Blown Film Unit Type 180

Blown Film Unit Type 180

Blown Film Unit Type 180

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

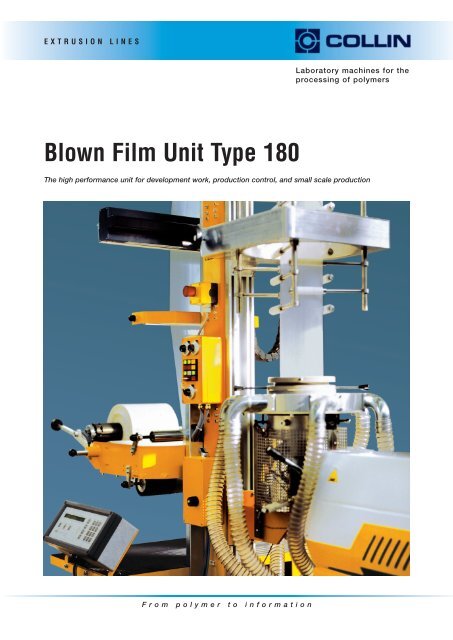

EXTRUSION LINESLaboratory machines for theprocessing of polymers<strong>Blown</strong> <strong>Film</strong> <strong>Unit</strong> <strong>Type</strong> <strong>180</strong>The high performance unit for development work, production control, and small scale productionFrom polymer to information

BLOWN FILM LINE TYPE <strong>180</strong>ApplicationIn development work: For approvalof the suitability of polymers or polymerblends. To check the maximumstretchability of polymers and theircharacteristics.In production control: For approvalof specks and pigments dispersion aspart of incoming inspection. In batchproduction for checking the dispersingefficiency of the compounder orextruder.In production: For production ofsmall diameter film tubes, whichwould be uneconomic to produce onlarge production lines. For examplethe production of thin tubes for foodpackaging, wrapping etc.<strong>Blown</strong> <strong>Film</strong> DieMain part of the blown film die is thecentrally fed spiral melt distributor,cobined with the cooling ring — highair stream, perfect distribution — doesgrant small thickness tolerances.<strong>Blown</strong> <strong>Film</strong> <strong>Unit</strong><strong>Type</strong> <strong>180</strong>Central Telescope ColumnThe main part of the equipment is thetelescope column which allows thetake-off rolls to be moved up anddown over a distance of approximately1000 mm or 1500 mm.This design makes it possible to setthe blowing line in optimum accordanceto the room height and theextruder position.Rails at the front side of the columnallow free, stepless positioning andsupporting of the die, the cooling ringand the calibration ring.Bubble support / calibrationTo stabilize the bubble a hand operatedsupport can as an option be substitutedwith centrally adjustable calibration.Lay flat unitThe blown film is collapsed by meansof adjustable wooden slats. As anoption easy running PTFE-coatedroller-stacks can be delivered.Take-offThe nip rollers consist of one rubbercoatedpneumatically adjustable rolland a chromium-plated coolable roll.They are mounted on top of thecentral column. Both rollers are drivenvia gears by a geared servo motordirectly attached to the nip rolls.WinderThe film wind-up is designed withwind-up shaft and bobbin holder.The film wind-up unit is offered assurface and/or central winder.BaseThe film blowing line also accommodatesthe blower for the cooling air aswell as control valves for inflation airand furthermore, the electric controlcabinet with the control elements forthe take-off and wind-up.The control of the haul-off and windupunit as well as the control of thesupporting and cooling air are positionedat the central column in a wayfor easy operation.Special equipment¥ Dual-lip cooling ring¥ Tubular film guiding support withcentral adjustment¥ Automatical lay flat width control¥ Side edge slitting device¥ Additional haul-off unit¥ Second winder¥ Winder for winding without cone¥ Oscillating unit¥ <strong>Blown</strong> film breaking control¥ Cooling machine¥ <strong>Film</strong> inspection system<strong>Blown</strong> <strong>Film</strong> <strong>Unit</strong> used for productioncontrol with automatic adjustment oflay flat width and special winder forwinding without cone.From the abstract polymer to the real properties

<strong>Blown</strong> <strong>Film</strong> Line <strong>Type</strong> <strong>180</strong> / 400consisting of:¥ Extruder 30 mm ¿ x 25 D withECS-microprocessor control,¥ <strong>Blown</strong> <strong>Film</strong> Die with a diameter of60 mm with Dual-lip cooling ring.¥ <strong>Blown</strong> <strong>Film</strong> <strong>Unit</strong> <strong>180</strong> / 400 withcentrally adjusted calibration and layflat unit with closed loop control.

BLOWN FILM LINE TYPE <strong>180</strong>Technical Data<strong>Type</strong> <strong>180</strong>/400 <strong>180</strong>/600Roll width (mm) 400 600Lay flat width max. (mm) 380 550Bubble diameter max. (mm) 240 350Die diameter (mm) 50 / 60 / 80 / 100 50 / 60 / 80 / 100Total height (mm) 2200 — 3200 2700 — 4200Cooling height over die (mm) 1000 — 2400 1000 — 3400Take-off speed (m/min) 0 — 12 / 30 0 — 50Throughput max. (kg/h) 2 — 20 5 — 40Weight (without extruder) (kg) 450 7003200-4200Technical data subject to changeVersion 12E1000DimensionsRepresented by:Dr. Collin GmbHSportparkstr. 2, D-85560 Ebersberg, GermanyPhone ++49 (0)8092/2096-0, Fax ++49 (0)8092/20862www.drcollin.de, eMail: collin@drcollin.de