cone crusher ease-of-use - KPI-JCI

cone crusher ease-of-use - KPI-JCI

cone crusher ease-of-use - KPI-JCI

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

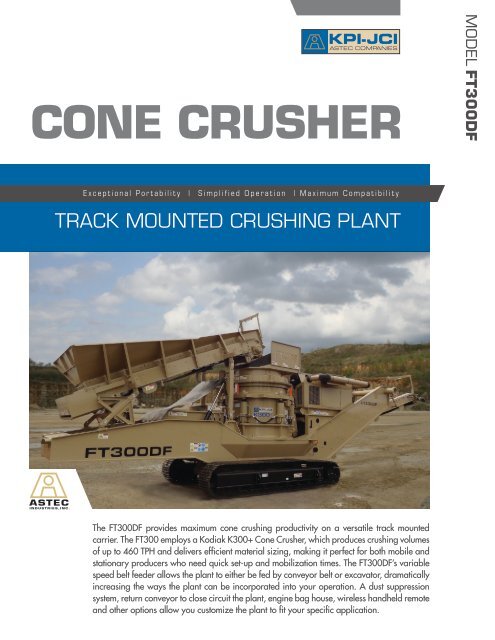

<strong>cone</strong> <strong>crusher</strong><br />

model FT300DF<br />

Exceptional Portability | Simplified Operation | Maximum Compatibility<br />

Track Mounted crushing plant<br />

The FT300DF provides maximum <strong>cone</strong> crushing productivity on a versatile track mounted<br />

carrier. The FT300 employs a Kodiak K300+ Cone Crusher, which produces crushing volumes<br />

<strong>of</strong> up to 460 TPH and delivers efficient material sizing, making it perfect for both mobile and<br />

stationary producers who need quick set-up and mobilization times. The FT300DF’s variable<br />

speed belt feeder allows the plant to either be fed by conveyor belt or excavator, dramatically<br />

increasing the ways the plant can be incorporated into your operation. A dust suppression<br />

system, return conveyor to close circuit the plant, engine bag ho<strong>use</strong>, wireless handheld remote<br />

and other options allow you customize the plant to fit your specific application.

This print is loaned subject to return upon demand, and<br />

upon the express condition that it not to be reproduced<br />

or copied, or information from it furnished to others,<br />

(541) 736-1400<br />

or be <strong>use</strong>d in any way detrimental to the interests <strong>of</strong> Johnson Crushers International, Inc. FAX: (541) 988-9401<br />

<strong>JCI</strong>, Inc. , an Astec company.<br />

All specifications are subject to change without notice.<br />

CHK'D:<br />

DWG TITLE:<br />

Machining: 0.015"<br />

DWN:<br />

DATE:<br />

SCALE:<br />

Fabricating: 0.062"<br />

Angles: 1<br />

SHEET:<br />

DWG NO.<br />

<strong>of</strong><br />

Finish:<br />

REV<br />

<strong>cone</strong> <strong>crusher</strong><br />

model FT300DF<br />

36” BELT<br />

(914mm)<br />

Variable speed belt feeder,<br />

heavy duty grade 1 belting<br />

440 HP<br />

(328 kw)<br />

Cat engine provides power for<br />

<strong>crusher</strong> and on-board conveyors<br />

9’4” X 46’ 8 1/2”<br />

(2.85m x 14.24cm)<br />

Operating Footprint<br />

UP TO 460 TPH<br />

(417mtph)<br />

Up to 460 TPH,<br />

Maximum TPH at 2” CSS<br />

P1<br />

P2<br />

PERFORMANCE<br />

Low Pr<strong>of</strong>ile<br />

Designed to simply drive <strong>of</strong>f transport<br />

and begin crushing.<br />

Compact Design<br />

System transports on standard lowboy,<br />

making it easy to transport.<br />

E1<br />

E2<br />

EASE-OF-USE<br />

Minimal Site Prep<br />

Spend time unloading and<br />

stockpiling instead.<br />

On-Site Portable<br />

These plants quickly relocate<br />

at the job site.<br />

D1<br />

S1<br />

DURABILITY<br />

Heavy-Duty Tracks<br />

Extremely durable and mobile.<br />

SAFETY<br />

Minimize Exposure<br />

Once positioned, the operator<br />

can feed the plant from the safety<br />

<strong>of</strong> the loading device.<br />

9'-4 1 4" [2853 mm]<br />

7'-6 3 4" [2303 mm]<br />

P2<br />

4'-5 3 4" [1367 mm]<br />

S1<br />

12'-2 1 2" [3720 mm]<br />

46'-8 1 2" [14238 mm]<br />

E1<br />

15'-1 3 4" [4619 mm]<br />

10'-8 1 4" [3258 mm]<br />

9'-1 3 4" [2786 mm]<br />

13'-9" [4194 mm]<br />

P1<br />

E2<br />

D1<br />

CALCULATED WEIGHT:<br />

SHEET<br />

SIZE<br />

TOLERANCES<br />

UNLESS NOTED<br />

D<br />

86470 Franklin Boulevard<br />

Eugene, OR 97405<br />

INSTALL FT300DF EXT<br />

THIRD ANGLE<br />

PROJECTION TOM-F 5/25/2011<br />

125 2 5 700429<br />

0<br />

CRUSHING CHAMBER<br />

Ideal combination <strong>of</strong> geometry, stroke<br />

and speed for aggressive and<br />

forgiving performance.<br />

INTERNAL COUNTERWEIGHTS<br />

Our patented internal counterweights<br />

are out <strong>of</strong> the material stream and never<br />

need re-balancing.<br />

Overload protection<br />

Our patented tramp iron relief system<br />

protects the <strong>crusher</strong> from costly failures<br />

while preventing back-pressure.<br />

www.kpijci.com<br />

Part <strong>of</strong> the Fast trax system ®<br />

Combine with the FT2650 Jaw and the<br />

FT6203 Screen for a portable crushing<br />

and screening system.<br />

SERVICE MADE EASY<br />

Beca<strong>use</strong> we’re dedicated to keeping you up and running, we’ve provided two resources<br />

for quality O.E.M. parts and 24/7 service. <strong>KPI</strong>-<strong>JCI</strong> and Astec Mobile Screens parts and<br />

service are available from your local dealer and/or representative.<br />

Find the dealer or representative nearest you at www.kpijci.com.<br />

Beca<strong>use</strong> <strong>KPI</strong>-<strong>JCI</strong> and Astec Mobile Screens may <strong>use</strong> in its catalog and literature, field photographs <strong>of</strong> their products which may have been modified by the owners, products furnished by <strong>KPI</strong>-<strong>JCI</strong> and Astec Mobile Screens may not necessarily be as illustrated<br />

therein. Also, the continuous design progress makes it necessary that specifications be subject to change without notice. All sales <strong>of</strong> the products <strong>of</strong> <strong>KPI</strong>-<strong>JCI</strong> and Astec Mobile Screens are subject to the provisions <strong>of</strong> their standard warranties. <strong>KPI</strong>-<strong>JCI</strong> and Astec<br />

Mobile Screens do not warrant or represent that their products meet any federal, state, or local statutes, codes, ordinances, rules, standards or other regulations, including OSHA and MSHA, covering safety, pollution, electrical, wiring, etc. Compliance with<br />

these statutes and regulations is the responsibility <strong>of</strong> the <strong>use</strong>r and will be dependent upon the area and the <strong>use</strong> to which the product is put by the <strong>use</strong>r. In some photographs, guards may have been removed for illustrative purposes only. This equipment should<br />

not be operated without all guards attached in their normal position. Placement <strong>of</strong> guards and other safety equipment is <strong>of</strong>ten dependent upon the area and the <strong>use</strong> to which the product is put. A safety study should be made by the <strong>use</strong>r <strong>of</strong> the application, and,<br />

if required, additional guards, warning signs, and other safety devices should be installed by the <strong>use</strong>r, wherever appropriate before operating the products.<br />

NOTE: SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE<br />

Rev_11/2012