Mastercam Ver. 9 (new) - CTMA: : The Canadian Tooling and ...

Mastercam Ver. 9 (new) - CTMA: : The Canadian Tooling and ...

Mastercam Ver. 9 (new) - CTMA: : The Canadian Tooling and ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Canadian</strong> <strong>Tooling</strong> & Machining Association November 2004<br />

<strong>CTMA</strong> VIEW<br />

J<br />

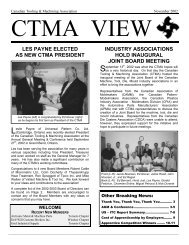

JAMIE BOWMAN ELECTED<br />

NEW <strong>CTMA</strong> PRESIDENT<br />

amie Bowman of J.P. Bowman Limited in Brantford,<br />

Ont. was elected as <strong>CTMA</strong>’s <strong>new</strong> President for 2004-<br />

2005 at the association’s Annual General Meeting on<br />

September 24 th , 2004. Jamie has served on the Board<br />

of Directors since 2000 as a Director, the Western<br />

Ontario Chapter Chair, <strong>and</strong> most recently as the national<br />

Vice President. Over the years, he has been actively<br />

involved on the Apprenticeship Competition Committee,<br />

the Conference Committee <strong>and</strong> he has been<br />

instrumental in spearheading the <strong>CTMA</strong>’s<br />

Apprenticeship Tax Credit Proposal that is beginning to<br />

see some results in a proposed tax credit for employers<br />

in Ontario. (See more about the AGM & Conference on<br />

pages 4-7.)<br />

New President Jamie Bowman<br />

with 2004-2005 Board of Directors<br />

Back Row (L-R): Paul Brisebois (Anchor Lamina), Trevor<br />

Ludolph (Anchor Lamina), Ron Spraggett (Tipco Inc.), David<br />

Glover (Harbour Advanced Machining), Rob Cattle<br />

(Micrometric Limited), Horst Just (HJ Machine & Pattern)<br />

Front Row (L-R): Horst Schmidt (Build-A-Mold), Ed Glover<br />

(Harbour Advanced Machining), Jamie Bowman (J.P.<br />

Bowman Limited), Les Payne (Universal Pattern)<br />

WELCOME<br />

RECENT NEW MEMBERS<br />

Active Tool & Die Inc....................... Western Ont. Chapter<br />

Advanced Machining Services Inc............Windsor Chapter<br />

Canada Fujian Jinxin Powder Metallurgy..Toronto Chapter<br />

Dumar Enterprises Ltd. ..................... Western Ont. Chapter<br />

GE Canada Equipment Financing ..............Toronto Chapter<br />

Gr<strong>and</strong> Precision Machining Inc......... Western Ont. Chapter<br />

Harvan Engineering Ltd.................... Western Ont. Chapter<br />

Narmco Group/Central Stampings ............Windsor Chapter<br />

IMTS 2004 SHOWS CLEAR<br />

SHIFT IN NEW TECHNOLOGIES<br />

By: Horst Schmidt Build-A-Mold Limited <strong>and</strong><br />

Ed Glover, Harbour Advanced Machining Ltd.<br />

<strong>The</strong> International Machine Tool Show in Chicago, Illinois<br />

(Sept. 4-17/04) was reduced in size from the show in<br />

2001, both in number of exhibitors <strong>and</strong> in the size of the<br />

booths by the major exhibitors. <strong>The</strong>re was a clear shift<br />

in the technologies exhibited with few if any manual<br />

machines being shown. Even upgrades to manual<br />

machines like electronic scales <strong>and</strong> add-on CNC<br />

controls were not being shown. <strong>The</strong> industry has clearly<br />

gone to CNC controlled machines <strong>and</strong> the CAD/CAM<br />

software that supports them. In the sheet metal side of<br />

the industry, the CNC punch press that used to nibble<br />

unique shapes in sheet metal has now been replaced by<br />

laser <strong>and</strong> water jet technology. <strong>The</strong> show is still clearly<br />

an international show with representation from almost<br />

every developed country recognized for their machine<br />

tools.<br />

Milling Machines<br />

Spindle speeds are still topping out at between 25,000<br />

<strong>and</strong> 32,000rpm’s but at higher horse power over a wider<br />

range, some even achieving 60% or more of their horse<br />

power at speeds as low as 60rpm. <strong>The</strong> preferred<br />

bearing structure for these rpm’s is still ceramic balls<br />

running on metal races with oil mist lubrication. Most<br />

high accuracy machines now have refrigerated water<br />

cooling through the ball screws <strong>and</strong> even the ways. Axis<br />

drive systems are still dominated by ball screws with<br />

only two or three linear motor machines being shown<br />

<strong>and</strong> then just in small table travel machines. <strong>The</strong>re have<br />

been continued developments toward better finishing<br />

capabilities with milling machines through faster travel,<br />

more rigid construction, <strong>and</strong> controls with tighter path<br />

capability. It also seems that the majority of machine<br />

control manufacturers are moving to true PC-based<br />

machine controls that are updatable <strong>and</strong> upgradeable<br />

without the cost of <strong>new</strong> proprietary hardware.<br />

Continued on page 8<br />

Other Breaking News:<br />

From the President’s Desk ........................ 3<br />

AGM & Conference................................. 4-6<br />

Apprenticeship Awards Luncheon ............ 7<br />

Bringing Service People Into Canada ....... 9<br />

Upcoming Events .................................... 12<br />

____________________________________________________________________________________________

_____________________________________________________________________________________________<br />

<strong>CTMA</strong> BOARD OF DIRECTORS<br />

President:<br />

Jamie Bowman, J.P. Bowman Limited<br />

Tel: (519) 752-6533 Fax: (519) 752-0672<br />

Vice President:<br />

Horst Schmidt, Build-A-Mold Limited<br />

Tel: (519) 737-6984 Fax: (519) 737-6572<br />

Treasurer:<br />

Horst Just, H.J. Machine & Pattern Ltd.<br />

Tel: (519) 746-7077 Fax: (519) 746-6872<br />

Past President:<br />

Leslie Payne, Universal Pattern Co. Ltd.<br />

Tel: (519) 622-8667 Fax: (519) 622-5758<br />

Chapter Chairs:<br />

Toronto<br />

Ron Spraggett, Tipco Inc.<br />

Tel: (905) 791-9811 Fax: (905) 791-4917<br />

Western Ontario<br />

Trevor Ludolph, Anchor Lamina Inc.<br />

Tel: (519) 242-4152 Fax: (519) 740-8213<br />

Windsor<br />

David Glover, Harbour Advanced Machining<br />

Tel: (519) 969-0641 Fax: (519) 969-0451<br />

Directors:<br />

Paul Brisebois, Anchor Lamina Inc.<br />

Tel: (905) 274-3448 Fax: (905) 274-7303<br />

Robert Cattle, Micrometric Ltd.<br />

Tel: (416) 291-1974 Fax: (416) 291-5011<br />

Ed Glover, Harbour Advanced Machining<br />

Tel: (519) 969-0641 Fax: (519) 969-0451<br />

Staff:<br />

Julie McFarlane, Office Manager<br />

Corey Brunsveld, Finance<br />

Susan Kemp, Office Assistant<br />

<strong>CTMA</strong> VIEW is published quarterly, <strong>and</strong><br />

features articles <strong>and</strong> information of<br />

interest to members <strong>and</strong> others allied to<br />

the precision metal cutting industry. To<br />

receive additional copies of this<br />

publication, or to make comments or<br />

submissions, please contact us at:<br />

<strong>Canadian</strong> <strong>Tooling</strong> &<br />

Machining Association<br />

140 McGovern Dr., Unit #3<br />

Cambridge, ON N3H 4R7<br />

Tel: (519) 653-7265<br />

Fax: (519) 653-6764<br />

Email: info@ctma.com<br />

www.ctma.com<br />

Active Tool & Die Inc.<br />

25 Gr<strong>and</strong> Avenue<br />

Kitchener, ON N2K 1B2<br />

CONTACT: John Jefferson<br />

Tel: (519) 744-5881 Fax: (519) 744-5497<br />

Email: active.tm@sympatico.ca<br />

� � � �<br />

Advanced Machining Services Inc.<br />

6490 Hawthorne Drive<br />

Windsor, ON N8T 1J9<br />

CONTACT: Norm<strong>and</strong> Marcoux<br />

Tel: (519) 944-3433 Fax: (519) 974-6266<br />

www.advancedmachiningservices.com<br />

Email: sales@2000ams.com<br />

� � � �<br />

Canada Fujian Jinxin Powder<br />

Metallurgy Co. Ltd.<br />

26 – 570 Hood Road<br />

Markham, ON L3R 4G7<br />

CONTACT: Liah Yan<br />

Tel: (905) 470-2362 Fax: (905) 470-8892<br />

Website: www.fjgoldenstar.com<br />

Email: fujianjinxin@bellnet.ca<br />

� � � �<br />

Dumar Enterprises Ltd.<br />

270 Southgate Drive<br />

Guelph, ON N1G 4P5<br />

CONTACT: Rodney Adams<br />

Tel: (519) 763-5217 Fax: (519) 826-9580<br />

Email: radams@dumarenterprises.com<br />

NEW MEMBERS<br />

GE Canada Equipment Financing<br />

2300 Meadowvale Blvd., Suite 100<br />

Mississauga, ON L5N 5P9<br />

CONTACT: Ron Tratch<br />

Tel: (905) 858-4900 Fax: (905) 858-4930<br />

Website: www.gecapitalcanada.com<br />

Email: ron.tratch@ge.com<br />

� � � �<br />

Gr<strong>and</strong> Precision Machining Inc.<br />

66 Sinclair Blvd.<br />

Brantford, ON N3S 7Y1<br />

CONTACT: John Stonham<br />

Tel: (519) 757-1055 Fax: (519) 757-0788<br />

Email: jstonham@worldchat.com<br />

� � � �<br />

Harvan Engineering Ltd.<br />

62 Jack Ross Ave., P.O. Box 24021<br />

Woodstock, ON N4S 8Y4<br />

CONTACT: Harry Vleuten<br />

Tel: (519) 537-8311 Fax: (519) 539-0521<br />

Website: www.harvan.com<br />

Email: harry@harvan.com<br />

� � � �<br />

Narmco Group/Central Stampings<br />

2575 Airport Road<br />

Windsor, ON N8W 1Z4<br />

CONTACT: Don Rodzik, Jr.<br />

Tel: (519) 969-3351 Fax: (519) 969-0063<br />

Email: drodzikjr@narmco.com<br />

_____________________________________________________________________________________________<br />

2

____________________________________________________________________________________________<br />

BY: Jamie Bowman, <strong>CTMA</strong> President<br />

J.P. Bowman Limited, Brantford, Ontario<br />

<strong>The</strong> <strong>CTMA</strong> has been the voice of the <strong>Canadian</strong> tooling<br />

industry for over 40 years now. We are largely a<br />

volunteer organization that serves to represent our<br />

industry <strong>and</strong> its interests <strong>and</strong> to speak on the issues that<br />

affect us most to anyone who will listen. Since 1963 the<br />

<strong>CTMA</strong> has seen our industry through good times <strong>and</strong><br />

bad, but never has our industry seen times like these.<br />

With pressures from OEM’s on cost <strong>and</strong> lead time<br />

reductions, rebates <strong>and</strong> unrealistic terms, to the outside<br />

pressures of foreign competition <strong>and</strong> increasing<br />

overhead costs, we seem to be getting hit at all angles.<br />

Never in our history has there been a greater need for<br />

the <strong>CTMA</strong>, <strong>and</strong> never before has there been a greater<br />

need for our industry to support it. It is only with the<br />

support of it’s members <strong>and</strong> dedicated volunteers that<br />

the association continues to grow.<br />

I am very fortunate to be the incoming President with<br />

such a talented, experienced <strong>and</strong> dedicated Board of<br />

Directors to support me. I know that we have an<br />

excellent team to tackle some very difficult issues facing<br />

us in the months ahead. I can’t tell you the work <strong>and</strong><br />

sacrifice that your Board members make on your behalf<br />

for the pure satisfaction of a job well done.<br />

As many of you know, Les Payne recently stepped down<br />

from the position of President. It would not be possible<br />

for the <strong>CTMA</strong> to grow or even exist without dedicated<br />

people like him. I can not properly describe or put into<br />

words what Les has done for this organization, but I can<br />

assure you that he has tirelessly represented us well<br />

beyond the last 2 years as President. He has been<br />

involved with the <strong>CTMA</strong> since 1987 <strong>and</strong> has held various<br />

positions on the Board of Directors such as Western<br />

Ontario Chapter Chairman, Treasurer <strong>and</strong> most recently<br />

as President. Les even worked as the General Manager<br />

of the association for seven years from 1989 to 1996.<br />

His approach to the <strong>CTMA</strong> is at such a personal level,<br />

that I think it will be quite some time before we will see<br />

another President like him. With considerable personal<br />

<strong>and</strong> professional sacrifice, Les has always put the best<br />

interests of our industry ahead of his own. And the<br />

<strong>CTMA</strong> is nothing but stronger for it.<br />

In each organization, there are unique individuals that<br />

are pivotal to the history <strong>and</strong> development of those<br />

organizations. For the <strong>CTMA</strong>, Les is one of those<br />

individuals. I know that sounds corny <strong>and</strong> I’m sure that<br />

you have heard comments like this before, but I can<br />

assure you, that this is truly the case when we are<br />

speaking of Les Payne. In my years of involvement with<br />

the <strong>CTMA</strong> Les has taught me the benefits of listening<br />

(although my wife might disagree!) <strong>and</strong> the value of<br />

compromise. Many times, I have witnessed impressive<br />

displays of wise leadership, always with a smile <strong>and</strong> a<br />

joke or two.<br />

FROM THE PRESIDENT’S DESK<br />

THANKS LES !!<br />

Incoming President Jamie Bowman (left)<br />

thanks Les Payne for his leadership & dedication<br />

to the <strong>CTMA</strong> during his term as President from 2002-2004<br />

<strong>and</strong> for his many years of service to the association.<br />

<strong>The</strong> tooling industry has been part of my life for over<br />

twenty years now <strong>and</strong> it is an honour to represent it on<br />

behalf of my peers. Although I will do my very best, I<br />

can only aspire to the level of vision <strong>and</strong> leadership that<br />

Les has displayed. I am very lucky to have him as a<br />

sounding board <strong>and</strong> to have him to call on for his<br />

respected advice. Thank you Les for all that you have<br />

done <strong>and</strong> continue to do for our association.<br />

<strong>The</strong> strength of the <strong>CTMA</strong> is only gauged by the strength<br />

of it’s members, so I call on all of our members to<br />

become more active within our association to help<br />

preserve & strengthen the tooling industry in Canada.<br />

Together, we have a voice. I look forward to the<br />

challenges in the months <strong>and</strong> years ahead <strong>and</strong> if you<br />

have any questions or comments regarding how the<br />

<strong>CTMA</strong> can help your business, we would be pleased to<br />

hear from you.<br />

Jamie Bowman, <strong>CTMA</strong> President<br />

____________________________________________________________________________________________<br />

3

_____________________________________________________________________________________________<br />

Members of the affiliated associations in the <strong>Canadian</strong><br />

Machine, Tool, Die & Mould Federation met together at<br />

the Oakwood Inn Resort & Golf in Gr<strong>and</strong> Bend, Ontario<br />

from September 24 to 26, 2004. <strong>The</strong> activities were<br />

planned to maximize members’ time in covering the<br />

many business agendas <strong>and</strong> providing delegates <strong>and</strong><br />

their families time to network <strong>and</strong> enjoy all the amenities<br />

that the resort <strong>and</strong> area have to offer.<br />

Board Members from <strong>CTMA</strong> <strong>and</strong> CAMM attended a<br />

Federation Board Meeting on Friday morning which was<br />

followed by the 11 th Annual Apprenticeship Competition<br />

Awards Luncheon (see Page 7). <strong>The</strong> Keynote Address<br />

was presented by Lori Nicholas on the “Health & Safety<br />

Dem<strong>and</strong>s in the TDM Industry – Underst<strong>and</strong>ing Current<br />

Trends” <strong>and</strong> Russell Gorham was presented with the<br />

<strong>CTMA</strong>’s inaugural Volunteer Appreciation Award for his<br />

excellent work with the Moulding Youth For Industry<br />

Program.<br />

Les Payne (left) presents <strong>CTMA</strong>’s inaugural<br />

Volunteer Appreciation Award to Russell Gorham<br />

Members attending the <strong>CTMA</strong>’s Annual General Meeting<br />

received <strong>and</strong> approved reports on all of the association’s<br />

activities over the past year <strong>and</strong> the elections for 2004-<br />

2005 Board of Directors took place (see page 1 for<br />

photo of <strong>CTMA</strong>’s <strong>new</strong> Board of Directors). <strong>The</strong><br />

<strong>Canadian</strong> Association of Moldmakers’ AGM was held<br />

concurrently.<br />

New CAMM President, Cyndi Butcher (far right),<br />

presents CAMM’S New Board of Directors<br />

during the Presidents’ Dinner.<br />

2004 AGM & CONFERENCE<br />

Members from all of the represented associations then<br />

joined together for the <strong>Canadian</strong> MTDM Federation’s<br />

AGM where delegates heard several reports from the<br />

Federation’s working committees <strong>and</strong> a presentation on<br />

outsourcing services by Vince Scialo from FIRST<br />

INDEX. Delegates also participated in an open<br />

discussion on global issues.<br />

2004-2006 CANADIAN MTDM FEDERATION BOARD<br />

L-R: Horst Just; Jamie Bowman, Horst Schmidt (Treasurer),<br />

Ed Bernard (Chair), Ed Glover, Ted Callighen, Les Payne<br />

(Past-Chair).<br />

Missing: Miguel Petrucci (Vice Chair), Charmian Entine, Ed<br />

Regan, Tom Meisels, Peter Sheliga<br />

We would like to thank our sponsors for their generous<br />

financial support. Your assistance greatly contributed to<br />

the event’s success. Thank You!!<br />

AGM & CONFERENCE SPONSORS<br />

ABB INC.<br />

ANCHOR LAMINA INC.<br />

CANADIAN PROGRESSIVE TOOL &<br />

TRANSFER LTD.<br />

COMPACT MOULD LTD.<br />

DADCO CANADA INC.<br />

DORMER TOOLS INC.<br />

FIRST INDEX<br />

J. P. BOWMAN LIMITED<br />

KALLER GAS SPRINGS<br />

MICROMETRIC LIMITED<br />

STEMA PUNCH & DIE INC.<br />

TIPCO INC.<br />

VALIANT MACHINE & TOOL INC.<br />

Thank You ! Thank You ! Thank You !<br />

_____________________________________________________________________________________________<br />

4

____________________________________________________________________________________________<br />

Weekend social events included the Presidents’ Dinner<br />

with the ever-popular Ladies’ Gift Exchange, Golf <strong>and</strong><br />

Tennis Tournaments, a 1970’s <strong>The</strong>me night “Saturday<br />

Night Fever” for the whole family; wrapping up with the<br />

Sunday Brunch & Sports Awards.<br />

EARLY REGISTRATION PRIZE WINNERS<br />

Conference Chair Paul Brisebois (centre) congratulates<br />

Irys & Karl Jurdens (BES Tool & Die Ltd.).<br />

LADIES’ GIFT EXCHANGE<br />

Carol-Ann Tough is congratulated by Dave S<strong>and</strong>ers of<br />

Cavalier Tool & Mfg. (left) <strong>and</strong> Trevor Ludolph of Anchor<br />

Lamina (right) on being the first name drawn.<br />

DIAMOND BRACELET WINNER<br />

Ron Spraggett (Tipco), Rob Cattle (Micrometric) <strong>and</strong> Elke Just<br />

(H.J. Machine) congratulate Paul Brisebois (Anchor Lamina)<br />

on winning the draw for a 14kt Gold & Diamond Bracelet.<br />

Thanks to Rob Cattle of Micrometric for donating the prize!<br />

MORE 2004 AGM & CONFERENCE<br />

TENNIS TOURNAMENT GANG<br />

Ladies Doubles Champs: Eileen Payne & Cathy Wilson<br />

Mens Doubles Champs: Scott Wilson & Jim McFarlane<br />

Mixed Doubles Champs: Eileen Payne & Jim McFarlane<br />

GOLF WINNERS<br />

Top Foursome: Les Payne, Ed & David Glover, Dan Hagell<br />

Ladies Longest Drive: Elaine Cattle, Micrometric<br />

Ladies Closest-To-Pin: Carol Ann Tough, Anchor Lamina<br />

Mens Longest Drive: Les Payne, Universal Pattern<br />

Mens Closest-To-Pin: Dave S<strong>and</strong>ers, Cavalier Tool<br />

BEST CHIP SHOT ON THE GOLF COURSE!!<br />

Brendan Wilson (son of Scott Wilson of Dormer Tools)<br />

____________________________________________________________________________________________<br />

5

_____________________________________________________________________________________________<br />

Mike & Catherine Moore, Valiant Machine & Tool Inc.<br />

Roy & Luella <strong>Ver</strong>straete, Anchor Lamina Inc.<br />

Thanks for your hospitality !!<br />

Jacques & Viviane Viau, DMG Canada<br />

PRESIDENTS’ DINNER 2004<br />

Scott & Cathy Wilson, Dormer Tools Inc.<br />

Cyndi Butcher-Hagell & Dan Hagell<br />

David Glover & Jennifer Katt, Harbour Advanced Machining<br />

Honourary Member Brian Taylor & Elizabeth Prokop<br />

Ron & Carole Spraggett, Tipco Inc.<br />

_____________________________________________________________________________________________<br />

6

____________________________________________________________________________________________<br />

BLOUNT CANADA LTD. RECEIVES<br />

<strong>CTMA</strong>’S APPRENTICESHIP<br />

AWARD OF EXCELLENCE<br />

Scott Watson (centre) accepts Blount Canada’s Award of<br />

Excellence in Apprenticeship Training from Carol<br />

Olinski (Ministry of Training, Colleges & Universities)<br />

<strong>and</strong> <strong>CTMA</strong> Director Rob Cattle (Micrometric Limited).<br />

At the Apprenticeship Awards Luncheon in September,<br />

the winning apprentices in the Senior Category of our<br />

11 th Annual Apprenticeship Competition were<br />

announced <strong>and</strong> presented with their awards <strong>and</strong> prizes.<br />

Awards in the Junior Category were not presented due<br />

to insufficient entries.<br />

Thank you to all of the companies that sponsored this<br />

event by donating cash <strong>and</strong> prizes valued at almost<br />

$8,000.00.<br />

APPRENTICESHIP COMPETITION WINNERS<br />

Winners are congratulated by Carol Olinski, MTCU (left) &<br />

Rob Cattle & Ron Spraggett, <strong>CTMA</strong> Competition Committee<br />

1 st Place: Steve Waechter, Blount Canada Ltd.<br />

2 nd Place: Ron Lushman, Blount Canada Ltd.<br />

3 rd Place: Thomas Armstrong, Sigma Engineering (Windsor)<br />

Employer Award: Scott Watson, Blount Canada Ltd.<br />

Honourable Mention: Dinesh Nadu, P.H. Molds Ltd.<br />

(from British Columbia – not shown)<br />

APPRENTICESHIP AWARDS LUNCHEON<br />

OUR THANKS TO THE FOLLOWING SPONSORS<br />

THAT SO GENEROUSLY SUPPORTED THE<br />

APPRENTICESHIP COMPETITION THROUGH<br />

DONATIONS TO THE<br />

GEORGE H. SHAFFER EDUCATIN FUND<br />

Blount Canada Ltd.<br />

Burloak Tool & Die Ltd.<br />

Brian Taylor<br />

<strong>Canadian</strong> Progressive Tool & Transfer Ltd.<br />

Densmore Tool & Die Works Limited<br />

Exactatherm Limited<br />

Frank J. Cox Sales Limited<br />

Guhring Corporation<br />

H. J. Machine & Pattern Ltd.<br />

J. P. Bowman Limited<br />

Manor Tool & Die<br />

Micrometric Limited<br />

O S G Canada Ltd.<br />

Prothane Limited<br />

Ross Strickl<strong>and</strong><br />

SECO Tools Canada Ltd.<br />

Sigma Engineering (Windsor) Inc.<br />

Tate Industrial Sales<br />

Tipco Inc.<br />

Ultratech Tool & Gauge Inc.<br />

Universal Pattern Co. Ltd.<br />

Valenite-Modco Ltd.<br />

Valiant Machine & Tool Inc.<br />

Without Your Support It Wouldn’t Have Been Possible!<br />

KEYNOTE ADDRESS<br />

Les Payne (right) thanks Lori Nicholas (left)<br />

for her Keynote Address on Health & Safety Issues in the<br />

TDM Industry at the Apprenticeship Competition Awards<br />

Luncheon on September 24 th , 2004.<br />

____________________________________________________________________________________________<br />

7

_____________________________________________________________________________________________<br />

Continued from Page 1<br />

In five axis the “A” <strong>and</strong> “C” axis in the milling head is still<br />

a major hold problem in anything over 40 horse power.<br />

For large horse power machines, the trend has been to<br />

place these axis in the table where there is more real<br />

estate to develop effective dynamic holding <strong>and</strong> motion<br />

systems.<br />

Lathes <strong>and</strong> Turning Machines<br />

<strong>The</strong> <strong>new</strong>s in these machines is that they have added<br />

milling heads so that both turning <strong>and</strong> milling operations<br />

may be completed on one machine in one setup.<br />

Controls on these machines are following the milling<br />

controls by moving to true PC-based controls.<br />

CAD / CAM<br />

This part of the industry has moved to solid modeling.<br />

Almost all suppliers are offering virtual assemble <strong>and</strong><br />

operation of final assemblies for on-screen verification of<br />

function of final design. Design of assemblies are<br />

integrated <strong>and</strong> linked so any changes made in one<br />

component are reflected <strong>and</strong> made in all affected<br />

components, thus design issues <strong>and</strong> conflicts are<br />

immediately recognized <strong>and</strong> corrected. In CAM there<br />

are very few good five-axis machining packages<br />

available. Everyone is still stuck on 3-plus-2-axis<br />

machining. It seems that most data transfer issues of<br />

the past have been resolved <strong>and</strong> data starvation in<br />

machining no longer seems to be an issue, even with<br />

closer placement of points <strong>and</strong> faster machining rates.<br />

Work Holding<br />

<strong>The</strong>re seems to be two major changes in work holding<br />

technology. First, the <strong>new</strong>est <strong>and</strong> most efficient device<br />

seems to be the electric switchable permanent magnet<br />

systems. Second, is the fact that the work pieces no<br />

longer need to be located square to the machine axis<br />

since the machine axis can now be electronically<br />

realigned to the work piece by way of touch probe<br />

referencing. <strong>The</strong>se systems are able to cut work piece<br />

setup time to as little as 2 minutes.<br />

Cutters <strong>and</strong> Holders<br />

Almost all cutter systems have moved to insertable<br />

types <strong>and</strong> the maximum number of flutes possible for a<br />

given diameter. Where the inserts become too small,<br />

the cutter system usually goes to interchangeable<br />

cutting tips. For very small <strong>and</strong> conventional cutter<br />

designs, solid carbide is now the st<strong>and</strong>ard. In almost all<br />

cases the inserts <strong>and</strong> solid carbides are all coated with a<br />

range of coatings based on the application of the<br />

intended use of the cutters. <strong>The</strong> tool holding system of<br />

choice is the shrink fit holder, which has the highest<br />

holding force of any holder available.<br />

Other Noted Technologies<br />

Laser micro-welding is being offered by more laser<br />

manufacturers but is still only used for small parts that<br />

could be placed in a small desktop welding chamber.<br />

Water jet cutting is now available in five axis. Further,<br />

there are systems that compensate for the 5 degree<br />

taper in the curf to keep the edge cut on the part square.<br />

Inspection touch probes are moving to a continuous<br />

contact system; part inspection is moving more to<br />

video/optical systems; more inspection systems are<br />

available for shop floor use (as opposed to clean room<br />

use); <strong>and</strong> more systems are portable so that they can<br />

move to the work piece as opposed to the work piece<br />

being brought to them.<br />

Visit to Wisconsin<br />

Contacts made just prior to the IMTS resulted in an<br />

opportunity to extend travel by one day to meet with<br />

some key contacts that could assist in marketing the<br />

capabilities of <strong>Canadian</strong> tooling companies. Two key<br />

meetings took place with Jackson Machinery Inc. in Port<br />

Washington, Wisconsin who is seeking a range of<br />

subcontractors to provide details <strong>and</strong> machining to their<br />

machine building operation, <strong>and</strong> Mercury Marine in Fond<br />

du Lac, Wisconsin to introduce the availability <strong>and</strong><br />

capabilities of <strong>CTMA</strong> member companies. In both<br />

cases, the individuals were provided with key contact<br />

information to search out <strong>and</strong> contact <strong>CTMA</strong> members<br />

for their future supplier needs.<br />

We appreciate the support provided by the Program for<br />

Export Marketing (PEMD) <strong>and</strong> the Dept. of Foreign<br />

Affairs & International Trade for their financial assistance<br />

<strong>and</strong> support of this activity.<br />

_____________________________________________________________________________________________<br />

8

____________________________________________________________________________________________<br />

NEW PROCEDURE FOR BRINGING<br />

SERVICE PEOPLE INTO CANADA<br />

<strong>The</strong> Federal government has implemented a <strong>new</strong> procedure for<br />

bringing service people into Canada for emergency <strong>and</strong>/or<br />

after-warranty service.<br />

Effective September 7, 2004, they will now be coming into<br />

Canada under Section 5.32 in the FW1 Foreign Worker<br />

Manual <strong>and</strong> are exempt from HRDC confirmation<br />

requirements.<br />

<strong>The</strong> service person should have the following:<br />

• Letter, fax or email from <strong>Canadian</strong> company stating the<br />

nature of the emergency <strong>and</strong> service required (helps to<br />

indicate that the service is needed to keep <strong>Canadian</strong>s<br />

working <strong>and</strong> keep your business operating)<br />

• Proof of citizenship, residence in country of origin<br />

• Letter from service company confirming employment <strong>and</strong><br />

remuneration from foreign service company<br />

<strong>The</strong> service person will be required to obtain a work permit at a<br />

current cost of $150.00 <strong>Canadian</strong> <strong>and</strong> this permit usually is<br />

specific to the one service call to the one <strong>Canadian</strong> company.<br />

For service companies that qualify under NAFTA: Under<br />

the provisions of NAFTA, sections 2.6 through 2.6.11, the<br />

service person may be exempt from requiring a work permit<br />

<strong>and</strong>/or may be able to obtain a work permit for up to a one-year<br />

duration (not specified to a specific customer). However, this<br />

work permit is specifically tied to equipment sold into Canada<br />

by the company. Base requirements include proof of<br />

citizenship of USA or Mexico, remuneration by foreign<br />

company <strong>and</strong> proof of foreign residence.<br />

MEMBERS IN THE NEWS<br />

TYSON TOOL COMPANY LIMITED<br />

of Toronto, Ont. is pleased to<br />

announce that Richard West has<br />

joined the company as Sales<br />

Manager. Richard has over 10 years<br />

experience in the cutting tool industry<br />

with a variety of well known cutting<br />

tool manufacturers, <strong>and</strong> will be<br />

responsible for the sales <strong>and</strong><br />

marketing of the Tyson Tool product lines (Widia, RTW,<br />

D’Andrea, Menlo, etc) across Canada.<br />

Keep more money in your<br />

business!!<br />

If you are working on projects that qualify<br />

for the Federal Government’s SR&ED<br />

program, we can help. Ward Weber<br />

Associates specializes in tracking <strong>and</strong><br />

claiming SR&ED. We help our clients<br />

from start to finish.<br />

Our clients have more money in their<br />

companies.<br />

Can you afford not to call?<br />

al@wardweber.com 519-342-9140<br />

____________________________________________________________________________________________<br />

9

_____________________________________________________________________________________________<br />

From the Desk of Gary Koenig<br />

Some time ago I wrote an article on Co-Insurance <strong>and</strong> it appears that it needs to be re-examined for two reasons;<br />

one, there still seems to be a great deal of confusion as to the proper meaning of this Clause <strong>and</strong>; two, we find that<br />

insurers are more frequently using this clause to reduce the amount payable on a claim. I am, therefore, presenting<br />

my previous article below in the hopes of bringing this very important issue to your immediate attention.<br />

I would like to address the consequences of violating what is known as a Co- Insurance Clause in your policy. This applies to<br />

some of the items insured such as Building, Contents, <strong>and</strong> Business Interruption. I would suggest that you review your limits of<br />

insurance for each of these items <strong>and</strong> be certain you have insured your contents <strong>and</strong> building (if you own) for at least 90% of the true replacement<br />

cost. You will violate this clause <strong>and</strong> the co-insurance requirement if the amount insured is less than the co-insurance percentage required, which is<br />

usually 80% Co or 90% Co. Such a violation will limit the amount paid to you following a loss or damage caused by an insured peril.<br />

HERE’S AN EXAMPLE<br />

Assume one hundred thous<strong>and</strong> dollars ($100,000) is the current replacement cost of a building & its contents (stock &<br />

equipment) owned by Smith’s Tool & Die. Replacement cost means, the cost of replacing, repairing, constructing or<br />

reconstructing the property on the same or adjacent site, with <strong>new</strong> property of like kind <strong>and</strong> quality <strong>and</strong> for like occupancy<br />

without deduction for depreciation.<br />

Smith's Tool & Die coverage is subject to a 90% Co-Insurance. <strong>The</strong> minimum limit of insurance is calculated at $90,000. But,<br />

Mr. Smith decides to insure his building & contents for $75,000. His thinking is that he probably will not incur a total loss <strong>and</strong><br />

wants to reduce his premium cost.<br />

Unfortunately, a water damage loss occurs in the amount of $15,000. Mr. Smith is a co-insurer to the extent he failed to properly<br />

insure his building, stock & equipment. As a result he receives $12,450. (less his deductible). Even though Smith had $75,000.<br />

of insurance, he loses $2,500 on his claim. You can calculate the penalty by using the following simple equation:<br />

“Should Insure” “Did Insure” “Under Insured or Co-Insured”<br />

$90,000. Minus $75,000. = $15,000. (approx. 17%)<br />

Suffered Loss of $15,000. Minus 17% “Co-Insured Amount” = $12,450. “Claim Received”<br />

This concept is an important consideration when determining your own insurance coverage. Also noteworthy is the fact that insurance companies<br />

are not too keen to provide insurance to a company that is under insuring itself. From past experience, insurance companies know the problems that<br />

can be encountered when it comes time to adjust a claim.<br />

Gary Koenig<br />

P.W. Harrison & Sons Insurance Broker<br />

P.W. Harrison & Sons is endorsed by the <strong>CTMA</strong> as a preferred broker specializing in industrial risk insurance for tooling<br />

& machining companies. To find out more about this <strong>CTMA</strong> Affinity Program, contact Gary Koenig at 1-888-280-8853.<br />

<strong>CTMA</strong> AFFINITY PROGRAMS<br />

DESIGNED TO $AVE YOU MONEY<br />

In addition to networking opportunities <strong>and</strong> many other benefits, your membership in the <strong>Canadian</strong> <strong>Tooling</strong> &<br />

Machining Association (<strong>CTMA</strong>) provides many advantages that you may not have considered. Pooled<br />

purchasing from these suppliers with other <strong>CTMA</strong> members means savings for you, your employees <strong>and</strong> your<br />

shareholders! Take a few moments <strong>and</strong> evaluate for yourself the savings with these affinity partners …<br />

www.toolingjobs.com<br />

GARY KOENIG<br />

P.W. Harrison & Son<br />

INSURANCE BROKERS INC.<br />

For more information on the affinity programs with any of these suppliers, contact the <strong>CTMA</strong> office at:<br />

Tel: (519) 653-7265 Email: info@ctma.com Fax: (519) 653-6764<br />

_____________________________________________________________________________________________<br />

10

____________________________________________________________________________________________<br />

ANTEC – 2004<br />

By: Horst Schmidt, <strong>CTMA</strong> Vice President<br />

In May this year, I recently traveled to Chicago to attend<br />

ANTEC 2004 (Annual Technical Conference) hosted by the<br />

Society of Plastic Engineers. Over the three day technical<br />

sessions more than 300 papers were presented covering 33<br />

subject areas. At most times 10 sessions were running<br />

simultaneously in 10 different rooms which only allowed you to<br />

change rooms between sessions. In addition an exhibition was<br />

running in the main exhibition space on the Navy Pier. <strong>The</strong><br />

papers themselves ranged from shop floor developments to the<br />

most sophisticated experiment conducted at the molecular<br />

level. Presenters ranged from well-seasoned shop floor<br />

practitioners to world-class scientists in the field <strong>and</strong> subject<br />

matter. Subject matter ranged from incremental improvements<br />

to ground breaking discoveries that had the potential of<br />

revolutionizing parts of our industry as we know it today. This<br />

was one of the most concentrated mass of knowledge in our<br />

industry that I have ever encountered.<br />

This event provided an overview of plastic technology for the<br />

near future with some indication as to where current technology<br />

is going <strong>and</strong> what future technology has in store for us. <strong>The</strong><br />

entire proceedings were available on disc to allow each<br />

participant to review those sessions that they were unable to<br />

attend due to being at another simultaneous session. Virtually<br />

every developed nation <strong>and</strong> some of the developing nations<br />

like China <strong>and</strong> India presented several papers.<br />

Each of the subject areas were supported by a minimum of six<br />

papers with some having as many as 36 papers on a given<br />

subject matter. If there was a development it was reported on<br />

at ANTEC.<br />

Conclusions/Recommendations:<br />

<strong>The</strong> ANTEC Conference needs to be attended every year to<br />

stay current with plastic technology in any given area of interest<br />

<strong>and</strong> to gain an insight into the direction that technological<br />

developments in plastic will be going in the short <strong>and</strong> long term.<br />

ANTEC also provides the opportunity to get onboard with some<br />

leading edge technology to establish a lead position in the<br />

industry <strong>and</strong> possibly globally. <strong>The</strong>re is also the opportunity to<br />

interface with the brightest leaders in the industry to resolve<br />

some of our most critical issues <strong>and</strong> problems in plastics.<br />

RECENT MEMBERSHIP PLAQUE RECIPIENT<br />

ALTOMAX INC.<br />

Alan Glen of Altomax Inc. (left) receives membership plaque<br />

From <strong>CTMA</strong> Director Rob Cattle of Micrometric Ltd.<br />

REMINDER !!<br />

WAGE & BUSINESS SURVEY 2004<br />

By now members will have received their 2004<br />

Wage & Business Survey questionnaires.<br />

REMEMBER, in order to receive the results,<br />

you must participate … be sure to take some<br />

time to go on-line to complete your survey or fill<br />

out the hardcopy questionnaire <strong>and</strong> submit it to the<br />

<strong>CTMA</strong> office.<br />

If you have any questions, or need another copy of<br />

the questionnaire, please contact Julie at the<br />

<strong>CTMA</strong> office Tel: (519) 653-7265 Email:<br />

info@ctma.com.<br />

Make sure your company<br />

gets its R&D Tax Credits!<br />

<strong>The</strong> <strong>Canadian</strong> <strong>and</strong> Ontario Governments both have tax<br />

incentive programs to encourage companies to do R&D.<br />

<strong>The</strong>se programs combined can reimburse your firm<br />

up to 70% of the R&D labour cost, as a cash refund<br />

or investment tax credit.<br />

From our experience with the tooling industry, we know<br />

that many plants have a lot of experimental<br />

development taking place on the shop floor.<br />

<strong>The</strong> key to getting the tax credits is preparing a claim<br />

that properly documents the R&D work <strong>and</strong> the<br />

associated costs. We can help you do this.<br />

Call Jim Moore in Windsor at (519) 944-0411<br />

Moore Global<br />

A MEMBER OF THE<br />

Magna Moore Group<br />

R&D Tax Credit Specialists<br />

____________________________________________________________________________________________<br />

11

_____________________________________________________________________________________________<br />

INDUSTRY PULSE RATE<br />

TAKEN OCTOBER 2004<br />

• Large shops that can take on entire programs are<br />

very busy; medium sized shops are steady; smallsized<br />

shops are struggling<br />

• Slow, but expect turn around to begin soon<br />

• Too busy, running out of capacity<br />

• Good opportunities currently exist in Midwest USA<br />

<strong>and</strong> Europe<br />

• Some customers that have outsourced to Asia are<br />

coming back to North America for tools<br />

• Steady, future uncertain<br />

• Business is inconsistent (slow, busy, then steady);<br />

work is coming in waves<br />

• Lots of overtime to get rush jobs out but slow again<br />

once they are delivered<br />

• Steady, but putting in overtime to meet deadlines<br />

• Quoting has slowed again<br />

• Cautiously optimistic<br />

• Healthy backlog; expect to be busy through Spring<br />

2005<br />

Solutions for CNC<br />

CAD/CAM & DNC<br />

CAD Interoperability – Full Tool Control<br />

Complete CNC Solutions<br />

<strong>Mastercam</strong> <strong>Ver</strong>. 9 (<strong>new</strong>)<br />

NC Programming & Machining<br />

• Intuitive, user friendly interface<br />

• Full Associativity: Dimensions - Model - NC Toolpath<br />

• Complete 3-Axis Multi-Surface Machining<br />

• Powerful 5-Axis (4-Axis) Machining w/ <strong>Ver</strong>ification<br />

• High Speed Cutting (Optimum Milling Strategies)<br />

• Advanced Solids Machining w/ Tool Control<br />

• Advanced Lathe with Live <strong>Tooling</strong><br />

• Easy to use 2 & 4-Axis Wire EDM<br />

Part Modeling <strong>and</strong> Editing<br />

• Hybrid Modeler – Surfaces, Solids <strong>and</strong> Wireframe<br />

• Stitch Surfaces into a Solid Model<br />

• Mold Cavity/Core Separation<br />

• Automatic Electrode Creation, Insertion & Mgmt.<br />

• Robust & Reliable Translators<br />

(519) 658-1471<br />

www.mastercam.ca<br />

UPCOMING EVENTS<br />

2004<br />

Oct. 21 <strong>CTMA</strong> Board Meeting Cambridge<br />

Oct. 26 Safety Group Sponsor Conf. Toronto<br />

Nov. 3 Western Ont. Chapter Meeting Cambridge<br />

Nov. 4 CAMM Moldmakers Trade Fair Windsor<br />

Nov. 15 Wage Survey Return Deadline National<br />

Nov. 17 Safety Group Meeting Windsor<br />

Nov. 25 CMTDM Federation Board Mtg. Toronto<br />

Nov. 25 Toronto Chapter/CPIA Meeting Brampton<br />

Dec. 1-4 Euromold Frankfort, GERMANY<br />

2005<br />

Jan. 10 Wage Survey Results Release National<br />

Jan. 10 ISTMA-Americas B.C. Survey National<br />

Jan. 12 <strong>CTMA</strong> Board Meeting Cambridge<br />

Jan. 21 CMTDM Federation Board Mtg. Cambridge<br />

Feb. 10 Toronto Chapter/CPIA Meeting Toronto<br />

Feb. 16 Safety Group Meeting Windsor<br />

Mar. 10 Western Ont. Chapter Mtg. Kitchener<br />

High Technology Cutting Tool Systems<br />

Truly the "Tools of Tomorrow", OSG's High<br />

Technology Cutting Tool Systems are designed<br />

specifically to help the hard machining, die <strong>and</strong><br />

mold making industry remain competitive in the<br />

<strong>new</strong> century.<br />

No one in the cutting tool industry offers a greater<br />

selection of high-tech cutting tool styles <strong>and</strong> sizes<br />

than OSG.<br />

Contact us today, for the Tools of Tomorrow...<br />

OSG Canada Ltd<br />

An ISO 9001 Certified Company<br />

538 King Forest Court, Burlington , Ontario L7P 5C1<br />

Phone; 1-800-263-4861 Fax; 905-632-8466<br />

www.osgtool.com<br />

<strong>CTMA</strong> VIEW - ADVERTISING RATES<br />

Advertising rates are $500.00 per year (4 issues). For<br />

further information, please contact our office:<br />

TEL: (519) 653-7265 or FAX us at (519) 653-6764.<br />

_____________________________________________________________________________________________<br />

12