RAP is a series of medium and large power parallel shafts ... - Famco

RAP is a series of medium and large power parallel shafts ... - Famco

RAP is a series of medium and large power parallel shafts ... - Famco

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

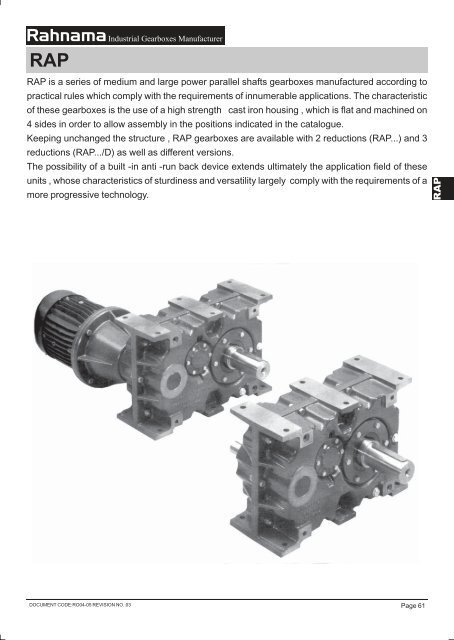

<strong>RAP</strong><br />

<strong>RAP</strong> <strong>is</strong> a <strong>series</strong> <strong>of</strong> <strong>medium</strong> <strong>and</strong> <strong>large</strong> <strong>power</strong> <strong>parallel</strong> <strong>shafts</strong> gearboxes manufactured according to<br />

practical rules which comply with the requirements <strong>of</strong> innumerable applications. The character<strong>is</strong>tic<br />

<strong>of</strong> these gearboxes <strong>is</strong> the use <strong>of</strong> a high strength cast iron housing , which <strong>is</strong> flat <strong>and</strong> machined on<br />

4 sides in order to allow assembly in the positions indicated in the catalogue.<br />

Keeping unchanged the structure , <strong>RAP</strong> gearboxes are available with 2 reductions (<strong>RAP</strong>...) <strong>and</strong> 3<br />

reductions (<strong>RAP</strong>.../D) as well as different versions.<br />

The possibility <strong>of</strong> a built -in anti -run back device extends ultimately the application field <strong>of</strong> these<br />

units , whose character<strong>is</strong>tics <strong>of</strong> sturdiness <strong>and</strong> versatility <strong>large</strong>ly comply with the requirements <strong>of</strong> a<br />

more progressive technology.<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03<br />

Page 61

DESIGNATION<br />

N.B. Geared motors can be supplied without the motors(P.A.M.), but when ordering, the<br />

motorsize must be specified.<br />

VERSION<br />

DESIGN<br />

DESIGN<br />

VERSION<br />

B3 B8 B3 B8<br />

N<br />

VD<br />

LS<br />

VL<br />

C<br />

CC<br />

LC<br />

LCC<br />

LD<br />

N.B.If not otherw<strong>is</strong>e specified the gearbox <strong>is</strong> supplied in version N-design B3.<br />

To change the execution from column B3 to column B8, it <strong>is</strong> sufficient to reverse the breather <strong>and</strong><br />

drain plugs.<br />

Page 62<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03

ANTI-RUN BACK DEVICE<br />

A built -in anti-run -back device <strong>is</strong> available upon request (<strong>RAP</strong>.../A) to allow one only direction <strong>of</strong><br />

rotation <strong>of</strong> the output shaft.<br />

The choice <strong>of</strong> direction <strong>is</strong> optional, therefore it should be indicated when ordering (left or<br />

right).<br />

The gearboxes <strong>of</strong> size 45-60-100-110 are designed to accept the BW anti-runback element as<br />

st<strong>and</strong>ard. size 70-90 need the anti-runback element support (A) as well.<br />

The element <strong>is</strong> easily fitted or d<strong>is</strong>assembled by following th<strong>is</strong> simple procedure.<br />

1) Remove cover A;<br />

2) Fit key E ( excluding <strong>RAP</strong> 45) And internal bush C;<br />

3) For sizes 45-60-100-110 also fit external bush D;<br />

4) Insert the clutch element BW into the seat <strong>of</strong> the cap ( <strong>of</strong> the support for sizes 70 <strong>and</strong> 90)<br />

5) Put thick grease into the ring <strong>and</strong> press outside the small block <strong>of</strong> the anti- runback device;<br />

6) Fit cap A ( or support) pressing with the h<strong>and</strong>s <strong>and</strong> turning the cap itself .<br />

7) Check that the direction <strong>of</strong> rotation <strong>is</strong> correct , by turning the gearbox input shaft by h<strong>and</strong>. If not<br />

correct, then repeat the above steps, but fit the clutch element in the opposite way around.<br />

N.B. For size <strong>RAP</strong> 45 the bush C must be fitted with loctite.<br />

DIRECTION OF ROTATION<br />

LUBRICATION<br />

The gearboxes <strong>of</strong> <strong>RAP</strong> <strong>series</strong> are oil lubricated. they are supplied empty <strong>and</strong> must be filled by<br />

the customer before use.<br />

These gearboxes are therefore fitted with fitting, draining <strong>and</strong> oil level plugs.<br />

LUBRICANT QUANTITIES OF <strong>RAP</strong> GEARBOXES (Liters)<br />

The above quantities refer to the mounting position B3.<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03<br />

Page 63

MOUNTING POSITIONS<br />

B3<br />

B8<br />

V1<br />

V3 VB VA<br />

• When ordering it <strong>is</strong> necessary to specify the mounting position if different form B3.<br />

• Together with the mounting position V1-V3-VA we suggest to indicate also the input speed if<br />

n 1<br />

CHARACTERISTICS OF M<strong>RAP</strong> SERIES MOTORIZED<br />

n 1 = 1400<br />

GEARBOXES When speed n 1<br />

>1400 see on page 5 <strong>and</strong> 6.<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03<br />

Page 65

CHARACTERISTICS OF <strong>RAP</strong> SERIES GEARBOXES<br />

n 1 = 1400<br />

When speed n 1<br />

>1400 see on page 5 <strong>and</strong> 6.<br />

Page 66<br />

DOCUMENT CODE:RO04-05 REVISION NO.:04

CHARACTERISTICS OF <strong>RAP</strong> SERIES GEARBOXES n 1 = 900<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03<br />

Page 67

CHARACTERISTICS OF <strong>RAP</strong> SERIES GEARBOXES n 1 = 500<br />

Page 68<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03

OVERALL DIMENSIONS<br />

M<strong>RAP</strong><br />

Dimensions X1 <strong>and</strong> Y1 vary according to the<br />

motor <strong>power</strong> (page 103,104)<br />

<strong>RAP</strong>.../N<br />

<strong>RAP</strong>.../C<br />

<strong>RAP</strong> 45÷130<br />

<strong>RAP</strong> 45/D÷130/D<br />

Vers. N-LS-LD-VD-VL<br />

DOCUMENT CODE:RO04-05 REVISION NO.:04<br />

Page 69

OVERALL DIMENSIONS<br />

INSTALLATION OF CLAMPING DEVICE ON HOLLOW OUTPUT SHAFT <strong>RAP</strong> 100-130<br />

Excluded from the supply<br />

Locking screws tightening torque MT<br />

ASSEMBLING<br />

Excluded from the supply<br />

Clean <strong>and</strong> degrease<br />

Lubricate with Molykote 321R<br />

Excluded from the supply<br />

DISASSEMBLING<br />

Excluded from the supply<br />

The gearbox type <strong>RAP</strong> 100-130 C <strong>and</strong> LC, hollow output shaft version comes complete with shrink<br />

d<strong>is</strong>c fitted, <strong>and</strong> to facilitate assembly <strong>of</strong> gearbox on driven shaft <strong>of</strong> machine, proceed as follows;<br />

1) Remove the locking bolts, then the shrink d<strong>is</strong>c.<br />

2) Clean the contact surface <strong>of</strong> the driven shaft <strong>and</strong> <strong>of</strong> the gearbox shaft thoroughly.<br />

3) Mount gearbox on driven shaft.<br />

4) Lubricate the conical surface <strong>of</strong> the stop collar <strong>and</strong> the inner ring with MOLYKOTE 321R or<br />

similar.<br />

5) Slide shrink d<strong>is</strong>c over hollow shaft <strong>of</strong> gearbox.<br />

6) Tighten all locking bolts <strong>of</strong> the shrink d<strong>is</strong>k gradually <strong>and</strong> in succession. Several passes are<br />

required until all screwes are tightening to specified torque.<br />

To know the exact position <strong>of</strong> the shrink d<strong>is</strong>k, see at page 97.<br />

N.B.: Spare parts for the assembly <strong>and</strong> d<strong>is</strong>assembly <strong>of</strong> the gearbox are not supplied by the factory.<br />

Page 70<br />

DOCUMENT CODE:RO04-05 REVISION NO.:04

TABLE OF MAXIMUM PERMISSIBLE RADIAL LOADS ON OUTPUT SHAFTS<br />

(expressed in daN)<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03<br />

Page 71

TABLE OF MAXIMUM PERMISSIBLE RADIAL LOADS ON INPUT SHAFTS<br />

(expressed in daN)<br />

CALCULATION OF RADIAL LOAD ON OUTPUT AND INPUT SHAFTS<br />

R= 2000.M.K<br />

D<br />

R= Radial load (daN)<br />

M= Torque ( daNm)<br />

D= Diameter(mm) <strong>of</strong> chain wheel , gear, belt pulley V, etc.<br />

K=1 - Chain wheel<br />

1.25 - Gear<br />

1.5 - Belt pulley V<br />

N.B.: The above resulting value <strong>of</strong> R must be lower than the value <strong>of</strong> the radial load relative to th<strong>is</strong><br />

type <strong>of</strong> gearbox.<br />

N.B.:<br />

•The values <strong>of</strong> the radial loads indicated in the table are nominal <strong>and</strong> are valid for loads acting at<br />

a d<strong>is</strong>tance, from the shoulder <strong>of</strong> the shaft, equal to half the length <strong>of</strong> the shaft itself.<br />

•The value for the maximum allowable thrust load <strong>is</strong> equal to 1/5th <strong>of</strong> the value indicated in the<br />

table .<br />

•The values referring to 300 rpm ( input shaft), 50 rpm extended (output shaft) <strong>and</strong> to 10 rpm<br />

(hollow output shaft) are the maximum perm<strong>is</strong>sible overhung loads the gearbox will withst<strong>and</strong>.<br />

•Loadings for speeds which do not appear in the table may be obtained by interpolation.<br />

•It <strong>is</strong> desirable to mount the pulley or gear in the table as near as possible to the shoulder <strong>of</strong> the<br />

shaft.<br />

•In the case <strong>of</strong> double - ended <strong>shafts</strong> , the loading which may be taken by each <strong>of</strong> the ends <strong>is</strong><br />

equal to 2/3rd <strong>of</strong> the value in the table, if the two loads are equal <strong>and</strong> operate in the same<br />

direction.<br />

Page 72<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03

POSSIBLE ASSEMBLINGS<br />

MOTORSIZE (UNEL MEC-B5)<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03<br />

Page 73

Dear Customer<br />

Your propensity to choose our products <strong>is</strong> sincerely<br />

most <strong>of</strong> grateful. Quality promotion <strong>and</strong> achieving higher<br />

desirability needs useful <strong>and</strong> w<strong>is</strong>e guidance, <strong>and</strong> any<br />

comment in th<strong>is</strong> respect would be kindly appreciated.<br />

Thank you in advance <strong>and</strong> we remain,<br />

Yours very affectionately,<br />

Saeid Rahnama<br />

Managing Director<br />

DOCUMENT CODE:RO04-05 REVISION NO.:03