Download Sales Sheet - KPI-JCI

Download Sales Sheet - KPI-JCI

Download Sales Sheet - KPI-JCI

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

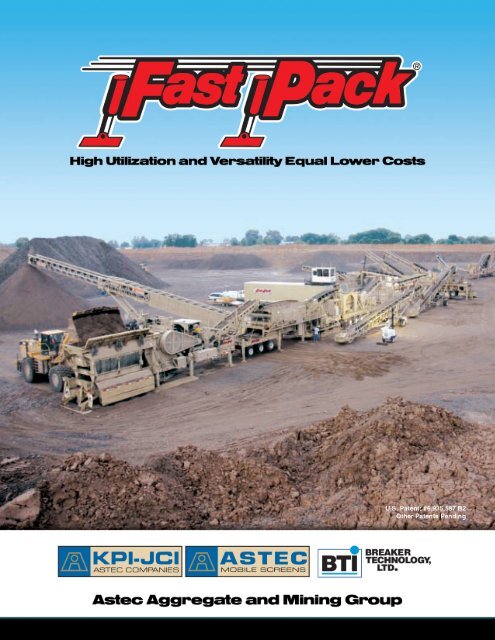

Small Footprint…BIG IMPRESSION<br />

What<br />

Can Do For You…<br />

2<br />

• Increased Profitability<br />

Increase plant availability.<br />

Reduce operating personnel.<br />

Lower energy cost per ton.<br />

Reduce mobilization expense.<br />

Reduce production cost.<br />

Reduce labor cost.<br />

• Reduce mobilization time<br />

Replace moving days with production days.<br />

Go to where the work is.<br />

Facilitates in pit moves to reduce haul cost.<br />

Makes small jobs economically feasible.<br />

• Replace several existing underutilized<br />

facilities with one high production<br />

FastPack<br />

Reduce operating costs at low volume sites.<br />

Replace antiquated high cost equipment with our<br />

state-of-the-art FastPack.<br />

• Flexible design allows high production of<br />

spec material in varying conditions.<br />

FastPack will operate as a complete system or as<br />

individual stand alone components capable of<br />

stockpiling up to seven different products.<br />

• Improve product quality<br />

Vanguard Series Jaw Crushers<br />

Kodiak ® Cone Crushers<br />

Triple Shaft Oval Motion Screens<br />

Vari-Vibe ® High Frequency Screen<br />

SuperStacker ® for non-segregated stockpiles<br />

• Improve on the job safety results<br />

No cribbing.<br />

No heavy electrical cables.<br />

Fewer conveyors.<br />

Folding walkways, conveyors and bulkhead.<br />

Less human interface.<br />

www.kpijci.com

Primary Jaw<br />

FEATURES<br />

Hydraulically<br />

Positioned Hopper<br />

Wings<br />

• Increases hopper capacity and<br />

reduces road travel height.<br />

• Greater flexibility—can be<br />

positioned to feed from either<br />

side of plant.<br />

Variable Speed<br />

Vibrating Grizzly Feeder<br />

• “Rock Solid” main frame<br />

construction for increased<br />

durability.<br />

• Provides smooth controlled<br />

feed rates while separating fines.<br />

Hydraulic Leveling<br />

Foundations<br />

• Quickly raises plant into<br />

operating position.<br />

• Increase stability with<br />

pontoon ground supports.<br />

• Reduces human interface providing<br />

a safer work environment.<br />

Discharge Conveyor<br />

• Hydraulically folds for quick<br />

set-up and teardown.<br />

• Eliminates the need for cranes.<br />

• Reduces human interface providing<br />

a safer work environment.<br />

Vanguard Series<br />

Jaw Crusher<br />

• The most advanced jaw<br />

crusher on the market today.<br />

• Quicker CSS adjustment<br />

through hydraulic dual wedge<br />

design.<br />

Hydraulic Raise / Lower<br />

Bulkheads<br />

• Used to quickly build charging<br />

ramps and protect axle<br />

assemblies.<br />

• For greater flexibility, bulkheads<br />

are mounted on both sides for<br />

multiple plant layouts.<br />

www.kpijci.com<br />

Diesel Power / Bag House<br />

• Tier III diesel…efficient / low<br />

emission design.<br />

• Facilities independent<br />

operation for maximum flexibility.<br />

• Equipped with self-cleaning<br />

“pulsating” plant mounted Bag<br />

House for increased engine life.<br />

Hydraulic Breaker<br />

• Increased production by<br />

properly sizing feed material.<br />

• Reduces hands on operator<br />

involvement providing a safer<br />

work environment.<br />

3

Primary Impact<br />

FEATURES<br />

4<br />

Primary Horizontal<br />

Shaft Impact Crusher<br />

• The most advanced impactor<br />

on the market today.<br />

• Delivers increased production<br />

through higher reduction ratios.<br />

Heavy Duty Rotor,<br />

Shaft & Bearings<br />

• Sculptured solid type rotor delivers<br />

high inertia for maximum impact<br />

energy.<br />

• Steel shaft, double row, selfaligning<br />

spherical roller bearings…<br />

larger than industry standards.<br />

Hydraulic Breaker<br />

Plate Adjustment<br />

• Adjustment is fast, safe and<br />

easy for precise product<br />

gradation control.<br />

• Features mono-block breaker<br />

plates for long life and<br />

increased utilization.<br />

Automated Hydraulic<br />

Relief System<br />

• Breaker plates lift to free<br />

material blockages for<br />

continuous crushing.<br />

• Automatically resets breaker<br />

plates with precise position<br />

sensors.<br />

www.kpijci.com<br />

Hydraulic Tilting Feed<br />

Plate<br />

• Provides operator a safe and<br />

effective method to clear feed<br />

bridging and blockage.<br />

• Handheld controls provide safe<br />

and quick clearing.<br />

Quick Change Wedge<br />

and Bars<br />

• Wedges are positively locked<br />

in place upon initial installation.<br />

• Safe Impeller bar changeout…no<br />

need to “throw out”<br />

bars to seat bars properly.<br />

Shaft Speed Control<br />

Sensor<br />

• PNP proximity switch is utilized<br />

to determine shaft speed and<br />

movement.<br />

• LED’s aid in product gradation<br />

control and potential<br />

troubleshooting.<br />

Impeller Bars<br />

• Four bar design with optional<br />

2+2 for increased gradation<br />

control and flexibility.<br />

• Various impeller bar<br />

composition available for<br />

multiple applications.

Secondary / Tertiary Cone<br />

FEATURES<br />

Kodiak ® Cone Crusher<br />

• The 400 HP cone is the<br />

heaviest in it’s class featuring<br />

roller bearing construction.<br />

• Unobstructed feed opening<br />

designed for increased<br />

thru-put.<br />

Hydraulic Leveling<br />

Foundations<br />

• Quickly raises plant into<br />

operating position.<br />

• Reduces human interface<br />

providing a safer work<br />

environment.<br />

Surge Hopper<br />

• Enables “choke feed” for<br />

optimal capacity and product<br />

cubicity.<br />

• Reduces plant production<br />

surges for increased capacity.<br />

• 16 cubic yard capacity.<br />

Variable Speed<br />

Vibrating Feeder<br />

• Provides smooth controlled<br />

feed rates for increased<br />

cone crusher optimization.<br />

Axle Configurations<br />

• Multiple axle configurations<br />

meet DOT specifications.<br />

• Retractable hydraulically<br />

activated for quick and easy<br />

cleanout.<br />

www.kpijci.com<br />

Cone Feed Conveyor<br />

• Eliminates cranes for set-up<br />

and tear-down.<br />

• Hydraulically folds for travel<br />

• Reduces human interface<br />

providing a safer work<br />

environment.<br />

Under Crusher Conveyor,<br />

Plant Mounted<br />

• Hydraulically folds for travel.<br />

• Interchangeable to either side<br />

for job site flexibility.<br />

• Increased discharge height for<br />

proper feed to stacking or transfer<br />

conveyors.<br />

Diesel Power / Bag House<br />

• Tier III diesel…efficient / low<br />

emission design.<br />

• Facilities independent<br />

operation for maximum flexibility.<br />

• Equipped with self-cleaning<br />

“pulsating” plant mounted Bag<br />

House for increased engine life.<br />

5

Secondary / Tertiary Impact<br />

FEATURES<br />

“Rock Eater” Horizontal<br />

Shaft Impact Crusher<br />

• The most rugged, flexible,<br />

high tonnage HSI on the<br />

market today.<br />

• Increased versatility as a<br />

primary, secondary or tertiary<br />

impactor.<br />

New Design Features<br />

• Large high angle feed entry for<br />

precise rotor penetration.<br />

• Hydraulically opens for safe<br />

and easy accessibility.<br />

Surge Hopper<br />

• Enables “controlled feed” for<br />

optimal capacity and product<br />

cubicity.<br />

• Eliminates plant production<br />

surges for increased capacity.<br />

• 16 cubic yard capacity.<br />

Impact Crusher<br />

Feed Conveyor<br />

• Eliminates cranes for set-up<br />

and tear-down.<br />

• Reduces human interface<br />

providing a safer work<br />

environment.<br />

MPR Rotor<br />

• Equipped with our “Maximum<br />

Performance Rotor,” you<br />

benefit from the integrity of a<br />

solid rotor and maintenance<br />

convenience of a segmented<br />

rotor.<br />

Hydraulic Leveling<br />

Foundations<br />

• Quickly raises plant into<br />

operating position.<br />

• Reduces human interface<br />

providing a safer work<br />

environment.<br />

6<br />

Heavy-Duty Shaft and<br />

Bearings<br />

• Withstands severe impacting<br />

and gives longevity with ease<br />

of maintenance.<br />

• Precision machined oversized<br />

shaft for increased durability.<br />

www.kpijci.com<br />

Under Crusher Conveyor,<br />

Plant Mounted<br />

• Hydraulically folds for travel.<br />

• Interchangeable to either side<br />

for job site flexibility.<br />

• Increased discharge height for<br />

proper feed to stacking or transfer<br />

conveyors.

Tertiary Vertical Shaft Impact<br />

FEATURES<br />

“Ultra-Spec” Vertical<br />

Shaft Impact Crusher<br />

• Designed for ease of service and<br />

adjustment while producing the<br />

maximum amount of spec<br />

material in a single pass with<br />

reduced wear costs.<br />

Impact Table<br />

Configurations<br />

• The impact crusher is available<br />

in two configurations; Autogenous,<br />

with the use of anvils in a rock shelf<br />

for “Rock-On-Rock” or Standard,<br />

with the use of multiple shoe and<br />

anvil impacting.<br />

Heavy-Duty Mainframe<br />

• Welded steel mainframe and<br />

tub assembly is the crusher<br />

foundation which provides<br />

proper internal clearances,<br />

pedestal support and integral<br />

drive tunnel.<br />

Surge Hopper<br />

• Enables “controlled feed” for<br />

optimum capacity and product<br />

cubicity<br />

• Eliminates plant product<br />

surges for increased capacity.<br />

• 12 cubic yard capacity.<br />

Impact Crusher Feed<br />

Conveyor<br />

• Eliminates cranes for set-up<br />

and tear-down.<br />

• Reduces human interface<br />

providing a safer work<br />

environment.<br />

Hydraulic Leveling<br />

Foundations<br />

• Quickly raises plant into<br />

operating position.<br />

• Reduces human interface<br />

providing a safer work<br />

environment.<br />

Hydra-Arm Lift<br />

• Positive wedge lid lock<br />

design provides quick and<br />

easy access.<br />

• The Hydra-Arm lifts the lid for<br />

a full 360 degree access for<br />

safe and efficient<br />

maintenance procedures.<br />

www.kpijci.com<br />

Under Crusher Conveyor,<br />

Plant Mounted<br />

• Hydraulically folds for travel.<br />

• Interchangeable to either<br />

side for job site flexibility.<br />

• Increased discharge height for<br />

proper feed to stacking or<br />

transfer conveyors.<br />

7

Triple Shaft Horizontal Screen<br />

FEATURES<br />

Oval Motion LP<br />

Horizontal Screen<br />

• The ultimate 8' x 20', triple deck<br />

screen fully adjustable for<br />

scalping and fine screening<br />

applications.<br />

• A unique oval motion is designed<br />

to be virtually non-plugging.<br />

Multiple Discharge<br />

Conveyors<br />

• Hydraulically folds for ease of<br />

travel and minimizes off-plant<br />

transfer conveyors.<br />

• Increased discharge height<br />

for proper feed to stacking or<br />

transfer conveyors.<br />

On Plant Generator<br />

• Supplies power to screen<br />

electric motor as well as<br />

additional radial stackers.<br />

• Complete power distribution<br />

panel w/breakers.<br />

Discharge Chutes<br />

• Multiple blending capabilities<br />

per required specifications with<br />

flop gate configuration.<br />

• With panel removal, additional<br />

blending is possible to<br />

produce specific product<br />

requirements.<br />

Folding Walkways<br />

• Hydraulically folds for<br />

quick set-up and road travel.<br />

• Reduces human interface<br />

providing a safer work<br />

environment.<br />

Hydraulic Leveling<br />

Foundations<br />

• Quickly raises plant into<br />

operating position.<br />

• Reduces human interface<br />

providing a safer work<br />

environment.<br />

8<br />

Dual / Reversing<br />

Underscreen Conveyors<br />

• Adjustable “forward and back”<br />

for infinite product gradation<br />

control.<br />

• Precision blending (0-100%) to<br />

produce multiple In-Spec<br />

products.<br />

www.kpijci.com<br />

Diesel Power / Bag House<br />

• Tier III diesel…efficient / low<br />

emission design.<br />

• Facilities independent<br />

operation for maximum flexibility.<br />

• Equipped with self-cleaning<br />

“pulsating” plant mounted Bag<br />

House for increased engine life..

Material Handling<br />

SUPERSTACKER<br />

Mobility<br />

• Standard features like the builtin<br />

counterweight and Gullwing<br />

Axle allow for quick set-up and<br />

transport eliminating the time,<br />

expense and manpower<br />

associated with manual<br />

configurations.<br />

Automation<br />

• Builds fully non-segregated<br />

stockpiles utilizing our<br />

automated control system.<br />

• Push button panels allow local<br />

and remote operations.<br />

STACKING & TRANSFER<br />

Dust Suppression<br />

• Dust suppression is available<br />

at all transfer points, including<br />

receiving end, as well as head<br />

end.<br />

• Minimizing dust at critical<br />

transfer points is our #1 priority.<br />

Road Travel Ready<br />

• Up to 150' long radial stacker,<br />

road ready in a matter of<br />

minutes. No external loads<br />

required.<br />

Constant Radial Travel<br />

• The standard cam-arm style<br />

rear undercarriage maintains a<br />

constant travel radius without<br />

the stockpile interruptions.<br />

• PLC controller allows extension /<br />

retraction and raise / lower<br />

adjustments.<br />

Versatility<br />

• With a low feed height of 5'-6",<br />

all LP SuperStackers are easy<br />

to position.<br />

• Plant mounted discharge<br />

conveyors easily discharge into<br />

low profile receiving hopper.<br />

All Hydraulic Folding<br />

Frame<br />

• Head and tail sections<br />

hydraulically fold for transport.<br />

Eliminates crane for set-up /<br />

teardown.<br />

Serious Stockpiling<br />

• Maximum tonnage for serious<br />

crushing.<br />

• 150' conveyors at 50'<br />

discharge height stockpiles<br />

over 43,000 tons at 90°.<br />

10<br />

www.kpijci.com

Control Center<br />

FEATURES<br />

PLC Control<br />

• High visibility touch screen,<br />

gives operator total viewing<br />

comfort in all lighted conditions.<br />

• The PLC control enables<br />

operation of the entire plant at<br />

the control house or can operate<br />

as independent on each plant.<br />

Instant Access<br />

• Profibus ® communications via<br />

serial cable provides the operator<br />

instant access and control to<br />

monitor all functions of the operation.<br />

• Standard cable is robust stranded<br />

wire for increased durability<br />

and flexibility.<br />

Dust Suppression<br />

• Dust suppression mounted in<br />

control trailer with pumps and<br />

valves for individual pieces.<br />

• Changeable nozzles allow fine<br />

tuning for specific applications.<br />

Touch Screen<br />

• User friendly touch screen<br />

provides simultaneous plant<br />

conditions in one location.<br />

• Ease of operation and instant<br />

feedback provide quick<br />

adjustments for precise control.<br />

Quick Set-up<br />

• The control van features a folding<br />

stairway and platform assembly for<br />

quick set-up and road travel<br />

convenience.<br />

• Hydraulic design reduces human<br />

interface providing a safer work<br />

environment.<br />

Engine Data<br />

• Power unit interface and<br />

engine performance monitoring<br />

on all units.<br />

• Engine data displays are<br />

viewable at ground level as<br />

well as in the control cab.<br />

Operator Cab<br />

• Oversized comfort control cab<br />

hydraulically raises for full<br />

visibility of the entire operation.<br />

• Control trailer/cab can be<br />

positioned at critical plant<br />

locations for increased visibility.<br />

Off-Plant Power<br />

• Power receptacles are<br />

conveniently located on each<br />

unit for off plant conveyors and<br />

stackers.<br />

www.kpijci.com<br />

11

Has Your Solutions!<br />

30" Material<br />

®<br />

<strong>KPI</strong> Pioneer Jaw<br />

6<br />

3<br />

1 1/2<br />

1<br />

<strong>JCI</strong> Horizontal<br />

Screen<br />

®<br />

<strong>JCI</strong> Kodiak Cone<br />

Problem<br />

Base product too coarse to meet<br />

material gradation specification.<br />

1 1/2 x 0 -3 +1 1/2<br />

®<br />

AMS Vari-Vibe Screen<br />

3/16<br />

#16<br />

<strong>JCI</strong><br />

Horizontal<br />

Screen<br />

3/4<br />

1/2<br />

3/8<br />

<strong>JCI</strong><br />

®<br />

Kodiak Cone<br />

-1/2 +3/8 -3/4 +1/2<br />

-3/8 +3/16 -3/16 +#16 -#16 +0<br />

Finer Base<br />

Solution<br />

Rotate high frequency screen 90° and<br />

feed material passing bottom deck<br />

(#16 x 0) and convey to base stockpile.<br />

Produces clean manufactured sand<br />

product (#4 x #16) without washing<br />

for (asphalt).<br />

1 1/2 x 0<br />

50.0°<br />

SUPERSTACKER<br />

JAW CRUSHER<br />

HORIZONTAL<br />

SCREEN<br />

CONTROL VAN<br />

3 x 1 1/2<br />

FOOT PRINT<br />

470' x 450'<br />

3/16 x #16<br />

CONE<br />

CRUSHER<br />

HORIZONTAL<br />

SCREEN<br />

CONE<br />

CRUSHER<br />

HIGH FREQUENCY<br />

SCREEN<br />

-3/4 x +1/2<br />

-3/8 x +3/16<br />

-1/2 x +3/8<br />

12<br />

www.kpijci.com

Has Your Solutions!<br />

-30" Material<br />

®<br />

<strong>KPI</strong> Pioneer Jaw<br />

6<br />

3<br />

1 1/2<br />

1<br />

<strong>JCI</strong> Horizontal<br />

Screen<br />

®<br />

<strong>JCI</strong> Kodiak Cone<br />

Problem<br />

Producing too much base product and<br />

desire is to produce more clean stone<br />

products.<br />

-1 1/2 +0 -3 +1 1/2<br />

®<br />

AMS Vari-Vibe Screen<br />

3/16<br />

#16<br />

3/4<br />

1/2<br />

3/8<br />

<strong>JCI</strong><br />

Horizontal<br />

Screen<br />

<strong>JCI</strong><br />

®<br />

Kodiak Cone<br />

-1/2 +3/8<br />

-3/4 +1/2<br />

-3/8 +3/16 -3/16 +#16 -#16 +0<br />

Too Much Base<br />

Solution<br />

Rotate the secondary crusher inline<br />

with the scalping screen. Travel the 3"<br />

x 1 1/2" product conveyor from the<br />

scalping screen 90 degrees<br />

discharging on to the tertiary screen<br />

feed conveyor.<br />

-1 1/2 x 0<br />

SUPERSTACKER<br />

JAW CRUSHER<br />

FOOT PRINT<br />

495' x 475'<br />

HORIZONTAL SCREEN<br />

CONTROL VAN<br />

SWIVEL CONVEYOR<br />

3 x 1 1/2<br />

CONE CRUSHER<br />

-#16 x 0<br />

HIGH FREQUENCY<br />

SCREEN<br />

HORIZONTAL<br />

SCREEN<br />

CONE<br />

CRUSHER<br />

-3/16 x +16<br />

-3/4 x +1/2<br />

+3/8 x +3/16<br />

-1/2 x +3/8<br />

www.kpijci.com<br />

13

Has Your Solutions!<br />

5<br />

®<br />

<strong>KPI</strong> Pioneer Jaw<br />

-24" Material<br />

3<br />

1 1/2<br />

1<br />

<strong>JCI</strong> Horizontal Screen<br />

®<br />

<strong>JCI</strong> Kodiak Cone<br />

Problem<br />

When producing 3/4" x 3/16" product<br />

for possible feed to external wash<br />

screen, the feed to the bottom deck on<br />

the 8' x 20' finish screen blinds over<br />

due to wet material and small screen<br />

opening.<br />

1 1/2 +0<br />

1<br />

3/4<br />

1/2<br />

3/16<br />

#16<br />

®<br />

AMS Vari-Vibe Screen<br />

<strong>JCI</strong> Horizontal Screen<br />

-3/4 +3/16<br />

<strong>JCI</strong><br />

®<br />

Kodiak Cone<br />

3/4 Wash<br />

3/16 +0<br />

Solution<br />

Replace the small screen opening on<br />

the bottom deck of the 8' x 20' finish<br />

screen, and install 3/16" on the top<br />

deck of the high frequency screen.<br />

Then send the 1/2" x 3/16" material<br />

to a 125' stacker and blend with the<br />

3/4" x 1/2" product producing a<br />

3/4" x 3/16" product.<br />

-1 1/2 x +0<br />

50.0°<br />

JAW CRUSHER<br />

CONTROL VAN<br />

HORIZONTAL SCREEN<br />

FOOT PRINT<br />

500' x 380'<br />

CONE CRUSHER<br />

SUPERSTACKER<br />

CONE CRUSHER<br />

HORIZONTAL<br />

SCREEN<br />

-3/4 x 3/16<br />

HIGH FREQUENCY SCREEN<br />

3/16 x +0<br />

14<br />

www.kpijci.com

Has Your Solutions!<br />

-30" Material<br />

®<br />

<strong>KPI</strong> Pioneer Jaw<br />

6<br />

2<br />

1 1/2<br />

1<br />

<strong>JCI</strong><br />

Horizontal<br />

Screen<br />

®<br />

<strong>JCI</strong> Kodiak Cone<br />

Problem<br />

Base product too fine and desire is to<br />

add coarse material to sweeten<br />

product.<br />

1 1/2 x 0<br />

®<br />

AMS Vari-Vibe Screen<br />

3/16<br />

#16<br />

<strong>JCI</strong><br />

Horizontal<br />

Screen<br />

3/4<br />

1/2<br />

3/8<br />

<strong>JCI</strong><br />

®<br />

Kodiak Cone<br />

-1/2 +3/8<br />

-3/4 +1/2<br />

-3/8 +3/16 -3/16 +#16 #16 x +0<br />

Coarser Base<br />

Solution<br />

Add (2) 80' conveyors for stockpiling<br />

3/4" x 1/2" product and (1) 110'<br />

transflite conveyor. Install splitter box<br />

at transfer point which will enable a<br />

separate pile for the coarse aggregate.<br />

The transflites sends the material to<br />

the base stockpile.<br />

1 1/2 x 0<br />

50.0°<br />

SUPERSTACKER<br />

JAW CRUSHER<br />

HORIZONTAL<br />

SCREEN<br />

FOOT PRINT<br />

428' x 428'<br />

CONTROL VAN<br />

CONE CRUSHER<br />

CONE CRUSHER<br />

-3/4 x +1/2<br />

HORIZONTAL<br />

SCREEN<br />

-#16 x 0 HIGH FREQUENCY<br />

SCREEN<br />

-3/16 x +#16<br />

-1/2 x +3/8<br />

-3/8 x +3/16<br />

www.kpijci.com<br />

15