You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

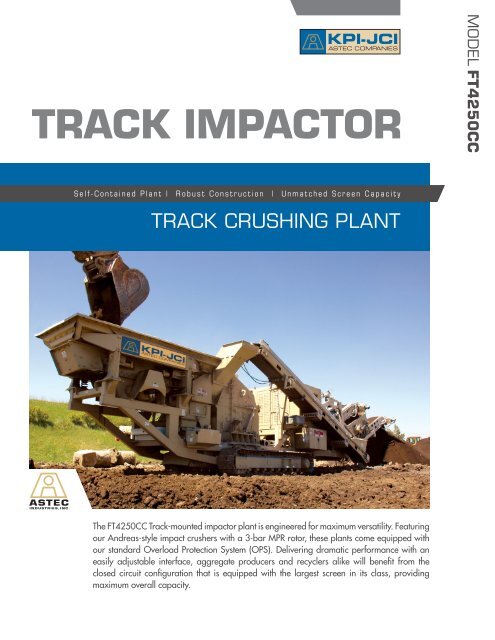

track impactor<br />

model ft4250cc<br />

Self-Contained Plant | Robust Construction | Unmatched Screen Capacity<br />

track crushing plant<br />

The FT4250CC Track-mounted impactor plant is engineered for maximum versatility. Featuring<br />

our Andreas-style impact crushers with a 3-bar MPR rotor, these plants come equipped with<br />

our standard Overload Protection System (OPS). Delivering dramatic performance with an<br />

easily adjustable interface, aggregate producers and recyclers alike will benefit from the<br />

closed circuit configuration that is equipped with the largest screen in its class, providing<br />

maximum overall capacity.

3'-6"<br />

Track Ft4250CC<br />

21” FEED<br />

(533 mm)<br />

Maximum crusher<br />

feed size<br />

FEEDER<br />

Equipped with vibrating<br />

grizzly fingers for<br />

increased capacity<br />

440 HP<br />

(328 kw)<br />

CAT C-13 Diesel engine with<br />

overload protection<br />

UP TO 500 TPH<br />

(450 mtph)<br />

Plant capacity (dependent on<br />

material characteristics)<br />

EASE-OF-USE<br />

PERFORMANCE<br />

DURABILITY<br />

E1<br />

Simplicity<br />

User-friendly controls and<br />

maintenance procedures are<br />

intended to minimize your<br />

downtime.<br />

P1<br />

Increased Capacity<br />

Our large 6’ x 12’ 2-deck screen<br />

provides up to 50 percent more<br />

capacity than comparable models.<br />

D1<br />

Rugged Dependability<br />

Equipped with a T1 steel hopper,<br />

tubular frame construction, and<br />

a solid crusher rotor for<br />

maximum durability.<br />

15'-2 3/8"<br />

E1<br />

P1<br />

11'-5 3/8"<br />

12'-3 15/16"<br />

D1<br />

9'-8 3/16"<br />

4'-6 3/16"<br />

17'-10 1/16"<br />

12'-2 7/16" 37'-7 1/2"<br />

6'-9 7/8" 1'-11 5/8"<br />

54'-3 1/16"<br />

10'-9 1/8"<br />

11'-11 3/4"<br />

1<br />

67'-8 1/16"<br />

Maximum Performance Rotor<br />

Large reduction ratio is achieved with our<br />

Maximum Performance Rotor (MPR).<br />

Crusher housing<br />

Hydraulically opens over center. Safe and<br />

easy access for maintenance.<br />

Blow Bar Retention<br />

Wedge-style blow bars create positive<br />

retention with ease of maintenance.<br />

www.kpijci.com<br />

PART OF THE FAST <strong>TRACK</strong> LINE<br />

Designed for portability with many of the same<br />

features as our stationary products.<br />

SERVICE MADE EASY<br />

Because we’re dedicated to keeping you up and running, we’ve provided two resources<br />

for quality O.E.M. parts and 24/7 service. <strong>KPI</strong>-<strong>JCI</strong> and Astec Mobile Screens parts and<br />

service are available from your local dealer and/or representative.<br />

Find the dealer or representative nearest you at www.kpijci.com.<br />

Because <strong>KPI</strong>-<strong>JCI</strong> and Astec Mobile Screens may use in its catalog and literature, field photographs of their products which may have been modified by the owners, products furnished by <strong>KPI</strong>-<strong>JCI</strong> and Astec Mobile Screens may not necessarily be as illustrated<br />

therein. Also, the continuous design progress makes it necessary that specifications be subject to change without notice. All sales of the products of <strong>KPI</strong>-<strong>JCI</strong> and Astec Mobile Screens are subject to the provisions of their standard warranties. <strong>KPI</strong>-<strong>JCI</strong> and Astec<br />

Mobile Screens do not warrant or represent that their products meet any federal, state, or local statutes, codes, ordinances, rules, standards or other regulations, including OSHA and MSHA, covering safety, pollution, electrical, wiring, etc. Compliance with<br />

these statutes and regulations is the responsibility of the user and will be dependent upon the area and the use to which the product is put by the user. In some photographs, guards may have been removed for illustrative purposes only. This equipment should<br />

not be operated without all guards attached in their normal position. Placement of guards and other safety equipment is often dependent upon the area and the use to which the product is put. A safety study should be made by the user of the application, and,<br />

if required, additional guards, warning signs, and other safety devices should be installed by the user, wherever appropriate before operating the products.<br />

NOTE: SPECIFICATIONS ARE SUBJECT TO CHANGE WITHOUT NOTICE<br />

Rev_11/2012