deva.metal Handbuch EN für GGB - Supresores

deva.metal Handbuch EN für GGB - Supresores

deva.metal Handbuch EN für GGB - Supresores

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

4<br />

Counter materials<br />

Counter<br />

materials<br />

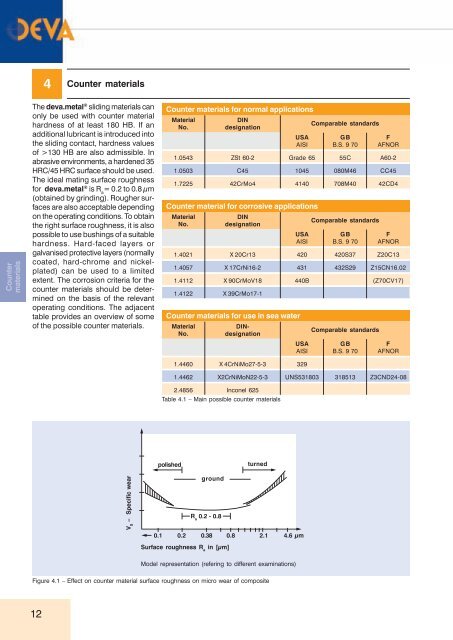

The <strong>deva</strong>.<strong>metal</strong> ® sliding materials can<br />

only be used with counter material<br />

hardness of at least 180 HB. If an<br />

additional lubricant is introduced into<br />

the sliding contact, hardness values<br />

of >130 HB are also admissible. In<br />

abrasive environments, a hardened 35<br />

HRC/45 HRC surface should be used.<br />

The ideal mating surface roughness<br />

for <strong>deva</strong>.<strong>metal</strong> ® is R a<br />

= 0.2 to 0.8 μm<br />

(obtained by grinding). Rougher surfaces<br />

are also acceptable depending<br />

on the operating conditions. To obtain<br />

the right surface roughness, it is also<br />

possible to use bushings of a suitable<br />

hardness. Hard-faced layers or<br />

galvanised protective layers (normally<br />

coated, hard-chrome and nickelplated)<br />

can be used to a limited<br />

extent. The corrosion criteria for the<br />

counter materials should be determined<br />

on the basis of the relevant<br />

operating conditions. The adjacent<br />

table provides an overview of some<br />

of the possible counter materials.<br />

Counter materials for normal applications<br />

Material<br />

No.<br />

1.0543<br />

1.0503<br />

1.7225<br />

DIN<br />

designation<br />

ZSt 60-2<br />

C45<br />

42CrMo4<br />

USA<br />

AISI<br />

Grade 65<br />

1045<br />

4140<br />

Counter material for corrosive applications<br />

Material<br />

No.<br />

1.4021<br />

1.4057<br />

1.4112<br />

1.4122<br />

DIN<br />

designation<br />

X 20Cr13<br />

X 17CrNi16-2<br />

X 90CrMoV18<br />

X 39CrMo17-1<br />

Counter materials for use in sea water<br />

Material<br />

No.<br />

DINdesignation<br />

USA<br />

AISI<br />

420<br />

431<br />

440B<br />

USA<br />

AISI<br />

Comparable standards<br />

GB<br />

B.S. 9 70<br />

55C<br />

080M46<br />

708M40<br />

Comparable standards<br />

GB<br />

B.S. 9 70<br />

420S37<br />

432S29<br />

Comparable standards<br />

GB<br />

B.S. 9 70<br />

F<br />

AFNOR<br />

A60-2<br />

CC45<br />

42CD4<br />

F<br />

AFNOR<br />

Z20C13<br />

Z15CN16.02<br />

(Z70CV17)<br />

F<br />

AFNOR<br />

1.4460<br />

1.4462<br />

X 4CrNiMo27-5-3<br />

X2CrNiMoN22-5-3<br />

329<br />

UNS531803 318513 Z3CND24-08<br />

2.4856<br />

Inconel 625<br />

Table 4.1 – Main possible counter materials<br />

polished<br />

turned<br />

V S<br />

– Specific wear<br />

ground<br />

R a<br />

0.2 - 0.8<br />

0.1 0.2 0.38 0.8 2.1 4.6 μm<br />

Surface roughness R a<br />

in [μm]<br />

Model representation (refering to different examinations)<br />

Figure 4.1 – Effect on counter material surface roughness on micro wear of composite<br />

12