CAM CLUTCH

CAM CLUTCH

CAM CLUTCH

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

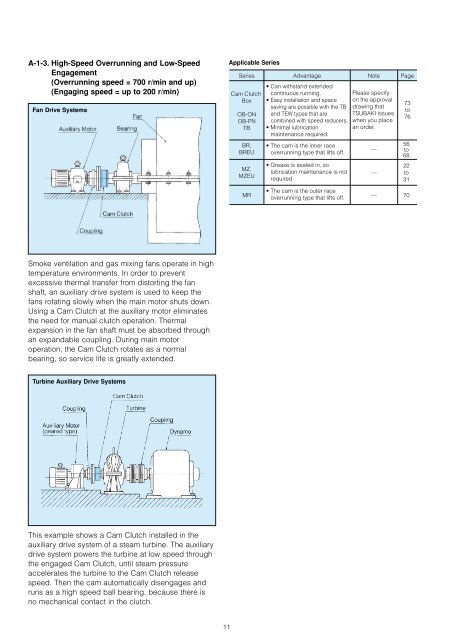

A-1-3. High-Speed Overrunning and Low-Speed<br />

Engagement<br />

(Overrunning speed = 700 r/min and up)<br />

(Engaging speed = up to 200 r/min)<br />

Fan Drive Systems<br />

Applicable Series<br />

Series Advantage Note Page<br />

Cam Clutch<br />

Box<br />

OB-ON<br />

OB-PN<br />

TB<br />

BR,<br />

BREU<br />

MZ,<br />

MZEU<br />

• Can withstand extended<br />

continuous running.<br />

• Easy installation and space<br />

saving are possible with the TB<br />

and TEW types that are<br />

combined with speed reducers.<br />

• Minimal lubrication<br />

maintenance required.<br />

• The cam is the inner race<br />

overrunning type that lifts off.<br />

• Grease is sealed in, so<br />

lubrication maintenance is not<br />

required.<br />

Please specify<br />

on the approval<br />

drawing that<br />

TSUBAKI issues<br />

when you place<br />

an order.<br />

—<br />

—<br />

73<br />

to<br />

76<br />

56<br />

to<br />

68<br />

22<br />

to<br />

31<br />

MR<br />

• The cam is the outer race<br />

overrunning type that lifts off.<br />

— 70<br />

Smoke ventilation and gas mixing fans operate in high<br />

temperature environments. In order to prevent<br />

excessive thermal transfer from distorting the fan<br />

shaft, an auxiliary drive system is used to keep the<br />

fans rotating slowly when the main motor shuts down.<br />

Using a Cam Clutch at the auxiliary motor eliminates<br />

the need for manual clutch operation. Thermal<br />

expansion in the fan shaft must be absorbed through<br />

an expandable coupling. During main motor<br />

operation, the Cam Clutch rotates as a normal<br />

bearing, so service life is greatly extended.<br />

Turbine Auxiliary Drive Systems<br />

This example shows a Cam Clutch installed in the<br />

auxiliary drive system of a steam turbine. The auxiliary<br />

drive system powers the turbine at low speed through<br />

the engaged Cam Clutch, until steam pressure<br />

accelerates the turbine to the Cam Clutch release<br />

speed. Then the cam automatically disengages and<br />

runs as a high speed ball bearing, because there is<br />

no mechanical contact in the clutch.<br />

11