recoSTAR compact

recoSTAR compact

recoSTAR compact

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ecycling technology<br />

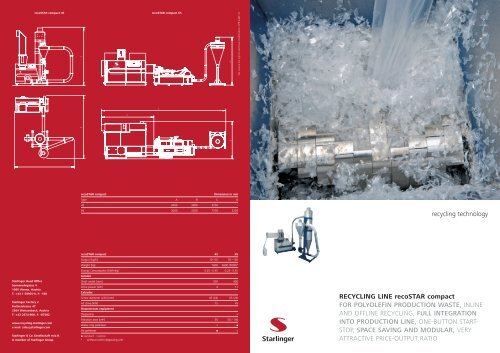

<strong>recoSTAR</strong> <strong>compact</strong> 45 <strong>recoSTAR</strong> <strong>compact</strong> 65<br />

<strong>recoSTAR</strong><br />

recycling technology<br />

r ecoSTAR <strong>compact</strong> 6 5<br />

A<br />

We reserve the right to technical modifications. DPR-24821-G<br />

C<br />

D<br />

B<br />

B<br />

A<br />

C<br />

<strong>recoSTAR</strong> <strong>compact</strong><br />

Dimension in mm<br />

Type A B C D<br />

45 3600 3900 3700 -<br />

65 3000 2350 7700 3250<br />

recycling technology<br />

Starlinger Head Office<br />

Sonnenuhrgasse 4<br />

1060 Vienna, Austria<br />

T: +43 1 59955-0, F: -180<br />

Starlinger Factory 2<br />

Furtherstrasse 47<br />

2564 Weissenbach, Austria<br />

T: +43 2674-800, F: -87582<br />

www.recycling.starlinger.com<br />

e-mail: sales@starlinger.com<br />

Starlinger & Co.Gesellschaft m.b.H.<br />

A member of Starlinger Group<br />

<strong>recoSTAR</strong> <strong>compact</strong> 45 65<br />

Output [kg/h] 10 – 50 30 – 150<br />

Weight [kg] 1600 3600 (5000)*<br />

Energy Consumption [kWh/kg] 0.25 – 0.35 0.25 – 0.35<br />

Grinder<br />

Shaft width [mm] 300 400<br />

Drive power [kW] 4 11<br />

Extruder<br />

Screw diameter (L/D) [mm] 45 (24) 65 (24)<br />

AC drive [kW] 15 45<br />

Downstream equipment<br />

Degassing<br />

Filtration area [cm 2 ] 50 50 / 140<br />

Water ring pelletiser ❍ ●<br />

Air pelletiser ● ❍<br />

● standard ❍ option<br />

* without (with) degassing unit<br />

❍<br />

RECYCLING LINE <strong>recoSTAR</strong> <strong>compact</strong><br />

FOR POLYOLEFIN PRODUCTION WASTE, INLINE<br />

AND OFFLINE RECYCLING, FULL INTEGRATION<br />

INTO PRODUCTION LINE, ONE-BUTTON START-<br />

STOP, SPACE SAVING AND MODULAR, VERY<br />

ATTRACTIVE PRICE-OUTPUT RATIO

Machine pictured may include equipment sold as options.<br />

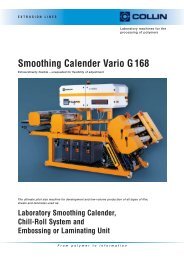

<strong>recoSTAR</strong> <strong>compact</strong><br />

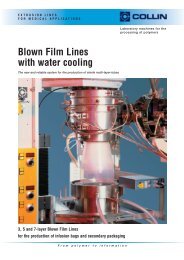

State-of-the-art recycling technology for the low-cost processing of<br />

edge trims, dry and clean film and waste of PP, PE, LD-PE, LLD-PE and<br />

HD-PE and multi-layer films with PA content. The ideal solution for entrance<br />

into the recycling of low quantities with throughput from 10 to 150 kg/h.<br />

1<br />

Advantages<br />

•Modular design<br />

•Best cost-output ratio<br />

•For inline production (automatic<br />

start-up and stand-by)<br />

•Low space requirements<br />

•Easy to use<br />

•One-button start/stop<br />

procedure<br />

•High lifespan of knives<br />

•Self-regulating processing<br />

speed<br />

•Constant output<br />

Constant feeding into<br />

the directly attached extruder<br />

is guaranteed by load<br />

of the extruder motor. The<br />

slowturning grinder results<br />

in high lifespan of knives.<br />

The included control<br />

unit allows simple startstop<br />

procedure, automatic<br />

shut-down and stand-by<br />

mode. The line can be operated<br />

completely automatically<br />

and fully integrated<br />

into the film production line.<br />

Safety filters, discontinuous<br />

and continuous filters<br />

are available for completely<br />

molten material. Equipped<br />

with degassing, the line<br />

can process diaper lining<br />

films and multi-layer films<br />

with PA content.<br />

Air and water ring<br />

pelletising can be used,<br />

depending on type of<br />

plastic and output. Our<br />

patented solution ensures<br />

exact cutting for increased<br />

pellet quality and reduced<br />

wear of knives.<br />

2<br />

3<br />

5<br />

4<br />

6<br />

11<br />

7 10<br />

12<br />

13<br />

1. Edge trim cyclone<br />

2. Nip roll feeder<br />

3. Conveyor belt with<br />

metal detector<br />

4. Grinder<br />

5. Extruder<br />

6. Venting extruder<br />

7. Melt filtration manual<br />

(discontinuous)<br />

8. Melt filtration continuous<br />

without backflushing<br />

9. Melt filtration continuous<br />

with backflushing<br />

10. Water ring pelletiser<br />

11. Air pelletiser with<br />

safety filter<br />

12. Storage silo<br />

13. Cooling cyclone<br />

8<br />

9