Coiled Tubing Fleet - C.A.T. GmbH Consulting - Agency - Trade

Coiled Tubing Fleet - C.A.T. GmbH Consulting - Agency - Trade

Coiled Tubing Fleet - C.A.T. GmbH Consulting - Agency - Trade

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

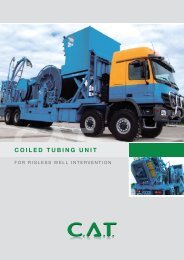

<strong>Coiled</strong> <strong>Tubing</strong> <strong>Fleet</strong><br />

truck mounted coiled tubing fleet<br />

<strong>Coiled</strong> <strong>Tubing</strong>

<strong>Coiled</strong> <strong>Tubing</strong> <strong>Fleet</strong><br />

designed for the well stimulation operations<br />

<strong>Coiled</strong> <strong>Tubing</strong> (CT) has been defined as any<br />

continuously-milled tubular product<br />

manufactured in lengths that require<br />

spooling onto a take-up reel, during the<br />

primary milling or manufacturing process.<br />

The tube is nominally straightened prior to<br />

being inserted into the wellbore and is<br />

recoiled for spooling back onto the reel. This<br />

Coil tubing reel is commonly placed on a<br />

mobile unit.<br />

<strong>Tubing</strong> diameter normally ranges from 0.75<br />

in. to 4 in., and single reel tubing lengths in<br />

excess of 30,000 ft. have been commercially<br />

manufactured. Common CT steels have<br />

yield strengths ranging from 55,000 PSI to<br />

120,000 PSI.<br />

CTU Crane<br />

This unit will be capable of lifting and moving<br />

CTU BOP’s and components onto and off of<br />

the wellhead.<br />

CTU Pumper<br />

This unit will be capable of operating at 700<br />

bar, and a minimum rate of 500 liters per<br />

minute.<br />

CTU Reel<br />

This unit will be capable of operating at 700<br />

bar, to a depth of 4500 meters with a<br />

maximum pull of 27270 kgs and a maximum<br />

snub force of 13600 kgs.<br />

C.A.T. <strong>Coiled</strong> <strong>Tubing</strong> Unit consists of a:<br />

Coil <strong>Tubing</strong> Reel Unit<br />

Coil <strong>Tubing</strong> Pump Unit<br />

Coil <strong>Tubing</strong> Crane Unit

<strong>Coiled</strong> <strong>Tubing</strong> Reel<br />

Main Components<br />

of a Coil <strong>Tubing</strong> Reel Unit<br />

Mobile Unit<br />

Power Pack<br />

<strong>Coiled</strong> <strong>Tubing</strong> Injector + gooseneck<br />

Reel + leverwind + coiled <strong>Tubing</strong><br />

Well Control Equipment (BOP, Stripper)<br />

Control Cab<br />

Acquisition System<br />

Mobile Unit<br />

To assure the mobility of the whole Coil<br />

<strong>Tubing</strong> Unit the main components must be<br />

mounted on a mobile unit (Truck, ship, track<br />

vehicle, mobile platforms).<br />

Control system<br />

This unit is designed with manual control<br />

systems. Installation of an automated system<br />

will be provided by C.A.T.<br />

Manual controls shall give the operator the<br />

capability to control all systems installed on<br />

this unit. Manual controls can be used to<br />

override automatic controls at any time<br />

during the operation of the unit.<br />

The control system consists of an<br />

assortment of components associated with<br />

harvesting data from sensors, displaying<br />

system information, entering operator<br />

commands and controlling the valves and<br />

other actuators that are part of the control<br />

system.<br />

Power Pack<br />

The Power Pack generates hydraulic and/or<br />

pneumatic, required to operate the Coil<br />

<strong>Tubing</strong> Reel Unit.<br />

<strong>Tubing</strong> Injector + gooseneck<br />

The injector provides the surface drive force<br />

to run into and retrieve the <strong>Coiled</strong> tubing from<br />

the wellbore. On the top of the injector a<br />

gooseneck is mounted, which is a<br />

semicircular support frame. This guides the<br />

tubing into the injector.<br />

Reel + <strong>Coiled</strong> <strong>Tubing</strong> + leverwind<br />

The Reel is for storage and transport of the<br />

<strong>Coiled</strong> <strong>Tubing</strong>.<br />

The leverwind is guidance to spool the tubing<br />

into and out of the wellbore.

<strong>Coiled</strong> <strong>Tubing</strong> Reel<br />

Coil <strong>Tubing</strong> Injector<br />

is designed for handling coiled tubing sizes<br />

from 1" OD trough 2-3/8" OD. It is designed<br />

for operation with both, open and closed loop<br />

hydraulic systems.<br />

Pull capacities are as follows:<br />

60,000 lbs. continous pull capacity @ 4400<br />

Psi<br />

Maximum speed 250 Feet/min (90 or 120<br />

g/min)<br />

Snubbing capacity is 30,000 lbs.<br />

All structures and ancillary systems are<br />

designed to the 60000 lb tubing load limit,<br />

plus gross weight of injector (10000 lbs).<br />

<strong>Tubing</strong> Reel<br />

speed @ 28 GPM/2500 PSIG<br />

Speed, Max first layer (bare reel): 326 ft/min<br />

(99 m/min)<br />

(Speed increases with each layer of tubing.)<br />

Pulling force, max first layer (bare reel): 3,250<br />

lb (1,474 kg)<br />

Pulling force, max last layer (full reel): 2,000 lb<br />

(907 kg)<br />

Maximum tubing size: 1.50"

<strong>Coiled</strong> <strong>Tubing</strong> <strong>Fleet</strong><br />

CTU Reel<br />

The coil tubing reel unit constructed by<br />

C.A.T. Company is mounted on a Heavy<br />

Duty Truck Chassis Type MB Actros 4141A,<br />

8x8.<br />

The MB will be equipped with a full sleeper<br />

cabin, Power Take Off (PTO), tyres<br />

14.00R20 and a subframe, which is<br />

constructed in a static equilibrium to<br />

withstand all stresses and forces during<br />

movement and neutral position<br />

CTU Crane<br />

Included with this unit shall be the following<br />

components or systems:<br />

Heavy Duty Truck Chassis Type MB Actros<br />

3341A, 6x6<br />

Hydraulic System<br />

Crane Rated to 25000 kg<br />

Air Compressor Rated to 350 Bar and 500<br />

Liter/Minute<br />

Enclosed Workstation Including BOP<br />

Service And Pressure Test Station<br />

Wireless Remote Operating System For<br />

Crane<br />

CTU Pumper<br />

Heavy Duty Truck Chassis Type MB Actros<br />

3341A, 6x6<br />

Hydraulic System<br />

Power End<br />

580 HP engine<br />

Allison Transmission<br />

700 Bar Fluid End<br />

6000 Liter fluid Holding Tank<br />

3.69 Million kilojoules water heating unit<br />

Control Cab<br />

Control and Acquisition System

C.A.T. Supply and Services<br />

C.A.T. provides Knowhow and Training<br />

in:<br />

Stimulation Engineering<br />

Hydraulic Fracturing<br />

<strong>Coiled</strong> <strong>Tubing</strong><br />

Cementing<br />

Workover Engineering<br />

Drilling Engineering<br />

Our Supply<br />

•Fracturing Process Equipment<br />

•Chemicals<br />

•Proppant<br />

•<strong>Coiled</strong> <strong>Tubing</strong> Equipment<br />

•Downhole Equipment<br />

•Wellhead Equipment<br />

•Production Equipment<br />

•Workover Equipment<br />

•Drilling Equipment<br />

•Cementing Units<br />

•Spare Parts<br />

Datasheet <strong>Coiled</strong> <strong>Tubing</strong> <strong>Fleet</strong> Nov. 2007<br />

<strong>Consulting</strong>-<strong>Agency</strong>-<strong>Trade</strong><br />

C.A.T. <strong>GmbH</strong> Phone: +49 (0)5141-9895 0<br />

Vorbruch 6 Fax: +49 (0)5141-9895 60<br />

29227 Celle info@consulting-agency-trade.de<br />

Germany<br />

www.consulting-agency-trade.de