technical sheet

technical sheet

technical sheet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>technical</strong><br />

<strong>sheet</strong><br />

MC1211<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

T-528<br />

2<br />

11/98<br />

1/11<br />

A track at roof level is required to allow the machine to traverse.<br />

Two different types of track may be considered: one in concrete and the other with two metal rails.<br />

1. Concrete track<br />

During the construction of the building, it is economic to<br />

lay a track in reinforced concrete, which should be<br />

strong enough to withstand the pressure imposed by the<br />

front and rear wheels of the machine.<br />

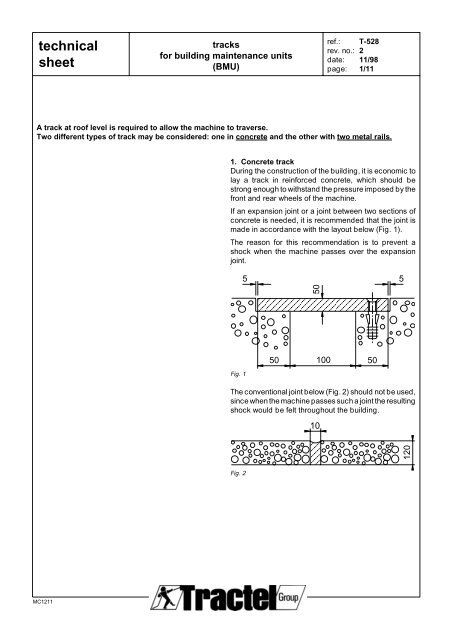

If an expansion joint or a joint between two sections of<br />

concrete is needed, it is recommended that the joint is<br />

made in accordance with the layout below (Fig. 1).<br />

The reason for this recommendation is to prevent a<br />

shock when the machine passes over the expansion<br />

joint.<br />

Fig. 1<br />

5 5<br />

50<br />

50<br />

100<br />

50<br />

The conventional joint below (Fig. 2) should not be used,<br />

since when the machine passes such a joint the resulting<br />

shock would be felt throughout the building.<br />

Fig. 2<br />

10<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

120

<strong>technical</strong><br />

<strong>sheet</strong><br />

110<br />

100-<br />

140<br />

MC1211<br />

270<br />

2200<br />

10<br />

100<br />

20 20<br />

40<br />

30<br />

L 100x50x6<br />

DIN 1029<br />

HOLE TROU Ø 15<br />

PLAT FLAT 40x10 PLATE 40x10<br />

DIN 1017<br />

500 1300 400<br />

230<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

Fig. 3<br />

Concrete track with<br />

"L" shaped guide rail<br />

for JUNIOR 213A machine.<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

T-528<br />

2<br />

11/98<br />

2/11<br />

1.1. Concrete track - with "L" shaped guide rail<br />

Angled metal guide rail fixed to the concrete.<br />

Hot galvanised for protection.<br />

The drawing below (Fig. 3) shows the track for a<br />

JUNIOR 213A machine:<br />

a) location and size of the trolley in relation to the track<br />

b) location of the track in relation to the parapet.<br />

concrete<br />

safety guide<br />

100x100<br />

concrete track<br />

weatherproofing<br />

insulation

<strong>technical</strong><br />

<strong>sheet</strong><br />

2200<br />

MC1211<br />

270<br />

230<br />

1700<br />

1530<br />

568<br />

330<br />

268<br />

930 1270<br />

concrete safety guide<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

R 1000<br />

268 979<br />

1530<br />

37°<br />

568<br />

330<br />

Fig. 4<br />

Example of layout<br />

of a concrete track<br />

with "L" shaped guide rail<br />

for JUNIOR 213A machine *<br />

R 1000<br />

R 700<br />

90°<br />

979<br />

268<br />

250<br />

1270 930<br />

R 1000<br />

37°<br />

164°<br />

R 3056<br />

100<br />

268<br />

*please consult SECALT<br />

for the other types of machine<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

250<br />

T-528<br />

2<br />

11/98<br />

3/11<br />

2200<br />

1700 230 270

<strong>technical</strong><br />

<strong>sheet</strong><br />

110<br />

100-<br />

140<br />

MC1211<br />

100<br />

270<br />

500 1300 400<br />

230<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

2200<br />

1.2. Concrete track - with concrete safety guide<br />

Fig. 5<br />

Concrete track with<br />

concrete guide for<br />

JUNIOR 213A machine.<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

T-528<br />

2<br />

11/98<br />

4/11<br />

concrete<br />

safety guide<br />

100x100<br />

concrete track<br />

weatherproofing<br />

insulation

<strong>technical</strong><br />

<strong>sheet</strong><br />

2200<br />

MC1211<br />

270<br />

230<br />

1700<br />

1530<br />

568<br />

330<br />

268<br />

930 1270<br />

concrete safety guide<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

R 1000<br />

268 979<br />

1530<br />

37°<br />

568<br />

330<br />

Fig. 6<br />

Exampl of layout<br />

of a concrete track with<br />

concrete guide<br />

for JUNIOR 213A machine *<br />

R 1000<br />

R 700<br />

90°<br />

979<br />

268<br />

250<br />

1270 930<br />

R 1000<br />

37°<br />

164°<br />

R 3056<br />

100<br />

268<br />

*please consult SECALT<br />

for the other types of machine<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

250<br />

T-528<br />

2<br />

11/98<br />

5/11<br />

2200<br />

1700 230 270

<strong>technical</strong><br />

<strong>sheet</strong><br />

Fig. 7<br />

Points for changing direction<br />

MC1211<br />

Curved<br />

rail section<br />

for change of<br />

direction<br />

straight rail section to be removed<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

T-528<br />

2<br />

11/98<br />

6/11<br />

1.3. Points for changing direction or parking<br />

In some cases the tracks on the roof must be fitted with<br />

points for :<br />

- the machine to change direction<br />

(in certain special cases)<br />

- parking the machine.<br />

The points consist in replacing a straight rail with a<br />

curved rail and vice versa so that the machine can<br />

change direction.<br />

The points are the same type as the guide rail on the<br />

roof, either an angled "L" rail, or concrete guide type.

<strong>technical</strong><br />

<strong>sheet</strong><br />

2. Metal track<br />

The rails are designed for fast and accurate assembly.<br />

The rail sections are joined together using bolted or<br />

welded fishplates. In open circuits, the last rail section<br />

must be attached using bolted fishplates.<br />

The rails and sleepers are hot galvanised to prevent<br />

corrosion. The size of the rail depends on the weight of<br />

the machine and the distance between the track support<br />

plinths.<br />

5 rail sizes are recommended (IPE160, IPE180, IPE200,<br />

HEA180, HEB200).<br />

The roller frames are defined by the type of BMU machine<br />

(Fig. 10, 11, 12, 13 and 14).<br />

MC1211<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

C<br />

A B<br />

6000<br />

5998<br />

Fig. 8<br />

Rail joint using<br />

2 bolted fishplates (A+B)<br />

= 2 flat plates 190x25x10 (IPE160) or<br />

230x30x10 (IPE180, IPE200,<br />

HEA180, HEB200)<br />

fishplate A<br />

with 4 countersunk holes<br />

fishplate B<br />

with 4 threaded holes M12<br />

2 1<br />

Fig. 9<br />

Rail joint using<br />

2 welded fishplates (A + B)<br />

= 2 flat plates 190x25x10 (IPE160) or<br />

230x30x10 (IPE180, IPE200,<br />

HEA180, HEB200)<br />

Bolt C:<br />

- For IPE and HEA<br />

Bolt M12x25<br />

DIN 7991 stainless steel<br />

- For HEB<br />

Bolt M12x30<br />

DIN 7991 stainless steel<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

T-528<br />

2<br />

11/98<br />

7/11

<strong>technical</strong><br />

<strong>sheet</strong><br />

MC1211<br />

Fig. 10<br />

VENUS roller frame<br />

1000 daN<br />

on IPE 160 rail<br />

Fig. 13<br />

Roller frame 3800 daN<br />

on HEA 180 rail<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

Fig. 11<br />

Roller frame 2400 daN<br />

on IPE 180 rail<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

Fig. 14<br />

Roller frame 4900 daN<br />

on HEB 200 rail<br />

T-528<br />

2<br />

11/98<br />

8/11<br />

Fig. 12<br />

Roller frame 2400 daN<br />

on IPE 200 rail

<strong>technical</strong><br />

<strong>sheet</strong><br />

rail<br />

sealing plate +<br />

packing<br />

cover<br />

reinforced concrete<br />

Fig. 15 - Concrete track support plinth<br />

rail<br />

sealing plate +<br />

packing<br />

cover<br />

reinforced concrete<br />

Fig. 16 - Concret plinth<br />

rail<br />

anchor flange<br />

sealing plate<br />

steel track<br />

support plinth<br />

MC1211<br />

M16 bolt<br />

separator<br />

cover<br />

reinforcing " I " type 125 Halfen M16<br />

type 50/30 bolt<br />

packing Halfen HTA 52/3 rail<br />

Fig. 17 - Potelet acier<br />

500<br />

500<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

anchor flange<br />

separator<br />

chemical plug<br />

type EPCON<br />

STIT M16<br />

anchor flange<br />

separator<br />

spacer<br />

M16 threaded rod<br />

The rails are supported on plinths every 2 or 3 m depending<br />

on the loading on the wheels of the machine.<br />

Three examples are given below:<br />

2.1. Concrete track support plinths (Fig. 15 & 16)<br />

A concrete track support plinth is made every 2 to 3 m<br />

to support the rail. The sleeper has a zinc cover and a<br />

seating plate which takes the adaptable rail fixing system.<br />

2.2. Steel track support plinths (Fig. 17)<br />

The steel track support plinth is a length of square hollow<br />

section to which a seating plate is soldered at one end.<br />

The adaptable rail fixing system is fitted to the seating<br />

plate.<br />

3000<br />

Fig. 18 - Position of seating plates<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

6000<br />

T-528<br />

2<br />

11/98<br />

9/11<br />

2.3. Rail fixing system<br />

The concrete or steel track support plinths are fitted with<br />

an adaptable rail fixing system. This system has a<br />

separator placed under the rail with 2 or 4 anchor<br />

flanges.<br />

The separator has been specially designed to allow for<br />

flexing and expansion in the rail when it is fixed.<br />

It has three functions:<br />

- to spread the load on the seating plate<br />

- to absorbe the uneven contact between the rail and<br />

the seating plate<br />

- to reduce the noise and vibrations.<br />

The anchor flanges have been specially designed to<br />

meet the requirements of our machines, and in particular<br />

regarding the transverse adjustment and resistance to<br />

the lateral pressure applied by the guide rollers.<br />

The low height of the anchor flanges allows the travel of<br />

the horizontal guide rollers. Between the anchor flanges<br />

and the rail there is a block of synthetic elastomer. The<br />

anchor flanges are fixed to the seating plate by M16<br />

bolts, quality 8.8 and are galvanised for protection.

<strong>technical</strong><br />

<strong>sheet</strong><br />

7200 7200 7200<br />

MC1211<br />

butoir*<br />

Fig. 19 - Example of layout of track on rails<br />

5074<br />

buffer*<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

5124<br />

5998<br />

1300 500<br />

5998<br />

2944<br />

5998<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

R700<br />

T-528<br />

2<br />

11/98<br />

10/11<br />

45°<br />

R2000<br />

*an end of track buffer<br />

must be used for<br />

"open" circuits<br />

45°

<strong>technical</strong><br />

<strong>sheet</strong><br />

100<br />

MC1211<br />

450<br />

190<br />

530<br />

Fig. 20<br />

Power point on concrte track support plinth<br />

gravel<br />

100<br />

weatherproofing<br />

thermic insulation<br />

stean shield<br />

concrete<br />

230<br />

500<br />

power point<br />

Fig. 21<br />

Power point on steel track support plinth<br />

110<br />

tracks<br />

for building maintenance units<br />

(BMU)<br />

300x300<br />

160<br />

100<br />

3. Power supply<br />

There should be power points every 40 m along the<br />

track (for JUNIOR and SENIOR machines) or every 30<br />

m for MINI machines.<br />

These power points may be fitted to the concrete (Fig.<br />

20) or steel sleepers (Fig. 21).<br />

chain link<br />

71<br />

tube 100x100x4<br />

150 70 120<br />

10 20<br />

ref.:<br />

rev. no.:<br />

date:<br />

page:<br />

HILTI HST M12/20-115 plug plate 10...200x200<br />

83<br />

T-528<br />

2<br />

11/98<br />

11/11<br />

130<br />

75<br />

Ø14<br />

100<br />

150<br />

200<br />

100<br />

790<br />

150<br />

200