ISSN : 2277-1328 (Online) - ISRM

ISSN : 2277-1328 (Online) - ISRM

ISSN : 2277-1328 (Online) - ISRM

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

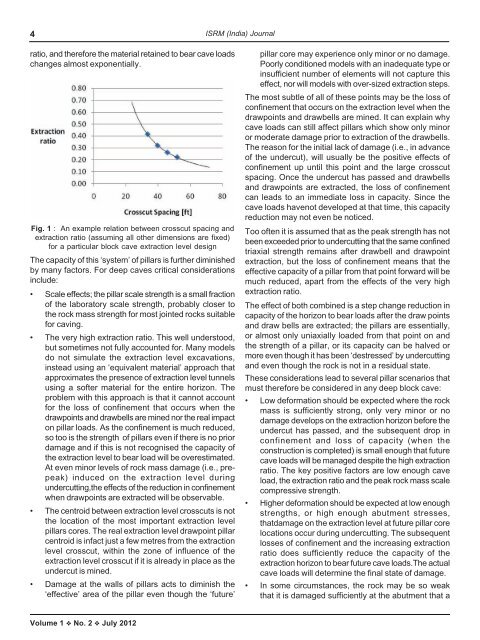

4 <strong>ISRM</strong> (India) Journal<br />

ratio, and therefore the material retained to bear cave loads<br />

changes almost exponentially.<br />

Fig. 1 : An example relation between crosscut spacing and<br />

extraction ratio (assuming all other dimensions are fixed)<br />

for a particular block cave extraction level design<br />

The capacity of this ‘system’ of pillars is further diminished<br />

by many factors. For deep caves critical considerations<br />

include:<br />

• Scale effects; the pillar scale strength is a small fraction<br />

of the laboratory scale strength, probably closer to<br />

the rock mass strength for most jointed rocks suitable<br />

for caving.<br />

• The very high extraction ratio. This well understood,<br />

but sometimes not fully accounted for. Many models<br />

do not simulate the extraction level excavations,<br />

instead using an ‘equivalent material’ approach that<br />

approximates the presence of extraction level tunnels<br />

using a softer material for the entire horizon. The<br />

problem with this approach is that it cannot account<br />

for the loss of confinement that occurs when the<br />

drawpoints and drawbells are mined nor the real impact<br />

on pillar loads. As the confinement is much reduced,<br />

so too is the strength of pillars even if there is no prior<br />

damage and if this is not recognised the capacity of<br />

the extraction level to bear load will be overestimated.<br />

At even minor levels of rock mass damage (i.e., prepeak)<br />

induced on the extraction level during<br />

undercutting,the effects of the reduction in confinement<br />

when drawpoints are extracted will be observable.<br />

• The centroid between extraction level crosscuts is not<br />

the location of the most important extraction level<br />

pillars cores. The real extraction level drawpoint pillar<br />

centroid is infact just a few metres from the extraction<br />

level crosscut, within the zone of influence of the<br />

extraction level crosscut if it is already in place as the<br />

undercut is mined.<br />

• Damage at the walls of pillars acts to diminish the<br />

‘effective’ area of the pillar even though the ‘future’<br />

pillar core may experience only minor or no damage.<br />

Poorly conditioned models with an inadequate type or<br />

insufficient number of elements will not capture this<br />

effect, nor will models with over-sized extraction steps.<br />

The most subtle of all of these points may be the loss of<br />

confinement that occurs on the extraction level when the<br />

drawpoints and drawbells are mined. It can explain why<br />

cave loads can still affect pillars which show only minor<br />

or moderate damage prior to extraction of the drawbells.<br />

The reason for the initial lack of damage (i.e., in advance<br />

of the undercut), will usually be the positive effects of<br />

confinement up until this point and the large crosscut<br />

spacing. Once the undercut has passed and drawbells<br />

and drawpoints are extracted, the loss of confinement<br />

can leads to an immediate loss in capacity. Since the<br />

cave loads havenot developed at that time, this capacity<br />

reduction may not even be noticed.<br />

Too often it is assumed that as the peak strength has not<br />

been exceeded prior to undercutting that the same confined<br />

triaxial strength remains after drawbell and drawpoint<br />

extraction, but the loss of confinement means that the<br />

effective capacity of a pillar from that point forward will be<br />

much reduced, apart from the effects of the very high<br />

extraction ratio.<br />

The effect of both combined is a step change reduction in<br />

capacity of the horizon to bear loads after the draw points<br />

and draw bells are extracted; the pillars are essentially,<br />

or almost only uniaxially loaded from that point on and<br />

the strength of a pillar, or its capacity can be halved or<br />

more even though it has been ‘destressed’ by undercutting<br />

and even though the rock is not in a residual state.<br />

These considerations lead to several pillar scenarios that<br />

must therefore be considered in any deep block cave:<br />

• Low deformation should be expected where the rock<br />

mass is sufficiently strong, only very minor or no<br />

damage develops on the extraction horizon before the<br />

undercut has passed, and the subsequent drop in<br />

confinement and loss of capacity (when the<br />

construction is completed) is small enough that future<br />

cave loads will be managed despite the high extraction<br />

ratio. The key positive factors are low enough cave<br />

load, the extraction ratio and the peak rock mass scale<br />

compressive strength.<br />

• Higher deformation should be expected at low enough<br />

strengths, or high enough abutment stresses,<br />

thatdamage on the extraction level at future pillar core<br />

locations occur during undercutting. The subsequent<br />

losses of confinement and the increasing extraction<br />

ratio does sufficiently reduce the capacity of the<br />

extraction horizon to bear future cave loads.The actual<br />

cave loads will determine the final state of damage.<br />

• In some circumstances, the rock may be so weak<br />

that it is damaged sufficiently at the abutment that a<br />

Volume 1 No. 2 July 2012