C2572 02 Apr-May 06 AW - LP Gas Magazine

C2572 02 Apr-May 06 AW - LP Gas Magazine

C2572 02 Apr-May 06 AW - LP Gas Magazine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

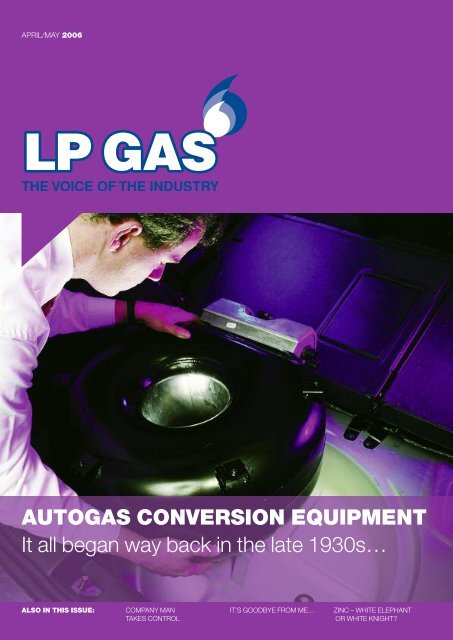

APRIL/MAY 20<strong>06</strong><br />

AUTOGAS CONVERSION EQUIPMENT<br />

It all began way back in the late 1930s…<br />

ALSO IN THIS ISSUE:<br />

COMPANY MAN<br />

TAKES CONTROL<br />

IT’S GOODBYE FROM ME…<br />

ZINC – WHITE ELEPHANT<br />

OR WHITE KNIGHT?

ATTENTION ALL <strong>LP</strong> GAS ASSOCIATION MEMBERS<br />

Your own EXCLUSIVE policy for <strong>LP</strong>GA members.<br />

• Your annual renewal membership fee with <strong>LP</strong>GA paid for by your insurer.<br />

• Retrospective rebate of up to 15% payable upon future renewal.<br />

• Policy underwritten by Allianz Cornhill with a Standard and Poor A+ rating.<br />

• Full insurance review by one of our experienced account managers.<br />

• Health and Safety advice with access to preferential rates for asbestos surveys<br />

and health and safety reviews.<br />

• This facility is also open to fuel stations selling <strong>LP</strong>G fuel!<br />

For a quotation please contact:<br />

David Lamb, F M Green Insurance Brokers, 39 Market Square, Witney, Oxon OX28 6AD<br />

Telephone: 01993 701300 Fax: 01993 779817 E-mail: insurance@fmgreen.co.uk<br />

Authorised and regulated by the Financial Services Authority<br />

TANKBOUW ROOTSELAAR BV<br />

Nijverheidsstraat 33, 3861 RJ Nijkerk, The Netherlands<br />

Phone: +31 33 247 14 90<br />

Fax: +31 33 246 05 01<br />

E-mail: root@tankbouwrootselaar.com<br />

Website: www.tankbouwrootselaar.com<br />

PART OF THE ROOTSELAAR GROUP<br />

<strong>LP</strong> GAS MAINTENANCE SERVICES LTD<br />

<strong>LP</strong>G FORECOURT LOGISTICS LTD<br />

The Headquarters, Nicks Lane,<br />

Brome, Eye, Suffolk IP23 8AN, UK<br />

Tel: 01379 871321<br />

Fax: 01379 871446<br />

E-mail: jtennens.lpgas@btconnect.com<br />

– Own development<br />

– Own facilities production<br />

– Supplying worldwide<br />

– Several projects for major UK supplier<br />

– ISO 9001 certified<br />

– Member of Dutch <strong>LP</strong> <strong>Gas</strong> Association VVG<br />

– CE-marking acc. PED 97/23/EC<br />

– ASME “U”/”U2”/”R”-Stamp holder<br />

TANKBOUW ROOTSELAAR for all your<br />

solutions in storage and transport of <strong>LP</strong> <strong>Gas</strong>.<br />

The company has almost half a century of<br />

experience in all aspects of <strong>LP</strong>G storage<br />

and transportation.<br />

Specialist in Refrigerant <strong>Gas</strong>es and<br />

Cryogenic Tanks for LIN/LOX/LAR/LNG.<br />

Please contact our Distributor for your UK<br />

vessel requirements<br />

DIRECT DISTRIBUTION FROM THE UK<br />

MEET ALL YOUR VESSEL REQUIREMENTS<br />

Tankbouw Rootselaar/De Visser from The<br />

Netherlands has appointed <strong>LP</strong> <strong>Gas</strong><br />

Maintenance Services Ltd and its subsidiary,<br />

<strong>LP</strong>G Forecourt Logistics Ltd,<br />

to become its UK distributor<br />

for <strong>LP</strong>G vessels as of<br />

March 2005.<br />

FULL SERVICE IN PRESSURE VESSELS AND CRYOGENICS

CONTENTS<br />

APRIL/MAY 20<strong>06</strong><br />

<strong>LP</strong> GAS<br />

THE VOICE OF THE UK <strong>LP</strong>G INDUSTRY<br />

Reflecting the objectives of a thriving, diverse<br />

industry and its customers, <strong>LP</strong> <strong>Gas</strong> is distributed<br />

free to <strong>LP</strong>GA members and registered readers.<br />

Individual copies: £4<br />

Overseas subscription: £40 pa.<br />

04 NEWS<br />

<strong>06</strong> COMPANY MAN TAKES CONTROL<br />

08 THE CARRERA SUDAMERICANA<br />

ISSN 1362-7813. APR/MAY 20<strong>06</strong><br />

10 IT’S GOODBYE FROM ME…<br />

12 ZINC – WHITE ELEPHANT OR WHITE KNIGHT?<br />

14 KEEPING A GRIP ON YOUR LEAD<br />

15 PRODUCTS<br />

16 AUTOGAS CONVERSION EQUIPMENT<br />

24 AUTOGAS<br />

26 <strong>LP</strong>GA FOCUS<br />

28 WORLD VIEW<br />

29 SPECIALIST SERVICES<br />

30 TRAINING<br />

EDITORIAL<br />

Picture Publishing<br />

The Point, College Road, Eastbourne,<br />

East Sussex BN21 4JJ<br />

Tel: 01323 646076<br />

Fax: 01323 411050<br />

email: ppl@prgltd.co.uk<br />

Web: www.lpgasmagazine.co.uk<br />

Publisher: Raymond Groves<br />

<strong>Magazine</strong> Manager: Faye Spiers<br />

Production: PRG Design<br />

Printed by: Adland Paul Green, London<br />

ADVERTISEMENT ENQUIRIES<br />

Space Marketing<br />

10 Clayfield Mews, Newcomen Road<br />

Tunbridge Wells, Kent TN4 9PA<br />

Tel: 01892 677740<br />

Fax: 01892 677743<br />

email: sales@spacemarketing.co.uk<br />

THE VOICE OF THE INDUSTRY<br />

NOTHING ENDURES BUT CHANGE<br />

Kevan Rock<br />

Chairman<br />

<strong>LP</strong> <strong>Gas</strong> Association<br />

Speaking as a Lancashire boy, the old joke used to be that the only good<br />

thing to come out of Yorkshire was the M62 motorway. Not true, of course<br />

(well, not entirely), and particularly not in the case of our <strong>LP</strong>GA director<br />

general, Tom Fidell, who is retiring at the end of <strong>May</strong>.<br />

If Tom does not have lpg in his blood, then it is certainly under his<br />

fingernails, after spending the last 13 years at the ‘coal face’ supporting the<br />

members, helping us to develop our industry and bringing the <strong>LP</strong>GA from<br />

the brink of existence to being the envy of many trade bodies.<br />

He has been a great help and support to me, personally, during my time as<br />

chairman, providing good, sound advice and helping to steer me through<br />

some difficult situations. I am sure everyone will join me in thanking Tom for<br />

the tremendous job he has done for us and wish him all the very best for the<br />

future wherever it may take him.<br />

This is just another illustration of the fact that the one thing we can<br />

certainly rely upon is the inevitability of change. It is the only constant. And<br />

the speed of change will continue to increase.<br />

We all see examples of this, daily, in our own businesses. Whether it is the<br />

Competition Commission enquiry, changes in employment law or the ever<br />

onerous legislation generated from and imposed on us by Brussels.<br />

We have to try to welcome change positively with open arms, because<br />

positive change can only mean growth. It is the responsibility of all of us to<br />

ensure that we harness all of the expertise and experience within our<br />

businesses, put our differences aside, and face the many challenges in front<br />

of us with a united and consistent position.<br />

The <strong>LP</strong>GA AGM & Conference in <strong>May</strong> will see the end of my tenure as<br />

chairman. I would like to thank my colleagues on the executive committee<br />

and the wider membership for their help and support over the past year and<br />

wish my good friend and very capable successor, John Tolchard, the very<br />

best of luck for the coming year!<br />

© Picture Publishing, 20<strong>06</strong><br />

All rights reserved. Reproduction of any part of this<br />

publication is prohibited without permission. Every effort is<br />

made to ensure accuracy, but the publishers accept no<br />

responsibility for editorial opinions or statements, and no<br />

liability for products or services described in this magazine.<br />

FRONT COVER PICTURE<br />

AUTOGAS CONVERSION EQUIPMENT<br />

See page 23<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong> 3

NEWS<br />

CC Consults on Market Remedies<br />

The Competition Commission (CC) is<br />

consulting on measures to remedy the<br />

adverse effect on competition it<br />

provisionally found in the markets for<br />

the supply of domestic bulk lpg in<br />

Great Britain and Northern Ireland.<br />

Peter Freeman, chairman of the<br />

inquiry group, said: “We provisionally<br />

found that competition was not<br />

working as effectively as it should and<br />

that consumers were losing out as a<br />

result. We are now bringing this<br />

investigation to a close.<br />

“Customers face a number of<br />

hurdles in switching supplier and this<br />

has restricted competition between<br />

suppliers, discouraged entry and<br />

expansion, and led to higher prices.<br />

We are now consulting on a package<br />

of measures that should make<br />

switching easier for customers by<br />

removing the need to change tanks<br />

when changing supplier, improving the<br />

terms of customer contracts, and<br />

giving customers more information.”<br />

The CC considers that the facilitation<br />

of tank transfer, standardisation of the<br />

switching process, changing customer<br />

contracts and better provision of<br />

information would address those<br />

features of the domestic bulk lpg<br />

market it has provisionally found as<br />

having an adverse effect on<br />

competition.<br />

An incoming supplier would have the<br />

right to buy the existing tank, valves,<br />

regulator and pipework from the<br />

outgoing supplier, which would be<br />

obliged to provide documentation on<br />

the tank and respond to emergency<br />

callouts for up to 14 days after transfer.<br />

A methodology to determine a<br />

backstop price for transferred tanks<br />

would be established.<br />

There would be no charges to the<br />

customer on termination of their<br />

contract, which would have to<br />

include information on the switching<br />

Calor Gets into Fuel Cells<br />

Calor <strong>Gas</strong> Ltd has announced that<br />

it has signed a memorandum of<br />

understanding (MOU) with Voller<br />

Energy Group plc, a leading<br />

commercial developer and<br />

manufacturer of portable fuel cell<br />

systems, to work together to<br />

develop the market for fuel cell<br />

generators and battery chargers<br />

with hydrogen derived from lpg.<br />

The MOU is for an initial period of<br />

two years, and will then continue<br />

indefinitely unless terminated by<br />

either party.<br />

Paul Blacklock, marketing<br />

manager at Calor, said: “Fuel cell<br />

technology is rapidly developing<br />

and will clearly be of benefit in<br />

rural areas where mains gas is not<br />

available, and where the quality of<br />

electricity supplies is often poorer.<br />

As we move towards a vision of a<br />

distributed energy infrastructure,<br />

lpg fuel cells will increasingly play<br />

a vital role.”<br />

Fuel cells offer an alternative to<br />

conventional energy generation<br />

from petrol or diesel. There has<br />

been speculation that a ‘hydrogen<br />

economy’ will emerge, replacing<br />

the current ‘carbon economy’ as<br />

carbon based fossil fuels, such as<br />

coal, gas and oil, become scarce.<br />

However, in spite of repeated<br />

government initiatives, hydrogen is<br />

still only available from specialist<br />

suppliers and there are no<br />

immediate plans to make<br />

hydrogen broadly accessible to<br />

consumers. By contrast, lpg is<br />

widely available.<br />

Fuel cells work by converting<br />

the chemical energy in hydrogen<br />

to electrical energy by<br />

combining it with oxygen across<br />

a special membrane. The<br />

outputs from the reaction are<br />

electricity, heat and water.<br />

Voller Energy is initially targeting<br />

commercially attractive areas,<br />

including cordless power tools,<br />

temporary buildings, leisure<br />

Shell Retains Lpg Business<br />

Shell has announced that, after a<br />

review of its global lpg marketing<br />

and distribution, it has decided to<br />

retain its lpg businesses, including<br />

that in the UK, in its downstream<br />

portfolio. Shell had previously<br />

announced that it was reviewing its<br />

options following an unsolicited offer.<br />

Some parts of Shell’s lpg business<br />

have been sold, however, including<br />

those in Portugal, Italy, Brazil,<br />

Paraguay and parts of the<br />

Caribbean.<br />

Ron Blakely, executive vice<br />

president finance Shell downstream,<br />

said: “We made clear all along in this<br />

process that our lpg business is<br />

robust and meets our portfolio<br />

criteria. Having fully tested the<br />

market, we have concluded that<br />

there is better value for Shell<br />

shareholders in retaining these<br />

profitable businesses.<br />

“Lpg generates a competitive<br />

process. Exclusivity periods would be<br />

capped at two years, and notice<br />

periods at 42 days. Notice periods<br />

where a switch is ready to be<br />

completed would be waived.<br />

Suppliers’ invoices will have to<br />

include the amount of lpg delivered in<br />

litres and the price paid in pence per<br />

litre so that customers can more easily<br />

compare quotes over the phone or on<br />

suppliers’ websites.<br />

The CC intends to recommend to<br />

the General Consumer Council for<br />

Northern Ireland that it include<br />

information on switching domestic bulk<br />

lpg suppliers with that on the opening<br />

to competition of domestic mains gas<br />

and electricity liberalisation in 2007 that<br />

will be sent to consumers.<br />

The CC expects that its remedies<br />

will include a transition period of no<br />

more than six months, allowing<br />

domestic bulk lpg suppliers to adapt<br />

to the measures.<br />

boating, recreational vehicles and<br />

military markets. It has said it is on<br />

target to achieve production of its<br />

first commercial product by the<br />

end of 2007.<br />

Stephen Voller, CEO of Voller<br />

Energy, said: “We are very excited<br />

by the potential opportunities<br />

offered by the relationship with<br />

Calor <strong>Gas</strong>. They are an ideal partner<br />

as we seek to develop portable fuel<br />

cells charged by hydrocarbons.<br />

With over 10,000 outlets in the UK<br />

and a strong presence in our key<br />

chosen markets, this agreement<br />

offers both companies benefits<br />

from the development of this<br />

important environmentally friendly<br />

technology.”<br />

The initial scope of the joint<br />

development will also include the<br />

potential development of new style<br />

canisters, possibly disposable, for<br />

use in generators and battery<br />

chargers, and health and safety<br />

considerations.<br />

return on capital employed, and will<br />

continue to be run as part of our<br />

downstream portfolio in our markets<br />

of choice. It will be very much<br />

business as usual going forward.”<br />

John Tolchard, managing director<br />

of Shell <strong>Gas</strong> (<strong>LP</strong>G) UK, said: "I<br />

welcome this announcement and<br />

feel we can now continue with our<br />

strategy of growing our UK business<br />

and giving the shareholder the best<br />

return on investment."<br />

Director General<br />

Appointed<br />

Rob<br />

Shuttleworth,<br />

formerly an<br />

<strong>LP</strong>GA executive<br />

committee<br />

member for<br />

ConocoPhillips, Rob Shuttleworth<br />

has been<br />

appointed as director general of<br />

the <strong>LP</strong> <strong>Gas</strong> Association and will<br />

take up the role on <strong>May</strong> 1 20<strong>06</strong>.<br />

The position becomes available<br />

after the retirement of the former<br />

director general, Tom Fidell.<br />

"I'm really pleased to be<br />

appointed as the new DG of the<br />

<strong>LP</strong> <strong>Gas</strong> Association,” said Rob<br />

Shuttleworth. “Tom has done a<br />

superb job over the last 13 years<br />

and I'm honoured to be following<br />

him. With energy in the news<br />

virtually every day, it is an exciting<br />

time to be taking over and I'm<br />

looking forward to working with<br />

the members of the industry to<br />

define the shape and role of the<br />

<strong>LP</strong>GA to meet these challenges."<br />

Kevan Rock, <strong>LP</strong>GA chairman,<br />

said: "In Rob Shuttleworth, we<br />

have been lucky enough to<br />

secure the services of a well<br />

known and popular figure with<br />

the experience and skills to take<br />

the association forward and build<br />

upon a very solid foundation."<br />

New MD for<br />

Flogas Ireland<br />

Patrick Mercer<br />

has retired as<br />

chief executive of<br />

Flogas Ireland. He<br />

was the last<br />

remaining<br />

member of the<br />

founding<br />

executive team to<br />

retire from the<br />

Patrick Mercer<br />

(left) and<br />

Richard Martin.<br />

company, which was incorporated in<br />

1977. He played a significant role in<br />

the development of Flogas, both in<br />

Ireland and Britain, and contributed<br />

greatly to the company's success,<br />

says Flogas.<br />

Richard Martin, formerly sales &<br />

marketing director, was appointed as<br />

managing director of Flogas Ireland<br />

on <strong>Apr</strong>il 1. Richard joined Flogas in<br />

1979 and has held a number of<br />

senior management roles, principally<br />

in the sales & marketing division of<br />

Flogas. As a key member of the<br />

management team, he has<br />

contributed significantly to the overall<br />

development of Flogas' operations in<br />

Ireland, said the company.<br />

4<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong>

If It’s autO<strong>Gas</strong> EquIPmEnt<br />

It has tO BE<br />

COmBInED <strong>Gas</strong> systEms<br />

• ComBINED gAS SYSTEmS is the lEADINg DISTRIBUToR for FISHER lPg CoNTRolS, FAS<br />

AUTogAS DISPENSERS & EqUIPmENT and gREINER SHUT-oFF vAlvES and FITTINgS.<br />

• We are pleased to offer our ClIENTS many NEW and INNovATIvE PRoDUCTS from the WIDE<br />

RANgE manufactured by these mARkET lEADERS.<br />

• We offer CoST EFFECTIvE SolUTIoNS backed by FIRST ClASS ENgINEERINg SUPPoRT for<br />

All PRoDUCTS in our range.<br />

• For FURTHER INFoRmATIoN phone 01925 767217 today.<br />

Key Lockable<br />

Ball Valves<br />

<strong>LP</strong>G Control<br />

Equipment<br />

Warrington Office: 13 Brookfield Road, Culcheth, Warrington, Cheshire WA3 4PB Tel: 01925 767217 Fax: 01925 762670<br />

Doncaster Office: Unit 3a, Plumtree Farm Industrial Estate, Harworth, Doncaster, South Yorks DN11 8EW Tel: 013<strong>02</strong> 711247

FEATURE<br />

Company Man Takes Control<br />

Following a structural review at<br />

ConocoPhillips, Pete George was<br />

appointed marketing manager for<br />

ConocoPhillips’ wholesale sales<br />

channel in November and replaces<br />

Rob Shuttleworth on the <strong>LP</strong>GA<br />

executive committee.<br />

Pete has worked at<br />

ConocoPhillips for over 30 years, all<br />

his working life, in fact, and has had<br />

dealings with the lpg division in a<br />

variety of ways over the years. He<br />

began his career at the Humber<br />

Refinery in the 1970s and has<br />

worked in the transport, supply,<br />

operations and retail divisions. In<br />

2004, he returned to the UK from<br />

Brussels to head up the distributor<br />

and bulk sales division (D&BS).<br />

Towards the end of 2005,<br />

ConocoPhillips reviewed the<br />

structure of its organisation. The<br />

review was prompted by the need to<br />

adapt to the ever-increasing<br />

expectations of our marketplace, it<br />

said. As part of these changes, the<br />

company amalgamated D&BS with<br />

the lpg and marine groups to form<br />

the wholesale sales channel and<br />

Pete was appointed marketing<br />

manager.<br />

“I am really enjoying the new role,”<br />

he said. “One of the key drives of our<br />

organisational change was to<br />

achieve even more customer focus<br />

across our marketing organisation,<br />

which now includes Ireland as well<br />

as the UK, since we have the refinery<br />

in Ireland from which to source<br />

supplies to our customers, as well as<br />

the refinery in North Lincolnshire.<br />

“My role is to ensure that the<br />

direction of the group meets our<br />

strategic ambitions, as well as<br />

fulfilling our customer requirements.<br />

The industry has always been a<br />

great place to be part of because of<br />

the challenges and opportunities<br />

that always present themselves, but<br />

I guess the current environment is as<br />

'interesting' as anyone can recall in<br />

recent times.<br />

“In respect of the lpg channel,<br />

many of the customers in lpg are<br />

also part of our D&BS portfolio. We<br />

obviously intend to remain a key part<br />

of this sector and will be looking to<br />

see if we can identify the right<br />

leverage opportunities within the<br />

wholesale group to consolidate and<br />

Pete George<br />

improve our position further.”<br />

Pete visited the offices of the <strong>LP</strong><br />

<strong>Gas</strong> Association in Ringwood soon<br />

after his appointment in January, and<br />

he believes its work is going in the<br />

right direction.<br />

“It was good to meet the team at<br />

the <strong>LP</strong>GA and the presentations<br />

given offered a good insight into the<br />

workings of the association and its<br />

importance to the industry,” he said.<br />

“It made me much more aware of<br />

the external pressures on the<br />

industry and how they can be<br />

managed.<br />

“My initial thoughts have been that<br />

lpg is like many others sectors of the<br />

industry, i.e. challenged with supply<br />

issues and margin and cost<br />

pressures, and I have not seen<br />

anything to date to change that view.<br />

The good news from my perspective<br />

is that I believe we have the right<br />

people, knowledge and resources to<br />

enable us to achieve the goals we<br />

have set ourselves. My early<br />

impressions are of a responsible and<br />

adaptable industry.<br />

And what does he think will be the<br />

talking points of the coming year?<br />

“During 20<strong>06</strong>, I guess autogas<br />

and what this will look like in the<br />

future is just one of the topics that<br />

come to mind, and I look forward to<br />

meeting colleagues within the<br />

industry during the year to discuss<br />

such issues.”<br />

6<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong>

What do you do for the <strong>LP</strong> gas industry?<br />

If you<br />

Refine, Store, Transport, Fill, Dispense,<br />

Bottle, Equip, Install, Test, Maintain,<br />

Calibrate, Decommission or Destench<br />

We can help.<br />

We supply Valves, Regulators, Compressors,<br />

Pumps, Hoses, Meters, Wear gauges,<br />

Forecourt equipment, Level gauges,<br />

Pressure gauges, Tank kits, Installation<br />

kits, Swivels, Filler guns, Pullaways,<br />

Thermometers, Left hand fittings,<br />

& much, much more…<br />

And when you’ve worn it out, our comprehensive<br />

reconditioning service can make it as good as new<br />

Competitive prices & free advice<br />

So give us a call on 01792 224000<br />

Fax us on 01792 892224<br />

Email sales@rmsgaseng.com<br />

www.rmsgaseng.com<br />

Re-Manufacturing Services Limited<br />

Features:<br />

• Truly non-invasive sensing technique<br />

• Sensor bonded to outside of tank base<br />

• Display / output to telemetry system<br />

• ATEX approved for hazardous areas<br />

Benefits:<br />

• No tank break-in – easy retrofit<br />

• Simple retrofit to existing tanks<br />

• No down-time during installation<br />

• No moving parts – no maintenance<br />

• Reliable & accurate <strong>LP</strong>G tank gauging<br />

Canongate Technology Limited, Edinburgh, Scotland<br />

Tel: +44 (0)131 455 7211 • sales@canongatetechnology.co.uk<br />

www.canongatetechnology.co.uk

FEATURE<br />

Joy Rainey in the lpg Grand Cherokee she will drive in the Carrera Sudamericana Rally.<br />

THE CARRERA SUDAMERICANA<br />

by Joy Rainey<br />

After driving in my first long distance<br />

rally – the London to Sydney<br />

Marathon in 2004 – I’ve since<br />

developed a strong desire to<br />

compete again in a similar event.<br />

The 30 day event might have been<br />

tough, driving up to six hundred<br />

miles a day over rough roads, but at<br />

the finish every competitor who<br />

made it to the Sydney Opera House<br />

was overwhelmed with high<br />

emotions and a sense of<br />

achievement.<br />

It was inevitable that, when I heard<br />

about the Carrera Sudamericana<br />

Rally, I wanted to enter.<br />

The event is due to start in<br />

Buenos Aires on <strong>May</strong> 6 20<strong>06</strong>, travel<br />

through Argentina, Bolivia and Peru<br />

and finish in Quito, Ecuador three<br />

weeks and 5,000 miles later.<br />

Entrants are promised rally stages<br />

at 16,000 feet above sea level in the<br />

Andes and roads that follow the<br />

spectacular route where Fangio<br />

started his legendary motor sport<br />

career. The route passes Incan<br />

archaeological remains and Spanish<br />

colonial towns, and we are to<br />

experience contrasting scenery from<br />

canyons, waterfalls, deserts and<br />

forests to coastal roads overlooking<br />

the Pacific.<br />

Now what car would produce<br />

suitable power to endure the tough<br />

road conditions, many at extremely<br />

high altitudes?<br />

My choice of car for the London to<br />

Sydney Marathon was a very unlikely<br />

vehicle – a 1970 Morris Minor – but this<br />

time I wanted to compete with<br />

something more modern and powerful.<br />

The issue was resolved with the offer of<br />

a V8 Jeep Grand Cherokee.<br />

Although I have a tendency to<br />

drive ‘unconventional’ cars, at first I<br />

felt slightly uneasy about competing<br />

in a ‘conventional’ 4x4. When<br />

Nicholson McLaren Engines offered<br />

sponsorship by converting the Jeep<br />

to lpg power, I could hardly contain<br />

my excitement – we would be the<br />

first vehicle to compete in a longdistance<br />

rally using lpg.<br />

That is definitely not<br />

‘conventional’.<br />

As a newcomer to lpg, I was<br />

surprised at the number of negative<br />

remarks I heard from the<br />

unconverted (pardon the pun).<br />

Comments such as “loss of power”,<br />

“unreliable” and “very few filling<br />

stations” seemed to be the most<br />

common, which didn’t contribute to<br />

my confidence in finishing the event.<br />

Once Nicholson McLaren Engines<br />

had finished the lpg conversion<br />

using the Teleflex SGi lpg dual fuel<br />

system, it was time to put the Jeep<br />

through its paces to convince myself<br />

(or not) that I had made the correct<br />

decision.<br />

My co-driver, Trevor Hulks, and I<br />

headed off to Wales on a crisp, clear<br />

morning to try to emulate driving<br />

conditions and roads similar to what<br />

we expect to encounter in South<br />

America. Well…it was difficult to find<br />

mountains to equal the steep roads<br />

of the Andes at 16,000 feet above<br />

sea level to test the Jeep’s<br />

performance level at high altitude,<br />

but we experienced a variety of road<br />

conditions from motorways and<br />

traffic jams in towns to a narrow,<br />

rough mountain track. Using petrol<br />

for the 257 mile round trip, the Jeep<br />

averaged 18.87 mpg at a cost of<br />

£56.77.<br />

I must admit that I felt relieved at<br />

that stage that I did not own the<br />

Jeep, as I usually average over<br />

20,000 miles in a year and the cost<br />

of petrol would be horrendous.<br />

Three days later, we headed off to<br />

cover the same route, this time using<br />

lpg. The result was an average of<br />

15.39 mpg, and the cost a<br />

favourable £35.50. That would<br />

provide a considerable saving over a<br />

year and convinced me that, from the<br />

financial aspect, lpg is the way to go.<br />

And, the “loss of power”? In my<br />

view, a myth. I tried fast acceleration<br />

from a standing start, gradual<br />

acceleration, fast cornering, on the<br />

flat and up the mountain road and I<br />

could not detect any difference in<br />

power between petrol and lpg.<br />

Before the cars are shipped out to<br />

Argentina, the Jeep is being fitted<br />

with specialist rally equipment, such<br />

as a roll-cage, a mesh cover to<br />

protect the radiator from stones, fire<br />

extinguishers, rally computer,<br />

brackets for extra spare wheels and<br />

extra pockets to place maps, note<br />

books, pencils – there must be a<br />

place for every bit of equipment so<br />

they can be found quickly. During<br />

the competitive rally stages, it can be<br />

a very emotional experience, with<br />

tensions running high between the<br />

crew as they endeavour to achieve<br />

the best results.<br />

A co-driver’s task on the stages is<br />

somewhat demanding, as he has<br />

more than one job to do at a time.<br />

He has to keep one eye on the rally<br />

odometer and the other on the<br />

detailed road book, and inform the<br />

driver in good time of the relevant<br />

instructions. To stand a chance of<br />

featuring in the results, the car has to<br />

be driven close to the average speed<br />

set for that route.<br />

The co-driver has to determine, by<br />

means of speed tables, calculator,<br />

stopwatches, average speed<br />

indicator and mental arithmetic,<br />

whether that speed is maintained<br />

throughout the route. To add to the<br />

co-driver’s anxiety, the location of<br />

timing points is secret, and penalties<br />

are based on seconds late or early at<br />

checkpoints.<br />

With several additional test and<br />

practice runs under our belt, we are<br />

well prepared for the start of the<br />

Carrera Sudamericana 20<strong>06</strong>, and I<br />

can honestly admit that I am now an<br />

lpg enthusiast.<br />

8<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong>

Tankgas Equipment Ltd<br />

Specialist Stockist & Distributors to the <strong>LP</strong> <strong>Gas</strong> Industry<br />

RegO: World’s most comprehensive range of Industrial<br />

Regulators, Valves and Equipment<br />

Smith Pumps: Positive Displacement <strong>LP</strong>G Pumps<br />

Liqua-Tech: Flowmeters<br />

Full Circle: Swivel Connectors and Flowmeter Vent Flanges<br />

LG Equipment: <strong>Gas</strong>Guard Refuelling Nozzles<br />

Manchester: Self Fill FLT Cylinders<br />

Rochester: Float Gauges & Remote Systems<br />

Tel: 0121 5<strong>06</strong> 2760 Fax 0121 5<strong>06</strong> 2769<br />

Email: info@tankgas.co.uk<br />

Web site: www.tankgas.co.uk<br />

Sterling Fluid Systems (UK) Ltd<br />

Atlantic Street, Altrincham, Cheshire WA14 5DH<br />

Email: uksales@sterlingfluid.com<br />

Tel: +44 (0)161 928 6371<br />

Fax: +44 (0)161 925 2129<br />

World Leader in Pumping <strong>LP</strong>G<br />

Submerged tank pumps<br />

Series: ZEB, CEB and CVGP<br />

Suction lift pumps<br />

Series: PC<br />

Flooded suction pumps<br />

Series: SC2000, CEH,<br />

ZEA and VEA<br />

Product benefits<br />

Low NPSH:<br />

Liquid & vapour<br />

handling:<br />

ATEX:<br />

Quiet:<br />

Mechanical seal &<br />

seal-less options:<br />

Service, repair &<br />

commissioning packages:<br />

Full operating capacity with<br />

cavitation-free operation<br />

Effective priming and<br />

continuous operation<br />

Plant safety<br />

Improved relationships with<br />

site neighbours<br />

Flexibility<br />

Contact us<br />

now for info<br />

on pump<br />

maintenance<br />

contracts<br />

Available to extend lifetime of pump<br />

Capacities up to 250m 3 /hr<br />

www.sterlingfluidsystems.com

DIRECTOR GENERAL<br />

IT’S<br />

GOODBYE<br />

FROM ME…<br />

by Tom Fidell,<br />

director general, <strong>LP</strong> <strong>Gas</strong> Association<br />

After 13 years running the <strong>LP</strong> <strong>Gas</strong> Association,<br />

Tom Fidell will be retiring in early June this year.<br />

Here, he says farewell to the industry.<br />

Tom Fidell<br />

My first day at the <strong>LP</strong>GA was a cold<br />

morning at the beginning of March<br />

1993 and, after seeing the generally<br />

run-down condition of the office, I<br />

thought I had better check through<br />

the accounts to see how things<br />

stood financially.<br />

This quickly showed that the<br />

association would run out of money<br />

in October of that year and, with<br />

subscription income not coming in<br />

until the following January, there<br />

would be no money to pay salaries<br />

in November and December!<br />

We had a big exhibition coming up<br />

in Telford that was supposed to<br />

bring in lots of money for the <strong>LP</strong>GA,<br />

but bookings had not gone as well<br />

as forecast and it was now going to<br />

make a loss. However, the exhibition<br />

organiser was clearly going to make<br />

a big profit and some tough<br />

negotiations with this organiser soon<br />

turned things around in our favour,<br />

such that we would at least make<br />

some profit from this event.<br />

It now became apparent why I<br />

had got the job at the Association<br />

as, at the interview, I knew I had<br />

been in competition with some<br />

executive committee members - it<br />

was because the association was<br />

looking for someone who could run<br />

a small business and make it<br />

profitable!<br />

We needed a sustainable solution,<br />

which meant cutting costs and<br />

getting in more income and, to save<br />

money, one of the things we did was<br />

to not pay rent for several months<br />

and then negotiate a 50% discount.<br />

To raise income, we clearly needed<br />

to increase subscription levels and<br />

increase the number of members<br />

(not an easy combination) but, at a<br />

special meeting that year, we<br />

managed to agree an increase in<br />

subscriptions and membership<br />

actually started to increase.<br />

How different things are today,<br />

with more than double the number<br />

of members compared to 1993 and<br />

more than £0.75 million in the bank!<br />

Today we have also got<br />

substantial credibility with the<br />

Government and are able to call on<br />

ministers and senior government<br />

officials when we have a problem<br />

and believe that they can help us.<br />

Compared to those early days in<br />

1993 when we never even came<br />

close to seeing a minister, we now<br />

have sometimes half a dozen<br />

meetings per year with ministers,<br />

and even get them to come along to<br />

speak at our Conference and<br />

undertake promotional launches!<br />

Some of the highlights over the<br />

years are as follows:<br />

PUBLICATION OF <strong>LP</strong>GA<br />

CODES OF PRACTICE<br />

Back in 1996, the HSE used to<br />

publish lpg Codes of Practice and so<br />

did the <strong>LP</strong>GA. This was a duplication<br />

of effort and confusing for the<br />

industry. I met with the director<br />

general of the HSE to agree a<br />

strategy whereby one set of Codes<br />

would be published by the <strong>LP</strong>GA but<br />

would bear the HSC logo and<br />

endorsement, where appropriate.<br />

At that time, we also moved from<br />

subcontracting the publication of the<br />

Codes of Practice (where we did not<br />

have an income stream) to in-house<br />

publication, where the income<br />

stream often covers 20% of the total<br />

cost of running the association.<br />

The Codes are highly regarded by<br />

both industry and government, and<br />

are sold on a worldwide basis,<br />

where other countries now adhere to<br />

<strong>LP</strong>GA standards.<br />

Reg Shipman recieves his<br />

MBE from The Queen.<br />

MBE FOR REG SHIPMAN<br />

Reg had been our technical<br />

manager for many years and, when<br />

he retired in 1999, we applied for<br />

and obtained an MBE for him. Reg<br />

had worked tirelessly for the<br />

association and the MBE was well<br />

deserved.<br />

CLIMATE CHANGE LEVY<br />

The biggest lobbying campaign we<br />

have ever done was on the Climate<br />

Change Levy in 2000, when Pat<br />

Kennedy was our chairman and also<br />

the chief executive of Calor <strong>Gas</strong>. The<br />

CCL could have been very harmful<br />

for our industry. Pat and I worked<br />

very closely together, having<br />

numerous meetings with<br />

government ministers and officials,<br />

putting forward a strong case for a<br />

reduction in the CCL on lpg.<br />

Our efforts were rewarded with a<br />

reduction in the initial CCL from<br />

1.5p/litre to 1p/litre, and then a<br />

further reduction to 0.5p/litre which<br />

was, in fact, half the CCL that is<br />

applied to natural gas. We also<br />

managed to get cylinder gas<br />

excluded from the CCL.<br />

This achievement put the <strong>LP</strong>GA<br />

on the map as being one of the most<br />

effective lobbying organisations in<br />

the UK. As a result, other<br />

associations asked us how such a<br />

small organisation could achieve<br />

such results time and time again. We<br />

were asked to give presentations to<br />

other associations on how to lobby<br />

government to achieve a required<br />

result.<br />

At this time in 2000, the method in<br />

which the association worked was<br />

changed in line with our chairman’s<br />

suggestion, and the association<br />

became more focussed on lobbying<br />

and getting results, rather than trying<br />

to be an association of all things for<br />

all people. The Association today still<br />

operates very much in the mould<br />

that was set by Pat Kennedy back in<br />

2000.<br />

AUTOGAS<br />

It soon became clear that we<br />

needed an extra stream of gas<br />

usage to compensate for the decline<br />

in the cylinder market, and autogas<br />

seemed to be the ideal candidate.<br />

We prepared a strong<br />

environmental case for autogas and<br />

started to lobby the Government to<br />

get the fuel duty rate down and, in<br />

1995, achieved a 15% reduction.<br />

This was followed by a 25%<br />

reduction in 1996, a 29% reduction<br />

in 1999 and, finally, a 40% reduction<br />

in 2001. At the same time, petrol<br />

and diesel prices were rising, and we<br />

ended up with one of the most<br />

favourable fiscal regimes in the world<br />

for autogas.<br />

The market is continuing to grow<br />

at 7–8% per annum, and now<br />

represents about 10% of total gas<br />

sales, with autogas companies<br />

representing about one third of the<br />

total membership of the <strong>LP</strong>GA.<br />

In the early days, we needed to<br />

get some publicity to accelerate the<br />

growth of autogas. Our first<br />

achievement came in 1998, when<br />

the Queen converted her fleet of<br />

vehicles to lpg. We organised the<br />

10<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong>

DIRECTOR GENERAL<br />

launch of this at the Royal Mews,<br />

with the Queen, Duke of Edinburgh<br />

and various ministers in attendance,<br />

and this event received substantial<br />

worldwide coverage.<br />

We followed this up with<br />

dedicated autogas conferences that<br />

attracted substantial delegate<br />

numbers of over 400 people. We<br />

were organising these conference<br />

for promotion, intending to break<br />

even but, with the huge numbers of<br />

people attending, we were actually<br />

making money as well.<br />

In 20<strong>02</strong>, we opened the 1,000th<br />

refuelling site, where we had, not just<br />

one, but two, ministers present<br />

during the launch and, once again,<br />

achieved substantial publicity for<br />

very little financial outlay.<br />

One of the ministers at the launch<br />

was Brian Wilson MP, the energy<br />

minister. I remember well an informal<br />

meeting I had with him shortly before<br />

the launch, when he advised that he<br />

wanted to carry out an initiative of his<br />

own and asked for my suggestions<br />

of what he could do. I advised that<br />

giving me some money would be<br />

nice, which could be used to<br />

promote autogas and also provide a<br />

subsidy for new companies joining<br />

the Approved Installer Scheme in<br />

order to improve standards in the<br />

conversion industry.<br />

To my surprise, the minister<br />

agreed to my request, and I came<br />

out of the meeting with the<br />

assurance of £1 million for the<br />

industry, which we actually only<br />

finished spending during the middle<br />

of 2005.<br />

Autogas has provided a major<br />

promotion platform for the<br />

association, and virtually every year<br />

we have undertaken various TV and<br />

radio interviews promoting its<br />

benefits, issue regular press releases<br />

and speak at conferences, which<br />

ensures that autogas receives a<br />

wide coverage in the media.<br />

Interestingly, much of this<br />

substantial promotion has been<br />

achieved without needing to spend<br />

huge amounts of money from the<br />

association’s funds.<br />

TECHNICAL STANDARDS<br />

It is not an easy task to get the whole<br />

industry and the HSE or, if<br />

appropriate, the DfT, to agree to the<br />

same technical standards, but this is<br />

what we have to achieve in order<br />

that all players in the industry can<br />

operate at the same level.<br />

The process is often difficult, and<br />

sometimes drawn-out, but we<br />

always manage to achieve our aim<br />

to keeping the standards up-to-date<br />

and at a high level of<br />

professionalism.<br />

For the future, I believe we have a<br />

thriving business with many<br />

opportunities, and I feel confident<br />

that the association will continue to<br />

play its role in ensuring that these are<br />

pursued in such a way as to keep<br />

the industry moving forward in a<br />

safe, profitable and effective way.<br />

The Queen’s fleet of Bentleys was converted to lpg in 1998.<br />

Used 52.5L w.c. <strong>LP</strong>G<br />

Cylinders for Sale<br />

We, National <strong>Gas</strong> & Industrialization Co.<br />

(GASCO) have decided to discontinue<br />

distribution of above type of cylinders.<br />

Therefore, around 500,000 of such cylinders<br />

in normal condition are available for immediate<br />

sale. If required, these cylinders can be<br />

refurbished and re-qualified in our modern<br />

state of the art Repair & Re-qualification Plant.<br />

Tom Fidell (left) with Brian Wilson MP.<br />

For further details please contact :<br />

GASCO, Riyadh 11421, Saudi Arabia<br />

Tel:+9661 4664 999 ext 300 or 301<br />

Fax: +966 1 4661 077<br />

e-mail – techdep@gasco.com.sa<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong><br />

11

ZINC SPRAYING<br />

ZINC – WHITE ELEPHANT<br />

OR WHITE KNIGHT?<br />

by Scott Ingram, quality manager, South Staffs Industries Ltd<br />

Corrosion protection on lpg cylinders has been a bone of contention within the industry for a<br />

number of years now, with more emphasis than ever placed on the importance of proactive<br />

measures to highlight the signs and prevention of corrosion. No wonder, when you consider that<br />

steel cylinders now equate to over 95% of the estimated 17 million cylinders in circulation<br />

(source: <strong>LP</strong>GA technical data 2004).<br />

We have all seen cylinders that have<br />

been returned from customers, in test,<br />

with the only failure being the<br />

deterioration of the paintwork – the<br />

topcoat cracked in areas that are<br />

rusting rapidly. From a cylinder integrity<br />

perspective, the cylinder may still be fit<br />

for purpose, but the excessive<br />

chipping of paint, although only an<br />

aesthetic problem, left unabated can,<br />

over a period of time, cause the<br />

cylinder to fail from corrosion.<br />

If you take into account the<br />

changes to the latest update of EN<br />

1440 – Transportable Refillable<br />

Welded Steel Lpg Cylinders –<br />

Periodic Inspection, which states<br />

that, for a cylinder to receive a 15<br />

year periodic inspection, the cylinder<br />

shall have “a system of external<br />

protection against corrosion that is<br />

being maintained”, this requirement<br />

falls under the responsibility of the<br />

REF EN 1439 TABLE 2<br />

owner of the cylinder.<br />

WHAT IS CORROSION?<br />

How long do we have…? I could<br />

write a thesis on this (and many<br />

have!) and we would still be none the<br />

wiser. Fundamentally, corrosion is<br />

defined as “a state of deterioration in<br />

metals caused by oxidation or<br />

chemical action”.<br />

There are various types and<br />

causes of corrosion. One of the main<br />

types is electrochemical corrosion.<br />

This occurs when the metal comes<br />

into contact with an electrolyte – a<br />

fluid that conducts electricity, such<br />

as rainwater or salt spray – and the<br />

metal will gradually corrode away.<br />

This is the form of corrosion found<br />

on lpg cylinders.<br />

HOW DO WE CHECK FOR<br />

CORROSION?<br />

Defects Description Rejection limit<br />

Visual checks – cylinder corrosion is<br />

predominantly found on the base area<br />

of the cylinder or in the shroud area.<br />

These are areas that are prone to the<br />

trapping of water. This means that, at<br />

each fill, every cylinder has to be<br />

assessed against a set of criteria by<br />

the filling plant operators to establish if<br />

any corrosion is evident. Any cylinder<br />

showing signs of corrosion is<br />

segregated in accordance with the<br />

requirements of BS EN 1439 –<br />

Procedure for Checking Before,<br />

During and After Filling. This states<br />

that, prior to filling, the operator will<br />

segregate cylinders “which are faulty<br />

or defective, e.g. where there is<br />

damage to shrouds, carry handles,<br />

foot rings or dents, fire damage or<br />

corrosion”, and that “the foot ring shall<br />

be inspected for visible corrosion”.<br />

Types of corrosion, descriptions<br />

and rejection limits are listed below:<br />

Isolated corrosion pits A pitting of metal occurring in isolated areas When the depth of discrete pits exceed<br />

0.6mm<br />

Excessive base corrosion.<br />

These requirements are somewhat<br />

difficult to adhere to if the cylinder still<br />

contains previous coatings. The most<br />

efficient way of working is to<br />

segregate any cylinder that has lost<br />

excessive coating, usually on the foot<br />

ring or shroud. These cylinders should<br />

then be sent for periodic inspection.<br />

Further inspections are then<br />

conducted to ascertain the full<br />

extent of the corrosion. If the cylinder<br />

is deemed fit for an additional 15-<br />

year cycle, the corrosion protection<br />

system should be reapplied. Any<br />

cylinder found with excessive<br />

corrosion above the requirements of<br />

the table should be scrapped<br />

immediately to prevent reuse.<br />

Area corrosion<br />

General corrosion<br />

Chain pitting/ line corrosion<br />

Crevice corrosion<br />

Reduction in wall thickness over an area not<br />

exceeding 20% of the cylinder surface<br />

A reduction in the wall thickness over an area<br />

exceeding 20% of the cylinder surface<br />

A series of pits or corroded cavities of<br />

limited width along the length or around the<br />

circumference<br />

Corrosion in the area of the intersection of<br />

the foot ring or shroud with the cylinder<br />

When the depth of any pit exceeds<br />

0.4mm<br />

When the depth of any pit exceeds 0.2m<br />

When the total length of the corrosion<br />

exceed 50% of the cylinder<br />

circumference and the depth of any pit<br />

exceeds 0.4mm<br />

When the depth exceeds 0.4mm or if the<br />

depth cannot be measured<br />

HOW DO WE PROTECT<br />

AGAINST CORROSION?<br />

When cylinders are manufactured,<br />

AND at every periodic inspection<br />

interval, each cylinder SHOULD<br />

receive the application of a layer of<br />

corrosion protection. Corrosion<br />

protection is applied in an array of<br />

methods, including zinc phosphatebased<br />

primers; epoxy based<br />

coating; zinc powder; galvanising or<br />

metallic zinc spray.<br />

The pros and cons of each<br />

individual coating material and<br />

application method are fiercely<br />

debated, but the most common<br />

method used at present is metallic<br />

zinc spray. Although the metallic zinc<br />

12<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong>

ZINC SPRAYING<br />

spray is perhaps not the cheapest<br />

option, it can demonstrate proven<br />

anti-corrosion properties over time.<br />

Each cylinder should be pretreated<br />

prior to any application. This<br />

basically means the cylinder body is<br />

cleaned so that its entire surface is<br />

free of any rust/ paint residue, etc,<br />

and that a suitable roughened<br />

surface is produced in order to<br />

accept the application. Shot blasting<br />

the entire external surface of the<br />

cylinder to the standard of SA 2 _ is<br />

most commonly used.<br />

After the previous coatings have<br />

been removed, we can get a clearer,<br />

more decisive view of the base<br />

metal. Particular attention should be<br />

given at this time to any cylinder<br />

crevices (the intersections of the foot<br />

ring or shroud with the cylinder).<br />

After shotblasting.<br />

Following the blast, the cylinders<br />

should have all surface areas coated<br />

with a layer of corrosion protection. It<br />

is of paramount importance to<br />

completely coat all corrosionsusceptible<br />

areas of the cylinder.<br />

Cylinders should be inspected to<br />

ensure consistency of coating. A<br />

minimum thickness of 40 microns is<br />

commonly used. However, some<br />

customers specify a thickness of 100<br />

microns in corrosion prone areas.<br />

A final/top coat can then be<br />

applied, either by painting or powder<br />

coating. This seals the zinc coat and<br />

is used for cosmetic purposes.<br />

WHAT DOES THE<br />

CORROSION<br />

PROTECTION DO?<br />

It is widely known that some<br />

cylinders are handled poorly and<br />

often damaged due to a lack of<br />

operator knowledge. For instance,<br />

when a cylinder is being used to tar<br />

a roof and the cylinder is empty, the<br />

roofer often throws the cylinder off<br />

the roof, thus causing damage to the<br />

cylinder’s integrity, frequently<br />

dropping onto the shroud area or<br />

base ring. Often, the only damage<br />

found on a cylinder is the chipping of<br />

the top coating. Any paint chipping<br />

off the cylinder will result in water<br />

penetrating behind the coating. This<br />

has the potential to cause corrosion.<br />

Without corrosion protection, the<br />

steel shell of the cylinder is now<br />

susceptible to all adverse operating<br />

and weather conditions and will<br />

deteriorate quite rapidly. This<br />

deterioration will undoubtedly mean<br />

the cylinder will be returned with<br />

excessive corrosion prior to its 15-<br />

year periodic inspection being due.<br />

With corrosion protection, the zinc<br />

will act in a sacrificial manner and<br />

prevent the steel shell of the cylinder<br />

being exposed. Thus, the zinc coating<br />

and not the base metal will corrode<br />

over time, reducing the potential for the<br />

cylinder failing due to corrosion. This<br />

should ensure all protected cylinders<br />

will remain in the marketplace until their<br />

next 15 year periodic inspection.<br />

Zinc spraying.<br />

THE COST OF ZINC<br />

As mentioned previously, the cost of<br />

metallic zinc is high. At the time of<br />

writing, the cost of zinc wire has<br />

increased by 80% over the last<br />

twelve months. However, it should<br />

be noted that this still represents a<br />

good investment for protecting the<br />

longevity of the cylinder.<br />

WHAT SHOULD WE DO?<br />

n Ensure that all cylinders have<br />

corrosion protection applied at<br />

point of manufacture and at time<br />

of every periodic inspection, and<br />

that the thickness of this coat is<br />

specified – the usual thickness is a<br />

minimum of 40 microns.<br />

n Ensure all filling plant personnel<br />

are aware of the requirements for<br />

checking for corrosion, removing<br />

cylinders that do not reach the<br />

stated criteria and returning these<br />

cylinders for periodic inspection.<br />

This will hopefully ensure that both<br />

new and existing cylinders will be far<br />

less susceptible to corrosion and the<br />

life span of cylinders can be<br />

prolonged.<br />

Contact South Staffs Industries<br />

on 0121 522 2373<br />

Integrated <strong>Gas</strong><br />

Technologies<br />

Manufacturer of <strong>LP</strong>G low presusre regulators<br />

& <strong>LP</strong>G cylinder valve from Cemco<br />

South Staffs Industries Ltd<br />

<strong>LP</strong>G cylinder refurbishment and<br />

periodic inspection to EN1440:2005.<br />

All in accordance with our quality<br />

assurance system ISO 9001:2000.<br />

Compact Valves & Regulators – 20,21,22 mm<br />

Jumbo Valves & Regulators – 35 mm<br />

Snap-On Valves and Regulators – 27 mm<br />

POL Valves & Regulators<br />

Euro-outlet Valves and Regulators<br />

Tel: + 45 45 76 99 21<br />

Fax: + 45 45 76 98 21<br />

Email: sales@igt-lpg.com<br />

www.igt-lpg.com<br />

Zinc-sprayed cylinders for a longer life!<br />

For more details, please contact Chris or Steve on<br />

0121 522 2373<br />

sales@southstaffsindustries.com<br />

South Staffs Industries Ltd<br />

Bloomfield Rd, Tipton Dudley, West Midlands DY4 9EE<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong><br />

13

FEATURE<br />

KEEPING A GRIP ON YOUR LEAD<br />

British businesses spend millions of pounds every year on various marketing tools, including<br />

advertising, direct mail, exhibitions and PR. However, according to Derek Vaughan, managing<br />

director of Quotatis, a recently launched pay-as-you-go system providing business leads to<br />

reputable tradesmen and suppliers, it’s just as important to follow up the enquiries and know<br />

where they came from, as it is to obtain them in the first place.<br />

Last year, in the UK, businesses<br />

spent over £19 million on advertising<br />

alone, which is a 5.4% increase on<br />

2004. The area of biggest growth<br />

was Internet advertising, with the<br />

first six months of 2005 seeing<br />

expenditure hit £490.8 million, up<br />

62% compared to the same time the<br />

previous year. Spending in all other<br />

marketing areas has increased,<br />

meaning that British companies are<br />

spending more than ever before on<br />

trying to increase revenue.<br />

However, with a lot of budget<br />

being allocated to generating<br />

interest and enquiries, is the majority<br />

of it wasted if the firm receiving the<br />

enquiry then does nothing about it<br />

and has no idea where it was<br />

generated from?<br />

There is little point in generating<br />

more leads and enquiries from<br />

advertising, etc, if the company’s<br />

existing conversion process results in<br />

most of the hard-won enquiries falling<br />

through the cracks. According to David<br />

Oliver from the consultancy company,<br />

Insight Marketing, sales enquiries are<br />

like warm milk – they go off.<br />

“Speed of response is everything<br />

when it comes to enquiries,” he said.<br />

“The Marketing Guild conducted a<br />

survey of 192 advertisers in eight trade<br />

journals and found that only 55% of<br />

enquiries were followed up, with the<br />

remaining 45% being ignored. There is<br />

an inverse relationship between<br />

enquiries and sales, meaning the<br />

longer the time between initial enquiry<br />

and follow up, the less likely the<br />

enquiry will lead to a sale.”<br />

Too many tradespeople are<br />

already generating a lot of leads and<br />

prospects but are unwittingly losing<br />

up to 95% of their sales<br />

opportunities and pouring money<br />

down the drain. In these<br />

circumstances, they need to<br />

conduct a complete audit of their<br />

promotional activities to find more<br />

cost effective ways to increase<br />

revenue that will bring them the most<br />

return on their often very limited<br />

available investment.<br />

However, ‘most return’ may not<br />

necessarily mean the most number<br />

of enquiries, as their aim should be<br />

to receive the level of enquiries that<br />

they are able to quickly respond to.<br />

Too many enquiries could actually be<br />

damaging to the tradesperson’s<br />

business if they take too long to<br />

respond, especially as the potential<br />

customer will have contacted<br />

competing businesses in the area.<br />

If these competitors are quicker to<br />

provide a satisfactory quote, they will<br />

not only get the job, but also be<br />

recommended to others. The ‘most<br />

return’ is therefore the most amount<br />

of revenue generation, not the<br />

number of enquiries.<br />

For example, a sole trader<br />

electrician might allocate £500 to the<br />

promotion of his business and needs<br />

to decide how best to spend this<br />

money. A direct mail drop in the<br />

surrounding neighbourhoods has the<br />

potential to help build up a good local<br />

reputation and generate qualified<br />

leads, which is important, as wasting<br />

time on unqualified leads is a primary<br />

factor that can affect sales success,<br />

as not everyone is a prime prospect<br />

for the electrician’s services.<br />

The electrician could be ‘busy’ all<br />

day talking to people and<br />

communicating in all the suitable<br />

places, but he will not convert sales<br />

unless he concentrates on qualified<br />

prospects, rather than offering his<br />

service to people who are<br />

unreceptive, not ready for, cannot pay<br />

for or are disinterested in what he is<br />

offering. However, the disadvantages<br />

are the time taken out of the working<br />

day to design and deliver the mailer<br />

when he could be working on<br />

revenue generating jobs, and also the<br />

limited number of people who will<br />

actually see and pick up the mailer or<br />

keep it for future reference if they<br />

need some work completing.<br />

Another option might be to<br />

advertise in regional press and<br />

magazines. The advantage of this is<br />

the high circulation, meaning the ad<br />

will be seen by many so, even if the<br />

return rate is low, some sales should<br />

be generated. However, what if<br />

many leads are generated?<br />

Can the electrician cope with<br />

trying to respond and then actually<br />

carry out the work within a<br />

reasonable time frame if the quote is<br />

successful? Will he remember to ask<br />

Derek Vaughan.<br />

each caller where they heard about<br />

the business and it’s offering so an<br />

idea of advertising costs per sale<br />

can be calculated?<br />

The cost of the ad also means that<br />

the electrician would only be able to<br />

afford to advertise once, meaning little<br />

opportunity to stand out from<br />

competitors and little chance to create<br />

a lasting impression with readers.<br />

The £500 budget could also be<br />

spent increasing the professionalism<br />

of the business through creating a<br />

website, business stationery and<br />

joining a trade association that<br />

properly vets its members and helps<br />

them generate new business.<br />

Through belonging to a trade<br />

association, the business will be<br />

vetted and then eligible to appear in<br />

various business directories,<br />

including www.quotatis.co.uk, a<br />

new system which texts, emails or<br />

faxes the requested amount of<br />

qualified leads to the registered<br />

tradesperson in the preferred<br />

regional area. This method means<br />

the electrician has a stored record of<br />

all leads and can deal with them in a<br />

systematic and timely way. He also<br />

knows that the lead has come from<br />

the website, so can calculate how<br />

cost effective this method is.<br />

Whichever methods tradespeople<br />

use to promote themselves, there are<br />

some important elements worth<br />

remembering to ensure they are<br />

making the most of their marketing<br />

mediums. Firstly, testing of a chosen<br />

method is very important before fully<br />

committing, especially as budgets will<br />

be tight or practically non-existent.<br />

Researching new and innovative<br />

ways to generate sales leads is<br />

important, rather than just using tried<br />

and tested methods that invariably<br />

competitors will also be<br />

implementing. Most important is the<br />

need to track where leads come<br />

from, so return on investment can be<br />

calculated for future allocation of<br />

promotion budget.<br />

Lastly, marketing and promotion<br />

does not end with receiving the<br />

enquiry - these should be dealt with<br />

properly and efficiently to ensure the<br />

reputation of the business is upheld<br />

and scarce resources are not wasted.<br />

Contact Quotatis at<br />

www.quotatis.co.uk<br />

14<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong>

PRODUCTS<br />

Mitsubishi Launches Lpg<br />

Cushion Tyre Forklift<br />

The new FGC N series of 2.0 to 3.0 tonne<br />

counterbalance models from Mitsubishi Forklift<br />

Trucks gives clear, all-round vision through the highvisibility<br />

mast, fork carriage and head guard, says<br />

the company. Safety features include a seat switch<br />

that prevents all movement of the forks and the<br />

truck if the driver is not securely seated as standard,<br />

as well as warning indicators to encourage proper<br />

use of the seatbelt and parking brake. A long<br />

service interval – 500 hours – will bring reductions in<br />

maintenance costs and downtime.<br />

The cushion tyres give traction on smooth<br />

surfaces, low rolling resistance, reduced energy<br />

consumption, better stability and greater residual<br />

capacities at high lifts, says Mitsubishi. They also<br />

minimise truck dimensions for greater<br />

manoeuvrability in tight spaces.<br />

“And as you would expect from any Mitsubishi<br />

forklift truck, the high specifications and<br />

performance of the new models are matched with<br />

competitive prices, low running costs and utter<br />

dependability to deliver outstanding value for<br />

money,” said Terry Foreman, general manager of<br />

Mitsubishi Forklift Trucks UK.<br />

Fasttflo, Andrews Water Heaters’ new range<br />

of wall hung, balanced flue continuous flow<br />

water heaters, are highly efficient and can<br />

be fitted almost anywhere – even outside –<br />

says the company. The range has been<br />

developed for commercial and larger<br />

residential applications where there is a<br />

constant requirement for hot water<br />

immediately on tap.<br />

The appliances measure incoming water<br />

flow and temperature via the primary circuit<br />

board and then modulate the burner up or<br />

down to meet demand within 1º C accuracy.<br />

There are no standby heat losses and an<br />

operating efficiency of 89% is achieved with<br />

auto ignition, so there are no running costs<br />

when the unit is idle.<br />

The lack of stored water inhibits scaling<br />

and reduces the risk of Legionella bacteria<br />

forming. The remote controller allows<br />

external adjustment of the required flow<br />

temperature and provides operation and<br />

fault diagnosis information. The range has<br />

two models for internal siting and two for<br />

external location that do not require<br />

additional weather protection.<br />

The Fasttflo WHX has been designed for<br />

external installation. The casing is<br />

impervious to the elements, says Andrews,<br />

and the appliance has an integral anti-freeze<br />

device. There is a choice of flue systems for<br />

internal models, including a twin pipe option<br />

that allows installation flexibility. External<br />

units require no flue.<br />

A quick connect multi system is available<br />

for the connection of two heaters that<br />

requires one remote controller and a quick<br />

connect cord. Up to six heaters can be<br />

connected using a system controller that<br />

The new Mitsubishi FGC20-30N series<br />

counterbalance forklift truck.<br />

The FGC20-30N is also offered with options,<br />

such as an integral side shifter, extra working<br />

lights, revolving lamps, a high-exit exhaust and<br />

dual front wheels.<br />

Contact Mitsubishi Foklift Trucks UK on<br />

0118 988 <strong>02</strong>21<br />

www.mitsubishi-forklift.co.uk<br />

New Fasttflo Range from Andrews<br />

can also regulate the circulation pump. In<br />

addition, it can change the priority for run<br />

and standby mode.<br />

Unvented system kits are available and<br />

Fasttflo models are available for use with<br />

lpg. Fasttflo water heaters can also be<br />

combined with the Andrews range of ST<br />

storage cylinders to provide large volumes<br />

of hot water for intermittent and large peak<br />

demand found in hospitals, hotels and<br />

sports facilities.<br />

Contact Andrews Water Heaters on<br />

0121 5<strong>06</strong> 7400<br />

www.andrewswaterheaters.co.uk<br />

TECHNICAL MANUALS<br />

AQUATECH PUBLICATIONS LTD.<br />

For Industrial Operating & Maintenance<br />

Manuals and Training.<br />

• Technical Editing<br />

• Desk Top Publishing<br />

• CAD Illustration<br />

• Training<br />

• Document Vetting<br />

• Production of<br />

Technical<br />

Documentation<br />

Specialists in<br />

Providing High Quality<br />

User-friendly<br />

Documentation since<br />

1994.<br />

Tel: +44 (0) 1244 531658<br />

Email: enquiries@aquatechpublications.co.uk<br />

TANKS<br />

AUTOMOTIVE TANKS LTD<br />

West Midlands based Automotive Tanks Ltd,<br />

one of the UK's remaining manufacturers of<br />

low pressure welded cylinders, are expanding<br />

their existing involvement further into the<br />

refurbishing and requalification of propane and<br />

butane cylinders.<br />

Tel: 019<strong>02</strong> 604207<br />

www.automotivetanks.ltd.uk<br />

SECURITY STORAGE CAGES<br />

THE KUDOS FOLDING CAGE FOR THE<br />

STORAGE OF <strong>LP</strong> GAS, HAZARDOUS<br />

MATERIALS, HIGH VALUE DISPLAY<br />

AND SEASONAL STOCK<br />

• Unique patented design available in 4 sizes<br />

• Available in painted or galvanised finish<br />

• Flat packed for<br />

delivery and storage<br />

• Quick and easy to<br />

install, no specialist<br />

tooling needed<br />

• No specialist lifting<br />

equipment required<br />

• Conforms to HSE<br />

guidelines<br />

Pictured above is our FSK16 folding storage cage. This is the entry level<br />

cage which has a capacity for 4 x 13/15/19 Kg <strong>LP</strong>G bottles. Contact us<br />

now for details on our full range of Folding Cages and Compounds<br />

PLEASE QUOTE <strong>LP</strong>G001 WHEN CONTACTING US<br />

Tel: 01525 843883<br />

kudos@insys-ltd.co.uk<br />

www.kudos2000.co.uk<br />

BARBECUES<br />

IF YOU LOVE YOU GARDEN,<br />

YOU’LL LOVE LIFESTYLE.<br />

For 20<strong>06</strong> our range encompasses an even<br />

wider choice of new and exciting alternatives to<br />

help you make the most of the great outdoors<br />

and year round alfresco entertaining.<br />

Lifestyle have gained an enviable reputation for<br />

distributing quality products backed up by an<br />

excellent after sales service.<br />

Contact our sale team for a full catalogue of<br />

products available.<br />

Tel: 01527 65126<br />

<strong>LP</strong> GAS MAGAZINE APRIL/MAY 20<strong>06</strong> 15

AUTOGAS CONVERSION EQUIPMENT<br />

Vintage Fiat 508cc 935 with Tartarini cng conversion, circa 1939.<br />

LONG, LONG AGO…<br />

by Nikki Key, operations manager, Autogas 2000 Ltd<br />

I wasn't quite sure where to start<br />

when Faye Spiers rang and asked<br />

me to compile a little piece for this<br />

issue. "Some technical information<br />

on lpg autogas conversions and how<br />

they work?" she suggested.<br />

Well, all of you engineers out there<br />

will know that's about as easy as<br />

estimating the dimensions of that<br />

infamous piece of string!<br />

Not being technical but having at<br />

hand some of the UK's most<br />

experienced time-served conversion<br />

engineers, it was agreed that a<br />

simple synopsis of the past and<br />

present conversion systems would<br />

be my motif.<br />

It may come as a surprise to many<br />

but it all began way back in the late<br />

1930s when shortages of petrol led<br />

to some innovative experimentation.<br />

The earliest conversions utilised the<br />

captured gaseous emissions from<br />

burning coal in a large bag, invariably<br />

carried on the roof of the vehicle.<br />

Fond memories of a classic Dad's<br />

Army episode spring to mind!<br />

This was soon followed with early<br />