Plastics Technology Practice - The Hong Kong Polytechnic University

Plastics Technology Practice - The Hong Kong Polytechnic University

Plastics Technology Practice - The Hong Kong Polytechnic University

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Plastics</strong> <strong>Technology</strong> <strong>Practice</strong><br />

• Specification of Moulding Machines<br />

Shot size and clamping force are usually used to describe a machine. We need<br />

to consider both shot size and clamp tonnage when choosing a machine.<br />

i) Shot size is the maximum amount of material the machine will inject<br />

per cycle (single shot) and the unit is ounces (oz) or grams (g). <strong>The</strong><br />

standard for shot size measurement is general purpose polystyrene<br />

moulding in single shot.<br />

ii) Clamping Force is the maximum force a machine can apply to a<br />

mould. <strong>The</strong> unit of clamping force is tons.<br />

3.1.3 Part Design for injection moulding<br />

Part design is a very important in injection moulding, good part design can reduce<br />

the manufacturing cost and reduce the defects during manufacturing.<br />

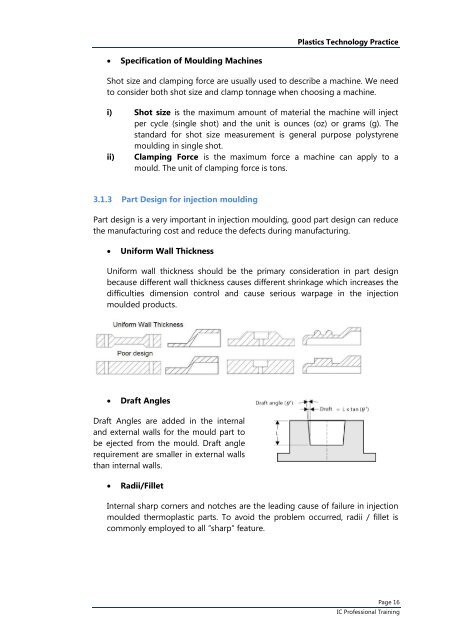

• Uniform Wall Thickness<br />

Uniform wall thickness should be the primary consideration in part design<br />

because different wall thickness causes different shrinkage which increases the<br />

difficulties dimension control and cause serious warpage in the injection<br />

moulded products.<br />

• Draft Angles<br />

Draft Angles are added in the internal<br />

and external walls for the mould part to<br />

be ejected from the mould. Draft angle<br />

requirement are smaller in external walls<br />

than internal walls.<br />

• Radii/Fillet<br />

Internal sharp corners and notches are the leading cause of failure in injection<br />

moulded thermoplastic parts. To avoid the problem occurred, radii / fillet is<br />

commonly employed to all “sharp” feature.<br />

Page 16<br />

IC Professional Training