Wainbee HMA Hydraulic Power Carts - Wainbee Limited

Wainbee HMA Hydraulic Power Carts - Wainbee Limited

Wainbee HMA Hydraulic Power Carts - Wainbee Limited

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

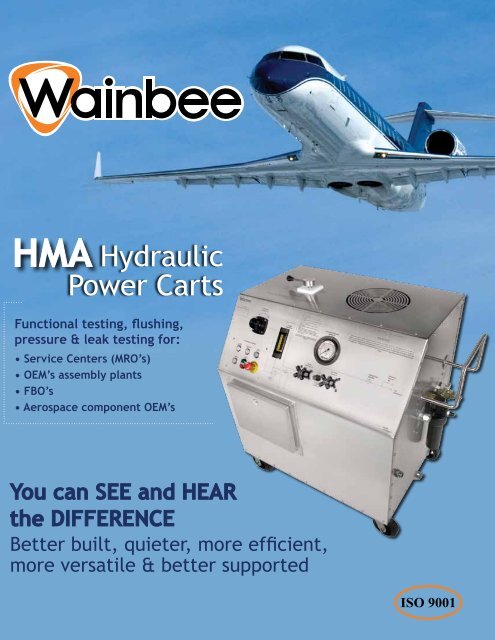

<strong>HMA</strong> <strong>Hydraulic</strong><br />

<strong>Power</strong> <strong>Carts</strong><br />

Functional testing, flushing,<br />

pressure & leak testing for:<br />

• Service Centers (MRO’s)<br />

• OEM’s assembly plants<br />

• FBO’s<br />

• Aerospace component OEM’s<br />

You can SEE and HEAR<br />

the DIFFERENCE<br />

Better built, quieter, more efficient,<br />

more versatile & better supported

Max flows at peak pressure<br />

Pressure line proof:<br />

0.66 GPM @ 5000 PSI (2.5 L/m @ 350 bar)<br />

Functional slam test:<br />

6.5, 15 or 24 GPM @ 3000 PSI<br />

(24.6, 56.8 or 91 L/m @ 210 bar)<br />

Nitrogen pre-test and purge: 500 PSI (35 bar)<br />

Motor sizes: 15 or 30 HP (11.2 or 22.4 kW)<br />

Max Flows: 8.5 or 15 GPM @ 3000 PSI<br />

(32.2 to 56.8 L/m @ 210 bar)<br />

Max flows at peak pressure<br />

HE2: 15 HP (11.2 kW) motor<br />

8.5 GPM @ 3000 PSI (32.2 L/m @ 210 bar)<br />

HE2M: 30 HP (22..4 kW) motor<br />

15 GPM @ 3000 PSI (56.8 L/m @ 210 bar)<br />

Notes: Flow rates will be reduced by 17% when running on 50Hz electric power.<br />

Higher flows and pressures available. Call us with your requirements<br />

Motor sizes: 5 or 10 HP (3.7 or 7.5 kW)<br />

Max flows: 2.2 to 5 GPM @ 3000 PSI<br />

(8.3 to 18.9 L/m @ 210 bar)<br />

Hand pump operation: 0.19 cu. in./min @ 5000 PSI<br />

(3cm 3 /stroke @ 350 bar)<br />

Filling cart provides clean oil for production, testing and maintenance<br />

needs.<br />

2 HP (1.49 kW) motor provides up to 7.5 GPM at 65 PSI. (28.4 L/min<br />

at 4.5 bar)<br />

Different models of these units pressure test hydraulic circuits, fuel<br />

systems and bleed air systems using compressed nitrogen or shop air.<br />

Sturdy handles provide multiple mounting options and easy transport<br />

between workstations.<br />

Why <strong>Wainbee</strong> <strong>Hydraulic</strong> <strong>Power</strong> <strong>Carts</strong><br />

are your best choice<br />

Better Built<br />

• Full high grade 304 stainless construction instead of corrosion-prone painted regular steel.<br />

• Schematic drawings and instructions applied to the unit exterior with ceramic powder<br />

rather than stickers or labels<br />

• Large reservoir capacity provides better heat dissipation and improved component life<br />

• Control cabinets built to CCSAUS standards<br />

Quieter<br />

• In-tank pump system dramatically reduces noise levels on frames 0, 1 and 2<br />

<strong>HMA</strong> MODELS Frame 0 Frame 1 Frame 2 Frame 3 Frame 4<br />

Flow capacity 2 – 6 GPM (8 – 23 LPM) 10 – 11 GPM (38 – 42 LPM) 15 – 20 GPM (58 – 77 LPM) 25 – 35 GPM (96 – 135 LPM) 50 GPM (190 LPM)<br />

Reservoir size 18 gallons (68 L) 30 gallons (113 L) 40 gallons (151 L) 70 gallons (265 L) 130 gallons (495 L)<br />

Electric motor sizes 3 – 7.5 HP (2 – 6 kW) 15– 25 HP (11– 19kW) 25 – 40 HP (19 – 30 kW) 40 – 75 HP (30 – 60 kW) 100 – 200 HP (75 – 150 kW)<br />

Width / height / depth (in.) 40 / 45 / 30 47 / 52 / 38 51 / 56 / 39 82 / 60 / 68 82 / 65 / 75<br />

Width / height / depth (cm) 102 / 114 / 76 119 / 132 / 97 130 / 142 / 99 208 / 152 / 173 208 / 165 / 190<br />

Weight Lb (kg) 475 (215) 600 (275) 750 (340) 2000 (900) 2800 (900 )<br />

Pressure Range PSI (Bar) 150 – 3500 (10 – 241) 150 – 4500 (10 – 310) 150 – 4500 (10 – 310) 250 – 5000 (17 – 345) 250 – 5000 (17 – 345)<br />

MODEL DESIGNATION<br />

<strong>HMA</strong><br />

More Efficient<br />

• High efficiency motors and pump controls reduce power consumption<br />

• Ergonomic control design simplifies operator training and reduces errors<br />

More Versatile<br />

• Wide range of flow and pressure combinations<br />

• 7000 PSI /483 Bar – (6000 PSI / 413 Bar fatigue rated) pressure filter – no bypass and<br />

large capacity return line filter<br />

Better supported<br />

<strong>Wainbee</strong> prides itself on following through with great after-sales support to make sure<br />

you are obtaining the greatest benefit possible from the operation of your hydraulic<br />

power cart.<br />

OTHER STANDARD FEATURES<br />

• Easy pressure and flow adjustment<br />

• Visual filter pressure differential indicator<br />

• Locking device<br />

• Generously sized cooling system<br />

• Handle also serves as hose and power cord hanger<br />

• Easily accessible air breather<br />

• Hourmeter<br />

• Pyrometer (temperature indicator)<br />

• Electrical reservoir level sensor<br />

• Phase reversing protection<br />

• Flow and pressure limitation charts on front panel exterior<br />

• Certified pressure gauge<br />

• Beacon light<br />

• Cabinet designed for easy access for maintenance<br />

• Fluid sample valve<br />

• Electrical control<br />

• Remote pressure control<br />

• Flow meter<br />

• Ceramic powder laser engraving<br />

• Pressure gauge<br />

• Gauge calibration port<br />

• Flow control valve<br />

• By-pass valve<br />

FRAME SIZE<br />

Symbol Description<br />

0 Frame 0<br />

1 Frame 1<br />

2 Frame 2<br />

3 Frame 3<br />

4 Frame 4<br />

FLOW<br />

Symbol Description Frame Size<br />

2 2 GPM (8 LPM)<br />

5 5.0 GPM (19 LPM) 0<br />

6 6.0 GPM (23 LPM)<br />

10 10 GPM (38 LPM)<br />

11 11 GPM (42 LPM)<br />

1<br />

15 15 GPM (58 LPM)<br />

20 20 GPM (77 LPM)<br />

2<br />

25 25 GPM (96 LPM)<br />

30 30 GPM (115 LPM) 3<br />

35 35 GPM (135 LPM)<br />

50 50 GPM (190 LPM) 4<br />

PRESSURE<br />

Symbol Description<br />

18 1800 PSI (124 bar)<br />

30 3000 PSI (207 bar)<br />

35 3500 PSI (241 bar)<br />

40 4000 PSI (275 bar)<br />

45 4500 PSI (310 bar)<br />

50 5000 PSI (345 bar)<br />

MOTOR VOLTAGE<br />

Symbol Description<br />

208 208 VAC<br />

220 220-240 VAC<br />

380 380-400 VAC<br />

415 415 VAC<br />

460 440-480 VAC<br />

575 575-600 VAC<br />

VOLTAGE<br />

FREQUENCY<br />

Symbol Description<br />

5 50 Hz<br />

6 60 Hz<br />

FLUID TYPE<br />

Symbol Description<br />

E Skydrol & Hyjet<br />

(EPDM)<br />

N MIL-H-5606<br />

(Nitrile)<br />

MIL-H-83282<br />

V (Fluorocarbon)<br />

MIL-H-87257<br />

marked (Optional)<br />

OPTIONS<br />

Symbol Description<br />

1 15 ft (4.6 m) hose kit<br />

2 25 ft (7.6 m) hose kit<br />

3 50 ft (15.2 m) hose kit<br />

4 Dual system<br />

5 Reservoir selector valve<br />

6 Overflow aircraft return line<br />

7 Reservoir fill hand pump<br />

8 5000 PSI hand pump with a<br />

1 micron non-bypass filter<br />

9 Aircraft functional test kit<br />

10 Nitrogen purge and<br />

pressure test kit<br />

11 Electrical filter clogging<br />

indicator<br />

12 Return line sight glass<br />

13 Temperature shut-off switch<br />

14 Towing kit<br />

15 CE marked<br />

SPECIALS<br />

Symbol Description<br />

None<br />

No special<br />

X****<br />

**** will be<br />

assigned at the factory<br />

Example Model Number<br />

<strong>HMA</strong>2-15304606E/2,5,11,13<br />

is a unit with frame size 2 and having a:<br />

PLC-CONTROLLED UNITS<br />

Our HE series of hydraulic carts adds the power of<br />

PLC controls to the reliability and robustness of the<br />

<strong>HMA</strong> series.<br />

Programs walk the operator through the hose<br />

connection and testing sequence reducing training<br />

times and the chances of errors.<br />

Available in single, dual and triple circuit models<br />

customizable to your exact requirements.<br />

Contact us to get a copy of the<br />

HE brochure.<br />

When it comes to intelligence and ease-of-use,<br />

WAINBEE’S TESTERS are at the top of the class<br />

Pressure, Leak and Functional Test Units<br />

• Multifunction units flush, pressure test and functionally test aircraft hydraulic circuits.<br />

• Sturdy welded construction with stainless steel cabinet and reservoir<br />

• Well-designed access panels simplify maintenance<br />

• Large diameter gauges and digital displays of key performance parameters<br />

• Each unit features high capacity filtration and a cooling system that allows continuous operation<br />

• Available in regular and high-flow models.<br />

HE3 Single circuit unit<br />

Partial Specifications<br />

HE6 Double circuit unit<br />

Partial Specifications<br />

HE2 Triple circuit unit<br />

Partial Specifications<br />

Functional Test, Filtration and Compact Test Units<br />

HE7<br />

Compact<br />

Testers<br />

HE8 Single circuit functional test unit<br />

Partial Specifications<br />

HE7 <strong>Hydraulic</strong> circuit filling cart<br />

Partial Specifications<br />

Compact Testers<br />

1-888-WAINBEE<br />

wainbee.com<br />

approved electrical panel<br />

• Reservoir selector valve<br />

<strong>HMA</strong> 3<br />

• maximum flow of 15 GPM<br />

• driven by a 460V / 3 Ph / 60 Hz<br />

electrical motor<br />

• built with seals for handling Skydrol<br />

or Hyjet, and having the following<br />

accessories:<br />

• 25 ft. hose, a reservoir selector valve,<br />

electrical filter clogging indicator and<br />

temperature shut-off switch.

Engineering Expertise<br />

For decades we have used our expertise in hydraulics, pneumatics, controls and<br />

electromechanics to produce innovative systems for the aerospace industry. Our<br />

strength in control design allows us to provide the option of making customer<br />

systems “smarter” which reduces both training time and the chances of operator<br />

error. We often use our engineering expertise to customize existing designs to<br />

exactly match customer requirements.<br />

Managed Quality from Design to Delivery<br />

<strong>Wainbee</strong> power carts are designed, built and tested in compliance to ISO 9001<br />

standard. This ensures complete and timely communication of customer<br />

requirements to our engineering and production departments as well as the<br />

thorough testing of all units against detailed checklists prior to shipment.<br />

Aerospace Experience<br />

<strong>Wainbee</strong> has been serving the aerospace industry since 1957 when we began<br />

selling pneumatic tools to aircraft mainframers. Since then we have developed<br />

and built:<br />

• Mobile and fixed hydraulic circuit pressure and functional testing<br />

systems for both mainframers and component manufacturers<br />

• Fuselage pressure testers<br />

• Servo actuators and controllers for fuselage-to-wing joining systems<br />

• Custom Oxygen and Nitrogen booster assemblies<br />

A Strong Partner<br />

An employee-owned, coast-to-coast company, <strong>Wainbee</strong> <strong>Limited</strong> provides<br />

components, systems and engineering expertise to many industries.<br />

This diversification, along with a prudent approach to growth, ensures that<br />

<strong>Wainbee</strong> has the financial strength to be a strong partner regardless of global<br />

economic conditions.<br />

1-888-WAINBEE<br />

www.wainbee.com<br />

Montreal * Toronto * Vancouver * Edmonton<br />

Prince George * Calgary * Saskatoon * Kitchener * Quebec<br />

Chicoutimi * Sept-Îles * Dartmouth * Winnipeg