<br />

Optimizer RT remote tilt technology.<br />

Even as the thunder of engines roars<br />

through the air, NASCAR race-goers need<br />

cellular coverage. Whether it’s the building<br />

excitement associated with Matt Kenseth’s<br />

quest to win consecutive NASCAR NEXTEL<br />

Cup Series titles, or Dale Earnhardt Jr.’s<br />

drive for his first championship, Nextel is<br />

determined that all NASCAR fans will be<br />

able to talk about it—using their mobile<br />

phones.<br />

Nextel Communications is one of the USA’s<br />

top six national wireless carriers, and<br />

operates the largest Motorola integrated<br />

digital enhanced network (iDEN) in the<br />

country. In June 2003, Nextel signed a<br />

which they occur at different venues<br />

thousands of miles apart, demanded a<br />

more comprehensive and robust solution.<br />

To meet these requirements, Nextel<br />

engineers began development of the<br />

largest mobile cell sites seen anywhere in<br />

the world—and dubbed them ‘NASCOWs’.<br />

<strong>Radio</strong> <strong>Frequency</strong> <strong>Systems</strong> was introduced<br />

into the project in late 2003. For the<br />

16 CELLULAR<br />

Each mast on the Nextel COWs has three RFS<br />

Optimizer APXV antennas with remote tilt to<br />

streamline coverage optimization.<br />

10-year agreement for the title sponsorship<br />

of NASCAR’s premier series—to take<br />

effect in 2004. The company immediately<br />

embarked upon a project to deliver<br />

consistent cellular coverage at all NASCAR<br />

NEXTEL Cup Series races.<br />

Since NASCAR holds its events around the<br />

USA at more than 23 race tracks—including<br />

the famous Daytona International and<br />

Indianapolis Motor Speedways—a portable<br />

cellular coverage solution was required. The<br />

mobile cell sites also needed to be flexible<br />

and sophisticated enough to accommodate<br />

the dramatic variation in racetrack size and<br />

topography—not to mention unpredictable<br />

peaks in mobile phone usage.<br />

NASCOWs<br />

The conventional means of providing<br />

coverage at large public events is to deploy<br />

mobile base stations—often dubbed ‘cells<br />

on wheels’ or COWs—which are used to<br />

augment existing networks for the duration<br />

of an event. However, the sheer scale of the<br />

NASCAR races, and the regularity with<br />

past three years, RFS has been working<br />

closely with Nextel as a key wireless<br />

solutions provider, delivering antennas, codeveloped<br />

Autotuner combiners, and<br />

assorted RF conditioning products for the<br />

operator’s 800-MHz time division multiple<br />

access (TDMA)-based iDEN network.<br />

“Nextel met head-on a fast-track project,”<br />

says Dick Cullinan, RFS Key Account<br />

Manager. “They had to conceive and build<br />

two NASCOWs and eight junior COWs<br />

(nicknamed ‘SUPERCOWs’) in just three<br />

months. Due to predicted optimization<br />

challenges, they had already decided to<br />

use remote tilt antenna control; so we<br />

demonstrated our Optimizer RT remote tilt<br />

solution, and Nextel decided it would be<br />

the right solution for the job. They had<br />

already been using standard Optimizer<br />

antennas in many of their markets.”<br />

According to Cullinan, the NASCOWs are<br />

self-contained 53-foot (16-metre) trailers<br />

featuring dual pneumatic antenna masts—<br />

essentially comprising two base stations. At<br />

each major NASCAR race, one NASCOW,<br />

plus three or four smaller (single-mast)<br />

SUPERCOWs, are deployed around the<br />

speedway. “Each mast has three of our<br />

Optimizer APXV antennas with remote<br />

tilt,” Cullinan says. “It’s just like having six<br />