A Study on Crystallization of Oxalic Acid in Batch Cooling ... - pierre

A Study on Crystallization of Oxalic Acid in Batch Cooling ... - pierre

A Study on Crystallization of Oxalic Acid in Batch Cooling ... - pierre

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

126 C. SRINIVASAKANNAN et al., A <str<strong>on</strong>g>Study</str<strong>on</strong>g> <strong>on</strong> Crystallizati<strong>on</strong> <strong>of</strong> <strong>Oxalic</strong> <strong>Acid</strong> …, Chem. Biochem. Eng. Q. 16 (3) 125–129 (2002)<br />

S<strong>in</strong>ce the c<strong>on</strong>trol <strong>of</strong> cool<strong>in</strong>g rate is quite easy with<br />

use <strong>of</strong> modern process c<strong>on</strong>trol, the present study attempts<br />

to study the effect <strong>of</strong> different cool<strong>in</strong>g<br />

modes <strong>on</strong> crystal size distributi<strong>on</strong> for a uni-modal<br />

crystal size distributi<strong>on</strong> <strong>of</strong> oxalic acid. The effects<br />

<strong>of</strong> various operat<strong>in</strong>g quantities <strong>on</strong> crystal size distributi<strong>on</strong><br />

for the best identified cool<strong>in</strong>g mode, has<br />

been studied.<br />

Experimental<br />

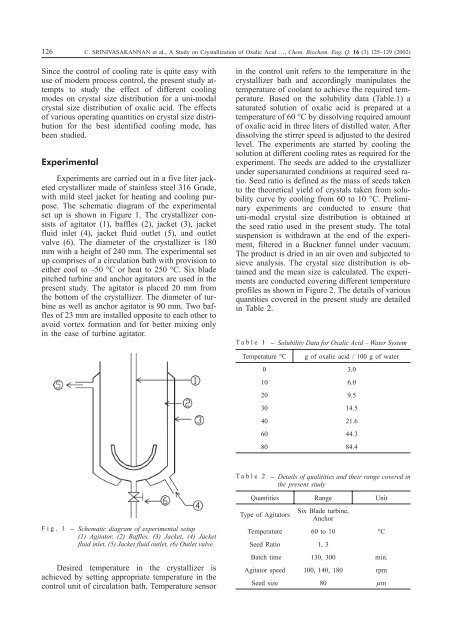

Experiments are carried out <strong>in</strong> a five liter jacketed<br />

crystallizer made <strong>of</strong> sta<strong>in</strong>less steel 316 Grade,<br />

with mild steel jacket for heat<strong>in</strong>g and cool<strong>in</strong>g purpose.<br />

The schematic diagram <strong>of</strong> the experimental<br />

set up is shown <strong>in</strong> Figure 1. The crystallizer c<strong>on</strong>sists<br />

<strong>of</strong> agitator (1), baffles (2), jacket (3), jacket<br />

fluid <strong>in</strong>let (4), jacket fluid outlet (5), and outlet<br />

valve (6). The diameter <strong>of</strong> the crystallizer is 180<br />

mm with a height <strong>of</strong> 240 mm. The experimental set<br />

up comprises <strong>of</strong> a circulati<strong>on</strong> bath with provisi<strong>on</strong> to<br />

either cool to –50 °C or heat to 250 °C. Six blade<br />

pitched turb<strong>in</strong>e and anchor agitators are used <strong>in</strong> the<br />

present study. The agitator is placed 20 mm from<br />

the bottom <strong>of</strong> the crystallizer. The diameter <strong>of</strong> turb<strong>in</strong>e<br />

as well as anchor agitator is 90 mm. Two baffles<br />

<strong>of</strong> 23 mm are <strong>in</strong>stalled opposite to each other to<br />

avoid vortex formati<strong>on</strong> and for better mix<strong>in</strong>g <strong>on</strong>ly<br />

<strong>in</strong> the case <strong>of</strong> turb<strong>in</strong>e agitator.<br />

<strong>in</strong> the c<strong>on</strong>trol unit refers to the temperature <strong>in</strong> the<br />

crystallizer bath and accord<strong>in</strong>gly manipulates the<br />

temperature <strong>of</strong> coolant to achieve the required temperature.<br />

Based <strong>on</strong> the solubility data (Table.1) a<br />

saturated soluti<strong>on</strong> <strong>of</strong> oxalic acid is prepared at a<br />

temperature <strong>of</strong> 60 °C by dissolv<strong>in</strong>g required amount<br />

<strong>of</strong> oxalic acid <strong>in</strong> three liters <strong>of</strong> distilled water. After<br />

dissolv<strong>in</strong>g the stirrer speed is adjusted to the desired<br />

level. The experiments are started by cool<strong>in</strong>g the<br />

soluti<strong>on</strong> at different cool<strong>in</strong>g rates as required for the<br />

experiment. The seeds are added to the crystallizer<br />

under supersaturated c<strong>on</strong>diti<strong>on</strong>s at required seed ratio.<br />

Seed ratio is def<strong>in</strong>ed as the mass <strong>of</strong> seeds taken<br />

to the theoretical yield <strong>of</strong> crystals taken from solubility<br />

curve by cool<strong>in</strong>g from 60 to 10 °C. Prelim<strong>in</strong>ary<br />

experiments are c<strong>on</strong>ducted to ensure that<br />

uni-modal crystal size distributi<strong>on</strong> is obta<strong>in</strong>ed at<br />

the seed ratio used <strong>in</strong> the present study. The total<br />

suspensi<strong>on</strong> is withdrawn at the end <strong>of</strong> the experiment,<br />

filtered <strong>in</strong> a Buckner funnel under vacuum.<br />

The product is dried <strong>in</strong> an air oven and subjected to<br />

sieve analysis. The crystal size distributi<strong>on</strong> is obta<strong>in</strong>ed<br />

and the mean size is calculated. The experiments<br />

are c<strong>on</strong>ducted cover<strong>in</strong>g different temperature<br />

pr<strong>of</strong>iles as shown <strong>in</strong> Figure 2. The details <strong>of</strong> various<br />

quantities covered <strong>in</strong> the present study are detailed<br />

<strong>in</strong> Table 2.<br />

Table 1<br />

Solubility Data for <strong>Oxalic</strong> <strong>Acid</strong> – Water System<br />

Temperature °C g <strong>of</strong> oxalic acid / 100 g <strong>of</strong> water<br />

0 3.0<br />

10 6.0<br />

20 9.5<br />

30 14.5<br />

40 21.6<br />

60 44.3<br />

80 84.4<br />

Table 2<br />

Details <strong>of</strong> qualitities and their range covered <strong>in</strong><br />

the present study<br />

Quantities Range Unit<br />

Fig. 1<br />

Schematic diagram <strong>of</strong> experimental setup<br />

(1) Agitator, (2) Baffles, (3) Jacket, (4) Jacket<br />

fluid <strong>in</strong>let, (5) Jacket fluid outlet, (6) Outlet valve.<br />

Desired temperature <strong>in</strong> the crystallizer is<br />

achieved by sett<strong>in</strong>g appropriate temperature <strong>in</strong> the<br />

c<strong>on</strong>trol unit <strong>of</strong> circulati<strong>on</strong> bath. Temperature sensor<br />

Type <strong>of</strong> Agitators<br />

Six Blade turb<strong>in</strong>e,<br />

Anchor<br />

Temperature 60 to 10 °C<br />

Seed Ratio 1, 3<br />

<strong>Batch</strong> time 130, 300 m<strong>in</strong>.<br />

Agitator speed 100, 140, 180 rpm<br />

Seed size 80 m