Rixson Duo Floor Closer Installation Instructions - Epivots

Rixson Duo Floor Closer Installation Instructions - Epivots

Rixson Duo Floor Closer Installation Instructions - Epivots

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

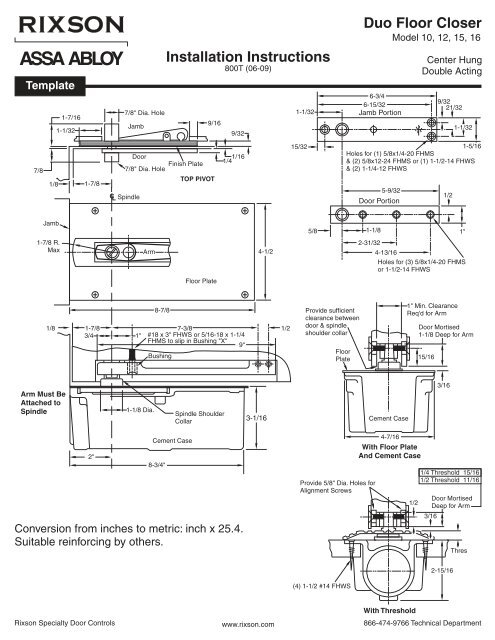

®<br />

RIXSON<br />

ASSA ABLOY<br />

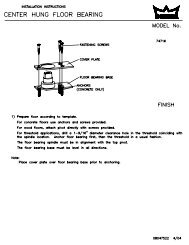

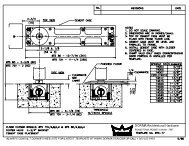

Template<br />

1-7/16<br />

1-1/32<br />

7/8" Dia. Hole<br />

Jamb<br />

<strong>Installation</strong> <strong>Instructions</strong><br />

800T (06-09)<br />

9/16<br />

9/32<br />

1-1/32<br />

<strong>Duo</strong> <strong>Floor</strong> <strong>Closer</strong><br />

Model 10, 12, 15, 16<br />

6-3/4<br />

6-15/32<br />

Jamb Portion<br />

Center Hung<br />

Double Acting<br />

7/8<br />

1/8<br />

1-7/8<br />

Door<br />

Finish Plate<br />

7/8" Dia. Hole<br />

TOP PIVOT<br />

C L Spindle<br />

1/16<br />

1/4<br />

15/32<br />

9/32<br />

21/32<br />

1-1/32<br />

1-5/16<br />

Holes for (1) 5/8x1/4-20 FHMS<br />

& (2) 5/8x12-24 FHMS or (1) 1-1/2-14 FHWS<br />

& (2) 1-1/4-12 FHWS<br />

5-9/32<br />

Door Portion<br />

1/2<br />

Jamb<br />

5/8 1-1/8<br />

1"<br />

1-7/8 R.<br />

Max<br />

Arm<br />

4-1/2<br />

2-31/32<br />

4-13/16<br />

Holes for (3) 5/8x1/4-20 FHMS<br />

or 1-1/2-14 FHWS<br />

<strong>Floor</strong> Plate<br />

8-7/8<br />

1/8 1-7/8 7-3/8 1/2<br />

3/4<br />

1" #18 x 3" FHWS or 5/16-18 x 1-1/4<br />

FHMS to slip in Bushing "X"<br />

9"<br />

Bushing<br />

Provide sufficient<br />

clearance between<br />

door & spindle<br />

shoulder collar<br />

<strong>Floor</strong><br />

Plate<br />

1" Min. Clearance<br />

Req'd for Arm<br />

Door Mortised<br />

1-1/8 Deep for Arm<br />

15/16<br />

Arm Must Be<br />

Attached to<br />

Spindle<br />

1-1/8 Dia.<br />

Spindle Shoulder<br />

Collar<br />

3-1/16<br />

Cement Case<br />

3/16<br />

2"<br />

Cement Case<br />

8-3/4"<br />

Conversion from inches to metric: inch x 25.4.<br />

Suitable reinforcing by others.<br />

Provide 5/8" Dia. Holes for<br />

Alignment Screws<br />

4-7/16<br />

With <strong>Floor</strong> Plate<br />

And Cement Case<br />

1/2<br />

1/4 Threshold 15/16<br />

1/2 Threshold 11/16<br />

Door Mortised<br />

Deep for Arm<br />

3/16<br />

Thres<br />

2-15/16<br />

(4) 1-1/2 #14 FHWS<br />

With Threshold<br />

<strong>Rixson</strong> Specialty Door Controls www.rixson.com 866-474-9766 Technical Department

PAGE 2<br />

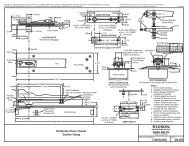

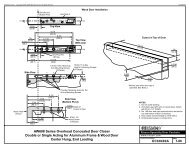

Face of Jamb<br />

WARNING: Do not strike closer with a hammer. The closer<br />

can be made completely inoperative by denting the closer<br />

tube with a hammer blow.<br />

1-3/32<br />

2-3/16<br />

Center<br />

of Spindle 1-9/16<br />

3-1/8<br />

1-7/8<br />

15/16<br />

1-9/16<br />

2"<br />

2-5/8<br />

DOOR MUST NOT BE PERMITTED TO OPEN BEYOND<br />

105°.<br />

Top Pivot Jamb Portion<br />

Top Pivot Door Portion<br />

Centerline<br />

Between Jambs<br />

6-1/8<br />

Bushing (X)<br />

Alignment Screws<br />

1-5/8<br />

13/16<br />

3/4 Dia. Typ.<br />

<strong>Installation</strong> <strong>Instructions</strong><br />

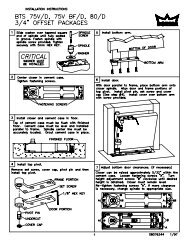

1. Locating <strong>Closer</strong><br />

Door<br />

Jamb<br />

Spindle Position<br />

Centerline of Door<br />

and Spindle<br />

2” From Face of<br />

Jamb to C L of Spindle<br />

A. Measure 2” out from door jamb on centerline of door. This<br />

is the location of the spindle center.<br />

2. Install <strong>Closer</strong> in <strong>Floor</strong><br />

LEVEL IN BOTH<br />

DIRECTIONS<br />

A. For floor plate application: the top of the closer case (or<br />

cement case as both are the same level) is set 1/16"<br />

below finished floor.<br />

B. For threshold application: the closer case is set flush with<br />

the finished floor.<br />

C. CEMENT FLOOR INSTALLATION:<br />

1. Set Cement case in floor and block in position.<br />

2. Case should be parallel with centerline of door.<br />

3. CEMENT CASE SHOULD BE LEVEL. Place levels per<br />

illustration.<br />

4. Grout in cement case with closer. Cement should not<br />

get between closer and case.<br />

D. WOOD FLOOR INSTALLATION:<br />

1. Locate center line of closer 2" out from face of frame.<br />

Using dimensioned outline of closer locate and bore (8)<br />

3/4" diameter holes. Cut out the floor using these bored<br />

holes and the dimensioned outline as a guide.<br />

2. Place arm on spindle of closer<br />

and set closer into opening, with Door Bushing (x)<br />

center of arm on line with center<br />

to C L of spindle<br />

of door. Draw a line around<br />

on C L of door<br />

overlapping square top of casting.<br />

Spindle<br />

Mortise for this overlap allowing<br />

1/16" for floor plate thickness. Top of closer case will be<br />

1/16" below finished floor.<br />

3. CLOSER CASE SHOULD BE LEVEL. Place levels per<br />

illustration.<br />

4. Fasten closer securely with screws furnished.<br />

5. Place floor plate on closer, mark around it and mortise<br />

into floor. Fasten with screws furnished.<br />

<strong>Rixson</strong> Specialty Door Controls www.rixson.com 866-474-9766 Technical Department

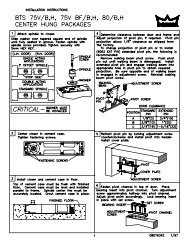

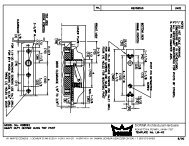

3. Install Top Pivot and <strong>Closer</strong> Arm<br />

PAGE 3<br />

A. Install top pivot in door per template.<br />

B. Install top pivot in jamb per template.<br />

C. Centerline of pivot should line up with centerline of<br />

closer. Use a plumb line to assure accuracy.<br />

D. Mortise door to receive arm. (Mortise varies if<br />

threshold is used–refer to template).<br />

E. Secure bushing to bottom of door with screw<br />

furnished.<br />

F. Drill two 5/8" holes for alignment screws.<br />

4. Hang Door<br />

Top Pivot<br />

Pin<br />

Centerline<br />

of Door<br />

Pin Retracting<br />

Screw<br />

A. Turn valve screw down. NEVER FORCE VALVE<br />

SCREW DOWN AS THIS WILL DAMAGE TIP<br />

SEATING.<br />

B. Fasten arm to closer spindle then turn spindle right<br />

(or left) until spindle and arm reach a door opening<br />

position of about 30°.<br />

C. Set door on arm and engage the top pivot pin by<br />

turning pin retracting screw up.<br />

D. Turn in arm alignment screws lightly.<br />

E. Open stroke valve (counter-clockwise) one turn.<br />

F. Adjust arm alignment screws until door rests in<br />

center of doorway.<br />

30°<br />

Adjusting Screw<br />

Alignment Screws<br />

<strong>Rixson</strong> Specialty Door Controls www.rixson.com 866-474-9766 Technical Department

<strong>Closer</strong> Adjustment<br />

PAGE 4<br />

Closing speeds can be adjusted to suit local conditions and<br />

requirements. Turn the adjusting screw that projects<br />

through the floor plate or threshold, either in or out as the<br />

case may be until the desired action is attained. Turn this<br />

valve screw to the right, clockwise, to decrease closing<br />

speed and to the left to increase the closing speed.<br />

FORCING THIS SCREW DOWN WILL IMPAIR ITS<br />

OPERATION.<br />

Spring Power Adjustments<br />

There is no spring power adjustment. If the spring power is<br />

not adequate a heavier duo-check should be installed. All<br />

duo-checks PH10, PH12, 15, 16 are interchangeable.<br />

<strong>Rixson</strong>® is a registered trademark of Yale Security Inc., an ASSA ABLOY Group company. Copyright© 2002, 2009, Yale Security Inc., an ASSA ABLOY Group company.<br />

All rights reserved. Reproduction in whole or in part without the express written permission of Yale Security Inc. is prohibited.<br />

RIXSON®<br />

ASSA ABLOY<br />

<strong>Rixson</strong> Specialty Door Controls www.rixson.com 866-474-9766 Technical Department