Solumstrand Wastewater Treatment Plant - AnoxKaldnes

Solumstrand Wastewater Treatment Plant - AnoxKaldnes

Solumstrand Wastewater Treatment Plant - AnoxKaldnes

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

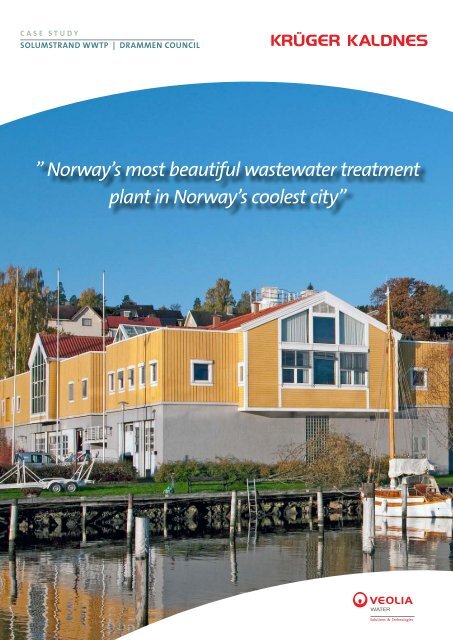

CASE STUDY<br />

SOLUMSTRAND WWTP | DRAMMEN Council<br />

” Norway’s most beautiful wastewater treatment<br />

plant in Norway’s coolest city”

The whole chemical handling system was<br />

housed in the existing basin hall.<br />

Actiflo® - from 0-100<br />

in 10 minutes!<br />

Greater capacity -<br />

same floor footprint!<br />

<strong>Solumstrand</strong> <strong>Wastewater</strong> <strong>Treatment</strong> <strong>Plant</strong> was built<br />

in 1991 with a capacity of 3.000 m 3 /h using primary<br />

calcium precipitation and seawater. A subsequent<br />

requirement for secondary treatment plus the need to<br />

increase the capacity to compensate for the closing of<br />

the Muusøya <strong>Treatment</strong> <strong>Plant</strong>, led to a major renewal<br />

and expansion of the plant in 2011. The new design<br />

capacity is 4.000 m 3 /h which includes both chemical<br />

precipitation and biological treatment.<br />

DESIGN<br />

Kaldnes MBBR Actiflo®<br />

Four parallel lines with<br />

2 Kaldnes MBBR in series followed by<br />

two Actiflo® units built on site<br />

Reactor volume/line 2 x 390 m 3 -<br />

Reactor Lamella surface/line - 2 x 26 m 2<br />

Fill-level biomedia 59 % -<br />

SALR (10°C) 11,5 g BOF 5<br />

/m 2 *d -<br />

Kaldnes biomedia Kaldnes K3 -<br />

Air capacity 18.400 Nm 3 /t -<br />

Solution<br />

Four of the existing 6 sedimentation basins were<br />

converted to Kaldnes MBBR reactors while the<br />

remaining two were rebuilt as dual-flow Actiflo®’s,<br />

each with a capacity of 2.750 m 3 /h. This released more<br />

space in the basins that could be used for storing<br />

chemicals and dosage equipment. This combination of<br />

processes increased the capacity and transformed the<br />

treatment process without having to extend the plant<br />

area.<br />

Creating water solutions in practice!<br />

CASE STUDY<br />

SOLUMSTRAND WWTP | DRAMMEN Council<br />

Existing sludge storage<br />

retained<br />

Previously:<br />

Lines 5-6 Chemical treatment stage<br />

Now:<br />

- Chemical treatment stage 1-2<br />

-Storage of precipitation chemicals<br />

- Polymer storage and pretreatment for<br />

water treatment and densifying.<br />

Existing gravity<br />

densifiers retained<br />

Previously:<br />

Lines 1-4 chemical<br />

treatment stage<br />

Now:<br />

Biological treatment<br />

stage 1-4

FACTS<br />

<strong>Solumstrand</strong> WWTP<br />

Kaldnes TM MBBR - completely<br />

sealed biological process<br />

Start-up 2011<br />

Client:<br />

Consultant:<br />

Drammen Council<br />

Norconsult, Sandvika<br />

Task:<br />

To design a treatment plant with expansion possibilities that<br />

can cater for large, seasonal variations in waste-water and<br />

organic loads.<br />

Solution:<br />

Combine two well-proven technologies - the compact<br />

Kaldnes MBBR process for removing organic waste and<br />

Actiflo® for chemical precipitation and solids separation.<br />

Design capacity:<br />

Qdim: 2000 m 3 /t<br />

Qmaksdim: 4000 m 3 /t<br />

Alfa Laval sludge<br />

densifiers.<br />

Organic loading:<br />

7755 kg BOF 5<br />

/d<br />

20350 kg KOF/d<br />

Discharge requirements<br />

BOF 5<br />

: < 25 mg/l or > 70 % of purification effect<br />

KOFCr: < 125 mg/l or >75 % of purification effect<br />

Tot-P: > 90% purification<br />

Plexiglas inspection hatches<br />

Polymer preparation

www.krugerkaldnes.no<br />

post@krugerkaldnes.no<br />

phone: +47 91 60 80 00<br />

<strong>Solumstrand</strong><br />

renseanlegg<br />

Oppstart<br />

2011<br />

Kunde<br />

Drammen kommune<br />

Konsulent: Norconsult<br />

Utfordring<br />

Å designe et renseanlegg med planlagt fremtidig utvidelse og store sesongvariasjoner i vannmengde og organisk<br />

belastning.<br />

Løsning<br />

Kombinere to vel prøvede teknologier. Den kompakte Kaldnes MBBR prosessen for fjerning av organisk stoff<br />

og Actiflo ® for kjemisk felling og partikkel separasjon.<br />

Design kapasitet<br />

Q dim : 2000 m 3 /t<br />

Q dim maks: 4000 m 3 /t<br />

Organisk belastning:<br />

7755 kg BOF 5 /d<br />

20350 kg KOF/d<br />

mg/l<br />

1000<br />

KOF inn<br />

KOF ut<br />

Utslippskrav<br />

BOF 5 :<br />

KOF Cr :<br />

Tot-P:<br />

< 25 mg/l eller > 70 % renseeffekt<br />

< 125 mg/l eller >75 % renseeffekt<br />

> 90% renseeffekt<br />

800<br />

600<br />

400<br />

Results from February - April, 2011<br />

Renseresultater<br />

200<br />

0<br />

17.01.2011 06.02.2011 26.02.2011 18.03.2011 07.04.2011 27.04.2011 17.05.2011<br />

mg<br />

BOF in BOF ut<br />

375<br />

350<br />

325<br />

300<br />

275<br />

250<br />

225<br />

200<br />

175<br />

150<br />

125<br />

100<br />

75<br />

50<br />

25<br />

0<br />

17.01.2011 06.02.2011 26.02.2011 18.03.2011 07.04.2011 27.04.2011 17.05.2011<br />

mg/l<br />

Tot-P inn Tot-P ut<br />

10<br />

9<br />

8<br />

7<br />

6<br />

5<br />

4<br />

3<br />

2<br />

1<br />

0<br />

17.01.2011 06.02.2011 26.02.2011 18.03.2011 07.04.2011 27.04.2011 17.05.2011<br />

mg/l<br />

KOF inn KOF ut<br />

1000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

17.01.2011 06.02.2011 26.02.2011 18.03.2011 07.04.2011 27.04.2011 17.05.2011<br />

Parameter Mean purification result Mean discharge<br />

BOF 5<br />

82 % 23 mg/L<br />

KOF 82 % 80 mg/L<br />

Resultater fra feb - apr 2011<br />

Parameter Tot-P Gjenomsnittlig Gjenomsnittlig<br />

93 % 0,25 mg/L<br />

renseresultat utløpsverdi<br />

Values based on daily mixed samples from the start-up period which<br />

BOF 5 82 % 23 mg/L<br />

included considerable adjustment and optimization..<br />

KOF 82 % 80 mg/L<br />

Tot-P 93 % 0,25 mg/L<br />

Verdier basert på døgnblandprøver fra den inledande<br />

periode som till stor del varit en periode med intrimning<br />

og optimalisering.<br />

JHR Produksjon - june, 2011<br />

mg/l<br />

10<br />

9<br />

8<br />

Tot-P inn<br />

Tot-P ut<br />

7<br />

6<br />

CASE STUDY<br />

5<br />

SOLUMSTRAND 4 WWTP | DRAMMEN Council<br />

3<br />

®<br />

2<br />

1<br />

0<br />

17.01.2011 06.02.2011 26.02.2011 18.03.2011 07.04.2011 27.04.2011 17.05.2011