Shell Bitumen - Cariphalte - Megget Resevoir Case Study

Shell Bitumen - Cariphalte - Megget Resevoir Case Study

Shell Bitumen - Cariphalte - Megget Resevoir Case Study

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

SHELL CARIPHALTE<br />

<strong>Bitumen</strong>ous grouting to repair and protect the reservoir<br />

supplying Scotland’s capital city with water<br />

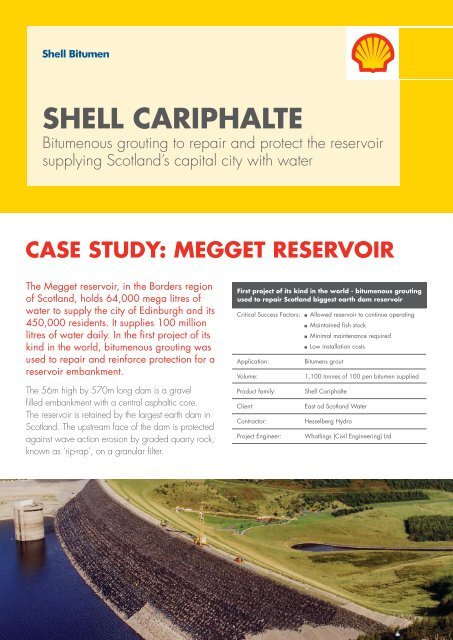

CASE STUDY: MEGGET RESERVOIR<br />

The <strong>Megget</strong> reservoir, in the Borders region<br />

of Scotland, holds 64,000 mega litres of<br />

water to supply the city of Edinburgh and its<br />

450,000 residents. It supplies 100 million<br />

litres of water daily. In the first project of its<br />

kind in the world, bitumenous grouting was<br />

used to repair and reinforce protection for a<br />

reservoir embankment.<br />

The 56m high by 570m long dam is a gravel<br />

filled embankment with a central asphaltic core.<br />

The reservoir is retained by the largest earth dam in<br />

Scotland. The upstream face of the dam is protected<br />

against wave action erosion by graded quarry rock,<br />

known as ‘rip-rap’, on a granular filter.<br />

First project of its kind in the world - bitumenous grouting<br />

used to repair Scotland biggest earth dam reservoir<br />

Critical Success Factors: Allowed reservoir to continue operating<br />

Maintained fish stock<br />

Minimal maintenance required<br />

Low installation costs<br />

Application: <strong>Bitumen</strong>s grout<br />

Volume: 1,100 tonnes of 100 pen bitumen supplied<br />

Product family: <strong>Shell</strong> <strong>Cariphalte</strong><br />

Client: East od Scotland Water<br />

Contractor: Hesselberg Hydro<br />

Project Engineer: Whatlings (Civil Engineering) Ltd

This has suffered continuous erosion since 1983 when the<br />

reservoir was filled and a wind-wave investigation showed that<br />

waves were greater than designers had anticipated. Repairs<br />

had to be carried out on an ongoing basis, resulting in high<br />

maintenance costs and considerable disruption.<br />

<strong>Bitumen</strong>ous grouting offers the best long term solution<br />

East Scotland Water undertook a study to evaluate methods for<br />

upgrading the existing rip-rap protection layer to ensure minimal<br />

maintenance and long term service. Options assessed included<br />

the installation of an additional layer using bigger rock elements,<br />

a shallower upstream slope angle, concrete block work or<br />

bituminous grouting.<br />

The contractors, Hesselberg Hydro, undertook on-site trials and<br />

visited asphaltic coastal defence structures in Holland which<br />

suffered a similar wave attack. As a result of extensive research,<br />

they selected bituminous grouting.<br />

“The <strong>Megget</strong> reservoir supplies 100 million<br />

litres of water daily and is the first project<br />

of its kind in the world. <strong>Bitumen</strong>ous grouting<br />

was used to repair and reinforce protection<br />

for a reservoir embankment.”<br />

Bituminous grout is an homogeneous mixture of mastic, consisting<br />

of penetration grade bitumen, limestone filler and natural medium<br />

to fine sand, together with small graded crushed stone or gravel.<br />

For further information<br />

please contact your <strong>Shell</strong> <strong>Bitumen</strong><br />

representative or visit;<br />

www.shell.com/bitumen<br />

The <strong>Shell</strong> emblem, <strong>Cariphalte</strong> and SHELL are trade marks of the <strong>Shell</strong> Group.<br />

03/2011/ CS5<br />

A tailored solution<br />

The <strong>Shell</strong> <strong>Bitumen</strong> team came on board and were able to quickly<br />

add value to the project, working in close collaboration with the<br />

main contractors, Hessel Hydro, advising on the best application<br />

method and product mix.<br />

A pattern grouting technique was selected to provide maximum<br />

strength, while also limiting the amount of grout, and maintaining<br />

adequate porosity of the rock layer to dissipate the hydraulic<br />

energy of breaking waves and water pressure. It also provided<br />

the most economical long-term solution.<br />

The viscosity of the mixture was critical to ensure the grouting<br />

penetrated the full depth of the rip-rap layer, but also gave sufficient<br />

stability to the existing rock after cooling, without sagging at<br />

ambient temperatures on the steep slope of the embankment.<br />

The most economic and practical solution<br />

Full scale site trials prior to the award of the main contract<br />

demonstrated the increased strength of the rock layer while<br />

retaining adequate porosity<br />

27,000m 2 upgraded with pattern grouting on a 2.5m grid<br />

On site production of 10,500 tonnes of mastic<br />

Full using made of mobile quality control laboratory<br />

Mastic grout applied hot from specially designed skips,<br />

penetration relying on gravity<br />

Completion was on time in and within budget.

![Download Shell AutoGas Stationen [Stand: Januar 2013] (PDF](https://img.yumpu.com/9982753/1/190x245/download-shell-autogas-stationen-stand-januar-2013-pdf.jpg?quality=85)