deva.metal Handbuch EN für GGB - Supresores

deva.metal Handbuch EN für GGB - Supresores

deva.metal Handbuch EN für GGB - Supresores

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

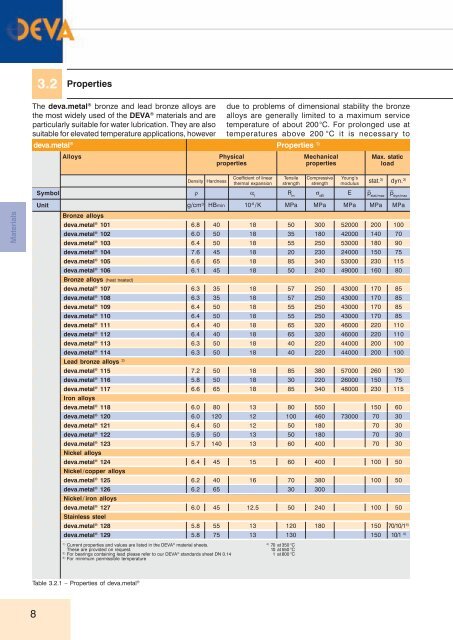

3.2<br />

Properties<br />

The <strong>deva</strong>.<strong>metal</strong> ® bronze and lead bronze alloys are<br />

the most widely used of the DEVA ® materials and are<br />

particularly suitable for water lubrication. They are also<br />

suitable for elevated temperature applications, however<br />

<strong>deva</strong>.<strong>metal</strong> ®<br />

Alloys<br />

due to problems of dimensional stability the bronze<br />

alloys are generally limited to a maximum service<br />

temperature of about 200 °C. For prolonged use at<br />

temperatures above 200 °C it is necessary to<br />

Properties 1)<br />

Physical<br />

properties<br />

Mechanical<br />

properties<br />

Max. static<br />

load<br />

Density<br />

Hardness<br />

Coefficient of linear<br />

thermal expansion<br />

Tensile<br />

strength<br />

Compressive<br />

strength<br />

Young’s<br />

modulus<br />

stat. 3) dyn. 3)<br />

Symbol<br />

ρ<br />

α 1<br />

R m<br />

σ dB<br />

E<br />

p – stat/max<br />

p – dyn/max<br />

Unit<br />

g/cm³ HBmin<br />

10 -6 /K<br />

MPa<br />

MPa<br />

MPa<br />

MPa<br />

MPa<br />

Materials<br />

Bronze alloys<br />

<strong>deva</strong>.<strong>metal</strong> ® 101<br />

<strong>deva</strong>.<strong>metal</strong> ® 102<br />

<strong>deva</strong>.<strong>metal</strong> ® 103<br />

<strong>deva</strong>.<strong>metal</strong> ® 104<br />

<strong>deva</strong>.<strong>metal</strong> ® 105<br />

<strong>deva</strong>.<strong>metal</strong> ® 106<br />

6.8<br />

6.0<br />

6.4<br />

7.6<br />

6.6<br />

6.1<br />

40<br />

50<br />

50<br />

45<br />

65<br />

45<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

50<br />

35<br />

55<br />

20<br />

85<br />

50<br />

300<br />

180<br />

250<br />

230<br />

340<br />

240<br />

52000<br />

42000<br />

53000<br />

24000<br />

53000<br />

49000<br />

200 100<br />

140 70<br />

180 90<br />

150 75<br />

230 115<br />

160 80<br />

Bronze alloys (heat treated)<br />

<strong>deva</strong>.<strong>metal</strong> ® 107<br />

<strong>deva</strong>.<strong>metal</strong> ® 108<br />

<strong>deva</strong>.<strong>metal</strong> ® 109<br />

<strong>deva</strong>.<strong>metal</strong> ® 110<br />

<strong>deva</strong>.<strong>metal</strong> ® 111<br />

<strong>deva</strong>.<strong>metal</strong> ® 112<br />

<strong>deva</strong>.<strong>metal</strong> ® 113<br />

<strong>deva</strong>.<strong>metal</strong> ® 114<br />

6.3<br />

6.3<br />

6.4<br />

6.4<br />

6.4<br />

6.4<br />

6.3<br />

6.3<br />

35<br />

35<br />

50<br />

50<br />

40<br />

40<br />

50<br />

50<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

18<br />

57<br />

57<br />

55<br />

55<br />

65<br />

65<br />

40<br />

40<br />

250<br />

250<br />

250<br />

250<br />

320<br />

320<br />

220<br />

220<br />

43000<br />

43000<br />

43000<br />

43000<br />

46000<br />

46000<br />

44000<br />

44000<br />

170 85<br />

170 85<br />

170 85<br />

170 85<br />

220 110<br />

220 110<br />

200 100<br />

200 100<br />

Lead bronze alloys 2)<br />

<strong>deva</strong>.<strong>metal</strong> ® 115<br />

<strong>deva</strong>.<strong>metal</strong> ® 116<br />

<strong>deva</strong>.<strong>metal</strong> ® 117<br />

Iron alloys<br />

<strong>deva</strong>.<strong>metal</strong> ® 118<br />

<strong>deva</strong>.<strong>metal</strong> ® 120<br />

<strong>deva</strong>.<strong>metal</strong> ® 121<br />

<strong>deva</strong>.<strong>metal</strong> ® 122<br />

<strong>deva</strong>.<strong>metal</strong> ® 123<br />

Nickel alloys<br />

<strong>deva</strong>.<strong>metal</strong> ® 124<br />

Nickel/copper alloys<br />

<strong>deva</strong>.<strong>metal</strong> ® 125<br />

<strong>deva</strong>.<strong>metal</strong> ® 126<br />

Nickel/ iron alloys<br />

<strong>deva</strong>.<strong>metal</strong> ® 127<br />

Stainless steel<br />

<strong>deva</strong>.<strong>metal</strong> ® 128<br />

<strong>deva</strong>.<strong>metal</strong> ® 129<br />

7.2<br />

5.8<br />

6.6<br />

6.0<br />

6.0<br />

6.4<br />

5.9<br />

5.7<br />

6.4<br />

6.2<br />

6.2<br />

6.0<br />

5.8<br />

5.8<br />

50<br />

50<br />

65<br />

80<br />

120<br />

50<br />

50<br />

140<br />

45<br />

40<br />

65<br />

45<br />

55<br />

75<br />

18<br />

18<br />

18<br />

13<br />

12<br />

12<br />

13<br />

13<br />

15<br />

16<br />

12.5<br />

13<br />

13<br />

85<br />

30<br />

85<br />

80<br />

100<br />

50<br />

50<br />

60<br />

60<br />

70<br />

30<br />

50<br />

120<br />

130<br />

380<br />

220<br />

340<br />

550<br />

460<br />

180<br />

180<br />

400<br />

400<br />

380<br />

300<br />

240<br />

180<br />

57000<br />

26000<br />

48000<br />

73000<br />

260 130<br />

150 75<br />

230 115<br />

150 60<br />

70 30<br />

70 30<br />

70 30<br />

70 30<br />

100 50<br />

100 50<br />

100 50<br />

150 70/10/1 4)<br />

150 10/1 4)<br />

1)<br />

Current properties and values are listed in the DEVA ® material sheets.<br />

These are provided on request.<br />

2)<br />

For bearings containing lead please refer to our DEVA ® standards sheet DN 0.14<br />

3)<br />

For minimum permissible temperature<br />

4)<br />

70 at 350 °C<br />

10 at 550 °C<br />

1 at 800 °C<br />

Table 3.2.1 – Properties of <strong>deva</strong>.<strong>metal</strong> ®<br />

8