pdf download: Diebold Gauge Systems.....âSimply the ... - Diebold HSK

pdf download: Diebold Gauge Systems.....âSimply the ... - Diebold HSK

pdf download: Diebold Gauge Systems.....âSimply the ... - Diebold HSK

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Diebold</strong> <strong>Gauge</strong> <strong>Systems</strong> “Simply <strong>the</strong> Finest”<br />

<strong>HSK</strong> Taper <strong>Gauge</strong><br />

SK/BT Taper <strong>Gauge</strong><br />

<strong>Diebold</strong> - Gauging<br />

<strong>Diebold</strong>, and many o<strong>the</strong>r manufacturers of close-tolerance tool holders and modular system that<br />

have tapers with face contact, have been using <strong>Diebold</strong> Gauging for many years. We are proud to<br />

offer our customers “Simply <strong>the</strong> Finest” in gauges and measurement products. These gauges will<br />

economically verify <strong>the</strong> dimensional accuracy of your tool holders, spindles and o<strong>the</strong>r precision<br />

equipment.<br />

Quality gauging demands high precision gauge masters, at <strong>Diebold</strong> we make our own to satisfy this<br />

need. Our plant has gauge masters calibrated and certified by some of <strong>the</strong> world`s most reputable<br />

calibration institutes. All of <strong>the</strong> masters that we manufacture are certified and traceable to <strong>the</strong><br />

applicable standard.<br />

You have made a significant investment in your machinery and tool holders. By utilizing <strong>Diebold</strong><br />

Gauging you can be sure you will get <strong>the</strong> most out of your investment!<br />

We are proud to offer our customers “Simply <strong>the</strong> Finest” in gauges and measurement products.<br />

These gauges will economically verify <strong>the</strong> dimensional accuracy of your tool holders, spindles and<br />

o<strong>the</strong>r precision equipment.<br />

Quality gauging demands high precision gauge masters; at <strong>Diebold</strong> we make our own to satisfy this<br />

need. Our plant has gauge masters calibrated and certified by some of <strong>the</strong> world`s most reputable<br />

calibration institutes. All of <strong>the</strong> masters that we manufacture are certified and traceable to <strong>the</strong><br />

applicable standard.<br />

By utilizing <strong>Diebold</strong> Gauging you can be sure you will get <strong>the</strong> most out of your investment!<br />

Helmut <strong>Diebold</strong> GmbH & Co. • An der Sägmühle 4 • D-72417 Jungingen • Telefon (0 74 77) 871-0 • Telefax (0 74 77) 871-30 • E-Mail: <strong>Diebold</strong>@hsk.com •<br />

www.hsk.com

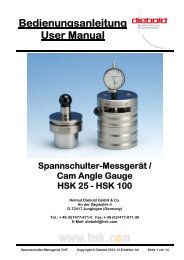

Inspection <strong>Gauge</strong>s for <strong>HSK</strong> Tapers<br />

<strong>Diebold</strong> manufactures mechanical gauges for <strong>the</strong><br />

inspection of tool holders and <strong>the</strong> machine spindle taper.<br />

The masters used to calibrate our high quality gauges are<br />

also produced by <strong>Diebold</strong>, and are certified by <strong>the</strong><br />

appropriate international standards organizations to<br />

guarantee traceability.<br />

<strong>HSK</strong> Taper measuring points according to DIN/ISO<br />

This gauging system will verify <strong>the</strong> following:<br />

- Toolholder taper diameters and angles<br />

- Location of <strong>the</strong> taper in relation to <strong>the</strong> flange<br />

- Runout of <strong>the</strong> taper in relation to <strong>the</strong> flange<br />

- Location of <strong>the</strong> internal gripper-engagement<br />

angle<br />

- Location of <strong>the</strong> ejection face in relation to<br />

<strong>the</strong> flange<br />

- Location of spindle taper in relation to <strong>the</strong><br />

spindle face<br />

- Parallelism of drive keys<br />

- Location of drive keys<br />

- Location of Gripper Actuating Cam Angle<br />

Helmut <strong>Diebold</strong> GmbH & Co. • An der Sägmühle 4 • D-72417 Jungingen • Telefon (0 74 77) 871-0 • Telefax (0 74 77) 871-30 • E-Mail: <strong>Diebold</strong>@hsk.com •<br />

www.hsk.com

<strong>HSK</strong> <strong>Gauge</strong>-Masters<br />

<strong>Diebold</strong> owns <strong>the</strong> Master for <strong>HSK</strong> taper gauges. Our masters have been calibrated and certified by<br />

<strong>the</strong> most recognized calibration institutes in Germany and Switzerland. Based on <strong>the</strong> accuracy of<br />

<strong>the</strong>se master gauges we are enabled to manufacture <strong>the</strong> finest taper gauges in modern industry.<br />

Worldwide many wellknown manufacturers of toolholders and PCB cutting tools are using our gauge<br />

systems and our certification service. Our gauge systems make sure that tapered tools are accurate<br />

and reliable in any machining process and that all dimension are made accordíng to <strong>the</strong> DIN or ISO<br />

standards.<br />

<strong>Diebold</strong> gauges are made of special gauge steel for extremely long life. Especially when <strong>the</strong>se<br />

gauges are being used in manufacturing where <strong>the</strong>y run through daily gauge setup procedures<br />

those gauges offer <strong>the</strong> best repeatability and quality.<br />

<strong>Diebold</strong> offers calibration and certification service according to ISO 9000. In our database we run a<br />

documentation of all new gauges and gauges that will be returned for service, calibration or recertification.<br />

<strong>HSK</strong> Master Taper<br />

Helmut <strong>Diebold</strong> GmbH & Co. • An der Sägmühle 4 • D-72417 Jungingen • Telefon (0 74 77) 871-0 • Telefax (0 74 77) 871-30 • E-Mail: <strong>Diebold</strong>@hsk.com •<br />

www.hsk.com

<strong>Diebold</strong> Test Bars<br />

High precision test bars, certified to satisfaction<br />

When you are looking for reliable test bars you will find <strong>the</strong> finest<br />

products at <strong>Diebold</strong>, produced in our climate controlled facility in<br />

Jungingen, Germany and certified with <strong>the</strong> best test equipment.<br />

Based on our 50 years of experience in manufacturing high quality<br />

tool holders we installed processes that enable us to manufacture<br />

<strong>the</strong> most reliable test arbors. Many machine tool manufacturers<br />

worldwide are using our test arbors for calibration of <strong>the</strong>ir machine<br />

tools.<br />

<strong>Diebold</strong> offers professional calibration and certification<br />

services for all test bar types according to ISO 9000.<br />

We use state of <strong>the</strong> art CMM systems for verification of our products. For certification of master<br />

tapers we installed processes according to <strong>the</strong> rules of <strong>the</strong> DKD (Deutscher Kalibrierdienst). Our<br />

CMM systems are working in a climate controlled zone class 2. Since 2006 we manufacture all high<br />

precision parts in our fully climate controlled manufacturing plant.<br />

Leitz CMM<br />

<strong>Diebold</strong> Factory<br />

Helmut <strong>Diebold</strong> GmbH & Co. • An der Sägmühle 4 • D-72417 Jungingen • Telefon (0 74 77) 871-0 • Telefax (0 74 77) 871-30 • E-Mail: <strong>Diebold</strong>@hsk.com •<br />

www.hsk.com

<strong>Diebold</strong> Pull Force <strong>Gauge</strong>s<br />

to determine <strong>the</strong> amount of pull force<br />

Meticulously crafted mechanical gauge used to determine <strong>the</strong><br />

amount of pull force being exerted on a toolholder in a spindle.<br />

Fatigued or damaged spring-packs, damaged or corroded internal<br />

components, or improper spindle cam angle, machining can result<br />

in potentially dangerously low pull force levels! In addition, runout<br />

and chatter will increase, and stiffness and repeatability will<br />

decrease. Our Mechanical Pull Force <strong>Gauge</strong> is accurate, robust,<br />

and cost-effective.<br />

Tool Presetter VEG-400<br />

For measuring length and diameter of milling and boring tools.<br />

<strong>Diebold</strong> presetters offer many features for setup of tools on <strong>the</strong> shop floor.<br />

With one fixed indictor it is very easy to calibrate <strong>the</strong> unit. The indicator<br />

touches <strong>the</strong> spindle diameter and spindle face for calibration of length and<br />

radius. The indicator touches <strong>the</strong> tip of <strong>the</strong> tool and <strong>the</strong> digital readout<br />

gives length and radius of <strong>the</strong> tool. The spindles of <strong>the</strong> presetter allows to<br />

use reductions for all <strong>HSK</strong> tapers and steep tapers.<br />

Test Arbor and Pull Force <strong>Gauge</strong> Sets<br />

Machine Tool builders love our gauge sets. According to <strong>the</strong>ir<br />

need we offer sets of test arbors combined with pull forcea<br />

gauges for service engineers. We supply case, gauges and<br />

inspection records for <strong>the</strong>se gauge sets.<br />

Helmut <strong>Diebold</strong> GmbH & Co. • An der Sägmühle 4 • D-72417 Jungingen • Telefon (0 74 77) 871-0 • Telefax (0 74 77) 871-30 • E-Mail: <strong>Diebold</strong>@hsk.com •<br />

www.hsk.com