CAM CLUTCH

CAM CLUTCH

CAM CLUTCH

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

B. INDEXING<br />

(INTERMITTENT FEED)<br />

Cam Behavior and Cam Clutch Operation<br />

In this application, reciprocal movement of a certain<br />

angle (θ) is provided at the outer race of the Cam<br />

Clutch to perform engagement and overrunning in turn<br />

continuously and obtain intermittent rotation. In the case<br />

of the Cam Clutch shown in the figure, when the outer<br />

race moves from A to B, the<br />

Cam Clutch engages to<br />

rotate the inner race (of the<br />

driven side) by angle θ, i.e.,<br />

from a to b. However, the<br />

Cam Clutch does not<br />

operate to stop the inner<br />

race at position b. When the<br />

outer race rotates in reverse<br />

from B to A, the Cam Clutch<br />

overruns while the inner race<br />

(of the driven side) does not rotate. By repeating this<br />

sequential movement, the inner race (of the driven side)<br />

rotates intermittently within the preset angle (θ).<br />

B-1. HIGH SPEED AND SMALL FEED<br />

ANGLE<br />

(Feed frequency: N = 300 to 1,200 times/min.)<br />

(Feed angle: θ = Up to 90°; N × θ = 20,000 max.)<br />

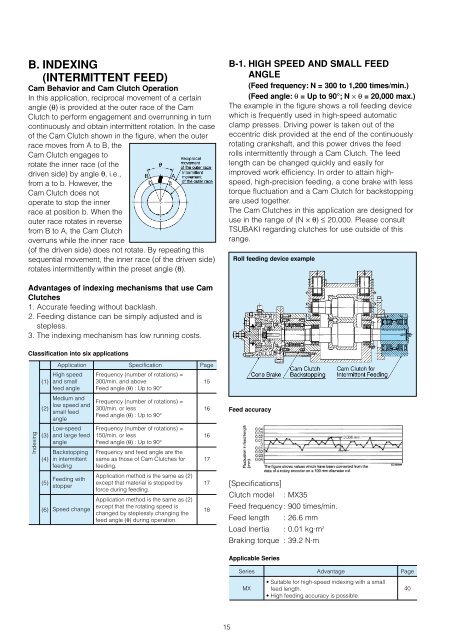

The example in the figure shows a roll feeding device<br />

which is frequently used in high-speed automatic<br />

clamp presses. Driving power is taken out of the<br />

eccentric disk provided at the end of the continuously<br />

rotating crankshaft, and this power drives the feed<br />

rolls intermittently through a Cam Clutch. The feed<br />

length can be changed quickly and easily for<br />

improved work efficiency. In order to attain highspeed,<br />

high-precision feeding, a cone brake with less<br />

torque fluctuation and a Cam Clutch for backstopping<br />

are used together.<br />

The Cam Clutches in this application are designed for<br />

use in the range of (N × θ) ≤ 20,000. Please consult<br />

TSUBAKI regarding clutches for use outside of this<br />

range.<br />

Roll feeding device example<br />

Advantages of indexing mechanisms that use Cam<br />

Clutches<br />

1. Accurate feeding without backlash.<br />

2. Feeding distance can be simply adjusted and is<br />

stepless.<br />

3. The indexing mechanism has low running costs.<br />

Classification into six applications<br />

Indexing<br />

(1)<br />

(2)<br />

(3)<br />

(4)<br />

(5)<br />

Application Specification Page<br />

High speed<br />

and small<br />

feed angle<br />

Medium and<br />

low speed and<br />

small feed<br />

angle<br />

Low-speed<br />

and large feed<br />

angle<br />

Backstopping<br />

in intermittent<br />

feeding<br />

Feeding with<br />

stopper<br />

(6) Speed change<br />

Frequency (number of rotations) =<br />

300/min. and above<br />

Feed angle (θ) : Up to 90°<br />

Frequency (number of rotations) =<br />

300/min. or less<br />

Feed angle (θ) : Up to 90°<br />

Frequency (number of rotations) =<br />

150/min. or less<br />

Feed angle (θ) : Up to 90°<br />

Frequency and feed angle are the<br />

same as those of Cam Clutches for<br />

feeding.<br />

Application method is the same as (2)<br />

except that material is stopped by<br />

force during feeding.<br />

Application method is the same as (2)<br />

except that the rotating speed is<br />

changed by steplessly changing the<br />

feed angle (θ) during operation.<br />

15<br />

16<br />

16<br />

17<br />

17<br />

18<br />

Feed accuracy<br />

[Specifications]<br />

Clutch model : MX35<br />

Feed frequency : 900 times/min.<br />

Feed length : 26.6 mm<br />

Load lnertia : 0.01 kg·m 2<br />

Braking torque : 39.2 N·m<br />

Applicable Series<br />

Series Advantage Page<br />

MX<br />

• Suitable for high-speed indexing with a small<br />

feed length.<br />

• High feeding accuracy is possible.<br />

40<br />

15