CAM CLUTCH

CAM CLUTCH

CAM CLUTCH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

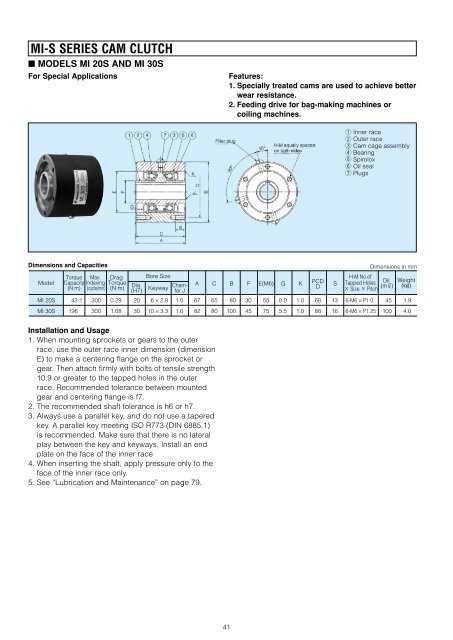

MI-S SERIES <strong>CAM</strong> <strong>CLUTCH</strong><br />

■ MODELS MI 20S AND MI 30S<br />

For Special Applications<br />

Features:<br />

1. Specially treated cams are used to achieve better<br />

wear resistance.<br />

2. Feeding drive for bag-making machines or<br />

coiling machines.<br />

q Inner race<br />

w Outer race<br />

e Cam cage assembly<br />

r Bearing<br />

t Spirolox<br />

y Oil seal<br />

u Plugs<br />

Dimensions and Capacities<br />

Model<br />

Torque<br />

Capacity<br />

(N·m)<br />

Max.<br />

Indexing<br />

(cycle/min)<br />

Drag<br />

Torque<br />

(N·m)<br />

Dia.<br />

(H7)<br />

Bore Size<br />

Keyway<br />

Chamfer<br />

J<br />

A<br />

C<br />

B<br />

F<br />

E(M6)<br />

G<br />

K<br />

PCD<br />

S<br />

Dimensions in mm<br />

H-M No.of<br />

Tapped Holes Oil<br />

(mr)<br />

Size Pitch<br />

Weight<br />

(o)<br />

MI 20S<br />

43.1<br />

300<br />

0.29<br />

20<br />

6 × 2.8<br />

1.0<br />

67<br />

65<br />

80<br />

30<br />

55<br />

8.0<br />

1.0<br />

D<br />

13<br />

68<br />

6-M6 × P1.0<br />

45<br />

1.9<br />

MI 30S<br />

196<br />

300<br />

1.08<br />

30<br />

10 × 3.3<br />

1.0<br />

82<br />

80<br />

100<br />

45<br />

75<br />

5.5<br />

1.0<br />

88<br />

16<br />

6-M6 × P1.25<br />

100<br />

4.0<br />

Installation and Usage<br />

1. When mounting sprockets or gears to the outer<br />

race, use the outer race inner dimension (dimension<br />

E) to make a centering flange on the sprocket or<br />

gear. Then attach firmly with bolts of tensile strength<br />

10.9 or greater to the tapped holes in the outer<br />

race. Recommended tolerance between mounted<br />

gear and centering flange is f7.<br />

2. The recommended shaft tolerance is h6 or h7.<br />

3. Always use a parallel key, and do not use a tapered<br />

key. A parallel key meeting ISO R773 (DIN 6885.1)<br />

is recommended. Make sure that there is no lateral<br />

play between the key and keyways. Install an end<br />

plate on the face of the inner race<br />

4. When inserting the shaft, apply pressure only to the<br />

face of the inner race only.<br />

5. See “Lubrication and Maintenance” on page 79.<br />

41