Environmental Statement 2008.FH10

Environmental Statement 2008.FH10

Environmental Statement 2008.FH10

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

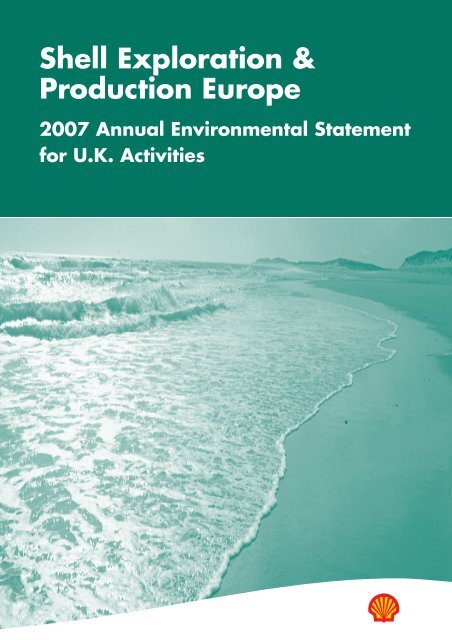

Shell Exploration &<br />

Production Europe<br />

2007 Annual <strong>Environmental</strong> <strong>Statement</strong><br />

for U.K. Activities

CONTENTS<br />

1. INTRODUCTION<br />

2. WHAT WE DO<br />

2.1 Our Exploration & Production Activities and Operations<br />

2.2 Map of our UK locations<br />

3 ENVIRONMENTAL MANAGEMENT<br />

3.1 Our <strong>Environmental</strong> Management System (EMS)<br />

3.2 Royal Dutch/Shell Commitment and Policy on HSE<br />

3.3 The <strong>Environmental</strong> Aspects of our Operations<br />

4 ENVIRONMENTAL PERFORMANCE<br />

4.1 Our <strong>Environmental</strong> Goals, Objectives and Targets<br />

4.2 Reducing Emissions and Discharges<br />

4.3 Use of Energy, Resources & Waste Management<br />

4.4 Biodiversity and Vulnerable Areas<br />

4.5 Monitoring Seabed Impacts<br />

4.6 Lateral Learning and Cooperation<br />

5 CONTACTS<br />

APPENDIX 1<br />

SHELL U.K. EXPLORATION & PRODUCTION EUROPE<br />

UK - ENVIRONMENTAL DATA TABLE<br />

APPENDIX 2<br />

OIL AND CHEMICHAL SPILLS AND OIL DISCHARGES<br />

APPENDIX 3<br />

2007 DRILLING LOCATIONS<br />

APPENDIX 4<br />

ABBREVIATIONS

1. INTRODUCTION<br />

By John Gallagher, Vice President Technical – Europe, Shell Exploration & Production Europe<br />

I am pleased to introduce this <strong>Environmental</strong> <strong>Statement</strong>,<br />

covering Shell U.K. Limited’s Exploration and Production<br />

(EP) activities during 2007.<br />

The purpose of this report is to explain our environmental<br />

performance and work programmes in 2007 in the UK, and<br />

to update our plans for improvement in 2008/9. The report<br />

is updated annually.<br />

In Section 2 you can see a map of our activities. In the UK<br />

sector of the North Sea we operate 35 platforms, 3 Floating<br />

Production Storage & Offloading (FPSO) vessels, and 18<br />

subsea installations; in total we have interests in 61 fields (52<br />

operated) and three onshore gas plants. Our European EP<br />

operations, and in turn the UK assets, are an important part<br />

of our global portfolio, and will remain so for years to come.<br />

We operate more production in Europe than any other<br />

International Oil Company (more than twice the second largest<br />

IOC). We are also one of the largest investors, averaging over<br />

$5 billion per year in Europe in the last five years and for the<br />

next five years and we have been and we will continue to be<br />

an industry leader in frontier technology developments.<br />

We are particularly pleased that, at the end of 2007, our<br />

<strong>Environmental</strong> Management System (EMS) was certified to<br />

ISO14001. This demonstrates that we have a systematic<br />

approach to managing our environmental risks that meets<br />

international standards. In 2008 we are continuing to work<br />

on improving our EMS.<br />

Our environmental objectives reflect our key challenges – to<br />

work with others and to provide our own contribution towards<br />

addressing climate change, to continue to reduce emissions,<br />

discharges and wastes from our locations and to ensure our<br />

operations in sensitive areas take account of the expectations<br />

of all stakeholders.<br />

Our performance shows that this is being achieved in some<br />

areas. There are also areas for improvement that we will act<br />

upon.<br />

Looking to the future, our business will continue to change.<br />

We will move forward with adjustments to our asset portfolio<br />

and address new challenges such as decommissioning. Our<br />

main target areas for performance improvement are currently<br />

in the areas of greenhouse gas (GHG) and energy management,<br />

continuing to reduce the risk from oil and chemical discharges<br />

and improving our environmental impact assessment processes.<br />

These will be delivered by focusing on legal requirements and<br />

Shell Group standards and through enhancements to our EMS.<br />

I hope you will agree our commitment to improving<br />

environmental performance is demonstrated throughout this<br />

report.

2. WHAT WE DO<br />

2.1 OUR E&P ACTIVITIES AND OPERATIONS<br />

Our <strong>Environmental</strong> Management System covers all of our<br />

UK activities and locations that are used in the exploration,<br />

production and processing of hydrocarbons.<br />

Our business is divided up into organisational units called<br />

Assets and Functions. Assets are typically groupings of four<br />

to six locations supported by onshore teams, and cover all<br />

our physical facilities including offshore fields, installations<br />

and associated wells, the onshore gas plants, and all associated<br />

pipelines. All our UK facilities can be viewed on the UK<br />

Map in Section 2.2. Functions typically manage the support<br />

Click Here to find out about Shell’s EP activities in the U.K.<br />

Figure 1 - Map of UK locations<br />

activities required by the Assets such as engineering and<br />

maintenance services, development planning, project planning<br />

and execution, survey work, organizing support vessels and<br />

helicopters, laboratory services, drilling wells and the<br />

management of our offices.<br />

Detailed descriptions of EP activities and operations are<br />

provided on the shell.com website.<br />

2.2 MAP OF U.K. LOCATIONS Click Here to view map of U.K. Locations

3. ENVIRONMENTAL MANAGEMENT IN SHELL EXPLORATION &<br />

PRODUCTION EUROPE<br />

3.1 OUR ENVIRONMENTAL MANAGEMENT SYSTEM (EMS)<br />

Figure 2 - <strong>Environmental</strong> Management System<br />

Shell Exploration & Production Europe’s Corporate<br />

Management System (CMS) documents the way in which the<br />

company conducts its business. The <strong>Environmental</strong><br />

Management System (EMS) is an integral part of the CMS.<br />

It consists of the elements shown in Figure 2 above.<br />

‘Policy and Strategic Objectives’ contains our HSE Policy<br />

and the Strategic <strong>Environmental</strong> Objectives. The HSE Policy<br />

(see Section 3.2) contains a commitment to protect the<br />

environment and states that we have a systematic approach<br />

to HSE management designed to ensure compliance with the<br />

law and to achieve continuous performance improvement.<br />

‘Organisation, Responsibilities, Resources, Competency’<br />

describes the organisational structure and the roles and<br />

responsibilities that deliver environmental management. The<br />

competency of personnel carrying out roles within the EMS<br />

are addressed and the resources necessary to ensure that the<br />

EMS is in place and maintained. Communication processes<br />

around environmental issues both within and outside of Shell<br />

are detailed.<br />

‘Risk Management’ covers the identification of environmental<br />

aspects and legal and other requirements that relate to our<br />

environmental aspects. It also contains the operational<br />

framework for managing significant environmental aspects.<br />

‘<strong>Environmental</strong> aspects’ are those elements of our activities<br />

that can interact with the environment (see Section 3.3).<br />

Leadership and Commitment<br />

Policy and Strategic Objectives<br />

Organisation, Responsibilities,<br />

Resources, Competency<br />

Risk Management<br />

Processes, Assets and Standards<br />

Planning<br />

Implementation<br />

(Reporting & Monitoring)<br />

Assurance<br />

(Including Management Review)<br />

Corrective Action<br />

‘Processes, Assets and Standards’ describes the processes<br />

that are undertaken to support our assets and the relevant<br />

standards. Processes and standards contain environmental<br />

information to ensure that the EMS is effectively implemented<br />

in the assets.<br />

‘Planning’ contains our Health, Safety and <strong>Environmental</strong><br />

(HSE) Plans, which contain objectives, targets and improvement<br />

programmes. In preparing our HSE Plans, we take into account<br />

our environmental aspects and legal and other requirements.<br />

This enables us to implement our HSE Policy commitments<br />

to achieve continuous performance improvement and ensure<br />

compliance with the law.<br />

‘Implementation (reporting and monitoring)’ covers the<br />

monitoring of activities that can have a significant environmental<br />

impact and monitoring of environmental performance. This<br />

section also covers the periodic evaluation of compliance with<br />

legal and other requirements.<br />

‘Assurance’ covers the internal audit process by which we<br />

check that the EMS continues to be effectively implemented.<br />

Management reviews are also conducted annually to ensure<br />

the EMS is effective and delivering improvements.

3.2 HSE Commitment and Policy<br />

Graphics, Media & Publication Services EPE : EPT-IT-EI Ref. No. 020037<br />

We care...<br />

Royal Dutch/Shell Group Commitment to Health, Safety and Environment<br />

In the Group we are all committed to:<br />

• pursue the goal of no harm to people;<br />

• protect the environment;<br />

• use material and energy efficiently to provide our products and services;<br />

• develop energy resources, products and services consistent with these aims;<br />

• publicly report on our performance;<br />

• play a leading role on promoting best practice in our industries;<br />

• manage HSE matters as any other critical business activity;<br />

• promote a culture in which all Shell employees share this committment.<br />

In this way we aim to have an HSE performance we can be proud of, to earn the confidence<br />

of customers, shareholders and society at large, to be a good neighbour and to contribute to<br />

sustainable development.<br />

Royal Dutch/Shell Group Health, Safety and Environment Policy<br />

Every Shell company:<br />

• has a systematic approach to HSE management designed to ensure<br />

compiance with the law and to achieve continuous performance improvement;<br />

• sets targets for improvement and measures, appraises and reports<br />

performance;<br />

• requires contractors to manage HSE in line with this policy;<br />

• requires joint ventures under its operational control to apply this policy and<br />

uses influence to promote it in other ventures;<br />

• includes HSE performance in the appraisal of all staff and rewards accordingly.<br />

Endorsed by the Committee of Managing Directors, March 1997 Reviewed 2000<br />

... all of us have a role to play<br />

“Each of us has a right and duty to intervene with unsafe acts and conditions or<br />

when activities are not in compliance with this HSE policy and Commitment”.<br />

June 2004<br />

Malcolm Brinded Thomas M. Botts<br />

Executive Director of Exploration & Production Executive Vice President EP Europe<br />

James M. Smith<br />

UK Country Chairman

3.3 The <strong>Environmental</strong> Aspects of our Operations<br />

<strong>Environmental</strong> aspects are elements of our activities, products<br />

or services that can interact with the environment. Figure<br />

3 illustrates the main environmental aspects we have identified<br />

for our offshore locations. We have grouped our significant<br />

environmental aspects into four areas:<br />

• Atmospheric emissions<br />

• Energy use<br />

• Discharges to water including spills<br />

• Waste<br />

3.3.1 Atmospheric Emissions<br />

We burn natural gas and sometimes diesel as fuel on our<br />

facilities to generate the power that is required to run our<br />

operations. In addition, our facilities are designed to ‘flare’<br />

(burn) and ‘vent’ (release unignited) a certain amount of<br />

hydrocarbon gas for safety reasons. Most locations have a<br />

continuous stream of gas to flare or vent designed to stop<br />

the ingress of air into the facilities that could cause explosive<br />

mixtures in the process. Additional amounts are also released<br />

through this route during installation shutdown, when all<br />

hydrocarbon gas systems are depressurised and when certain<br />

equipment items are out of service (either planned or<br />

unplanned).<br />

The majority of our emissions to air are the products of<br />

these combustion processes. The emissions include carbondioxide,<br />

nitrogen oxides, sulphur dioxide, carbon monoxide,<br />

unburnt hydrocarbons and particulates. These atmospheric<br />

pollutants have global (climate change), regional (acidification)<br />

and local (air quality) effects.<br />

3.3.2 Energy Use<br />

In addition to atmospheric emissions, consumption of diesel<br />

and gas to provide energy is an important issue from the<br />

point of view of depletion of natural resources. We are<br />

currently developing GHG and Energy Management Plans<br />

for each of our major installations.<br />

3.3.3 Discharges to water<br />

Most of our discharges to water consist of surplus water<br />

from our oil and gas wells. This "produced water" is a mixture<br />

of naturally occurring water in the reservoir, and seawater<br />

that has been injected into the reservoir to support the<br />

pressure and sweep oil towards the production wells. We<br />

separate the produced water from the oil and gas, and discharge<br />

most of it into the sea. The separated water contains a small<br />

amount of residual oil as well as chemicals both naturally<br />

occurring such as salts, and others such as corrosion inhibitors<br />

and de-oilers.<br />

As well as produced water, many of our wells produce sand<br />

and scale which accumulates in pipework and vessels and<br />

needs to be cleaned out from time to time. When pipework<br />

and vessels are cleaned, the sand and scale is also cleaned to<br />

remove as much oil as possible before it is discharged.<br />

Produced sand contains similar materials to produced water<br />

and may also contain small amounts of Naturally Occurring<br />

Radioactive Material (NORM) which may occur naturally in<br />

an oil or gas reservoir. All discharges are monitored and<br />

recorded.<br />

We also use seawater for cleaning purposes. After use any<br />

‘wash water’ is cleaned before being discharged back into the<br />

sea via specially designed drains. Legally permitted levels of<br />

cleaning chemicals and some oil may remain in the water<br />

when it is discharged. Other drains on our installations<br />

discharge surface water, such as accumulated rainwater or<br />

seawater, which do not normally contain any oil or chemicals,<br />

as well as emergency fire-fighting water and foam, directly<br />

into the sea.<br />

Finally the smallest contribution to our discharges to the sea<br />

comes from leaks and spills from our wells and equipment.<br />

Such spills may consist of oil, gas, chemicals, or a mixture of<br />

the three. Continuous monitoring, adherence to procedures<br />

and rehearsal of emergency response keeps these unintended<br />

discharges to a minimum.<br />

3.3.4 Waste<br />

A variety of solid and liquid wastes are produced from both<br />

our on and offshore operations including drilling waste such<br />

as cuttings and spent muds; wastes such as oily rags, fluorescent<br />

tubes and batteries, and also office and packaging wastes such<br />

as paper, card and wood.<br />

Some wastes can be treated and re-injected into reservoirs<br />

e.g. drill cuttings under the appropriate legal licences. However<br />

the majority of wastes are shipped to shore for onshore<br />

disposal. All waste, irrespective of where it is produced, is<br />

transferred to licensed facilities for either treatment and<br />

disposal; or sorting and bulking prior to transportation for<br />

final disposal.<br />

All waste is transported and disposed of in accordance with<br />

our European waste management policy, in particular through<br />

application of the waste hierarchy to prevent and reduce<br />

waste as far as possible and minimise the volume of waste<br />

to landfill.

RAW AND<br />

AUXILIARY<br />

MATERIAL<br />

ENERGY<br />

MATERIALS<br />

WATER<br />

REUSE<br />

NOISE, DUST<br />

ODOUR OR LIGHT<br />

PRODUCT<br />

EXTRACTION<br />

RADIATION<br />

MATERIALS TO<br />

DEEP SUBSOIL<br />

GASEOUS<br />

EMMISIONS<br />

PRODUCT<br />

WASTE<br />

LIQUID<br />

FLOWS<br />

TO WATER<br />

LIQUID FLOWS<br />

TO THE SOIL<br />

Figure 3 - Summary of <strong>Environmental</strong> Aspects

4. ENVIRONMENTAL PERFORMANCE<br />

4.1 Our <strong>Environmental</strong> Goals, Objectives and Targets<br />

Shell Exploration and Production in Europe maintains<br />

environmental management systems that are certified to<br />

the ISO14001 standard and we strive for continuous<br />

environmental improvement through the following strategic<br />

objectives, covering our significant environmental aspects<br />

(Section 3.3):<br />

• Reduce discharges to sea and emissions to air through<br />

continuous improvement, operational excellence<br />

and deployment of technological step changes.<br />

• Manage use of energy and resources and minimize<br />

the generation of waste.<br />

• Work with others to maintain ecosystems and<br />

minimise interference with biodiversity and<br />

vulnerable areas.<br />

• Optimise the potential for lateral learning from cooperation<br />

with external environmental stakeholders<br />

Improvement programmes to deliver the above cover legal<br />

compliance and the fourteen elements of the Shell Group<br />

Global <strong>Environmental</strong> Standards (GES).<br />

Each objective is translated into key targets (where relevant)<br />

and improvement programmes year on year to drive<br />

continuous improvement across our UK operations. The<br />

current targets, performance and improvement plans for<br />

each objective are summarised in the sections below. More<br />

environmental data for 2004-2007 are provided in<br />

Appendix 1.

4.2 Reduce Emissions and Discharges<br />

Our first objective drives our requirement to improve the<br />

way we conduct our activities by focusing on reducing key<br />

emissions and discharges.<br />

4.2.1 Greenhouse Gas Management<br />

Burning fuel gas and diesel, flaring and venting are our main<br />

sources of GHG emissions, although there are also<br />

contributions from transportation and office energy use.<br />

We support the Shell Group’s publicly committed voluntary<br />

target to have CO2 emissions in 2010 5% below the 1990<br />

level. Annual GHG targets are established for our European<br />

activities and these are translated into targets for each of<br />

our assets.<br />

Figure 4 shows the mass of GHG emitted from each of the<br />

main sources on each of our major platforms and onshore<br />

plants during 2007. In 2007 we emitted 3.51 million tonnes<br />

of GHG from our UK operations and activities.<br />

Approximately 78% of the GHG emissions came from<br />

combustion and 22% from flaring and venting. After taking<br />

into account the effect of portfolio changes (we sold Auk<br />

and Fulmar fields in November 2006), GHG emissions were<br />

2.1% lower than in 2006.<br />

In 2007, we flared 230,000 tonnes of hydrocarbon gas. This<br />

is significantly lower than the 272,000 tonnes flared in 2006<br />

GHG Breakdown tonnes<br />

350,000<br />

300,000<br />

250,000<br />

200,000<br />

150,000<br />

100,000<br />

50,000<br />

0<br />

(2006 figures corrected for portfolio changes). Reductions<br />

were seen on most installations, Cormorant Alpha being the<br />

only installation flaring significantly more than in 2006. This<br />

rise was due to a failure of the main compressor bundle<br />

which resulted in flaring of associated gas for several weeks<br />

During 2007 we operated under Phase 1 of the mandatory<br />

EU Emissions Trading Scheme for CO2 (EU ETS). It<br />

should be noted that in 2008 the EU ETS will be expanded<br />

to Phase 2 which will include CO2 from flaring. Work is in<br />

progress to upgrade flare monitoring and reporting to achieve<br />

the higher accuracies needed for EU ETS.<br />

There are programmes underway in the business aimed at<br />

future reductions in GHG from our facilities, including:<br />

• Increased focus on operational flaring. Following our<br />

adoption of the new Shell Global <strong>Environmental</strong><br />

Standards, we have enhanced our controls on operational<br />

flaring.<br />

• Implementation of recommendations made by energy<br />

efficiency assessments made as part of PPC permit<br />

applications. In 2008, we plan to implement 16 different<br />

projects.<br />

Fuel Gas<br />

Diesel<br />

Flare and Vent<br />

Other<br />

Anasuria<br />

Brent Alpha<br />

Brent Bravo<br />

Brent Charlie<br />

Brent Delta<br />

Cormorant Alpha<br />

Curlew<br />

Dunlin<br />

Eider<br />

Gannet<br />

Leman<br />

Nelson<br />

North Cormorant<br />

Pierce<br />

Sean<br />

Shearwater<br />

Solepit Clipper<br />

Tern<br />

Mobile Rigs<br />

Bacton<br />

Fife<br />

St Fergus<br />

Figure 4 - Greenhouse Gas Emissions

4.2.2 Oil in Produced Water<br />

An annual oil in produced water target is established for our<br />

European activities and is translated into targets for each of<br />

our assets. These discharges are subject to the<br />

recommendations under the OSPAR Convention implemented<br />

in the UK through The Offshore Petroleum Activities (Oil<br />

Pollution Prevention and Control) Regulations 2006 and also<br />

our own Shell Group <strong>Environmental</strong> Standards. In 2001<br />

OSPAR set a goal to ensure that the total quantity of oil in<br />

produced water discharged into the sea in the year 2006 from<br />

all offshore installations within the jurisdiction of each OSPAR<br />

member country should be reduced by a minimum of 15%<br />

compared to the equivalent discharge in the year 2000. In<br />

2007 our installations discharged 868 tonnes of oil in produced<br />

water to sea compared with 1,800 tonnes in 2000, a reduction<br />

Oil to Sea (tonnes)<br />

200<br />

180 Actual Oil to Sea (tonnes)<br />

160<br />

2007 Target (tonnes)<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

Anasuria<br />

Brent Bravo<br />

Brent Charlie<br />

Brent Delta<br />

Cormorant Alpha<br />

Curlew<br />

Dunlin (Incl. Osprey Merlin)<br />

Eider<br />

Gannet<br />

Leman<br />

Nelson<br />

North Cormorant<br />

Pierce<br />

Sean<br />

Shearwater<br />

Solepit Clipper<br />

Tern (Incl. Hudson)<br />

Figure 5 - Oil Discharged to Sea<br />

of more than 50% (although we have divested some assets<br />

* in the period).<br />

The chart below shows the actual amount of oil discharged<br />

to sea by each of our installations compared to our targets.<br />

Most of our installations discharged below our targets and<br />

the total oil to sea was well within our overall company target<br />

for 2007. However, the Dunlin platform went over target<br />

owing to less than expected performance of the chemical deoiler<br />

and low production volumes passing through the separate<br />

Osprey/Merlin process which reduces separation of oil.<br />

Nelson missed its target because the Produced Water Re-<br />

Injection (PWRI) system was not working to its full capacity.<br />

* Kittiwake field divested November 2003, Ketch & Schooner fields divested March 2005,<br />

Auk and Fulmar fields divested November 2006

Figure 6 shows the actual volume of produced water discharged<br />

to sea by each of our installations and the average measured<br />

concentration of oil dispersed within it. On three installations;<br />

Sean, Shearwater and Solepit Clipper, although the volume<br />

of discharge is small, the concentration of oil in produced<br />

water is well above 30 mg/l.<br />

The Sean field is a swing gas producer and started-up<br />

production for only two months at the end of 2007, the<br />

average OIW concentration was 159 mg/l.<br />

On Shearwater there has been a decrease in OIPW overboard<br />

Water Discharged 000’s m3<br />

9,000<br />

8,000<br />

7,000<br />

6,000<br />

5,000<br />

4,000<br />

3,000<br />

2,000<br />

1,000<br />

0<br />

Anasuria<br />

Brent Bravo<br />

quality in 2007 due to excess sand production and bringing<br />

on line production from satellite fields which cools down the<br />

production process and hence impairs the oil water separation<br />

process. In 2008, we will continue to search for a solution.<br />

On Solepit Clipper, despite installing two centrifuges in 2005<br />

at a cost of some £1.9 million, the problem persists particularly<br />

during periods of less water throughput. Therefore we are<br />

now planning to install PWRI surface facilities in 2008 and<br />

then prepare a well and commence produced water re-injection<br />

into a subsurface reservoir in 2009.<br />

Brent Charlie<br />

Brent Delta<br />

Cormorant Alpha<br />

Curlew<br />

Dunlin (inc Osprey Merlin)<br />

Eider<br />

Gannet<br />

Leman<br />

Nelson<br />

North Cormorant<br />

Pierce<br />

Sean<br />

Shearwater<br />

Solepit Clipper<br />

Tern (inc Hudson)<br />

Figure 6 - Produced Water Discharged to Sea<br />

4.2.3 Accidental spills<br />

All loss of containment (whether it reaches the sea or is<br />

contained and recovered on the location) is reported through<br />

our incident reporting system and subject to assessment and<br />

incident investigation depending on the risk posed to the<br />

environment. See Appendix 2 for more details of reportable<br />

spills.<br />

Analysis of our spills shows an increase from an average of<br />

around 10 significant spills (oil, gas & chemicals > 100 kg)<br />

over recent years to 20 in 2007. The causes of these spills<br />

Water Discharged 000’s m3<br />

OIW Concentration mg/l<br />

fall into three main categories: equipment failure, human<br />

error and corrosion. We have instigated a programme to<br />

review these spills in order to understand the root causes<br />

better.<br />

For 2008 onwards, an annual target for significant oil spills<br />

(>100 kg) of 24 tonnes has been established for our European<br />

activities. Because of their variable nature, this is not translated<br />

into targets for each of our assets.<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0

4.2.4 Chemical Management<br />

Our use and discharge of chemicals in production and drilling<br />

operations is subject to The Offshore Chemicals Regulations<br />

2002 (OCR) and our own Shell Group Standards. The historic<br />

trend in production chemical discharge is relatively stable.<br />

This is the result of two counteracting trends where our<br />

efforts to switch to better chemicals and reduce treatment<br />

concentrations are balanced by greater consumption due to<br />

increasing water production.<br />

Chemicals Discharged tonnes<br />

2,000<br />

1,800<br />

1,600<br />

1,400<br />

1,200<br />

1,000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

Production chemical use and discharge varies amongst our<br />

installations. Those in the Southern North Sea (Clipper,<br />

Leman, Sean) use relatively little because they are predominantly<br />

gas processing facilities; whereas our Northern North Sea<br />

installations use more owing to factors like reservoir chemistry,<br />

water cut and high produced and injected water volumes. As<br />

can be seen from the chart, we predominantly use low<br />

risk/hazard products, but some platforms use a higher level<br />

of SUBs mainly corrosion inhibitors that are highly effective<br />

but carry substitution warnings. We are committed to phasing<br />

out these chemicals. Our substitution programme is delivering<br />

an overall decline in the use of SUBs, but the numbers fluctuate<br />

as a result of the re-classifying of products when new rules<br />

are applied to the screening process by CEFAS, or when new<br />

data is submitted to CEFAS by the chemical vendors.<br />

E/D/Gold Discharged Others Discharged SUB Discharged<br />

Figure 7 shows the total weight of chemicals discharged to<br />

sea by each of our installations. Discharges have been grouped<br />

into two categories, with the green colour representing the<br />

'low risk/hazard' groups and the red depicting the 'more<br />

hazardous/higher risk' groups. Overlying this is a line that<br />

represents ‘SUB’s – chemicals which have been flagged with<br />

a Substitution Warning by the Centre for Environment,<br />

Fisheries and Aquaculture Science (CEFAS).<br />

Anasuria<br />

Brent Alpha<br />

Brent Bravo<br />

Brent Charlie<br />

Brent Delta<br />

Clipper<br />

Cormorant Alpha<br />

Curlew<br />

Dunlin<br />

Eider<br />

Gannet<br />

Goldeneye<br />

Leman<br />

Nelson<br />

North Cormorant<br />

Pierce<br />

Sean<br />

Shearwater<br />

Tern<br />

Figure 7 - Production Chemicals Disharged<br />

Offshore Chemical Notification<br />

Scheme (OCNS)<br />

CHARM Model Hazard Quotient<br />

Highest Risk<br />

Lowest Risk<br />

Non-CHARM Model Letter Grouping<br />

Highest hazard<br />

Poses Little<br />

or No Risk<br />

Purple<br />

Orange<br />

Blue<br />

White<br />

Silver<br />

Gold<br />

A<br />

B<br />

C<br />

D<br />

E

4.3 Use of Energy, Resource and Waste Minimisation<br />

4.3.1 Energy Use and Resource Management<br />

The efficient use of energy and the minimisation of upset<br />

flaring is an integral part of our operational excellence<br />

philosophy to minimise the waste from our operations and<br />

conserve valuable natural resource. They also represent the<br />

main areas of improvement with regard to reducing our<br />

emissions of GHG as described in Section 4.2.1 above.<br />

Energy use is mainly from power generation on our locations<br />

where we burn fuel gas or diesel to run pumps, compressors,<br />

engines, heaters and general platform services. We also report<br />

on electrical energy purchased onto sites and offices. A<br />

certain amount of flaring is a design feature at most of our<br />

locations for safety reasons during steady operations, but<br />

additional amounts of ‘process upset’ flaring occurs when<br />

equipment fails or during planned shutdown of facilities for<br />

maintenance work.<br />

Although energy use has reduced, production rates have<br />

dropped at a faster rate leading to an increase in energy<br />

intensity over the last two years. Increasing energy intensity<br />

is characteristic of maturing fields in the North Sea and is<br />

caused by such factors as reducing reservoir pressures and<br />

increasing water cuts of the wells. Improvement programmes<br />

have already been described under 4.2.1 GHG Management.<br />

MOST<br />

FAVOURED<br />

OPTION<br />

LEAST<br />

FAVOURED<br />

OPTION<br />

Figure 8 - The Waste Hierarchy<br />

4.3.2 Waste Minimisation<br />

In order to move waste disposal up the waste hierarchy, we<br />

work closely with our contractors to reduce the volume of<br />

waste going to landfill. While our overall tonnage of waste<br />

production increased by 10% from 2006 to 2007, the<br />

proportion sent to landfill was reduced by 30%. This can be<br />

attributed mainly to the success of a mud treatment process<br />

developed by our waste contractors. Prior to this development,<br />

waste drilling fluids were mixed with solids and land-filled,<br />

thereby actually increasing the volume of waste to landfill.<br />

The new process reduces the requirement for landfill to less<br />

than 30% of the original volume.<br />

During 2007, our assets were encouraged to segregate their<br />

waste effectively, thereby ensuring legal compliance and<br />

maximising recycling opportunities. A series of skip<br />

segregation exercises were held throughout the year and the<br />

results fed back to the assets to demonstrate areas for<br />

improvement. Proven to be a very useful tool for raising<br />

awareness, the number of these audits has been doubled in<br />

2008.<br />

Other smaller changes to reduce waste in the offices have<br />

been introduced and similar initiatives are being developed<br />

in 2008 which will encourage our staff awareness on waste<br />

management and give further success in years to come.<br />

PREVENTION<br />

MINIMISATION<br />

REUSE<br />

RECYCLING<br />

ENERGY RECOVERY<br />

DISPOSAL

tonnes<br />

1,200<br />

1,000<br />

800<br />

600<br />

400<br />

200<br />

0<br />

Figure 9 shows the weight of waste produced on each<br />

of our production installations grouped into hazardous<br />

and non-hazardous categories. On Brent Delta the high<br />

level of hazardous waste was mostly drilling fluids from<br />

increased well engineering activities, namely one well on<br />

DISCHARGE<br />

41%<br />

Hazardous Waste tonnes<br />

Non-Hazardous Waste tonnes<br />

Anasuria<br />

Brent Alpha<br />

Brent Bravo<br />

Brent Charlie<br />

Brent Delta<br />

Cormorant Alpha<br />

Curlew<br />

Dunlin<br />

Eider<br />

Gannet<br />

Leman<br />

Nelson<br />

North Cormorant<br />

Pierce<br />

Sean<br />

Shearwater<br />

Solepit Clipper<br />

Tern<br />

Figure 9 - Waste Production<br />

TREATMENT<br />

10%<br />

a satellite field (Barnacle) developed by a third party<br />

(Energy Development Partners) responsible for its own<br />

permits. On Cormorant Alpha, the peak was from around<br />

300 tonnes of steel tubulars and 300 tonnes of nonhazardous<br />

chemicals.<br />

REUSE<br />

6%<br />

RECYCLING<br />

16%<br />

LANDFILL<br />

20%<br />

This chart shows how we managed our waste in 2007 by showing the proportion going to<br />

each disposal route.<br />

Figure 10 - Summary of Waste Fates<br />

WASTE<br />

TO ENERGY<br />

7%<br />

INCINERATION<br />

0%

4.4 BIodiversity and Vulnerable Areas<br />

The Shell Group Biodiversity Policy and Commitment states<br />

our commitment to work with others to maintain ecosystems<br />

and respect protected areas through the application of<br />

environmental impact assessment and development of<br />

biodiversity action plans for operations in the areas of high<br />

biodiversity value.<br />

Two of our onshore facilities (Braefoot Bay Terminal and<br />

Bacton Gas Plant) operate in close proximity to (though not<br />

actually in) environmentally sensitive areas. In addition, several<br />

of our offshore installations and pipelines are located in the<br />

areas of potentially sensitive marine habitats. These sensitive<br />

sites and locations are recognised internally as “High<br />

Biodiversity Value Areas” according to the Shell Group<br />

Standards. We support these areas through membership of<br />

local forums and consultation with relevant national agencies.<br />

Using the <strong>Environmental</strong> Impact Assessment process, we<br />

apply appropriate controls for plants and installations and<br />

projects that have the potential to impact on these areas.<br />

4.5 Monitoring Seabed Impacts<br />

<strong>Environmental</strong> seabed surveys are one way to monitor the<br />

impacts of our activities. Contaminants enter the marine<br />

environment through discharge of cuttings, muds, produced<br />

water, and even deposition from the atmosphere. Seabed<br />

sediments provide a sink for these contaminants. Sediment<br />

quality and diversity of seabed plants and creatures are good<br />

indicators of impacts and recovery. It is important for us<br />

to have scientific evidence to evaluate our impacts, especially<br />

around older installations and those in proposed conservation<br />

areas. In 2007 we developed a long term seabed monitoring<br />

programme. Using a risk-based approach, several sites were<br />

selected for three and six year monitoring. The programme<br />

was reviewed and supported by BERR and JNCC. We started<br />

in 2007 with surveys around Brent and Gannet fields. Leman<br />

and Clipper fields are scheduled for surveying in 2008.<br />

4.6 Lateral Learning and Cooperation<br />

We believe in being involved in the environmental agenda in<br />

the local areas where we operate and in addressing wider<br />

regional and global concerns where we have a role to play.<br />

To this end, we participate in various stakeholder, government<br />

and industry fora and provide resources and expertise in key<br />

areas to help define our role in environmental protection.<br />

In addition, we jointly fund research and technology<br />

Paguridae (hermit crab) at Gannet D<br />

Anemones at Indefatigable J<br />

programmes in areas where more information or design work<br />

is required to enable us to decide the best way forward. For<br />

example, in 2007 we sponsored a Joint Industry study to<br />

investigate a metric for the assessment of the behavioural<br />

and audiological effects on underwater animals of man-made<br />

underwater noise.

5. Contacts<br />

This report aims to summarise the environmental controls, performance and programmes of Shell Exploration & Production<br />

Europe, as applicable to our UK operations and activities. This report will be updated and published annually on our external<br />

website.<br />

Our preferred route of publication is electronic although hard copies can be printed off as required by individuals accessing<br />

our external website.<br />

Further information can be obtained by contacting:<br />

EPE <strong>Environmental</strong> Discipline Lead – Ross Clephan<br />

HSE Department<br />

Shell U.K. Limited<br />

1 Altens Farm Road<br />

Aberdeen AB12 3FY<br />

Or calling (UK) 01224 882000 and asking for Ross Clephan or Alistair Cameron

APPENDIX 1 – SHELL EXPLORATION & PRODUCTION EUROPE<br />

UK – ENVIRONMENTAL DATA TABLE<br />

GHG (tonnes CO2 equivalent)<br />

Total Gas to Flare - incl. CO2 etc. (tonnes)<br />

Total Fuel Gas Used (tonnes)<br />

Total Diesel Used (tonnes)<br />

Energy Efficiency (GJ/tonne HC Equivalent)<br />

OIPW Oil to Sea (tonnes)<br />

Hazardous Waste (tonnes)<br />

Non-Hazardous Waste (tonnes)<br />

Production Chemical Use (tonnes)<br />

% Discharge<br />

Wells Chemical Use (tonnes)<br />

% Discharge<br />

Fines<br />

2004<br />

4,480,172<br />

326,582<br />

1,117,155<br />

73,171<br />

1.44<br />

1,274<br />

26,572<br />

14,560<br />

14,297<br />

60%<br />

46,481<br />

20%<br />

£7,000<br />

2005<br />

4,261,907<br />

358,112<br />

1,084,724<br />

70,098<br />

tonnes<br />

Scope: The figures shown above relate to all Shell operated offshore installations and 3rd Party fields that produce to them<br />

plus onshore plants and mobile rigs in the UK – all as reported to EEMS. Some changes are due to asset divestment.<br />

Global Warming Potential: The 2007 figure is lower than trend owing to divestments and several prolonged shutdowns.<br />

In 2008, the figures will be affected by:<br />

• Norwegian gas being piped to St Fergus<br />

• Nelson PWRI load and improved reliability<br />

• Further divestments<br />

Production Chemicals: 2007 chemical use was relatively high due to a single once-off activity on the Dunlin platform where<br />

15,000 tonnes of a foaming chemical was used to displace 'attic' oil from the seabed storage cells. In Figure 3 these are<br />

coloured orange at the base of the platform. The cells are now decommissioned and filled with water. Before decommissioning,<br />

the foaming chemical was used to displace oil downwards to the level of the withdrawal pipe within the cells. This single<br />

activity accounts for the higher use and the drop in percentage discharge. Without it chemical use and discharge would be<br />

very similar to 2006.<br />

1.68<br />

1,215<br />

10,760<br />

8,752<br />

12,079<br />

75%<br />

19,770<br />

22%<br />

£3,000<br />

2006<br />

4,066,604<br />

318,428<br />

1,046,907<br />

74,297<br />

1.95<br />

1,067<br />

33,094<br />

10,678<br />

11,853<br />

75%<br />

48,003<br />

6%<br />

£0<br />

2007<br />

3,510,783<br />

300,875<br />

906,955<br />

66,558<br />

2.03<br />

868<br />

36,177<br />

11,390<br />

26,908<br />

29%<br />

35,106<br />

11%<br />

£0

APPENDIX 2 - OIL AND CHEMICAL SPILLS AND OIL DISCHARGES<br />

Notifiable (PON 1) Oil and Chemical Spills Number<br />

Notifiable (PON 1) Oil and Chemical Spills Total Mass (tonnes)<br />

Spill of Sodium Bicarbonate solution due to a loading hose failure on Dunlin when pumping from a supply<br />

vessel.<br />

Subsea leak of crude oil from Gannet C due to a weld failure while carrying out pigging operations.<br />

Subsea leak of hydraulic fluid from Gannet D.<br />

Subsea leak of hydraulic fluid from Pierce.<br />

Spill of Monoethylene Glycol (MEG) on Goldeneye due to a pipe failure.<br />

Failure of bellows on cooling medium system on Shearwater resulted in the cooling system leaking onto the<br />

platform deck and then into the open drains system.<br />

While filling the Caravel Monotower, there was a leak of bentonite (natural clay) gel from a bellows installed<br />

around the gas export riser at the point where it exits the monotower a little above the seabed.<br />

PON 1 = Petroleum Operations Notice No.1<br />

We are required to notify the relevant authorities of all accidental/unplanned discharges or spills of oil or chemicals to sea,<br />

regardless of volume, using a PON1 to:<br />

• nearest Coastguard Station<br />

• Department for Business, Enterprise and Regulatory Reform;<br />

• Joint Nature Conservation Committee (JNCC)<br />

• any relevant Statutory Nature Conservation Agency<br />

The list of spills above shows only those greater than 2 tonnes.<br />

79<br />

319<br />

Brief Descriptions – Oil and Chemical Spills > 2 tonnes tonnes<br />

157<br />

3.2<br />

8.2<br />

41.8<br />

26.0<br />

39.5<br />

32.2

APPENDIX 3 - 2007 DRILLING LOCATIONS<br />

Well Start Date Rig Well Name<br />

19/05/06<br />

05/09/06<br />

05/09/06<br />

02/10/06<br />

16/10/06<br />

22/10/06<br />

15/11/06<br />

15/12/06<br />

19/12/06<br />

20/12/06<br />

21/12/06<br />

27/12/06<br />

29/01/07<br />

08/02/07<br />

13/02/07<br />

21/02/07<br />

10/03/07<br />

22/03/07<br />

25/03/07<br />

26/03/07<br />

02/05/07<br />

04/05/07<br />

06/05/07<br />

06/05/07<br />

11/05/07<br />

JW McLean<br />

GSF Magellan<br />

GSF Monarch<br />

Cormorant A<br />

JW McLean<br />

GSF Arctic 3<br />

Nelson<br />

TO 711<br />

GSF Britannia<br />

MSV Seawell<br />

Ocean Guardian<br />

MSV Seawell<br />

MSV Seawell<br />

MSV Seawell<br />

GSF Magellan<br />

GSF Monarch<br />

GSF Monarch<br />

GSF Monarch<br />

GSF Monarch<br />

GSF Monarch<br />

GSF Magellan<br />

GSF Monarch<br />

MSV Seawell<br />

MSV Seawell<br />

JW McLean<br />

Merganser A01 (ME)<br />

Shearwater A5s1<br />

Galleon PG10/05<br />

Cormorant A35s4 + s5<br />

Teal P2 + s1<br />

Gannet D A05s2 + s3<br />

Nelson N26W / X / Y<br />

Pierce 23/22a-LA3<br />

Carrack QA-06<br />

Corm AU-W4s1<br />

Penguin D3<br />

Corm AU-P7s1<br />

Corm AU-P2s5<br />

Corm AU-P4s3<br />

Shearwater A8s1<br />

Galleon PG07/04<br />

Inde L1225<br />

Inde L1215<br />

Inde L1210<br />

Inde L1200<br />

Shearwater A4<br />

Inde L1220<br />

Gannet C A101s2<br />

Gannet C A103<br />

Starling 29/3-PW<br />

Well Start Date Rig Well Name<br />

17/05/07<br />

20/05/07<br />

22/05/07<br />

26/05/07<br />

01/06/07<br />

11/06/07<br />

18/06/07<br />

21/06/07<br />

09/07/07<br />

22/07/07<br />

24/07/07<br />

31/07/07<br />

10/08/07<br />

12/08/07<br />

18/08/07<br />

19/08/07<br />

29/08/07<br />

31/08/07<br />

02/09/07<br />

17/09/07<br />

22/09/07<br />

09/10/07<br />

29/10/07<br />

23/11/07<br />

07/12/07<br />

MSV Seawell<br />

GSF Arctic 4<br />

MSV Seawell<br />

GSF Monarch<br />

MSV Seawell<br />

MSV Seawell<br />

MSV Seawell<br />

JW McLean<br />

MSV Seawell<br />

MSV Seawell<br />

MSV Seawell<br />

MSV Seawell<br />

MSV Seawell<br />

JW McLean<br />

Tern Alpha<br />

MSV Seawell<br />

GSF Britannia<br />

MSV Seawell<br />

GSF Britannia<br />

JW McLean<br />

GSF Magellan<br />

JW McLean<br />

MSV Seawell<br />

GSF Magellan<br />

MSV Seawell<br />

Gannet C A102<br />

Curlew D-P4 + P4A<br />

Gannet C A202<br />

Inde L1205<br />

Kingfisher BP1.1<br />

Osprey U-P1s2<br />

Osprey U-W4s1<br />

Starling 29/3-PE<br />

Merlin P11<br />

Pierce A2Y<br />

Pierce A5<br />

Pierce A4<br />

Pierce B2<br />

Corm AU-P8s1<br />

Tern A09s1<br />

Pelican U-P12s1<br />

Caravel AB QR02/02<br />

Pelican U-P11<br />

Caravel AH QR01/04<br />

Corm AU-W3s1<br />

Shearwater A9<br />

Corm AU-W2<br />

Bittern A3<br />

Shearwater A9<br />

Gannet B A01s1

APPENDIX 4 -ABBREVIATIONS<br />

Asset Use internally in Shell to describe a collection of locations, typically four to six offshore platforms and<br />

supporting services, but also includes onshore plants and interconnecting pipelines.<br />

Associated Gas Gas liberated from oil as the pressure is reduced from subsurface conditions to the surface separation<br />

facilities.<br />

Benthos Flora (plants) and fauna (animals) found at the bottom of ocean, sea or lake.<br />

Bentonite Natural clay used to thicken/gel well engineering and completion fluids.<br />

BERR Department for Business Enterprise & Regulatory Reform (formerly Department of Trade and Industry<br />

DTI).<br />

CEFAS Centre for Environment, Fisheries & Aquaculture Science<br />

CMS Corporate Management System<br />

De-oiler Chemical used in the production process to promote separation of oil from produced water<br />

EEMS <strong>Environmental</strong> Emissions Monitoring System (Oil & Gas UK)<br />

EU ETS Council Directive 2003/87/EC establishing a scheme for greenhouse gas emission allowance trading<br />

with the community<br />

EMS <strong>Environmental</strong> Management System<br />

EP Exploration and Production<br />

FPSO Floating Production, Storage and Offloading vessel<br />

GES Shell Group Global <strong>Environmental</strong> Standards<br />

GHG Greenhouse Gases (mainly carbon dioxide, methane, nitrous oxide, CFC’s and HCFC’s)<br />

ISO14001 International Standard Specification for <strong>Environmental</strong> Management Systems.<br />

JNCC Joint Nature Conservation Committee<br />

MEG Monoethylene Glycol<br />

NUI Normally Unmanned Installation<br />

OCNS Offshore Chemical Notification Scheme<br />

OIPN Oil In Produced Water<br />

OPPC Offshore Petroleum Activities (Oil Pollution Prevention and Control) Regulations 2005<br />

OSPAR Convention for the Protection of the Marine Environment of the North-East Atlantic. In 1998 this<br />

replaced the Oslo Convention (for the Prevention of Marine Pollution by Dumping from Ships and<br />

Aircraft) and the Paris Convention (for the Prevention of Marine Pollution from Land-Based Sources).<br />

PPC Pollution Prevention and Control Act 1999 and Offshore Combustion Installations (Prevention and<br />

Control of Pollution) Regulations 2001<br />

PWRI Produced Water Re-Injection<br />

TEG Triethylene Glycol (antifreeze)<br />

UMC Underwater Manifold Centre (Subsea production)

![Download Shell AutoGas Stationen [Stand: Januar 2013] (PDF](https://img.yumpu.com/9982753/1/190x245/download-shell-autogas-stationen-stand-januar-2013-pdf.jpg?quality=85)