Shell Global Solutions - CEM Brochure

Shell Global Solutions - CEM Brochure

Shell Global Solutions - CEM Brochure

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

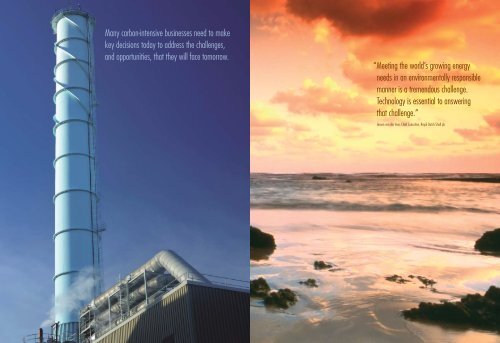

Many carbon-intensive businesses need to make<br />

key decisions today to address the challenges,<br />

and opportunities, that they will face tomorrow.<br />

“Meeting the world’s growing energy<br />

needs in an environmentally responsible<br />

manner is a tremendous challenge.<br />

Technology is essential to answering<br />

that challenge.”<br />

Jeroen van der Veer, Chief Executive, Royal Dutch <strong>Shell</strong> plc

The <strong>CEM</strong> programme integrates technology<br />

and expertise from across <strong>Shell</strong> to help the<br />

organisation reduce its own and its clients’<br />

carbon footprints.<br />

The flexible and modular programme assesses<br />

a client’s energy use and carbon dioxide<br />

production and compares its current position<br />

with the most desirable operating practices.<br />

Strategies for mitigation are then proposed,<br />

which may include energy-efficiency or carbon<br />

optimisation programmes, and the trading of<br />

emissions allowances.<br />

Developing a road map<br />

The first step in a <strong>CEM</strong> programme often<br />

involves making an assessment of your energy<br />

and carbon position with a view to saving<br />

energy, reducing costs and lowering carbon<br />

dioxide emissions. Working closely with your<br />

key staff, we will first analyse your position<br />

and capabilities, and then review the response<br />

options. A gap analysis is performed, and the<br />

financial value of closing this gap is quantified.<br />

Creating a carbon and energy inventory<br />

Steps can be taken to validate your opportunities<br />

for carbon optimisation and energy-efficiency<br />

improvements in more depth. Baselining,<br />

benchmarking and equipment and systems<br />

performance gap analysis methodologies are<br />

important techniques here. The cost and ease of<br />

their implementation are also recorded.<br />

These assessments may include the following:<br />

• country-wide or enterprise-wide – portfolio<br />

analysis; fuel switching options; funding<br />

or offsetting within the Clean Development<br />

Mechanism (CDM) or with Joint<br />

Implementation (JI) projects; and change<br />

readiness indicators;<br />

• site-wide – benchmarking; site energy and<br />

loss assessments; utilities modelling; project<br />

analysis; and risk analysis; and<br />

• equipment performance – equipment<br />

gap analysis and benchmarking (for fired<br />

equipment, heat exchangers and turbines,<br />

for example); data mining; and process<br />

simulation for heat or energy flows.<br />

Figure 1: A cost-of-carbon-abatement study brings CO 2 emissions into the business planning process.<br />

The carbon and energy management offer framework<br />

Evaluating strategic choices<br />

Investment options undergo a full cost–benefit<br />

analysis that takes account of the required<br />

operational or capital expenditure, the impact<br />

on carbon dioxide emissions, and energy<br />

cost savings or carbon allowance prices. This<br />

is a complex analysis, but a cost-of-carbonabatement<br />

study can help by prioritising<br />

possible energy saving and emissions<br />

mitigation measures in terms of the amount<br />

of carbon dioxide saved and the cost of the<br />

project work needed to achieve the saving<br />

(Figure 1).<br />

Strategic choices to be made could include<br />

carbon dioxide abatement through make-or-buy<br />

decisions for power; fuel switching evaluations;<br />

and heat/power technologies such as<br />

cogeneration.<br />

Delivering on the strategy<br />

Depending on the findings of the analyses<br />

carried out previously, we may recommend<br />

activity across three key areas: energy<br />

efficiency, carbon optimisation and<br />

emissions trading.<br />

Energy efficiency solutions may include best<br />

available technology assessments, hydrocarbon<br />

management reviews, integrated equipment<br />

performance evaluations, catalyst optimisation,<br />

as well as our proven energy-efficiency<br />

programme. Energy cost savings are typically<br />

achieved through the intelligent application of<br />

technology and by modifying behaviours and<br />

processes. Programmes can be structured around<br />

minimal capital expenditure for rapid payback.<br />

<strong>Shell</strong>’s technology solutions<br />

<strong>Shell</strong> has been active in deploying<br />

technology across three key areas in order<br />

to reduce emissions:<br />

a) improve energy efficiency – examples<br />

include energy optimisation and<br />

operational-excellence programmes;<br />

Carbon optimisation solutions may stem<br />

from an earlier cost-of-carbon abatement<br />

study. A masterplan could be considered that<br />

provides a structured approach to delivering<br />

carbon mitigation implementation proposals<br />

in the context of your business’ operating<br />

environment. Implementation activities may<br />

include optimising catalysts, sequestration<br />

or biofuels opportunities, carbon dioxide<br />

mineralisation, and carbon dioxide sales.<br />

Through our links with <strong>Shell</strong> Trading, one of<br />

Europe’s leading emissions trading desks, we<br />

can also offer value-adding services around<br />

the Kyoto Protocol’s flexible mechanisms.<br />

For instance, we can help you to trade<br />

allowances. We can also support you as you<br />

b) generate energy cleanly – introduce<br />

renewable energy sources or switch to<br />

less carbon-intensive fuels; and<br />

c) mitigate emissions – prevent the release of<br />

carbon dioxide into the environment by<br />

capturing it for sale to industrial users or for<br />

underground storage.<br />

Figure 2: <strong>Shell</strong> technology options that are available now – and those that are likely to be<br />

commercialised in the future.<br />

seek to identify qualifying opportunities for JI<br />

and CDM projects, and to register them.<br />

Ongoing support<br />

To help capture value effectively and<br />

provide sustainable results, we can also<br />

offer implementation assistance and ongoing<br />

support. For instance, we can assist with<br />

detailed change-management programmes,<br />

build in operator training programmes and<br />

facilitate knowledge transfer.<br />

We also offer a sophisticated energy<br />

management system. This is a combination<br />

of structured management processes and<br />

monitoring tools – linked to real-time data<br />

– that aims to operate a plant and its energyusing<br />

systems at their most energy-efficient<br />

operating points. Human intervention is an<br />

integral part of the energy management<br />

system and so the data is made available to<br />

operations and production staff for them to<br />

monitor and, where necessary, take action.

![Download Shell AutoGas Stationen [Stand: Januar 2013] (PDF](https://img.yumpu.com/9982753/1/190x245/download-shell-autogas-stationen-stand-januar-2013-pdf.jpg?quality=85)