Choosing Skilled Trades - CTMA: The Canadian Tooling and ...

Choosing Skilled Trades - CTMA: The Canadian Tooling and ...

Choosing Skilled Trades - CTMA: The Canadian Tooling and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

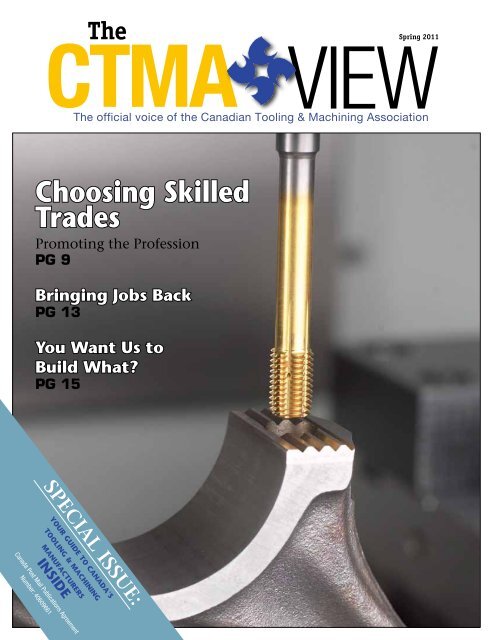

<strong>The</strong> Spring 2011<br />

<strong>CTMA</strong> view<br />

<strong>The</strong> official voice of the <strong>Canadian</strong> <strong>Tooling</strong> & Machining Association<br />

<strong>Choosing</strong> <strong>Skilled</strong><br />

<strong>Trades</strong><br />

Promoting the Profession<br />

PG 9<br />

Bringing Jobs Back<br />

PG 13<br />

You Want Us to<br />

Build What?<br />

PG 15<br />

SPECIAL ISSUE:<br />

your Guide to canada’s<br />

tooling & machining<br />

manufacturers<br />

Canada Post Mail Publications Agreement<br />

inside<br />

Number: 40609661

contents<br />

Spring 2011<br />

UP FRONT<br />

7 A Message from the <strong>CTMA</strong> President<br />

21 <strong>The</strong> 2011 Board of Directors<br />

16<br />

ON THE COVER<br />

9 Ontario College of <strong>Trades</strong> Studies for High Grades<br />

Cover Photo Credit: Image of a carbide form tap (Guhring Series 1581) about to<br />

thread a steel connecting rod provided by Guhring.<br />

FEATURES<br />

13 Reshoring Initiative Bringing Jobs Back<br />

15 Unusual Items Produced by the <strong>Canadian</strong><br />

<strong>Tooling</strong> Industry<br />

17<br />

MEMBER PROFILE<br />

16 Rice Tool & Manufacturing Inc.<br />

<strong>CTMA</strong> HEADLINES<br />

17 13th Annual Shotgun Golf Tournament<br />

17 <strong>CTMA</strong> Launches Annual Bursary Program<br />

24 NTMA-PMA Contract Manufacturing Purchasing<br />

Fair<br />

20<br />

20 TOOLS OF THE TRADE<br />

IN EVERY ISSUE<br />

21 <strong>CTMA</strong> Welcomes New Member Companies<br />

22 <strong>CTMA</strong> Chapter News<br />

23 2011 Calendar of Upcoming Events<br />

24 Upcoming SME Events<br />

SPECIAL SECTION: YOUR GUIDE TO<br />

CANADA’S TOOLING & MACHINING<br />

MANUFACTURERS<br />

25 Alphabetical Listing of <strong>CTMA</strong> Member Companies<br />

26 <strong>CTMA</strong> Member’s Capability Index<br />

28 <strong>CTMA</strong> Member’s Guide<br />

38 BUYER’S GUIDE<br />

Spring 2011<br />

Published For:<br />

<strong>The</strong> <strong>Canadian</strong> <strong>Tooling</strong> & Machining<br />

Association<br />

140 McGovern Drive, Unit 3<br />

Cambridge, Ontario N3H 4R7<br />

Tel: (519) 653-7265<br />

Fax: (519) 653-6764<br />

info@ctma.com<br />

www.ctma.com<br />

<strong>The</strong> contributed articles presented in<br />

this magazine represent the opinions of<br />

the authors <strong>and</strong> the interviewees. <strong>The</strong>ir<br />

inclusion does not directly or implicitly<br />

denote concurrence by the <strong>Canadian</strong> <strong>Tooling</strong><br />

& Machining Association. Articles were<br />

selected for inclusion based on the issues<br />

<strong>and</strong> views of interest to the industry.<br />

Published By:<br />

Matrix Group Publishing Inc.<br />

Return all undeliverable addresses to:<br />

52 Donald Street, Suite 300<br />

Winnipeg, Manitoba R3C 1L6<br />

Toll Free: (866) 999-1299<br />

Toll Free Fax: (866) 244-2544<br />

www.matrixgroupinc.net<br />

Canada Post Mail Publications<br />

Agreement Number: 40609661<br />

President & CEO<br />

Jack Andress<br />

Senior Publisher<br />

Maurice LaBorde<br />

Editor-in-Chief<br />

Shannon Savory<br />

ssavory@matrixgroupinc.net<br />

Editor<br />

Alex<strong>and</strong>ra Walld<br />

awalld@matrixgroupinc.net<br />

Karen Kornelson<br />

Lara Schroeder<br />

Finance/Administration<br />

Shoshana Weinberg, Pat Andress,<br />

Nathan Redekop<br />

accounting@matrixgroupinc.net<br />

Director of Marketing & Circulation<br />

Shoshana Weinberg<br />

Sales Manager - Winnipeg<br />

Neil Gottfred<br />

Sales Manager - Hamilton<br />

Jessica Potter<br />

Sales Team Leader<br />

Brian Davey<br />

Matrix Group Publishing Inc.<br />

Account Executives<br />

Colleen Bell, Trish Bird, Albert Brydges,<br />

Rob Choi, Chantal Duchaine, Aaron<br />

Enwright, Garrett Friend, Bruno Fucchin,<br />

Jim Hamilton, Rick Kuzie, Brian<br />

Macintyre, Miles Meagher, Gary Nagy,<br />

Declan O’Donovan, Ken Percival, Peter<br />

Schulz, Benjamin Schutt, Earle Wayne<br />

Advertising Design<br />

James Robinson<br />

Layout & Design<br />

Travis Bevan<br />

©2011 Matrix Group Publishing Inc. All rights reserved.<br />

Contents may not be reproduced by any means, in whole or<br />

in part, without the prior written permission of the publisher.<br />

<strong>The</strong> opinions expressed in this publication are not necessarily<br />

those of Matrix Group Publishing Inc. Printed in Canada.<br />

5<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association

up front<br />

Friends, this message is<br />

being written when it’s officially Spring<br />

but it certainly doesn’t feel like it in<br />

Ontario; however, we know warmer<br />

weather is on the way. This reality reflects<br />

the economic <strong>and</strong> business conditions<br />

during the <strong>CTMA</strong> community’s first<br />

quarter. “Cautiously optimistic” are the<br />

descriptive words—we know a true economic<br />

recovery is on its way but hasn’t<br />

arrived yet. As most indicators of business<br />

conditions point to a sustainable<br />

economic recovery in North America, we<br />

are susceptible to the backdrop of global<br />

events beyond our control. From a micro<br />

frame of reference based on Q1-2011<br />

actuals, companies in our membership<br />

are, on average, witnessing incremental<br />

improvements in overall business conditions<br />

<strong>and</strong> outlook.<br />

As you know, the <strong>CTMA</strong> is a member<br />

of the <strong>Canadian</strong> Manufacturing Coalition<br />

(CMC) <strong>and</strong> I attended one of its events in<br />

Ottawa which was organized by Jayson<br />

Myers, president of the <strong>Canadian</strong> Manufacturers<br />

& Exporters Association. We<br />

had the privilege of listening to Finance<br />

Minister Jim Flaherty <strong>and</strong> Industry Minister<br />

Tony Clement speak about the federal<br />

A Message from the <strong>CTMA</strong> President<br />

government’s support to the manufacturing<br />

sector. Mr. Myers recently mentioned<br />

that recognition <strong>and</strong> support for initiatives<br />

for <strong>Canadian</strong> manufacturing came<br />

from all political parties. This is a testament<br />

to the efforts by the CMC in getting<br />

the issue on everyone’s priority list.<br />

A colleague recently inquired about<br />

having a back-up plan for his back-up<br />

plan to cover all eventualities for his<br />

company. This was a challenging discussion<br />

since having a viable back-up plan<br />

is a significant achievement in itself, let<br />

alone a second back-up-plan. When I<br />

considered it, he was really engaging in<br />

scenarios planning, looking at a series of<br />

possible business outcomes <strong>and</strong> devising<br />

action plans to minimize negative<br />

impacts on company performance. It’s<br />

a valuable exercise <strong>and</strong> provides management<br />

with nodding acquaintance<br />

when dealing with unexpected events.<br />

<strong>CTMA</strong> member companies might try it if<br />

they are not already using similar tools.<br />

One caveat is not to get carried away in<br />

accounting for every possible scenario<br />

as you attempt to grasp outcomes in an<br />

ever-changing domestic <strong>and</strong> global business<br />

environment.<br />

Your <strong>CTMA</strong> team is in the process of<br />

arranging chapter events consisting of a<br />

plant tour with keynote speakers <strong>and</strong> dinner.<br />

<strong>CTMA</strong> Vice-President David Glover<br />

<strong>and</strong> Colin Docherty, Ralph Schippanoski<br />

<strong>and</strong> Steve Watson, chapter chairs for<br />

Western Ontario, Toronto <strong>and</strong> Windsor<br />

respectively, together with Les Payne are<br />

leading our initiatives for these successful<br />

events. Our Board of Directors also participates<br />

in suggestions for events. Please<br />

contact any <strong>CTMA</strong> team member if you<br />

would like to suggest a particular plant<br />

tour or keynote speaker. <strong>The</strong>se events<br />

provide a unique chance to observe new<br />

technologies, products <strong>and</strong> processes<br />

which could be beneficial to your company<br />

as well providing you with networking<br />

opportunities.<br />

<strong>The</strong> idea of establishing a <strong>CTMA</strong><br />

President’s Forum was mentioned in my<br />

last message. I anticipate it will provide<br />

valuable feedback, opinions <strong>and</strong> discussions<br />

on timely topics <strong>and</strong> issues. Please<br />

contact me at esuphal@ctma.com if you<br />

would like to participate.<br />

I would be remiss if I didn’t mention<br />

the events in Japan <strong>and</strong> the possible<br />

impact on supply chains to various<br />

manufacturing sectors, especially the<br />

automotive sector. Some of our members<br />

are directly affected by changes in<br />

Japanese North American automotive<br />

plant operations because of supply chain<br />

disruptions originating in Japan. We can<br />

only keep monitoring the situation with<br />

the view to react as quickly as possible to<br />

unfolding events <strong>and</strong> offer encouragement<br />

to the people affected by these<br />

tragedies.<br />

Finally, Spring brings fair weather <strong>and</strong><br />

blossoming scenery to nature <strong>and</strong> I trust<br />

it will bring them to our <strong>CTMA</strong> member<br />

companies. Cheers!<br />

Emerson Suphal<br />

<strong>CTMA</strong> President<br />

Go to page 21 for a list of the<br />

<strong>CTMA</strong>’s Board of Directors!<br />

<strong>CTMA</strong> President Emerson Suphal (left) <strong>and</strong> Finance Minister Jim<br />

Flaherty (right). Photo courtesy of <strong>Canadian</strong> Manufacturers &<br />

Exporters, Derek Lothian.<br />

<strong>CTMA</strong> President Emerson Suphal (left) <strong>and</strong> Industry Minister Tony<br />

Clement (right). Photo courtesy of <strong>Canadian</strong> Manufacturers &<br />

Exporters, Derek Lothian.<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association<br />

7

On the cover<br />

Ontario College of <strong>Trades</strong> Studies<br />

for High Grades<br />

<strong>The</strong> Ontario College of <strong>Trades</strong> will fund itself <strong>and</strong> promote choosing a skilled<br />

trade as a profession but some <strong>Canadian</strong> tooling industry professionals are<br />

unsure of the benefits it will bring.<br />

By Alex<strong>and</strong>ra Walld<br />

T<br />

he Ontario College of<br />

<strong>Trades</strong> (COT), which will<br />

promote the value of choosing a<br />

skilled trade as a profession, is in<br />

the process of being formed by<br />

the Ontario government. To date,<br />

trade committees have provided<br />

input on curriculum, apprenticeship<br />

programs <strong>and</strong> training st<strong>and</strong>ards for<br />

Ontario colleges through the Provincial<br />

Advisory Committee (PAC) under the<br />

<strong>Trades</strong> Qualification <strong>and</strong> Apprenticeship<br />

Act (TQAA), which applies to construction<br />

trades, <strong>and</strong> the Industry Committee<br />

(IC) under the Apprenticeship <strong>and</strong> Certification<br />

Act (ACA), which applies to the<br />

service, motive power <strong>and</strong> manufacturing/industrial<br />

sectors.<br />

<strong>The</strong> college will operate under a separate<br />

act, the Ontario COT <strong>and</strong> Apprenticeship<br />

Act, eliminating the PAC <strong>and</strong><br />

IC <strong>and</strong> some industry professionals are<br />

unsure of the benefits the college will<br />

bring to skilled trades.<br />

“PACs <strong>and</strong> ICs set training st<strong>and</strong>ards<br />

<strong>and</strong> certification requirements, which are<br />

key to developing apprentices <strong>and</strong> are<br />

the requirements for accreditation in the<br />

trades. It’s driven by the belief the industry<br />

tells us what they need; any individual<br />

entering a trade must achieve those<br />

st<strong>and</strong>ards,” says Carol Olinski, retired<br />

program coordinator for the Program<br />

St<strong>and</strong>ards Unit at the Ministry of Training,<br />

Colleges <strong>and</strong> Universities (MTCU).<br />

For nearly 20 years, Olinski was the<br />

coordinator for many trades, some of<br />

which include machinist, mould maker,<br />

tool <strong>and</strong> die maker, patternmaker <strong>and</strong><br />

machine-tool builder <strong>and</strong> integrator.<br />

“For the past 12 years, there was<br />

one act for volunteer trades <strong>and</strong> one for<br />

compulsory trades; once the new college<br />

is running, there’ll be new regulations<br />

<strong>and</strong> anything under the old acts will be<br />

gone, encompassed under the COT <strong>and</strong><br />

its new legislation,” she says.<br />

While the COT will be overseen by<br />

the minister of government affairs, it’ll<br />

be managed by a board of governors<br />

with 21 members—four from each of<br />

the four sectors (two employees <strong>and</strong><br />

two employers); four members from the<br />

public with no college or trade affiliation;<br />

<strong>and</strong> one member from the public<br />

college sector. Rod Cameron, chair of<br />

the appointments council for the COT,<br />

says the board of governors should be in<br />

place by July.<br />

Once the board of governors is set,<br />

the appointments council will populate<br />

four division boards—construction,<br />

industrial, motive power <strong>and</strong> service—<br />

made of four members each. <strong>The</strong>y will<br />

advise the board of governors regarding<br />

trade-related issues within their sector.<br />

In addition, trade boards made up of<br />

four to 12 members each will advise<br />

the divisional boards on issues relating<br />

to the trade or groups of trades they<br />

represent. <strong>The</strong> trade boards will replace<br />

the PAC <strong>and</strong> IC <strong>and</strong> Cameron says for<br />

the boards with multiple trades clustered<br />

together, the college will<br />

appoint four board members<br />

per trade.<br />

“We need to be careful<br />

<strong>and</strong> make sure there’s a balance<br />

of representatives for<br />

the sectors. We have to take<br />

the time to do it right,” says<br />

Cameron. “One of the main<br />

features of the COT, which<br />

is getting the most traction<br />

with trades people <strong>and</strong><br />

employers, is the arms’ length<br />

operation from the government. Until<br />

now, the government has looked after<br />

many things the COT will be undertaking,<br />

partly dealing with st<strong>and</strong>ards <strong>and</strong><br />

certificates of qualification.”<br />

Curriculum Upgrade, Fee Upgrade<br />

One concern in the manufacturing<br />

sector, Cameron says, is the currency of<br />

present training curriculum; there have<br />

been tremendous changes in industry<br />

technology. He says the board of<br />

governors <strong>and</strong> the trade boards within<br />

the college can consider the particular<br />

st<strong>and</strong>ards <strong>and</strong> training<br />

done previously<br />

<strong>and</strong> take action<br />

to keep training<br />

current, making<br />

changes<br />

to curriculum<br />

that, in some<br />

cases, could be<br />

10 years old.<br />

“I know in<br />

9<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association

10<br />

manufacturing it’s been a bone of contention<br />

for some time; we hope to set<br />

up schedules of reviews that’ll allow us<br />

to have curriculum for training that’s<br />

up there with the best in North America<br />

<strong>and</strong> potentially the world,” says Cameron.<br />

“Once authority is transferred<br />

from the government to the COT, we’ll<br />

hopefully be in a position to make those<br />

changes.”<br />

With the exception of start-up money<br />

from the government, the COT will be<br />

funded through membership fees <strong>and</strong><br />

license renewals paid by those in the 21<br />

compulsory trades, who must become<br />

a member of the college to obtain or<br />

renew certification. It will also be funded<br />

by fees from those in voluntary trades<br />

who choose to become a member. Currently,<br />

there are no compulsory trades in<br />

the industrial sector <strong>and</strong> Cameron says<br />

depending on input, the college may or<br />

may not initiate reviews to see whether<br />

or not a trade will become compulsory<br />

in the future.<br />

“For an occupation to become compulsory<br />

there needs to be a case <strong>and</strong><br />

you will not find anything that is in<br />

self-interest for the board or the COT,”<br />

he says, referring to speculation that voluntary<br />

trades will be made compulsory<br />

to further fund the college.<br />

Current license renewal fees, according<br />

to Cameron, are about $60 for a<br />

three-year renewal. He says over the<br />

next three years, the licenses of the<br />

160,000 people working in compulsory<br />

trades will expire <strong>and</strong> they will have to<br />

join the college <strong>and</strong> pay the membership<br />

fee, which has yet to be determined.<br />

A pre-legislation consultation<br />

suggests $100 per year but no decisions<br />

have been made <strong>and</strong> fees will remain<br />

unknown until costs <strong>and</strong> membership<br />

are determined. Some people who currently<br />

hold their license don’t practice<br />

but renew it because the cost is low, says<br />

Cameron, adding that with an increase<br />

in renewal fees, some will likely let go of<br />

their licenses <strong>and</strong> the 160,000 in compulsory<br />

trades could shrink to 120,000.<br />

“As for voluntary trades, our hope is<br />

that having a membership in the college<br />

will hold enough benefits that it<br />

will be desirable to seek the certificate<br />

of qualification <strong>and</strong> keep it valid once<br />

the ministry stops issuing them,” Cameron<br />

says. “One of the things that isn’t<br />

currently done in trades is having an<br />

ethics board in place—similar things<br />

could happen in the COT <strong>and</strong> there<br />

could be discipline with professional<br />

development or license revocation if<br />

there is a complaint <strong>and</strong> we feel you’re<br />

a danger to the public. To protect the<br />

occupation, the college will ensure<br />

everyone adheres to the st<strong>and</strong>ards set<br />

by the industry, the occupation <strong>and</strong> the<br />

people in it; the public has reasonable<br />

expectations, too.”<br />

Cameron hopes union <strong>and</strong> nonunionized<br />

skilled workers <strong>and</strong> industry<br />

tool shop owners, who can’t increase<br />

rates without more companies closing<br />

<strong>and</strong> more people losing jobs, won’t see<br />

the college as “evil overseers of the work<br />

they do” <strong>and</strong> will support the COT.<br />

“We’ve committed to ourselves<br />

<strong>and</strong> the ministry <strong>and</strong> stakeholders we<br />

want to get it right, which takes time.<br />

We recognize seven or eight percent<br />

of Ontario’s workforce is involved in<br />

skilled trades <strong>and</strong> we recognize the<br />

potential impact on them,” he says.<br />

www.ctma.com

“We want to enhance the occupations<br />

in the skilled trades sector, raise<br />

the level of professionalism <strong>and</strong> attract<br />

the right people to the occupation.<br />

At the end of the day, the COT is an<br />

instrument of its members—the trades<br />

people—<strong>and</strong> to have an impact, we’re<br />

hoping they’ll become a member <strong>and</strong><br />

have a voice.”<br />

Olinski agrees with Cameron <strong>and</strong> says<br />

the intent of the college is to raise the<br />

profile of the professions <strong>and</strong> give recognition<br />

<strong>and</strong> accreditation for the occupations<br />

within the skilled trades. She urges<br />

members of the industry to get involved<br />

<strong>and</strong> be a part of the process.<br />

“<strong>The</strong> COT is there to promote trades<br />

<strong>and</strong> apprenticeship. <strong>The</strong> difference is<br />

that instead of the ministry being the<br />

driving force, the industry will now be<br />

the driving force behind increasing<br />

apprenticeship.” ❙❙❙<br />

?<br />

FOR MORE INFORMATION:<br />

Any questions about this<br />

article can be directed to<br />

www.collegeoftrades.ca.<br />

11<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association

12<br />

www.ctma.com

FEATURE<br />

Reshoring Initiative<br />

Bringing Jobs Back<br />

<strong>The</strong> Reshoring Initiative teaches North American companies<br />

the benefits of domestic sourcing <strong>and</strong> how underst<strong>and</strong>ing the<br />

true cost of offshoring can save money <strong>and</strong> bring jobs back.<br />

By Alex<strong>and</strong>ra Walld<br />

W<br />

ith the hit our<br />

economy has<br />

taken, companies<br />

have been offshoring<br />

projects in an effort to<br />

cut costs. Harry Moser,<br />

founder of Reshoring<br />

Initiative, was inducted<br />

into Industry Week’s Hall of Fame 2010<br />

for the anticipated success of his work to<br />

counteract this trend. By helping Original<br />

Equipment Manufacturers (OEMS) better<br />

underst<strong>and</strong> the total cost of ownership<br />

<strong>and</strong> the benefits of reshoring/backshoring,<br />

Moser hopes to battle the trade deficit<br />

<strong>and</strong> bring manufacturing jobs back home.<br />

<strong>The</strong> Reshoring Initiative was set in<br />

motion about three years ago when<br />

Moser proposed the idea to the<br />

Association for Manufacturing Technology<br />

<strong>and</strong> the National <strong>Tooling</strong> & Machining<br />

Association <strong>and</strong> told them they would<br />

eventually cease to exist if manufacturing<br />

continued to decline. Since early 2010,<br />

more companies are becoming aware of<br />

the concept <strong>and</strong> are jumping on board.<br />

“<strong>The</strong> goal is to bring manufacturing<br />

jobs back <strong>and</strong> by so doing, reduce<br />

the trade deficit, budget deficit <strong>and</strong><br />

unemployment <strong>and</strong> strengthen the whole<br />

economy,” says Moser, who also serves<br />

as president of the Swiss Machine Tool<br />

Society <strong>and</strong> just retired as North American<br />

president of the International Special<br />

<strong>Tooling</strong> <strong>and</strong> Machining Association. “One<br />

reason companies offshore is they believe<br />

they’ll make more money because of<br />

lower salaries <strong>and</strong> other costs; it makes<br />

sense to them but they don’t think about<br />

the total cost—companies typically<br />

miss 20 percent or more of costs when<br />

offshoring <strong>and</strong> we help them see the<br />

missed costs.”<br />

<strong>The</strong> typical “offshore is cheaper”<br />

mindset needs to be replaced with<br />

“buying or manufacturing domestically<br />

reduces the total cost of ownership,”<br />

says Moser. While most companies<br />

consider price, duty <strong>and</strong> freight when<br />

offshoring, many hard costs—travel <strong>and</strong><br />

the carrying cost of a product—<strong>and</strong> soft<br />

costs—intellectual property or quality—<br />

are recorded under overhead instead of<br />

aggregating them against the product.<br />

To help companies identify those costs,<br />

make better sourcing decisions <strong>and</strong> avoid<br />

commoditization, the Reshoring Initiative<br />

offers free Total Cost of Ownership (TCO)<br />

Estimator software <strong>and</strong> a library of articles<br />

on successful reshoring.<br />

<strong>The</strong> biggest challenge for bringing<br />

manufacturing back to North America,<br />

according to Moser, is getting big<br />

companies like tier one auto suppliers to<br />

change their behaviour.<br />

“Many of them will offshore 40<br />

percent of the time <strong>and</strong> ignore these<br />

other costs; it’s very hard to get them<br />

to change their mind,” says Moser.<br />

“I think if big companies apply the<br />

total cost of ownership system, maybe<br />

20 percent of the trade deficit would<br />

be fixed…if companies <strong>and</strong> suppliers<br />

used lean, automation <strong>and</strong> design for<br />

manufacturability <strong>and</strong> assembly, maybe<br />

we could get back another 30 percent.<br />

<strong>The</strong> more you want to bring back, the<br />

more of those things you have to do.”<br />

This year, the Reshoring Initiative<br />

is focusing on proving the process<br />

Harry Moser, retired Chairman Emeritus<br />

of GF AgieCharmilles, is teaching North<br />

American companies how they can<br />

bring jobs back by participating in the<br />

Reshoring Initiative. Photo courtesy of GF<br />

AgieCharmilles.<br />

works. A five-step plan has begun in<br />

Illinois with a coalition of 35 trade<br />

associations, chambers of commerce,<br />

economic development administrations<br />

<strong>and</strong> government offices promoting the<br />

process to big companies like Deere<br />

<strong>and</strong> CAT, who are then educated on<br />

how to use the materials <strong>and</strong> tools,<br />

including the TCO Estimator. Following<br />

that, suppliers are trained in TCO <strong>and</strong> in<br />

behavioural changes that will help them<br />

st<strong>and</strong> out against foreign competitors.<br />

<strong>The</strong> suppliers then “speed date” with the<br />

customers in hopes that a relationship<br />

will grow. Finally, the Initiative’s success<br />

is measured by the amount of work<br />

brought back.<br />

“I’ve had e-mails from people who<br />

said, “We were offshoring 70 percent<br />

but now we’re trying to bring it back,”<br />

says Moser. “<strong>The</strong> initiative has gotten<br />

enough momentum <strong>and</strong> credibility that<br />

companies want to try it.” ❙❙❙<br />

<strong>The</strong> Reshoring Initiative is a nonprofit<br />

supported by AMT; Sescoi; GF<br />

AgieCharmilles; AME; NTMA; BIGKaiser; <strong>and</strong><br />

SMTS.<br />

<strong>CTMA</strong> members can participate in the Reshoring Initiative by:<br />

• Posting links to the Initiative website, www.reshorenow.org to attract large<br />

customers to bring work back;<br />

• Mentioning the Initiative in your newsletters;<br />

• E-mailing successful reshoring cases to harry.moser@comcast.net or info@<br />

ctma.com for publicity;<br />

• Using the TCO Estimator to optimize component sourcing <strong>and</strong> convince customers<br />

to reshore; <strong>and</strong><br />

• Sponsoring the Initiative.<br />

13<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association

14<br />

www.ctma.com

FEATURE<br />

Unusual Items Produced by the<br />

<strong>Canadian</strong> <strong>Tooling</strong> Industry<br />

W<br />

hile at his cottage one day in Meaford,<br />

ON, Andy McTear, president<br />

of Prothane Inc./Amathane Inc., was<br />

asked by a friend to make a replica of<br />

the Stanley Cup that was hollow in the<br />

centre.<br />

<strong>The</strong> friend, who spends many hours at<br />

the cottage, owns a funeral home in the<br />

Sarnia area; one might assume it was a special<br />

request for an urn. Anyone familiar with McTear knows his<br />

answer to the request was, “Sure, pal,” <strong>and</strong> he was asked<br />

to complete the replica as soon as possible. He originally<br />

considered producing the urn from an exotic wood but<br />

finally settled on aluminum <strong>and</strong> designed it as a five-piece<br />

part.<br />

Much of McTear’s professional life has been marked<br />

with making the right decision at the right time. He demonstrated<br />

the ability once again by turning over the project<br />

to his highly-skilled patternmaking son, Sean, who, along<br />

with staff from Halton Machining, created a solid model<br />

replica of the Stanley Cup using their Mastercam program.<br />

<strong>The</strong> lower part was made of an aluminum tube that<br />

was CNC-machined by the highly-skilled machinists at<br />

Halton Machining. Solid aluminum stock was used for the<br />

detailed upper portion <strong>and</strong> the interior was bored to create<br />

the internal volume needed for the urn. To complete<br />

the project, a wooden base was produced by Andy himself.<br />

Graham Williams of Cambridge Engravers purchased<br />

the top bowl from one of his trophy suppliers, manufactured<br />

the New Jersey Devils team logo with the latest laser<br />

engraving machine <strong>and</strong> applied it to the side as per the<br />

customer’s request.<br />

Following the assembly of the Stanley Cup replica urn,<br />

they stepped it up a notch <strong>and</strong> had it nickel-chrome plated<br />

by Cambridge Custom Chrome.<br />

As you can see, it turned out great! <strong>The</strong> final product<br />

st<strong>and</strong>s 16 inches tall <strong>and</strong> six inches in diameter. ❙❙❙<br />

?<br />

FOR MORE INFORMATION:<br />

Sean McTear, Vice President<br />

Phone: (905) 878-7233<br />

E-mail: sales@prothane.ca<br />

Web: www.prothane.ca<br />

OTHER UNSUAL ITEMS PRODUCED BY THE CANADIAN<br />

TOOLING INDUSTRY<br />

• A model of the Canadarm was first made by a pattern<br />

shop in Toronto;<br />

• A prototype casing for the first BlackBerry was made by a<br />

<strong>Canadian</strong> pattern shop;<br />

• <strong>The</strong> Maple Leaf on the Dieppe monument in France <strong>and</strong><br />

Windsor, ON was cut by a <strong>Canadian</strong> CNC shop; <strong>and</strong><br />

• <strong>The</strong> premier cup honoring the first Canada VS Russia<br />

hockey tournament was produced by a <strong>Canadian</strong> foundry.<br />

15<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association

MEMBER PROFILE<br />

Rice Tool & Manufacturing, Inc.<br />

Since 1952, Rice Tool & Manufacturing<br />

has been machining aluminum,<br />

specializing in automotive, defence<br />

<strong>and</strong> alternative energy component<br />

manufacturing <strong>and</strong> has recently delved<br />

into aerospace component production.<br />

<strong>The</strong> company, started by Frank Rice,<br />

was purchased by Neil Teague <strong>and</strong> his<br />

business partner Ted Rosts. Since taking<br />

over January 1, 2011, the team has<br />

made significant investments in equipment<br />

to satisfy customers’ needs <strong>and</strong><br />

the Rice family is so impressed with dayto-day-operations<br />

that their business<br />

relationship has turned into a friendship<br />

as well.<br />

As the company approaches its<br />

60 th anniversary, Teague is hoping to<br />

increase its presence at local colleges<br />

<strong>and</strong> help young men <strong>and</strong> women get<br />

into skilled trades or an accredited<br />

apprenticeship. He is also hoping to<br />

further grow <strong>and</strong> diversify Rice Tool &<br />

Manufacturing.<br />

“To a degree, automotive is the<br />

lifeblood of the manufacturing sector<br />

in Ontario—the last two or three years<br />

have shown it’s extremely difficult to<br />

survive in automotive alone <strong>and</strong> you are<br />

sometimes left with no choice but to<br />

battle the tough economic times <strong>and</strong><br />

the work going offshore by diversifying<br />

<strong>and</strong> making your company stronger,”<br />

says Teague, president of Rice Tool &<br />

Manufacturing.<br />

<strong>The</strong> facility is spread out between<br />

two buildings <strong>and</strong> over 40,000 sq. ft.<br />

With 58 employees, a full engineering<br />

department—including CAD/CAM—a<br />

production supportive tool room <strong>and</strong><br />

skilled tradespersons on site, Rice Tool<br />

& Manufacturing is TS-certified <strong>and</strong> has<br />

a quality control department with stateof-the-art<br />

measurement equipment <strong>and</strong><br />

techniques in place to guarantee their<br />

customers are satisfied.<br />

“We believe that we have the<br />

capability to offer a technical solution to<br />

keep work from going overseas—work<br />

that should be staying in Canada,” says<br />

Teague. “That’s a big part of what we<br />

do; the ‘busier’ the part, the more our<br />

strengths in engineering <strong>and</strong> production<br />

set us apart from our competitors.<br />

It’s a shame to see all of this work going<br />

overseas <strong>and</strong> we’re doing our bit to<br />

keep it here.”<br />

While the company is both working<br />

through <strong>and</strong> rebuilding from a challenging<br />

economy, it is also continuing to<br />

consider the less fortunate <strong>and</strong> focusing<br />

on being good corporate <strong>and</strong> charitable<br />

citizens, says Teague. Rice Tool & Manufacturing<br />

is proud to announce it has<br />

aligned itself with McMaster Children’s<br />

Hospital to support significant initiatives.<br />

“It’s not enough to rebuild your business<br />

after this economy; you have to<br />

rebuild the community as well <strong>and</strong> we<br />

are well aware of that,” says Teague.<br />

“Our employees have helped this community<br />

through some difficult times <strong>and</strong><br />

we are happy that we have been able<br />

to work in the right direction to keep<br />

everybody. We’re pretty excited about<br />

the future here.” ❙❙❙<br />

WHY DOES RICE TOOL &<br />

MANUFACTURING VALUE ITS <strong>CTMA</strong><br />

MEMBERSHIP?<br />

“It’s a way of staying in touch with<br />

the industry. We see a lot of value in what<br />

<strong>CTMA</strong> offers, from interacting in peer<br />

conversation to attending industry events<br />

put on through <strong>CTMA</strong> with competitors,<br />

where you can meet in a neutral environment<br />

to discuss challenges <strong>and</strong> how we<br />

can face them,” President of Rice Tool &<br />

Manufacturing, Neil Teague.<br />

?<br />

FOR MORE INFORMATION:<br />

Head Office<br />

2247 Harold Road<br />

Burlington, ON L7P 2J7<br />

Tel: (905) 335-0181<br />

Fax: (905) 335-0395<br />

www.ricetool.com<br />

neil@ricetool.com<br />

16<br />

A seven-axis Twin Spindle with live tooling capability. Photo<br />

courtesy of Rice Tool & Manufacturing.<br />

www.ctma.com<br />

Rice Tool & Manufacturing’s head office in Burlington, ON.<br />

Photo courtesy of Rice Tool & Manufacturing.

ctma headlines<br />

13th Annual Shotgun<br />

Golf Tournament<br />

Join us for the <strong>CTMA</strong>’s 13th Annual Shotgun Golf Tournament<br />

on Tuesday, June 7th, 2011 at the Pine Knot Golf & Country Club in<br />

Dorchester, Ontario.<br />

Over the years, this very successful event has attracted more<br />

<strong>and</strong> more people from the tool, die, mould, pattern <strong>and</strong> machining<br />

industries since it began <strong>and</strong> we expect this year’s event to be<br />

a sell-out once again!<br />

<strong>The</strong> day will begin with a Putting Contest <strong>and</strong> Registration at<br />

9:00 am, followed by the shotgun tournament at 10:30 am with a<br />

boxed-lunch. <strong>The</strong> 19th Hole Reception on the clubhouse terrace, a<br />

steak dinner <strong>and</strong> an awards presentation will complete the day.<br />

This prestigious event is also a great opportunity for companies<br />

to promote their products <strong>and</strong> services by becoming an event<br />

sponsor. Several levels of sponsorship are available, including Evening<br />

Sponsorship, Hole Sponsorship or donations of gifts for the<br />

Prize Table.<br />

<strong>The</strong> tournament is limited to 124 golfers so be sure to register<br />

early!<br />

Visit www.ctma.com or contact the <strong>CTMA</strong> office at (519) 653-<br />

7265 or info@ctma.com for registration <strong>and</strong> sponsorship information.<br />

<strong>CTMA</strong> Launches Annual<br />

Bursary Program<br />

<strong>The</strong> <strong>CTMA</strong> is pleased to announce a new annual bursary<br />

program which will recognize <strong>and</strong> provide encouragement<br />

to apprentices, promote the value of apprenticeship training<br />

<strong>and</strong> skilled trades <strong>and</strong> contribute to an improved tooling <strong>and</strong><br />

machining industry for Canada.<br />

<strong>The</strong> new program will replace <strong>CTMA</strong>’s long-running<br />

apprenticeship competition <strong>and</strong> is open to all apprentices<br />

employed by <strong>CTMA</strong> member companies, who may nominate<br />

up to two apprentices each year for consideration. Recipients<br />

will receive an award of at least $1,000 <strong>and</strong> a selection of<br />

tools <strong>and</strong> other trade-related items.<br />

Support apprenticeship training by making a financial<br />

donation to the George H. Shaffer Education Fund, which<br />

was established in 1994 to support <strong>and</strong> encourage apprenticeship<br />

training. Interest generated from the endowment<br />

fund will support the bursary awards.<br />

To become a sponsor, submit a nomination or learn more<br />

about this exciting new program, visit www.ctma.com or<br />

e-mail info@ctma.com.<br />

17<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association

18<br />

www.ctma.com

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association<br />

19

Tools of the trade<br />

High Density Kurt MoveLock® Vise Setup Maximizes Machining<br />

Productivity in a Robot-Tended Process at Haas Automation<br />

Haas Automation maximizes<br />

productivity with the hydraulic<br />

actuated clamping system utilizing Kurt<br />

MoveLock vises.<br />

“We have several setups, varying from<br />

one to four MoveLock stations mounted<br />

on trunion tables,” reports Phillip<br />

Linscheid, machine shop manager<br />

for Haas Automation. “A Motoman<br />

Hp 165 robot provides the load/<br />

unload operations. <strong>The</strong>re’s no fixture<br />

set-up labor required once the premachined<br />

jaw plates are installed in the<br />

MoveLocks…the different setups—one<br />

to four clamping stations—give us the<br />

flexibility <strong>and</strong> efficiency needed for<br />

varying quantities.”<br />

<strong>The</strong> MoveLock vises assure rigidity,<br />

producing up to 2,500 lbs of clamping<br />

force <strong>and</strong> using 3,200 lbs of hydraulic<br />

pressure. With a 5/16 in. stroke, they<br />

can be positioned on a base plate so<br />

the jaw opening is limited only by the<br />

work envelope <strong>and</strong> produces adequate<br />

clamping pressure to accommodate a<br />

variety of part sizes. Incorporation of<br />

the Anglock design prevents jaw lift<br />

during clamping—for every pound of<br />

clamping force there is a half-pound of<br />

force exerted on the movable jaw.<br />

Without the MoveLock vises, Haas<br />

Automation couldn’t run parts in a<br />

robot cell to achieve two to three times<br />

greater output versus earlier setups.<br />

www.haascnc.com<br />

www.kurtworkholding.com<br />

Severance Tools of Canada appointed <strong>Canadian</strong> master distributor for<br />

Canela Corporation Tools’ Indexable Tool Holders<br />

Severance Tools of Canada is now<br />

the <strong>Canadian</strong> master distributor for<br />

Canela Corporation Tools, which<br />

manufactures high quality Indexable<br />

Tool Holders.<br />

With a large selection of ceramic<br />

turning tool holders, boring bars <strong>and</strong><br />

milling cutter bodies, Severance Tools<br />

of Canada now also stocks cartridges<br />

for custom made tools, parting off<br />

blocks <strong>and</strong> blades, indexable insert<br />

drills, CAT <strong>and</strong> BT milling holders.<br />

Providing the ultimate in tooling<br />

products, the company offers tooling<br />

for Swiss style lathes, threading—both<br />

internal <strong>and</strong> external—<strong>and</strong> slot cutters.<br />

<strong>The</strong>y also provide customers with a<br />

variety of options like carbide, cermet<br />

or ceramic indexable inserts for their<br />

tooling products.<br />

This is an exciting new venture for<br />

the company but with many years<br />

of knowledge in indexable tooling,<br />

Severance Tools of Canada is confident<br />

it can continue to help customers find<br />

what they are looking for in all their<br />

tooling needs.<br />

When performance counts, count<br />

on Severance.<br />

www.canelacorp.com<br />

www.severancecanada.com<br />

20<br />

www.ctma.com

IN EVERY ISSUE<br />

<strong>CTMA</strong> Welcomes New Member<br />

Companies<br />

ANDERDON MACHINE TOOL &<br />

MANUFACTURING INC.<br />

Tom Gagnon (left), Philip<br />

KOMET OF CANADA TOOLING<br />

SOLUTIONS ULC<br />

David Toomey (right) of Komet of<br />

ULTIMATE MANUFACTURED<br />

SYSTEMS<br />

Drage Ristovski (right) <strong>and</strong><br />

ACTIVE BURGESS MOULD &<br />

DESIGN<br />

David Read of Active Burgess<br />

Gagnon Jr. (centre) <strong>and</strong> Laurie Lafleur<br />

Canada <strong>Tooling</strong> Solutions ULC accepts<br />

Gino Longo (left) of Ultimate<br />

Mould & Design proudly displays<br />

(right) of Anderdon Machine Tool<br />

membership plaque from Colin<br />

Manufactured Systems are pleased<br />

their new membership plaque.<br />

& Manufacturing Inc. are pleased to<br />

Docherty, Windsor Chapter Chairman<br />

to accept their <strong>CTMA</strong> membership<br />

have their membership plaque.<br />

of Clinton Aluminium (left).<br />

plaque.<br />

BARTEL MACHINE<br />

Steve Bartel (left) <strong>and</strong> John<br />

Bartel (right) proudly display their<br />

membership plaque.<br />

<strong>CTMA</strong> 2011 BOARD OF DIRECTORS<br />

President:<br />

Emerson Suphal<br />

ESS Business<br />

Strategies Inc.<br />

Vice-President:<br />

David Glover<br />

Harbour Advanced<br />

Machining Ltd.<br />

Treasurer:<br />

Horst Just<br />

H. J. Machine &<br />

Pattern Ltd<br />

Past President:<br />

Robert Cattle<br />

Micrometric Ltd.<br />

Toronto Chapter<br />

Chair:<br />

Steve Watson<br />

Century Tools &<br />

Machinery Ltd.<br />

Western Ontario<br />

Chapter Chair:<br />

Ralph Schippanoski<br />

XL Tool Ltd.<br />

Windsor Chapter<br />

Chair:<br />

Colin Docherty<br />

Clinton Aluminum<br />

of Canada ULC<br />

Directors:<br />

Ted Callighen<br />

Schmolz+Bickenbach<br />

Canada Inc.<br />

Jim Gale<br />

Guhring<br />

Corporation<br />

Horst Schmidt<br />

H.S. Enterprizes<br />

Ron Spraggett<br />

Tipco Inc.<br />

Ryan Wozniak<br />

Anchor Danly<br />

21<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association

IN EVERY ISSUE<br />

<strong>CTMA</strong> Chapter News<br />

<strong>The</strong> Windsor Chapter<br />

<strong>The</strong> Windsor Chapter of the<br />

<strong>CTMA</strong> was very pleased to host a<br />

plant tour & dinner meeting on<br />

February 22, 2011 that featured<br />

a visit to Nemak Canada Corporation.<br />

Nemak specializes in the<br />

production of aluminum cylinder<br />

heads, engine blocks <strong>and</strong> transmission<br />

parts, among other aluminum<br />

components for automotive<br />

applications since it was founded<br />

in 1979. <strong>The</strong> company was created<br />

as a joint venture between Alfa<br />

<strong>and</strong> Ford Motor Company. Today,<br />

with 27 manufacturing facilities<br />

located in 12 different countries in<br />

Asia, Europe <strong>and</strong> North & South<br />

America, it employs nearly 15,000<br />

employees worldwide. Nemak<br />

Windsor Aluminum Plant is a<br />

state-of-the-art aluminum foundry<br />

which opened in 1990. This<br />

casting facility is fully automated<br />

<strong>and</strong> was the first of its kind to<br />

launch production of aluminum<br />

engine blocks derived from the<br />

Cosworth casting process used in<br />

racecar engine technology. With<br />

an expansion of 110,000 sq. ft.<br />

launched in 2006, Nemak Windsor<br />

Aluminum Plant is capable of<br />

producing 750,000 aluminum<br />

cylinder blocks per year.<br />

Participants were very<br />

impressed with the technology<br />

being utilized by Nemak, having<br />

had the opportunity to see:<br />

• Aluminum cylinder block production<br />

of the 3.0L Duratec<br />

Engine block for Ford Motor<br />

Company <strong>and</strong> the HF 3.6L<br />

V6 Engine block for General<br />

Motors;<br />

• S<strong>and</strong> core making process <strong>and</strong><br />

core package assembly;<br />

• Aluminum casting process<br />

to produce a cylinder engine<br />

block;<br />

• <strong>The</strong>rmal S<strong>and</strong> Removal <strong>and</strong><br />

reclamation process; <strong>and</strong><br />

• Initial (rough cube) machining<br />

of castings for final machining<br />

at engine assembly plants.<br />

Following the tour, members<br />

enjoyed dinner at the Ambassador<br />

Golf Club <strong>and</strong> a presentation by<br />

Lloyd Maisonville, Nemak USA/<br />

Canada operations director. His<br />

presentation covered the history<br />

of Nemak Canada beginning with<br />

the Joint Venture between Ford<br />

<strong>and</strong> Alfa <strong>and</strong> he explained how<br />

they have been able to survive the<br />

past decade as well as the worst<br />

automotive downturn in history.<br />

Proceeds from the 50/50<br />

draw during the event were<br />

donated by the Windsor Chapter<br />

to F.W. Begley Public School for<br />

its Breakfast Program, which not<br />

only gives students very healthy,<br />

nutritious snacks but also supports<br />

other needs in the community.<br />

Special thanks to BRT Solutions,<br />

Jesse Garant & Associates<br />

Metrology Centre <strong>and</strong> Spartan<br />

Sling Mfg. Inc. for their sponsorship<br />

of this event!<br />

www.nemak.com ❙❙❙<br />

Colin Docherty, <strong>CTMA</strong> Windsor Chapter Chair (centre)<br />

thanks Lloyd Maisonville (right) <strong>and</strong> Barb Pelat (left) for<br />

the fascinating tour of Nemak Canada Corporation.<br />

Thanks to Cliff Black (left) <strong>and</strong> Dustin Black (centre) of<br />

Spartan Sling Mfg. Inc. for their support of the Windsor<br />

Chapter’s Plant Tour & Dinner Meeting in February<br />

2011.<br />

Thanks to Wally Saadi of BRT Solutions for their support<br />

of the Windsor Chapter’s Plant Tour & Dinner Meeting in<br />

February 2011.<br />

22<br />

50/50 Draw Winner Glenn Byczynski of Nemak (left) is congratulated<br />

by David Glover, <strong>CTMA</strong> Vice President (centre) &<br />

Colin Docherty, Windsor Chapter Chair (right).<br />

www.ctma.com<br />

Thanks to Jesse Garant & Associates Metrology Center for their<br />

support of the Windsor Chapter’s Plant Tour & Dinner Meeting,<br />

shown here with R<strong>and</strong>y Cyr of R.J. Cyr Co. Inc.

IN EVERY ISSUE<br />

2011 Calendar of Events<br />

May 16<br />

Carbide & High Speed Steel<br />

Annual Meeting<br />

Kitchener, Ontario<br />

MAY 17<br />

Toronto Chapter Tour & Dinner<br />

Meeting<br />

Oshawa, Ontario<br />

MAY 17-19<br />

Plant Management & Design<br />

Engineering Show<br />

Montreal, Quebec<br />

www.pmds.ca<br />

June 28-July 2<br />

GIFA 12th International Foundry<br />

Trade Fair<br />

Düsseldorf, Germany<br />

www.gifa.com<br />

September 6-7<br />

NTMA/PMA/<strong>CTMA</strong> Purchasing<br />

Fair<br />

Chicago, Illinois, USA<br />

September 14<br />

Annual General Meeting &<br />

Dinner<br />

Ingersoll, Ontario<br />

June 7<br />

13th Annual Shotgun Golf<br />

Tournament<br />

Dorchester, Ontario<br />

June 14-16<br />

Western Manufacturing<br />

Technology Show<br />

Edmonton, Alberta<br />

www.wmts.ca<br />

June 22<br />

Board of Directors Meeting<br />

Cambridge, ON<br />

September 19-24<br />

EMO Hannover<br />

<strong>The</strong> World of Metalworking<br />

Hannover, Germany<br />

www.emo-hannover.de<br />

October 17-20<br />

<strong>Canadian</strong> Manufacturing<br />

Technology Show<br />

Toronto, Ontario<br />

www.cmts.ca<br />

Visit www.ctma.com for<br />

details on all of these<br />

events!<br />

23<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association

IN EVERY ISSUE<br />

Canada’s Leading Manufacturing Shows Set to Launch in<br />

Edmonton <strong>and</strong> Toronto<br />

Coming June 14 to 16 at the<br />

Edmonton Expo Centre is<br />

the Western Manufacturing<br />

Technology Show (WMTS),<br />

produced in partnership with <strong>Canadian</strong><br />

Weld Expo. WMTS is a platform where<br />

manufacturing professionals, specifically<br />

from Western Canada, will gather to<br />

seek solutions, the latest technologies<br />

<strong>and</strong> compare equipment side-by-side,<br />

under one roof. Attendees can walk<br />

the show floor to meet face-to-face<br />

with distributors, watch live product<br />

demonstrations, compare products<br />

<strong>and</strong> attend conferences run by leading<br />

industry professionals.<br />

One of many show highlights includes<br />

a keynote session with Justin Reimer,<br />

assistant deputy minister of finance <strong>and</strong><br />

enterprise for the government of Alberta.<br />

Mr. Reimer will discuss the results of<br />

the Alberta Competitiveness Initiative, a<br />

government study which measures how<br />

well Alberta ranks among 14 jurisdictions<br />

<strong>and</strong> benchmarks the competitiveness of<br />

Alberta’s petrochemical <strong>and</strong> chemical<br />

industries. In addition, WMTS will feature<br />

a full technical conference <strong>and</strong> multiple<br />

networking opportunities both on <strong>and</strong> off<br />

the show floor.<br />

<strong>The</strong> <strong>Canadian</strong> Manufacturing<br />

Technology Show (CMTS), Canada’s<br />

ultimate manufacturing event, returns<br />

to Toronto’s Direct Energy Centre<br />

October 17 to 20. Live demonstrations<br />

of the latest machine tools, automation<br />

technologies <strong>and</strong> production methods<br />

give manufacturers the chance to<br />

break through the everyday clutter of<br />

information to make informed purchase<br />

decisions.<br />

More than 600 exhibitors <strong>and</strong><br />

distributors will feature cutting-edge<br />

technologies <strong>and</strong> ideas that speed<br />

new product development time, cut<br />

costs <strong>and</strong> deliver world-class quality.<br />

Beyond the show floor, attendees<br />

will experience a timely <strong>and</strong> relevant<br />

keynote, interactive town hall panels<br />

<strong>and</strong> a full technical conference.<br />

Premium networking opportunities,<br />

SME networking reception, awards<br />

program <strong>and</strong> VIP experience are just<br />

some of the new <strong>and</strong> exciting features<br />

for 2011. For more information, please<br />

visit www.cmts.ca or call Nick Samain,<br />

Show Manager, (888) 322-7333, ext.<br />

206.<br />

24<br />

www.ctma.com

SPECIAL SECTION: YOUR GUIDE TO CANADA’S TOOLING & MACHINING MANUFACTURERS<br />

Alphabetical Listing Of <strong>CTMA</strong> Member Companies<br />

A T S, Automation <strong>Tooling</strong> Systems Inc................ 28<br />

A.V. Gauge & Fixture Inc..................................... 28<br />

A.W. Miller Technical Sales (Canada)................... 28<br />

Accredited Calibration Services/Marsh<br />

Metrology......................................................... 28<br />

Active Burgess Mould & Design........................... 28<br />

Airtronic Metal <strong>and</strong> Machine Parts Limited........... 28<br />

Aluminum Mold & Pattern Ltd............................. 28<br />

Amerjy Tool <strong>and</strong> Mould....................................... 28<br />

Ammco Industrial Equipment Ltd........................ 28<br />

Anchor Danly....................................................... 28<br />

Anchor Danly - Reliance Fabrications................... 28<br />

Anderdon Machine Tool And Mfg. Inc................. 29<br />

Answer Precision.................................................. 29<br />

Applied Precision Inc........................................... 29<br />

Appolo Machine Tool Ltd.................................... 29<br />

Armo Tool Ltd..................................................... 29<br />

ATI Stellram......................................................... 29<br />

Atlantic Heat Treating 2001 Ltd........................... 29<br />

Axis Tool & Gauge Inc......................................... 29<br />

Bartel Machine.................................................... 29<br />

Blount Canada Ltd............................................... 29<br />

Bolzano Tool & Die Company Ltd........................ 29<br />

Burlington Technologies Cen. Div........................ 29<br />

Burloak Tool & Die Ltd........................................ 29<br />

C.M. Morris Design Ltd....................................... 30<br />

Cambridge Heat Treating.................................... 30<br />

Canada Mold Technology Inc.............................. 30<br />

Cana-Datum Moulds Ltd..................................... 30<br />

Cardinal Couriers................................................. 30<br />

CenterLine (Windsor) Limited.............................. 30<br />

Century Tools & Machinery Ltd........................... 30<br />

Circle 5 Tool & Mold Inc..................................... 30<br />

Clarkson-Osborn Tools Ltd................................... 30<br />

Clinton Aluminum of Canada ULC....................... 30<br />

Clover Tool Manufacturing Ltd............................ 30<br />

Comber Tool & Mold Eng. Inc............................. 30<br />

Compact Mould Ltd............................................ 30<br />

CVD Diamond Corporation................................. 31<br />

Dadco Canada Inc............................................... 31<br />

Dayton Progress Canada Ltd................................ 31<br />

Delcam................................................................ 31<br />

Densmore Tool & Die Works Limited................... 31<br />

Diemedic Tool & Machine................................... 31<br />

Duradie Technologies Inc.................................... 31<br />

E S S Business Strategies Inc................................. 31<br />

Eagle Press & Equipment Co. Ltd......................... 31<br />

Electromac Group (<strong>The</strong>)....................................... 31<br />

Exactatherm Limited............................................ 31<br />

Exco Engineering Limited.................................... 31<br />

F & K Mfg. Co. Limited........................................ 31<br />

FBT Inc................................................................ 32<br />

Footage Tools Inc................................................ 32<br />

Fred Hall & Son Ltd............................................. 32<br />

G.S. Die & Design Inc.......................................... 32<br />

Glider Guard Tool & Die Inc................................ 32<br />

Graff Diamond Products Limited.......................... 32<br />

Greenfield Industries Inc...................................... 32<br />

Guhring Corporation........................................... 32<br />

H D Patterns & Matchplates Inc........................... 32<br />

H. Beck Machinery Ltd......................................... 32<br />

H. J. Machine & Pattern Ltd................................. 32<br />

H.S. Enterprizes................................................... 32<br />

Hallink RSB Inc..................................................... 32<br />

Halton Machining................................................ 32<br />

Harbour Advanced Machining Ltd....................... 32<br />

Hartford Technology Ltd...................................... 33<br />

Harvan Engineering Ltd....................................... 33<br />

Hub International Ontario Ltd.............................. 33<br />

Husky Injection Molding Systems Ltd................... 33<br />

In-House Solutions Inc......................................... 33<br />

Inspection Air Gauge Limited............................... 33<br />

Iscar Tools Inc...................................................... 33<br />

J & C Tool & Die Limited..................................... 33<br />

J.P. Bowman Limited............................................ 33<br />

Javelin Technologies Inc....................................... 33<br />

Kapco Tool & Die Limited.................................... 33<br />

Komet of Canada <strong>Tooling</strong> Solutions ULC............. 33<br />

Manor Tool & Die Ltd.......................................... 33<br />

Massiv Die-Form (Div. of Magna)......................... 34<br />

Mazak Corporation Canada................................. 34<br />

Megatel Inc......................................................... 34<br />

Memex Automation Inc....................................... 34<br />

Metric Mold (1983) Inc....................................... 34<br />

MicroMetric Ltd................................................... 34<br />

NACHI Canada Inc............................................... 34<br />

Narmco Group (<strong>The</strong>)........................................... 34<br />

New Era Tool & Die Ltd....................................... 34<br />

Niagara Precision Limited.................................... 34<br />

Nickleson Machine & Tool Inc............................. 34<br />

Novatec Machining Inc........................................ 34<br />

O S G Canada Ltd................................................ 34<br />

Omega Tool Corp................................................ 35<br />

Omni Tool Ltd..................................................... 35<br />

P. W. Harrison & Son Insurance........................... 35<br />

Precision Dormer Inc........................................... 35<br />

Prothane Ltd........................................................ 35<br />

Ramstar Carbide Tool Inc..................................... 35<br />

Rice Tool & Manufacturing Inc............................ 35<br />

Russell Tool & Die Limited................................... 35<br />

Sabre Machine Tool Inc....................................... 35<br />

Samco Machinery Ltd.......................................... 35<br />

S<strong>and</strong>vik Canada Inc. - Coromant Div................... 35<br />

Schaller Tool & Machine Inc................................ 35<br />

Schmolz+Bickenbach Canada Inc......................... 35<br />

Sciens Industries Inc............................................. 36<br />

Sci-Mech Technical Services Inc........................... 36<br />

Seco Tools Canada Inc......................................... 36<br />

Severance Tools of Canada Ltd............................ 36<br />

SGS Tool Company............................................. 36<br />

Sigma Engineering (Windsor) Inc......................... 36<br />

Sirco Machinery Company Limited...................... 36<br />

Special Machining Company Inc.......................... 36<br />

Stema Punch & Die Inc........................................ 36<br />

Thames Machine & Tool Ltd................................ 36<br />

Thomas Wire Die Limited..................................... 36<br />

Tipco Inc............................................................. 36<br />

Top Grade Molds Ltd........................................... 36<br />

Toshiba Machine Machinery Co., Ltd................... 36<br />

Tungaloy America Inc.......................................... 37<br />

Tycos Tool & Die................................................. 37<br />

Tyson Tool Company Limited.............................. 37<br />

Ultimate Manufactured Systems.......................... 37<br />

Ultra Machine Sales Co. Ltd................................. 37<br />

Uratech <strong>Tooling</strong> Technologies Inc........................ 37<br />

Valiant Machine & Tool Inc................................. 37<br />

Walter Canada Inc............................................... 37<br />

WindsorEssex Economic Development<br />

Corporation...................................................... 37<br />

Woodbine Tool & Die Mfg. Ltd........................... 37<br />

XL Tool Inc.......................................................... 37<br />

25<br />

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association

26<br />

SPECIAL SECTION: YOUR GUIDE TO CANADA’S TOOLING & MACHINING MANUFACTURERS<br />

<strong>CTMA</strong> Member’s Capability Index<br />

TOOL & DIE MANUFACTURERS<br />

Anchor Danly.................................... 28<br />

Anchor Danly - Reliance<br />

Fabrications.................................... 28<br />

Anderdon Machine Tool<br />

And Mfg. Inc.................................. 29<br />

Armo Tool Ltd.................................. 29<br />

Blount Canada Ltd............................ 29<br />

Bolzano Tool & Die Company Ltd..... 29<br />

Burloak Tool & Die Ltd..................... 29<br />

Cana-Datum Moulds Ltd.................. 30<br />

Clover Tool Manufacturing Ltd......... 30<br />

Densmore Tool & Die<br />

Works Limited................................. 31<br />

Diemedic Tool & Machine................ 31<br />

Duradie Technologies Inc................. 31<br />

Electromac Group (<strong>The</strong>).................... 31<br />

F & K Mfg. Co. Limited..................... 31<br />

FBT Inc............................................. 32<br />

G.S. Die & Design Inc....................... 32<br />

Glider Guard Tool & Die Inc............. 32<br />

J & C Tool & Die Limited.................. 33<br />

J.P. Bowman Limited......................... 33<br />

Kapco Tool & Die Limited................. 33<br />

Manor Tool & Die Ltd....................... 33<br />

Massiv Die-Form (Div. of Magna)...... 34<br />

MicroMetric Ltd................................ 34<br />

Narmco Group (<strong>The</strong>)........................ 34<br />

Russell Tool & Die Limited................ 35<br />

Sabre Machine Tool Inc.................... 35<br />

Schaller Tool & Machine Inc............. 35<br />

Sigma Engineering (Windsor) Inc...... 36<br />

Tipco Inc.......................................... 36<br />

Uratech <strong>Tooling</strong> Technologies Inc..... 37<br />

Woodbine Tool & Die Mfg. Ltd........ 37<br />

XL Tool Inc....................................... 37<br />

MOULD MANUFACTURERS<br />

A T S, Automation <strong>Tooling</strong>................ 28<br />

Systems Inc..................................... 28<br />

Active Burgess Mould & Design........ 28<br />

Amerjy Tool <strong>and</strong> Mould.................... 28<br />

Anchor Danly.................................... 28<br />

Anchor Danly - Reliance<br />

Fabrications.................................... 28<br />

Burlington Technologies Cen. Div..... 29<br />

Canada Mold Technology Inc........... 30<br />

Circle 5 Tool & Mold Inc.................. 30<br />

Comber Tool & Mold Eng. Inc.......... 30<br />

Compact Mould Ltd......................... 30<br />

H. J. Machine & Pattern Ltd.............. 32<br />

Hallink RSB Inc.................................. 32<br />

Husky Injection Molding<br />

Systems Ltd.................................... 33<br />

Metric Mold (1983) Inc.................... 34<br />

MicroMetric Ltd................................ 34<br />

Prothane Ltd..................................... 35<br />

Top Grade Molds Ltd........................ 36<br />

Tycos Tool & Die.............................. 37<br />

XL Tool Inc....................................... 37<br />

PRECISION MACHINING / EQUIVALENT<br />

SERVICES<br />

A T S, Automation <strong>Tooling</strong><br />

Systems Inc..................................... 28<br />

Active Burgess Mould & Design........ 28<br />

Airtronic Metal <strong>and</strong> Machine Parts<br />

Limited........................................... 28<br />

Anchor Danly.................................... 28<br />

Anchor Danly - Reliance<br />

Fabrications.................................... 28<br />

Answer Precision............................... 29<br />

Appolo Machine Tool Ltd................. 29<br />

Atlantic Heat Treating 2001 Ltd........ 29<br />

Axis Tool & Gauge Inc...................... 29<br />

Bartel Machine................................. 29<br />

Burloak Tool & Die Ltd..................... 29<br />

C.M. Morris Design Ltd.................... 30<br />

Cambridge Heat Treating................. 30<br />

Cana-Datum Moulds Ltd.................. 30<br />

Clinton Aluminum of Canada ULC.... 30<br />

Densmore Tool & Die Works<br />

Limited........................................... 31<br />

Diemedic Tool & Machine................ 31<br />

Exactatherm Limited......................... 31<br />

FBT Inc............................................. 32<br />

Footage Tools Inc............................. 32<br />

Fred Hall & Son Ltd.......................... 32<br />

Glider Guard Tool & Die Inc............. 32<br />

H. Beck Machinery Ltd...................... 32<br />

H. J. Machine & Pattern Ltd.............. 32<br />

H.S. Enterprizes................................ 32<br />

Halton Machining............................. 32<br />

Harbour Advanced Machining<br />

Ltd.................................................. 32<br />

Hartford Technology Ltd................... 33<br />

Harvan Engineering Ltd.................... 33<br />

Kapco Tool & Die Limited................. 33<br />

MicroMetric Ltd................................ 34<br />

New Era Tool & Die Ltd.................... 34<br />

Niagara Precision Limited................. 34<br />

Nickleson Machine & Tool Inc.......... 34<br />

Novatec Machining Inc..................... 34<br />

Omni Tool Ltd.................................. 35<br />

Rice Tool & Manufacturing Inc......... 35<br />

Samco Machinery Ltd....................... 35<br />

Schmolz+Bickenbach Canada Inc...... 35<br />

Sciens Industries Inc.......................... 36<br />

Special Machining Company Inc....... 36<br />

Stema Punch & Die Inc..................... 36<br />

Thames Machine & Tool Ltd............. 36<br />

Thomas Wire Die Limited.................. 36<br />

Tipco Inc.......................................... 36<br />

Ultimate Manufactured Systems....... 37<br />

Valiant Machine & Tool Inc.............. 37<br />

XL Tool Inc....................................... 37<br />

GAUGES, FIXTURES & GENERAL TOOLING<br />

A T S, Automation <strong>Tooling</strong> Systems Inc.<br />

A.V. Gauge & Fixture Inc. ................ 28<br />

Accredited Calibration Services/Marsh<br />

Metrology....................................... 28<br />

Active Burgess Mould & Design........ 28<br />

Airtronic Metal <strong>and</strong> Machine Parts<br />

Limited........................................... 28<br />

Aluminum Mold & Pattern Ltd.......... 28<br />

Ammco Industrial Equipment Ltd..... 28<br />

Anchor Danly.................................... 28<br />

Anchor Danly - Reliance<br />

Fabrications.................................... 28<br />

Answer Precision............................... 29<br />

Appolo Machine Tool Ltd................. 29<br />

Armo Tool Ltd.................................. 29<br />

Axis Tool & Gauge Inc...................... 29<br />

Bartel Machine................................. 29<br />

Burloak Tool & Die Ltd..................... 29<br />

C.M. Morris Design Ltd.................... 30<br />

Dayton Progress Canada Ltd............. 31<br />

Densmore Tool & Die Works<br />

Limited........................................... 31<br />

Diemedic Tool & Machine................ 31<br />

FBT Inc............................................. 32<br />

Glider Guard Tool & Die Inc............. 32<br />

H. J. Machine & Pattern Ltd.............. 32<br />

Harbour Advanced Machining Ltd.... 32<br />

Hartford Technology Ltd................... 33<br />

Inspection Air Gauge Limited............ 33<br />

Kapco Tool & Die Limited................. 33<br />

Niagara Precision Limited................. 34<br />

Nickleson Machine & Tool Inc.......... 34<br />

Omni Tool Ltd.................................. 35<br />

Russell Tool & Die Limited................ 35<br />

Samco Machinery Ltd....................... 35<br />

Special Machining Company Inc....... 36<br />

Stema Punch & Die Inc..................... 36<br />

Thames Machine & Tool Ltd............. 36<br />

Ultimate Manufactured Systems....... 37<br />

Valiant Machine & Tool Inc.............. 37<br />

Woodbine Tool & Die Mfg. Ltd........ 37<br />

XL Tool Inc....................................... 37<br />

RAPID PROTOTYPING & ADDITIVE<br />

MANUFACTURERS<br />

H D Patterns & Matchplates Inc........ 32<br />

Manor Tool & Die Ltd....................... 33<br />

Prothane Ltd..................................... 35<br />

PATTERN & MODEL MAKERS<br />

Aluminum Mold & Pattern Ltd.......... 28<br />

Exco Engineering Limited................. 31<br />

H D Patterns & Matchplates Inc........ 32<br />

H. J. Machine & Pattern Ltd.............. 32<br />

Massiv Die-Form (Div. of Magna)...... 34<br />