Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Jobber drills with straight shank DIN 338

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Precision Drilling Tools<br />

2005

Precision Drilling Tools<br />

2005<br />

This edition supersedes all previous editions.<br />

We reserve the right to modify the design as a result of<br />

new developments or modified standards.<br />

Claims due to any printing errors, including the technical specifications,<br />

are not admitted.<br />

0000 8,009/0408-IX-06<br />

This publication may not, in part or whole<br />

be reproduced.

Important hints<br />

We distinguish between standard range and obsolete range<br />

The basis of our range is the standard range, which we have designed to enable the economical solution of<br />

most cutting tasks. The products in our standard range are produced in batches and are generally in stock,<br />

i.e. available immediately. Tools from the standard range are illustrated by black points in the catalogue.<br />

The products in our obsolete range are seldom required (less current). They are illustrated by rings in the<br />

catalogue and are available only as long as the product is in stock.<br />

Once out of stock they can be obtained by special order, prices on request.<br />

Production capability exists at Hartner for all tools in the obsolete range! The ordering process is therefore<br />

usually quick and simple.<br />

For your information: structure of the table at the program pages<br />

Tool material<br />

Solid carb<br />

Article no.<br />

Solid carbide<br />

Price group<br />

Cutting direction<br />

Type or form<br />

Surface finish<br />

○<br />

<br />

○<br />

○<br />

○<br />

<br />

○<br />

○

Quick Reference<br />

Straight Shank Twist Drills<br />

made of HSS, HSS-E, Carbide<br />

bright and coated<br />

Taper Shank Twist Drills<br />

made of HSS, HSS-E, Carbide<br />

bright and coated<br />

TS-Drills<br />

High-Tech-Tools made of Carbide<br />

bright and coated<br />

Step Drills<br />

Stub step <strong>drills</strong>, subland <strong>drills</strong> made of HSS<br />

<strong>with</strong> <strong>straight</strong> <strong>shank</strong> and taper <strong>shank</strong><br />

Center Drills<br />

made of HSS, HSS-E, Carbide<br />

bright and coated<br />

Multiplex<br />

Twist drill system <strong>with</strong> interchangeable blade<br />

and internal cooling<br />

Additional Charges<br />

Manufacturerʼs Quality Certifications<br />

Technical Part<br />

Dimensions, definitions, recommendations

Important Hints<br />

Conditions of sale<br />

Goods supplied are subject to our conditions,<br />

available on request.<br />

Conditions of sale for special tools<br />

When ordering special tools, the quantity delivered can deviate by an average of 10%, at least 2 items from<br />

the original order. Payment is for quantity supplied.<br />

Conditions of sale for small batches<br />

On small orders, an additional surcharge may be added.<br />

Packaging details<br />

Tool group Standard Units per package<br />

Straight <strong>shank</strong> HSS<br />

twist <strong>drills</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

<strong>DIN</strong> 1897<br />

and similar Works standards<br />

<strong>DIN</strong> 339<br />

<strong>DIN</strong> 340<br />

and similar Works standards<br />

≤ Ø 7.50 mm packed in units of 10<br />

> Ø 7.50 ... Ø 10.60 mm packed in units of 5<br />

> Ø 10.60 mm 1 unit per package<br />

≤ Ø 6.70 mm packed in units of 10<br />

> Ø 6.70 ... Ø 10.60 mm packed in units of 5<br />

> Ø 10.60 mm 1 unit per package<br />

<strong>DIN</strong> 1869 ≤ Ø 7.50 mm packed in units of 10<br />

> Ø 7.50 ... Ø 10.60 mm packed in units of 5<br />

> Ø 10.60 mm 1 unit per package<br />

Taper <strong>shank</strong> HSS<br />

twist <strong>drills</strong><br />

all <strong>DIN</strong> standards<br />

and Works standards<br />

all sizes supplied 1 unit per package<br />

Carbide and carbide tipped<br />

twist <strong>drills</strong><br />

all <strong>DIN</strong> standards<br />

and Works standards<br />

all sizes supplied 1 unit per package<br />

Micro-precision <strong>drills</strong> <strong>DIN</strong> 1899 all sizes supplied 10 units per package<br />

Centre <strong>drills</strong> <strong>DIN</strong> 333<br />

form A, form R<br />

<strong>DIN</strong> 333<br />

form B<br />

≤ Ø 4.00 mm packed in units of 10<br />

> Ø 4.00 mm 1 unit per package<br />

≤ Ø 2.50 mm packed in units of 10<br />

> Ø 2.50 mm 1 unit per package<br />

Bank details<br />

Deutsche Bank AG Albstadt<br />

BLZ 653 700 75<br />

Account no. 146 415<br />

SWIFT-Code DEUT DE SS 653<br />

IBAN-Code DE74653700750014641500<br />

2

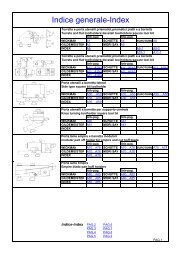

Contents<br />

Arranged in ascending order by code number.<br />

Article<br />

no.<br />

Page<br />

Price<br />

group<br />

Standard<br />

Surface<br />

finish<br />

Description Tool material Type<br />

81010 15 30 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

81011 15 34 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E N<br />

81013 25 34 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, INOX-DRILL HSS-E IS<br />

81015 15 34 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

81017 15 32 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

81020 30 34 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS H<br />

81025 30 34 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS H<br />

81030 30 34 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS W<br />

81035 30 38 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS W<br />

81040 25 36 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

81041 25 36 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FN<br />

81045 25 38 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

81061 25 34 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E S<br />

81110 51 32 <strong>DIN</strong> 1897 Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

81115 51 34 <strong>DIN</strong> 1897 Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

81120 59 38 <strong>DIN</strong> 1897 Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS H<br />

81130 59 38 <strong>DIN</strong> 1897 Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS W<br />

81140 57 36 <strong>DIN</strong> 1897 Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

81145 57 38 <strong>DIN</strong> 1897 Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

81171 51 34 <strong>DIN</strong> 1897 Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E V<br />

81173 51 38 <strong>DIN</strong> 1897 Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E IS<br />

81176 51 38 <strong>DIN</strong> 1897 Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E V<br />

81190 72 34 Works std. Double ended body <strong>drills</strong> HSS N<br />

81191 70 34 Works std. Spotting <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 120° HSS N<br />

81192 70 34 Works std. Spotting <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 90° HSS N<br />

81210 81 34 <strong>DIN</strong> 339 Bushing <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

81310 83 32 <strong>DIN</strong> 340 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

81311 83 34 <strong>DIN</strong> 340 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E N<br />

81315 83 38 <strong>DIN</strong> 340 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

81320 92 34 <strong>DIN</strong> 340 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS H<br />

81330 92 34 <strong>DIN</strong> 340 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS W<br />

81340 88 36 <strong>DIN</strong> 340 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

81341 88 36 <strong>DIN</strong> 340 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FN<br />

81350 92 36 <strong>DIN</strong> 340 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FW<br />

81361 88 34 <strong>DIN</strong> 340 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E S<br />

81410 96 34 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 1 HSS N<br />

81440 96 36 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 1 HSS FN<br />

81441 97 36 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 1 HSS-E FN<br />

81450 96 38 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 1 HSS FW<br />

81510 100 34 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 2 HSS N<br />

81540 100 36 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 2 HSS FN<br />

81541 101 38 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 2 HSS-E FN<br />

81550 100 38 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 2 HSS FW<br />

81610 103 38 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 3 HSS N<br />

81640 103 36 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 3 HSS FN<br />

81650 103 38 <strong>DIN</strong> 1869 Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 3 HSS FW<br />

81740 105 36 Works std. Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

81810 106 38 <strong>DIN</strong> 1898 Taper pin hole <strong>drills</strong> HSS N<br />

82010 116 32 <strong>DIN</strong> 345 Twist <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS N<br />

82011 116 34 <strong>DIN</strong> 345 Twist <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS-E N<br />

82012 121 34 <strong>DIN</strong> 345 Twist <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, INOX-DRILL HSS-E IS<br />

82191 126 38 Works std. Spotting <strong>drills</strong> <strong>with</strong> taper <strong>shank</strong> 120° HSS N<br />

82192 126 38 Works std. Spotting <strong>drills</strong> <strong>with</strong> taper <strong>shank</strong> 90° HSS N<br />

82210 127 32 <strong>DIN</strong> 341 Taper <strong>shank</strong> bushing <strong>drills</strong> HSS N<br />

82211 127 38 <strong>DIN</strong> 341 Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E N<br />

82250 127 38 <strong>DIN</strong> 341 Taper <strong>shank</strong> bushing <strong>drills</strong> HSS FW<br />

82340 130 36 <strong>DIN</strong> 1870 Extra length <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, series 1 HSS FN<br />

82410 132 38 <strong>DIN</strong> 1870 Extra length <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, series 2 HSS N<br />

82440 133 36 <strong>DIN</strong> 1870 Extra length <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, series 2 HSS FN<br />

82466 134 38 Works std. Special length <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS FN<br />

82467 134 38 Works std. Special length <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS FN<br />

82468 134 38 Works std. Special length <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS FN<br />

82469 134 38 Works std. Special length <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS FN<br />

82515 140 38 Works std. Long series oil feed <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS-E FN<br />

82521 136 38 Works std. Long series oil feed <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS N<br />

82525 136 38 Works std. Long series oil feed <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS-E FN<br />

bright steam tempered nitrided lands T TiN F FIRE A TiAlN C TiCN<br />

3

Contents<br />

Arranged in ascending order by code number.<br />

Article<br />

no.<br />

Page<br />

Price<br />

group<br />

Standard<br />

Surface<br />

finish<br />

Description Tool material Type<br />

82535 136 38 Works std. Long series oil feed <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS FN<br />

82543 138 37 Works std. Long series oil feed <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS FN<br />

82551 236 - Works std. Coolant feed chucks MT<br />

82556 138 37 Works std. Coolant inductors, complete for 82543<br />

82571 238 50 Works std. Coolant pipe niples<br />

82578 238 50 Works std. Fast action coupling<br />

82590 237 - Works std. ISO taper coolant feed chucks<br />

82591 237 - Works std. Reduction bush cylindrical<br />

82593 237 - Works std. Reduction bush MT<br />

82709 79 39 Works std. T Oil feed <strong>drills</strong>, length <strong>DIN</strong> <strong>338</strong> HSS-E N<br />

82710 78 36 Works std. Oil feed <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

82759 80 39 Works std. T Oil feed <strong>drills</strong> <strong>with</strong> reinforced <strong>straight</strong> <strong>shank</strong> HSS-E N<br />

82761 78 34 Works std. Oil feed <strong>drills</strong> HSS-E FN<br />

82971 123 34 Works std. Twist <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, extra short HSS-E V<br />

82972 123 38 Works std. Twist <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, extra short INOX-DRILL HSS-E IS<br />

83000 215 38 <strong>DIN</strong> 333 Center <strong>drills</strong> <strong>with</strong>out flat, step angle 60°, form R HSS<br />

83100 215 32 <strong>DIN</strong> 333 Center <strong>drills</strong> <strong>with</strong>out flat, step angle 60°, form A HSS<br />

83101 215 38 <strong>DIN</strong> 333 Center <strong>drills</strong> <strong>with</strong>out flat, step angle 60°, form A HSS-E<br />

83105 215 38 <strong>DIN</strong> 333 Center <strong>drills</strong> <strong>with</strong>out flat, step angle 60°, form A HSS<br />

83110 217 38 Works std. Center <strong>drills</strong> <strong>with</strong>out flat, form A, long HSS<br />

83200 218 38 <strong>DIN</strong> 333 Center <strong>drills</strong> <strong>with</strong>out flat, form B HSS<br />

83300 215 38 <strong>DIN</strong> 333 Center <strong>drills</strong> <strong>with</strong>out flat, step angle 60°, form A, annular bead HSS<br />

83500 219 38 <strong>DIN</strong> 333 Center <strong>drills</strong> <strong>with</strong> flat, form R HSS<br />

83600 219 38 <strong>DIN</strong> 333 Center <strong>drills</strong> <strong>with</strong> flat, form A HSS<br />

83700 220 38 <strong>DIN</strong> 333 Center <strong>drills</strong> <strong>with</strong> flat, form B HSS<br />

84400 61 33 <strong>DIN</strong> 1897 T Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

84405 36 31 <strong>DIN</strong> <strong>338</strong> T <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

84415 36 37 <strong>DIN</strong> <strong>338</strong> T <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

84418 83 33 <strong>DIN</strong> 340 T Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

84423 88 37 <strong>DIN</strong> 340 T Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

84425 97 37 <strong>DIN</strong> 1869 T Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 1 HSS FN<br />

84426 101 39 <strong>DIN</strong> 1869 T Extra length <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, series 2 HSS FN<br />

84434 70 39 Works std. T Spotting <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 120° HSS N<br />

84435 70 35 Works std. T Spotting <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 90° HSS N<br />

84445 203 39 Works std. T Stub step <strong>drills</strong>, <strong>straight</strong> <strong>shank</strong>, tap. size hole, medium finish 90° HSS N<br />

84450 215 33 <strong>DIN</strong> 333 T Center <strong>drills</strong> <strong>with</strong>out flat, step angle 60°, vorm A HSS<br />

84460 118 33 <strong>DIN</strong> 345 T Twist <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS N<br />

84461 80 35 Works std. T Oil feed <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FN<br />

84464 127 33 <strong>DIN</strong> 341 T Long series <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS N<br />

84501 61 33 <strong>DIN</strong> 1897 F Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

84502 40 37 <strong>DIN</strong> <strong>338</strong> F <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

84503 61 35 <strong>DIN</strong> 1897 F Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E V<br />

84504 40 37 <strong>DIN</strong> <strong>338</strong> F <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FN<br />

84505 40 35 <strong>DIN</strong> <strong>338</strong> F <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E S<br />

84506 88 37 <strong>DIN</strong> 340 F Long series <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS FN<br />

84507 45 15 Works std. F <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> reinforced <strong>straight</strong> <strong>shank</strong> PM HSS-E FN 500<br />

84511 65 15 <strong>DIN</strong> 1897 F Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> PM HSS-E FN 500<br />

84615 36 37 <strong>DIN</strong> <strong>338</strong> A <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FN<br />

84660 121 39 <strong>DIN</strong> 345 A Twist <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, extra short HSS-E FN<br />

84715 36 37 <strong>DIN</strong> <strong>338</strong> C <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FN<br />

84760 121 39 <strong>DIN</strong> 345 C Twist <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, extra short HSS-E FN<br />

84800 36 37 <strong>DIN</strong> <strong>338</strong> T <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FN<br />

84801 43 15 Works std. T <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> reinforced <strong>straight</strong> <strong>shank</strong> HSS-E FU 500<br />

84802 47 15 <strong>DIN</strong> <strong>338</strong> T <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FU500DZ<br />

84803 61 35 <strong>DIN</strong> 1897 T Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E V<br />

84804 47 15 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FU500DZ<br />

84805 67 15 Works std. T Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E FU 500<br />

84807 36 35 <strong>DIN</strong> <strong>338</strong> T <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E S<br />

84810 73 35 <strong>DIN</strong> 1899 T Micro-precision <strong>drills</strong>, form A HSS-E N<br />

84811 47 15 <strong>DIN</strong> <strong>338</strong> T <strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> PM HSS-E FN500DZ<br />

84816 61 37 <strong>DIN</strong> 1897 T Stub <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS-E EN<br />

85010 205 38 <strong>DIN</strong> 8374 Subland <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 90°, fine finish HSS N<br />

85110 206 38 <strong>DIN</strong> 8374 Subland <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 90°, fine medium HSS N<br />

85210 207 38 <strong>DIN</strong> 8376 Subland <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 180°, fine medium HSS N<br />

85216 208 38 Works std. Subland <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 180° HSS N<br />

85310 204 38 <strong>DIN</strong> 8378 Subland <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> for tapping size hole, 90° HSS N<br />

4<br />

bright steam tempered nitrided lands T TiN F FIRE A TiAlN C TiCN

Article<br />

no.<br />

Page<br />

Price<br />

group<br />

Standard<br />

Surface<br />

finish<br />

Description Tool material Type<br />

85510 210 38 <strong>DIN</strong> 8375 Subland <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, medium finish, 90° HSS N<br />

85610 211 38 <strong>DIN</strong> 8377 Subland <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, medium finish, 180° HSS N<br />

85616 212 38 Works std. Subland <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, 180° HSS N<br />

85710 209 38 <strong>DIN</strong> 8379 Subland <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong>, for tapping size hole, 90° HSS N<br />

85910 196 38 Works std. Step <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, <strong>with</strong> flatted body HSS N<br />

85911 196 38 Works std. Step <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, <strong>with</strong> flatted body HSS N<br />

85912 197 38 Works std. Step <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

85914 198 38 Works std. Step <strong>drills</strong> <strong>with</strong> Morse taper <strong>shank</strong> HSS N<br />

85916 199 38 Works std. Stub step <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, fine finish, 90° HSS N<br />

85917 200 38 Works std. Stub step <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, medium finish, 90° HSS N<br />

85918 201 38 Works std. Stub step <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, medium finish, 180° HSS N<br />

85920 203 38 Works std. Stub step <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, tap. size hole, med. finish 90° HSS N<br />

86010 110 38 <strong>DIN</strong> 344 Core <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

86110 141 38 <strong>DIN</strong> 343 Core <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> HSS N<br />

86602 235 50 Works std. T Interchangeable blades <strong>with</strong> flat grind HSS-E<br />

86605 235 50 Works std. T Interchangeable blades <strong>with</strong> flat grind HSS-E<br />

86608 235 50 Works std. F Interchangeable blades <strong>with</strong> flat grind HSS-E<br />

86609 235 50 Works std. A Interchangeable blades <strong>with</strong> flat grind PM HSS-E MP05<br />

86612 225 50 Works std. Straight <strong>shank</strong> holders, 3 x D<br />

86622 225 50 Works std. Straight <strong>shank</strong> holders, 5 x D<br />

86624 225 50 Works std. Straight <strong>shank</strong> holders, 7 x D<br />

86630 231 50 Works std. Morse taper <strong>shank</strong> holders, short type<br />

86640 231 50 Works std. Morse taper <strong>shank</strong> holders, short type<br />

86650 231 50 Works std. Morse taper <strong>shank</strong> holders, long type<br />

86660 231 50 Works std. Morse taper <strong>shank</strong> holders, long type<br />

86670 231 50 Works std. Morse taper <strong>shank</strong> holders, short type, for coolant inductors<br />

86680 231 50 Works std. Morse taper <strong>shank</strong> holders, long type, for coolant inductors<br />

86690 238 50 Works std. Coolant inductors for article 86670 and 86680<br />

86701 233 50 Works std. F Interchangeable Carbide blades, <strong>with</strong>out lands Sol. Carb.<br />

86702 233 50 Works std. F Interchangeable Carbide blades, <strong>with</strong> lands Sol. Carb.<br />

86703 236 50 Works std. Reversable blades for countersink rings Sol. Carb. XPEW<br />

86704 236 50 Works std. Reversable blades for countersink rings Sol. Carb. XPET<br />

86705 236 50 Works std. Reversable blades for countersink rings Sol. Carb. XPEW<br />

86706 236 50 Works std. Reversable blades for countersink rings Sol. Carb. XPET<br />

86708 233 50 Works std. T Interchangeable Carbide blades, <strong>with</strong> lands Sol. Carb.<br />

86709 233 50 Works std. T Interchangeable Carbide blades, <strong>with</strong>out lands Sol. Carb.<br />

86730 230 50 Works std. Straight <strong>shank</strong> holders for step drill holes 180°<br />

86740 229 50 Works std. Straight <strong>shank</strong> holders for step drill holes 90°<br />

86750 227 50 Works std. Holders <strong>with</strong> guide grooves for countersink rings<br />

86780 228 50 Works std. Countersink rings 90°<br />

86807 236 50 Works std. Torx screws for interchangeable blades<br />

86836 238 50 <strong>DIN</strong> 912 Clamping screws for countersink rings<br />

86842 238 50 Works std. Torx screw drivers<br />

86850 236 50 Works std. Reversable blades for step <strong>drills</strong> Sol. Carb. EPMW<br />

86851 236 50 Works std. Reversable blades for step <strong>drills</strong> Sol. Carb. EPMT<br />

86860 236 50 Works std. Reversable blades for step <strong>drills</strong> Sol. Carb. EPMW<br />

86861 236 50 Works std. Reversable blades for step <strong>drills</strong> Sol. Carb. EPMT<br />

87011 73 34 <strong>DIN</strong> 1899 Micro-precision <strong>drills</strong>, Form A HSS-E N<br />

87016 73 38 <strong>DIN</strong> 1899 Micro-precision <strong>drills</strong>, Form A HSS-E N<br />

88001 49 30 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> sets HSS N<br />

88013 49 30 <strong>DIN</strong> <strong>338</strong> <strong>Jobber</strong> <strong>drills</strong> sets HSS N<br />

88303 46 Metal cases or stands<br />

89235 51 55 <strong>DIN</strong> 6539 Stub <strong>drills</strong> Sol. Carb. N<br />

89237 153 21 <strong>DIN</strong> 6539 T TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 3xD Sol. Carb. TS 100 U<br />

89238 184 09 <strong>DIN</strong> 6539 TS-Drill, 3-fluted, <strong>with</strong>out coolant ducts, 3xD Sol. Carb. TS 3 G<br />

89239 185 09 <strong>DIN</strong> 6539 TS-Drill, 3-fluted, <strong>with</strong>out coolant ducts, 5xD Sol. Carb. TS 3 G<br />

89241 185 09 <strong>DIN</strong> 6539 T TS-Drill, 3-fluted, <strong>with</strong>out coolant ducts, 5xD Sol. Carb. TS 3 F<br />

89242 70 02 Works std. Spotting <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 120° Sol. Carb. N<br />

89243 70 02 Works std. Spotting <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong> 90° Sol. Carb. N<br />

89244 15 55 Works std. <strong>Jobber</strong> <strong>drills</strong> Sol. Carb. N<br />

89246 107 02 Works std. Extra short special <strong>drills</strong> Sol. Carb. N<br />

89247 187 55 <strong>DIN</strong> 6537 TS-Drill, 3-fluted, <strong>with</strong>out coolant ducts, 5xD Sol. Carb. TS 3 G<br />

89254 202 02 Works std. Stub step <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, medium finish, 90° Sol. Carb. N<br />

89264 158 21 <strong>DIN</strong> 6537 T TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 3xD Sol. Carb. TS 100 U<br />

89265 167 21 <strong>DIN</strong> 6537 T TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 3xD Sol. Carb. TS 100 G<br />

89266 168 21 <strong>DIN</strong> 6537 T TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 3xD Sol. Carb. TS 100 U<br />

5

Contents<br />

Arranged in ascending order by code number.<br />

Article<br />

no.<br />

Page<br />

Price<br />

group<br />

Standard<br />

Surface<br />

finish<br />

Description Tool material Type<br />

89271 172 21 <strong>DIN</strong> 6537 T TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 5xD Sol. Carb. TS 100 G<br />

89272 173 21 <strong>DIN</strong> 6537 T TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 5xD Sol. Carb. TS 100 U<br />

89275 156 21 Works std. T TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 5xD Sol. Carb. TS 100 U<br />

89281 73 02 Works std. Micro-precision <strong>drills</strong> Sol. Carb. N<br />

89292 181 21 Works std. TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 4xD Sol. Carb. TS150GG<br />

89293 181 55 Works std. TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 10xD Sol. Carb. TS150GG<br />

89301 108 02 <strong>DIN</strong> 8037 Twist <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, carbide-tipped Carbide N<br />

89302 125 02 <strong>DIN</strong> 8041 Twist <strong>drills</strong> <strong>with</strong> taper <strong>shank</strong>, extra short, carbide-tipped Carbide N<br />

89303 108 02 <strong>DIN</strong> 8038 Twist <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong>, carbide-tipped Carbide N<br />

89306 147 28 <strong>DIN</strong> 6538 T TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 3xD Carbide TS 80 U<br />

89307 149 28 <strong>DIN</strong> 6538 T TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 5xD Carbide TS 80 U<br />

89308 151 28 <strong>DIN</strong> 6538 T TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 7xD Carbide TS 80 U<br />

89401 153 21 <strong>DIN</strong> 6539 F TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 3xD Sol. Carb. TS 100 U<br />

89402 158 55 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 3xD Sol. Carb. TS 100 U<br />

89403 161 21 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 3xD Sol. Carb. TS 100 F<br />

89404 163 21 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 5xD Sol. Carb. TS 100 F<br />

89405 167 21 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 3xD Sol. Carb. TS 100 F<br />

89406 172 21 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 5xD Sol. Carb. TS 100 F<br />

89407 172 21 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 5xD Sol. Carb. TS 100 F<br />

89408 173 55 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 5xD Sol. Carb. TS 100 U<br />

89410 168 55 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 3xD Sol. Carb. TS 100 U<br />

89411 173 55 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 5xD Sol. Carb. TS 100 U<br />

89412 177 55 Works std. F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 7xD Sol. Carb. TS 100 U<br />

89413 158 55 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 3xD Sol. Carb. TS 100 U<br />

89414 164 55 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 5xD Sol. Carb. TS 100 U<br />

89415 168 55 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 3xD Sol. Carb. TS 100 U<br />

89416 177 55 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 7xD Sol. Carb. TS 100 U<br />

89417 164 55 <strong>DIN</strong> 6537 F TS-Drill, 2-fluted, <strong>with</strong>out coolant ducts, 5xD Sol. Carb. TS 100 U<br />

89418 179 55 Works std. F TS-Drill, 2-fluted, <strong>with</strong> coolant ducts, 12xD Sol. Carb. TS 100<br />

89501 188 - Works std. Gun <strong>drills</strong> Sol. Carb. -<br />

89502 188 - Works std. Gun <strong>drills</strong> Sol. Carb. -<br />

6<br />

bright steam tempered nitrided lands T TiN F FIRE A TiAlN C TiCN

Straight Shank Twist Drills<br />

HSS, HSS-E, Carbide<br />

bright and coated<br />

Straight Shank<br />

Twist Drills<br />

Precision Drilling Tools

Contents<br />

Straight Shank Twist Drills<br />

Tool material <strong>DIN</strong> Type Cutting<br />

and surface finish direction<br />

Article<br />

no.<br />

Price<br />

group<br />

Page<br />

<strong>Jobber</strong> <strong>drills</strong> HSS <strong>338</strong> N R 81010 30 15<br />

<strong>Jobber</strong> <strong>drills</strong> HSS <strong>338</strong> N L 81015 34 15<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E <strong>338</strong> N R 81011 34 15<br />

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> tang HSS <strong>338</strong> N R 81017 32 15<br />

<strong>Jobber</strong> <strong>drills</strong> Carbide <strong>338</strong> N R 89244 55 15<br />

<strong>Jobber</strong> <strong>drills</strong> HSS <strong>338</strong> FN R 81040 36 25<br />

<strong>Jobber</strong> <strong>drills</strong> HSS <strong>338</strong> FN L 81045 38 25<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E <strong>338</strong> FN R 81041 36 25<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E <strong>338</strong> S R 81061 34 25<br />

<strong>Jobber</strong> <strong>drills</strong> INOX-DRILL HSS-E <strong>338</strong> IS R 81013 34 25<br />

<strong>Jobber</strong> <strong>drills</strong> HSS <strong>338</strong> H R 81020 34 30<br />

<strong>Jobber</strong> <strong>drills</strong> HSS <strong>338</strong> H L 81025 34 30<br />

<strong>Jobber</strong> <strong>drills</strong> HSS <strong>338</strong> W R 81030 34 30<br />

<strong>Jobber</strong> <strong>drills</strong> HSS <strong>338</strong> W L 81035 38 30<br />

8<br />

bright steam tempered nitrided lands T TiN-coated F FIRE-coated A TiAlN-coated C TiCN-coated

Tool material <strong>DIN</strong> Type Cutting<br />

and surface finish direction<br />

Article<br />

no.<br />

Price<br />

group<br />

Page<br />

<strong>Jobber</strong> <strong>drills</strong> HSS T <strong>338</strong> N R 84405 31 36<br />

<strong>Jobber</strong> <strong>drills</strong> HSS T <strong>338</strong> FN R 84415 37 36<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E T <strong>338</strong> FN R 84800 37 36<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E A <strong>338</strong> FN R 84615 37 36<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E C <strong>338</strong> FN R 84715 37 36<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E T <strong>338</strong> S R 84807 35 36<br />

<strong>Jobber</strong> <strong>drills</strong> HSS F <strong>338</strong> FN R 84502 37 40<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E F <strong>338</strong> FN R 84504 37 40<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E F <strong>338</strong> S R 84505 35 40<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E <strong>338</strong><br />

FU500<br />

DZ R 84804 15 47<br />

<strong>Jobber</strong> <strong>drills</strong> HSS-E T <strong>338</strong><br />

FU500<br />

DZ R 84802 15 47<br />

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> reinforced <strong>shank</strong> HSS-E T WS FU500 R 84801 15 43<br />

<strong>Jobber</strong> <strong>drills</strong> PM HSS-E T <strong>338</strong><br />

FN500<br />

DZ R 84811 15 47<br />

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> reinforced <strong>shank</strong> PM HSS-E F WS FN500 R 84507 15 43<br />

9

Contents<br />

Straight Shank Twist Drills<br />

Tool material <strong>DIN</strong> Type Cutting<br />

and surface finish direction<br />

Article<br />

no.<br />

Price<br />

group<br />

Page<br />

Sets of jobber <strong>drills</strong> HSS <strong>338</strong> N R<br />

88001<br />

88013 30 49<br />

Stub <strong>drills</strong> HSS 1897 N R 81110 32 51<br />

Stub <strong>drills</strong> HSS 1897 N L 81115 34 51<br />

Stub <strong>drills</strong> HSS-E 1897 V R 81171 34 51<br />

Stub <strong>drills</strong> HSS-E 1897 V L 81176 38 51<br />

Stub <strong>drills</strong> HSS T 1897 N R 84400 33 61<br />

Stub <strong>drills</strong> HSS-E T 1897 V R 84803 35 61<br />

Stub <strong>drills</strong> HSS-E T 1897 EN R 84816 37 61<br />

Stub <strong>drills</strong> HSS 1897 H R 81120 38 59<br />

Stub <strong>drills</strong> HSS 1897 W R 81130 38 59<br />

Stub <strong>drills</strong>, INOX-DRILL HSS-E 1897 IS R 81173 38 51<br />

Stub <strong>drills</strong> Carbide 1897 N R 89235 55 51<br />

Stub <strong>drills</strong> HSS 1897 FN R 81140 36 57<br />

Stub <strong>drills</strong> HSS 1897 FN L 81145 38 57<br />

10<br />

bright steam tempered nitrided lands T TiN-coated F FIRE-coated

Tool material <strong>DIN</strong> Type Cutting<br />

and surface finish direction<br />

Article<br />

no.<br />

Price<br />

group<br />

Page<br />

Stub <strong>drills</strong> HSS F 1897 N R 84501 33 61<br />

Stub <strong>drills</strong> HSS-E F 1897 V R 84503 35 61<br />

Stub <strong>drills</strong> PM HSS-E F 1897 FN500 R 84511 15 65<br />

Stub <strong>drills</strong> HSS-E T WS FU500 R 84805 15 67<br />

NC-spotting <strong>drills</strong> 120° HSS WS N R 81191 34 70<br />

NC-spotting <strong>drills</strong> 90° HSS WS N R 81192 34 70<br />

NC-spotting <strong>drills</strong> 120° HSS T WS N R 84434 39 70<br />

NC-spotting <strong>drills</strong> 90° HSS T WS N R 84435 35 70<br />

NC-spotting <strong>drills</strong> 120° Carbide WS N R 89242 02 70<br />

NC-spotting <strong>drills</strong> 90° Carbide WS N R 89243 02 70<br />

Double ended body <strong>drills</strong> HSS WS N R 81190 34 72<br />

Micro-precision <strong>drills</strong> form A HSS-E 1899 N R 87011 34 73<br />

Micro-precision <strong>drills</strong> form A HSS-E 1899 N L 87016 38 73<br />

Micro-precision <strong>drills</strong> form A HSS-E T 1899 N R 84810 35 73<br />

11

Contents<br />

Straight Shank Twist Drills<br />

Tool material <strong>DIN</strong> Type Cutting<br />

and surface finish direction<br />

Article<br />

no.<br />

Price<br />

group<br />

Page<br />

Micro-precision <strong>drills</strong> Carbide WS N R 89281 02 73<br />

Oil feed <strong>drills</strong> HSS WS FN R 82710 36 77<br />

Oil feed <strong>drills</strong> HSS-E WS FN R 82761 34 78<br />

Oil feed <strong>drills</strong> HSS-E T WS FN R 84461 35 78<br />

Oil feed <strong>drills</strong> HSS-E T WS N R 82709 39 79<br />

Oil feed <strong>drills</strong> <strong>with</strong> reinforced <strong>shank</strong> HSS-E T WS N R 82759 39 80<br />

Bushing <strong>drills</strong> HSS 339 N R 81210 34 81<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS 340 N R 81310 32 83<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS T 340 N R 84418 33 83<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS 340 N L 81315 38 83<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS-E 340 N R 81311 34 83<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS 340 FN R 81340 36 88<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS T 340 FN R 84423 37 88<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS F 340 FN R 84506 37 88<br />

12<br />

bright steam tempered nitrided lands T TiN-coated F FIRE-coated

Tool material <strong>DIN</strong> Type Cutting<br />

and surface finish direction<br />

Article<br />

no.<br />

Price<br />

group<br />

Page<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS-E 340 FN R 81341 36 88<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS-E 340 S R 81361 34 88<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS 340 H R 81320 34 92<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS 340 W R 81330 34 92<br />

Long series <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS 340 FW R 81350 36 92<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 1 HSS 1869 N R 81410 34 96<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 1 HSS 1869 FN R 81440 36 96<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 1 HSS 1869 FW R 81450 38 96<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 1 HSS-E 1869 FN R 81441 36 97<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 1 HSS T 1869 FN R 84425 37 97<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 2 HSS 1869 N R 81510 34 100<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 2 HSS 1869 FN R 81540 36 100<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 2 HSS 1869 FW R 81550 38 100<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 2 HSS-E 1869 FN R 81541 38 101<br />

13

Contents<br />

Straight Shank Twist Drills<br />

Tool material <strong>DIN</strong> Type Cutting<br />

and surface finish direction<br />

Article<br />

no.<br />

Price<br />

group<br />

Page<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 2 HSS T 1869 FN R 84426 39 101<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 3 HSS 1869 N R 81610 38 103<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 3 HSS 1869 FN R 81640 36 103<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong>, series 3 HSS 1869 FW R 81650 38 103<br />

Extra length <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> HSS WS FN R 81740 36 105<br />

Taper pin hole <strong>drills</strong> HSS 1898 N R 81810 38 106<br />

Stub <strong>drills</strong> Carbide WS N R 89246 02 107<br />

Tungsten carbide tipped <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> Carbide 8037 N R 89301 02 108<br />

Tungsten carbide tipped <strong>straight</strong> <strong>shank</strong> <strong>drills</strong> Carbide 8038 N R 89303 02 108<br />

Core <strong>drills</strong> HSS 344 N R 86010 38 110<br />

14<br />

bright steam tempered nitrided lands

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

Range of applications<br />

Manufacturing specifications<br />

HSS<br />

Article no. 81010<br />

Article no. 81015<br />

Type N<br />

R<br />

L<br />

Standard drill for drilling steel and cast<br />

steel, alloyed and unalloyed, grey cast<br />

iron, spheroidal iron, sintered powder<br />

metal, German silver, graphite.<br />

Point grinding: relieved cone<br />

Point angle: 118˚<br />

Web thinned: > Ø 14.00 mm to<br />

<strong>DIN</strong> 1412, form A<br />

Helix angle: standard<br />

Web thickness: standard<br />

Web taper: standard<br />

Flute form: standard<br />

Tolerance on Ø: h8<br />

Other manufacturing specifications<br />

to <strong>DIN</strong> 1414<br />

HSS-E<br />

Article no. 81011<br />

Type N<br />

R<br />

High heat-resistant drill for drilling alloyed<br />

and unalloyed steels and castings <strong>with</strong> a<br />

tensile strength over 800 N/mm 2 .<br />

Especially suitable for hot and cold-rolled<br />

steels as well as case hardening and<br />

heat treatable steels.<br />

Point grinding: relieved cone<br />

Point angle: 118˚<br />

Web thinned: > Ø 2.36 mm to<br />

<strong>DIN</strong> 1412, form A<br />

Helix angle: standard<br />

Web thickness: greater than standard<br />

Web taper: standard<br />

Flute form: standard<br />

Tolerance on Ø: h8<br />

Other manufacturing specifications<br />

to <strong>DIN</strong> 1414<br />

HSS<br />

Article no. 81017<br />

Type N<br />

<strong>with</strong> tang to <strong>DIN</strong> 1809<br />

R<br />

Standard drill for drilling steel and cast<br />

steel, alloyed and unalloyed, grey cast<br />

iron, spheroidal iron, sintered powder<br />

metal, German silver, graphite.<br />

Point grinding: relieved cone<br />

Point angle: 118˚<br />

Web thinned: > Ø 14.00 mm to<br />

<strong>DIN</strong> 1412, form A<br />

Helix angle: standard<br />

Web thickness: standard<br />

Web taper: standard<br />

Flute form: standard<br />

Tolerance on Ø: h8<br />

Other manufacturing specifications<br />

to <strong>DIN</strong> 1414<br />

Solid carbide<br />

Article no. 89244<br />

Type N<br />

dimensions to <strong>DIN</strong> <strong>338</strong><br />

R<br />

A standard drill for the drilling of high<br />

tensile steels, cast steel, grey cast iron,<br />

chilled cast iron, austenitic manganese<br />

steel, CrNi-steels, bronzes, light metals<br />

and nonferrous metals. Ideally suited to<br />

the economic machining of abrasive<br />

materials (AlSi-alloys), fiber-reinforced<br />

plastics and other Duroplastics liable to<br />

cause severe abrasion on cutting lip and<br />

lands.<br />

Point grinding: 2-facet<br />

Point angle: 118˚<br />

Web thinned: > Ø 3.00 mm<br />

web thinned to <strong>DIN</strong> 1412, form A<br />

Helix angle: standard<br />

Web thickness: standard<br />

Web taper: standard<br />

Flute form: standard<br />

Tolerance on Ø: h7<br />

Relief angle: 15˚/25˚<br />

Other manufacturing specifications<br />

to <strong>DIN</strong> 6540<br />

15

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

0,20...0,80 HSS HSS-E Carbide<br />

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

81010 81015 81017 81011 89244<br />

#d1# 30 34 32 34 55<br />

R L R R R<br />

N N N N N<br />

0.20 19 2.5 ≥ Ø 3.00 ≥ Ø 1.00<br />

0.22 | | <br />

0.23 | | ○<br />

0.24 | 2.5 ○<br />

0.25 | 3 ○<br />

0.26 | | <br />

0.27 | | <br />

0.28 | | <br />

0.29 | | <br />

0.30 | 3 <br />

0.31 | 4 <br />

0.32 | | <br />

0.33 | | <br />

0.35 | | <br />

0.36 | | <br />

0.37 | | ○<br />

0.38 19 4 <br />

0.39 20 5 <br />

0.40 | | <br />

0.41 | | <br />

0.42 | | <br />

0.43 | | <br />

0.44 | | <br />

0.45 | | <br />

0.46 | | <br />

0.47 | | <br />

0.48 20 5 <br />

0.49 22 6 <br />

0.50 | | <br />

0.51 | | <br />

0.52 | | <br />

0.53 22 6 <br />

0.54 24 7 ○<br />

0.55 | | ○<br />

0.56 | | <br />

0.57 | | <br />

0.58 | | <br />

0.59 | | <br />

0.60 24 7 <br />

0.61 26 8 <br />

0.62 | | <br />

0.63 | | <br />

0.64 | | <br />

0.65 | | <br />

0.66 | | <br />

0.67 26 8 <br />

0.68 28 9 ○<br />

0.69 | | <br />

0.70 | | <br />

0.71 | | <br />

0.72 | | <br />

0.73 | | <br />

0.74 | | <br />

0.75 28 9 ○ <br />

0.76 30 10 <br />

0.77 | | <br />

0.78 30 10 <br />

bright<br />

steam tempered<br />

16

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

HSS HSS-E Carbide<br />

81010 81015 81017 81011 89244<br />

#d1# 30 34 32 34 55<br />

R L R R R<br />

N N N N N<br />

0.79 30 10 ≥ Ø 3.00<br />

0.80 | | <br />

0.81 | | <br />

0.82 | | <br />

0.83 | | <br />

0.84 | | <br />

0.85 30 10 <br />

0.86 32 11 <br />

0.87 | | <br />

0.88 | | ○<br />

0.90 | | <br />

0.91 | | <br />

0.92 | | <br />

0.93 | | <br />

0.94 | | ○<br />

0.95 32 11 ○ <br />

0.96 34 12 ○<br />

0.97 | | <br />

0.98 | | <br />

0.99 | | <br />

1.00 | | <br />

1.01 | | ○<br />

1.02 | | <br />

1.03 | | <br />

1.04 | | ○<br />

1.05 34 12 ○ <br />

1.07 36 14 <br />

1.08 | | ○<br />

1.09 | | ○<br />

1.10 | | <br />

1.11 | | ○<br />

1.12 | | <br />

1.13 | | <br />

1.14 | | <br />

1.15 | | ○ <br />

1.16 | | ○<br />

1.17 | | <br />

1.18 36 14 <br />

1.19 38 16 ○<br />

1.20 | | ○<br />

1.21 | | ○<br />

1.22 | | <br />

1.23 | | ○ <br />

1.24 | | <br />

1.25 | | <br />

1.26 | | ○<br />

1.28 | | ○<br />

1.30 | | <br />

1.31 38 16 ○<br />

1.35 40 18 ○ <br />

1.40 | | ○<br />

1.43 | | ○<br />

1.45 | | ○<br />

1.46 | | <br />

1.47 | | ○<br />

1.48 | | ○<br />

1.50 40 18 <br />

17

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

HSS HSS-E Carbide<br />

81010 81015 81017 81011 89244<br />

#d1# 30 34 32 34 55<br />

R L R R R<br />

N N N N N<br />

* * *<br />

1.51 43 20 ○ ≥ Ø 3.00<br />

1.52 | | ○<br />

1.53 | | ○<br />

1.55 | | ○ <br />

1.56 | | ○ ○<br />

1.57 | | ○<br />

1.58 | | <br />

1.59 | | ○<br />

1.60 | | <br />

1.61 | | ○<br />

1.62 | | ○<br />

1.63 | | ○<br />

1.65 | | ○ <br />

1.66 | | ○<br />

1.67 | | ○<br />

1.68 | | ○<br />

1.70 43 20 ○<br />

1.72 46 22 ○<br />

1.73 | | ○<br />

1.74 | | <br />

1.75 | | ○ <br />

1.76 | | ○<br />

1.78 | | ○<br />

1.80 | | <br />

1.81 | | <br />

1.82 | | <br />

1.83 | | <br />

1.84 | | ○<br />

1.85 | | <br />

1.87 | | ○<br />

1.89 | | ○<br />

1.90 46 22 ○<br />

1.95 49 24 ○ ○<br />

1.97 | | ○<br />

1.98 | | <br />

2.00 | | <br />

2.02 | | <br />

2.03 | | <br />

2.05 | | <br />

2.08 | | ○<br />

2.10 49 24 <br />

2.14 53 27 ○<br />

2.15 | | <br />

2.17 | | ○<br />

2.20 | | <br />

2.21 | | ○<br />

2.25 | | <br />

2.30 | | <br />

2.34 | | ○<br />

2.35 | | ○<br />

2.36 53 27 ○<br />

2.37 57 30 <br />

2.38 | | ○ <br />

2.40 | | <br />

2.44 | | ○<br />

2.45 | | ○ <br />

2.46 57 30 <br />

bright<br />

steam tempered<br />

18

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

HSS HSS-E Carbide<br />

81010 81015 81017 81011 89244<br />

#d1# 30 34 32 34 55<br />

R L R R R<br />

N N N N N<br />

2.50 57 30 <br />

2.53 | | ○<br />

2.55 | | <br />

2.58 | | ○ ○<br />

2.59 | | ○<br />

2.60 | | <br />

2.64 | | ○<br />

2.65 57 30 ○ ○<br />

2.70 61 33 <br />

2.71 | | ○<br />

2.75 | | <br />

2.78 | | ○ <br />

2.80 | | <br />

2.82 | | ○<br />

2.85 | | ○<br />

2.88 | | ○<br />

2.90 | | <br />

2.94 | | ○<br />

2.95 | | <br />

3.00 61 33 <br />

3.01 65 36 <br />

3.02 | | ○<br />

3.05 | | <br />

3.06 | | ○<br />

3.07 | | <br />

3.09 | | ○<br />

3.10 | | <br />

3.15 | | <br />

3.16 | | ○<br />

3.17 | | <br />

3.18 | | ○<br />

3.20 | | <br />

3.25 | | ○<br />

3.26 | | ○<br />

3.28 | | ○<br />

3.30 | | <br />

3.32 | | ○<br />

3.35 65 36 <br />

3.40 70 39 ○ <br />

3.45 | | ○<br />

3.50 | | <br />

3.55 | | <br />

3.56 | | ○<br />

3.57 | | ○ <br />

3.60 | | <br />

3.65 | | ○<br />

3.67 | | ○<br />

3.68 | | <br />

3.70 | | ○ <br />

3.75 70 39 ○ ○<br />

3.80 75 43 <br />

3.81 | | ○<br />

3.85 | | ○ ○<br />

3.90 | | <br />

3.92 | | ○<br />

3.93 | | ○<br />

3.94 75 43 ○<br />

* > Ø 2.36<br />

19

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

HSS HSS-E Carbide<br />

81010 81015 81017 81011 89244<br />

#d1# 30 34 32 34 55<br />

R L R R R<br />

N N N N N<br />

3.95 75 43 ○<br />

3.97 | | <br />

3.99 | | ○<br />

4.00 | | ○ <br />

4.04 | | <br />

4.05 | | ○<br />

4.06 | | ○<br />

4.10 | | ○ <br />

4.15 | | ○<br />

4.20 | | ○ <br />

4.22 | | ○<br />

4.25 75 43 ○ ○<br />

4.30 80 47 <br />

4.32 | | ○<br />

4.35 | | ○<br />

4.37 | | <br />

4.39 | | ○<br />

4.40 | | ○ <br />

4.45 | | ○<br />

4.50 | | ○ <br />

4.53 | | ○<br />

4.55 | | ○ ○<br />

4.57 | | ○<br />

4.60 | | ○ <br />

4.62 | | ○<br />

4.65 | | ○<br />

4.70 | | ○ <br />

4.74 | | ○<br />

4.75 80 47 ○<br />

4.76 86 52 ○ <br />

4.78 | | ○<br />

4.80 | | ○ <br />

4.83 | | <br />

4.85 | | ○ ○<br />

4.90 | | <br />

4.92 | | ○<br />

4.95 | | ○<br />

5.00 | | <br />

5.03 | | <br />

5.05 | | ○<br />

5.06 | | ○<br />

5.10 | | <br />

5.11 | | ○<br />

5.15 | | <br />

5.16 | | ○ <br />

5.20 | | ○ ○<br />

5.22 | | ○<br />

5.25 | | ○<br />

5.30 86 52 <br />

5.31 93 57 ○<br />

5.35 | | <br />

5.40 | | ○ ○ ○<br />

5.41 | | ○<br />

5.42 | | ○<br />

5.45 | | ○ ○<br />

5.50 | | ○ <br />

5.53 93 57 ○<br />

bright<br />

steam tempered<br />

20

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

HSS HSS-E Carbide<br />

81010 81015 81017 81011 89244<br />

#d1# 30 34 32 34 55<br />

R L R R R<br />

N N N N N<br />

5.55 93 57 <br />

5.56 | | ○ <br />

5.60 | | ○ ○<br />

5.61 | | ○<br />

5.62 | | ○<br />

5.65 | | ○<br />

5.70 | | <br />

5.75 | | ○ ○<br />

5.79 | | ○<br />

5.80 | | ○<br />

5.85 | | <br />

5.90 | | ○ ○ ○<br />

5.95 | | ○ <br />

6.00 93 57 <br />

6.05 101 63 ○<br />

6.10 | | ○<br />

6.15 | | ○<br />

6.20 | | ○ ○<br />

6.25 | | ○<br />

6.26 | | ○<br />

6.30 | | ○ <br />

6.35 | | ○ <br />

6.40 | | ○<br />

6.45 | | <br />

6.50 | | <br />

6.55 | | ○<br />

6.60 | | <br />

6.65 | | ○<br />

6.70 101 63 ○ ○ ○<br />

6.75 109 69 <br />

6.80 | | ○ <br />

6.85 | | <br />

6.90 | | ○<br />

6.95 | | ○<br />

7.00 | | ○ <br />

7.05 | | <br />

7.10 | | ○<br />

7.14 | | ○ <br />

7.15 | | <br />

7.20 | | ○ ○<br />

7.25 | | ○ ○<br />

7.30 | | ○ ○<br />

7.35 | | ○<br />

7.40 | | ○ ○<br />

7.45 | | ○<br />

7.50 109 69 <br />

7.60 117 75 ○ ○ ○<br />

7.65 | | ○<br />

7.70 | | ○ ○ ○ ○<br />

7.75 | | ○ <br />

7.80 | | ○ <br />

7.85 | | ○<br />

7.90 | | ○ <br />

7.94 | | <br />

7.95 | | <br />

7.97 | | ○<br />

8.00 117 75 <br />

21

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

HSS HSS-E Carbide<br />

81010 81015 81017 81011 89244<br />

#d1# 30 34 32 34 55<br />

R L R R R<br />

N N N N N<br />

8.05 117 75 <br />

8.10 | | ○<br />

8.15 | | ○<br />

8.20 | | ○<br />

8.25 | | ○<br />

8.30 | | ○<br />

8.33 | | ○<br />

8.35 | | ○<br />

8.40 | | ○<br />

8.45 | | ○<br />

8.50 117 75 ○ <br />

8.55 125 81 <br />

8.60 | | ○ ○ ○<br />

8.70 | | ○ ○ ○<br />

8.73 | | ○ <br />

8.75 | | ○ ○<br />

8.80 | | ○ ○ ○<br />

8.85 | | <br />

8.90 | | ○ ○ ○<br />

8.95 | | ○<br />

9.00 | | ○ <br />

9.05 | | ○<br />

9.10 | | ○ ○ ○<br />

9.13 | | ○<br />

9.14 | | ○<br />

9.15 | | ○<br />

9.20 | | ○ ○ ○ ○<br />

9.25 | | ○<br />

9.30 | | ○<br />

9.35 | | ○<br />

9.40 | | ○ ○ ○<br />

9.45 | | ○<br />

9.50 125 81 ○ <br />

9.52 133 87 ○<br />

9.55 | | ○<br />

9.60 | | ○ ○<br />

9.65 | | <br />

9.70 | | ○ ○<br />

9.75 | | ○<br />

9.80 | | ○ ○ ○<br />

9.90 | | ○ ○ ○<br />

9.92 | | ○<br />

9.95 | | ○<br />

10.00 | | <br />

10.05 | | ○<br />

10.08 | | ○<br />

10.10 | | ○ ○<br />

10.20 | | <br />

10.25 | | ○<br />

10.30 | | ○ ○<br />

10.32 | | ○<br />

10.40 | | ○<br />

10.50 | | <br />

10.60 133 87 ○<br />

10.70 142 94 <br />

10.72 | | ○<br />

10.75 142 94 ○<br />

bright<br />

steam tempered<br />

22

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

HSS HSS-E Carbide<br />

81010 81015 81017 81011 89244<br />

#d1# 30 34 32 34 55<br />

R L R R R<br />

N N N N N<br />

10.80 142 94 ○ ○<br />

10.90 | | ○ ○<br />

11.00 | | <br />

11.10 | | ○<br />

11.11 | | <br />

11.20 | | ○<br />

11.25 | | ○<br />

11.30 | | ○<br />

11.40 | | <br />

11.50 | | ○ <br />

11.51 | | ○<br />

11.60 | | ○ ○<br />

11.70 | | <br />

11.75 | | ○ ○<br />

11.80 142 94 ○ ○<br />

11.90 151 101 ○<br />

11.91 | | ○ <br />

12.00 | | ○ <br />

12.10 | | ○ <br />

12.20 | | ○ ○<br />

12.25 | | ○ ○<br />

12.30 | | ○<br />

12.40 | | <br />

12.50 | | ○ <br />

12.60 | | <br />

12.65 | | ○<br />

12.70 | | ○<br />

12.75 | | ○<br />

12.80 | | ○ ○<br />

12.85 | | ○<br />

12.90 | | <br />

13.00 | | ○ <br />

13.10 | | <br />

13.20 151 101 ○<br />

13.25 160 108 <br />

13.30 | | ○<br />

13.40 | | ○<br />

13.49 | | ○<br />

13.50 | | ○ <br />

13.60 | | <br />

13.70 | | ○<br />

13.75 | | <br />

13.80 | | ○ ○<br />

13.90 | | <br />

14.00 160 108 ○ <br />

14.10 169 114 <br />

14.20 | | <br />

14.25 | | <br />

14.29 | | ○<br />

14.30 | | ○<br />

14.40 | | ○<br />

14.50 | | ○ ○<br />

14.68 | | ○<br />

14.70 | | ○ ○<br />

14.75 | | <br />

14.80 | | <br />

14.90 169 114 ○<br />

23

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

HSS HSS-E Carbide<br />

81010 81015 81017 81011 89244<br />

#d1# 30 34 32 34 55<br />

R L R R R<br />

N N N N N<br />

15.00 169 114 ○ ≤ Ø 13.00 ≤ Ø 12.00<br />

15.08 178 120 ○<br />

15.10 | | ○<br />

15.20 | | <br />

15.25 | | <br />

15.30 | | ○<br />

15.40 | | ○<br />

15.50 | | ○ ○<br />

15.60 | | ○<br />

15.75 | | ○<br />

15.80 | | <br />

15.87 | | ○<br />

16.00 178 120 <br />

16.10 184 125 ○<br />

16.20 | | ○<br />

16.30 | | ○<br />

16.50 | | ○ ○<br />

16.60 | | ○<br />

16.70 | | ○<br />

16.90 | | ○<br />

17.00 184 125 ○ ○<br />

17.07 191 130 ○<br />

17.50 | | <br />

17.75 | | ○<br />

18.00 191 130 <br />

18.25 198 135 ○<br />

18.26 | | ○<br />

18.50 | | ○<br />

18.75 | | ○<br />

19.00 198 135 ○<br />

19.50 205 140 ○<br />

19.84 | | ○<br />

20.00 205 140 ○<br />

bright<br />

steam tempered<br />

24

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

Range of applications<br />

Manufacturing specifications<br />

HSS<br />

Article no. 81040<br />

Article no. 81045<br />

Type FN<br />

R<br />

L<br />

A robust tool for drilling in difficult conditions<br />

such as when swarf congestion prevents<br />

an adequate flow of coolant. For<br />

use in steel and cast iron having a hardness<br />

of up to 1000 N/mm 2 . Not recommended<br />

for nickel-chrome steels or<br />

similar materials.<br />

Well suited for drilling depths greater<br />

than 3 x D (nitrided lands and<br />

wide flutes).<br />

Point grinding: relieved cone<br />

Point angle: 130˚<br />

Web thinned: to <strong>DIN</strong> 1412, form A<br />

Helix angle: greater than standard<br />

Web thickness: greater than standard<br />

Web taper: none<br />

Flute form: very wide flutes <strong>with</strong><br />

„rolled-off“ heels<br />

Tolerance on Ø: h8<br />

Other manufacturing specifications to<br />

<strong>DIN</strong> 1414<br />

HSS-E<br />

Article no. 81041<br />

Type FN<br />

R<br />

High heat resistant drill <strong>with</strong> wide chip<br />

space. Suitable for drilling alloyed and<br />

unalloyed steels and castings <strong>with</strong> a<br />

tensile strength over 800 N/mm 2 .<br />

Particularly suitable for drilling hot and<br />

cold-rolled steels, antifriction bearing<br />

steel, high alloyed steels as well as case<br />

hardening and heat-treatable steels.<br />

Well suited for drilling depths greater<br />

than 3 x D (nitrided lands and wide<br />

flutes).<br />

Point grinding: relieved cone<br />

Point angle: 130˚<br />

Web thinned: to <strong>DIN</strong> 1412, form A<br />

Helix angle: greater than standard<br />

Web thickness: greater than standard<br />

Web taper: none<br />

Flute form: very wide flutes <strong>with</strong><br />

„rolled-off“ heels<br />

Tolerance on Ø: h8<br />

Other manufacturing specifications to<br />

<strong>DIN</strong> 1414<br />

HSS-E<br />

Article no. 81061<br />

Type S<br />

R<br />

Extra rigid, high heat resistant drill <strong>with</strong><br />

large helix angle (35°). Preferential application<br />

in titanium and titanium alloys,<br />

stainless steels, acid and heat resisting<br />

austenitic steels. Also suitable for high<br />

tensile strength steels from approx.<br />

900N/mm 2 and above, forming short<br />

chips (antifriction bearing steel) <strong>with</strong><br />

shallow drilling depth up to approx. 3 x D.<br />

Limited suitability for special alloys such<br />

as Hastelloy, Inconel, Nimonic etc.<br />

Point grinding: relieved con<br />

Point angle: 130˚<br />

Web thinned: > Ø 0,95 mm<br />

special web thinning<br />

Helix angle: greater than standard (35˚)<br />

Web thickness: greater than standard<br />

Web taper: standard<br />

Flute form: standard<br />

Tolerance on Ø: h8<br />

Other manufacturing specifications to<br />

<strong>DIN</strong> 1414<br />

HSS-E<br />

Article no. 81013<br />

Type IS<br />

R<br />

Extra rigid, high heat resistant drill <strong>with</strong><br />

large helix angle. Preferential application<br />

in stainless steels, acid and heat resisting<br />

austenitic steels (V2A).<br />

Point grinding: relieved cone<br />

Point angle: 130˚<br />

Web thinned: none<br />

Helix angle: greater than standard<br />

Web thickness: smaller than standard<br />

Web taper: standard<br />

Flute form: standard<br />

Tolerance on Ø: h8<br />

Other manufacturing specifications to<br />

<strong>DIN</strong> 1414<br />

25

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

0,20...2,80 HSS HSS-E<br />

#d1#. 81040 81045 81013 81041 81061<br />

36 38 34 36 34<br />

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

R L R R R<br />

FN FN IS FN S<br />

* * *<br />

0,20 19 2,5 <br />

0,25 | 3 ○<br />

0,28 | | ○<br />

0,30 19 3 <br />

0,40 20 5 <br />

0,47 | | ○<br />

0,48 20 5 ○<br />

0,50 22 6 <br />

0,58 24 7 ○<br />

0,60 24 7 <br />

0,65 26 8 <br />

0,70 28 9 <br />

0,75 28 9 <br />

0,77 30 10 ○<br />

0,80 | | <br />

0,84 | | ○<br />

0,85 30 10 <br />

0,90 32 11 <br />

0,95 32 11 <br />

1,00 34 12 ○ <br />

1,05 34 12 <br />

1,10 36 14 ○ <br />

1,18 36 14 ○<br />

1,20 38 16 <br />

1,25 | | <br />

1,30 38 16 <br />

1,35 40 18 <br />

1,40 | | <br />

1,45 | | ○ <br />

1,50 40 18 <br />

1,52 43 20 ○<br />

1,55 | | ○ ○ <br />

1,60 | | <br />

1,63 | | ○<br />

1,65 | | <br />

1,70 43 20 <br />

1,73 46 22 ○<br />

1,75 | | ○ <br />

1,77 | | ○<br />

1,80 | | <br />

1,82 | | <br />

1,85 | | ○ <br />

1,90 46 22 <br />

1,95 49 24 <br />

2,00 | | <br />

2,05 | | <br />

2,10 49 24 <br />

2,15 53 27 <br />

2,20 | | <br />

2,25 | | <br />

2,30 | | <br />

2,35 53 27 ○ <br />

2,40 57 30 <br />

2,45 | | <br />

2,50 | | <br />

2,55 | | ○ <br />

2,60 57 30 <br />

bright<br />

nitrided lands<br />

26

2,85...6,75 HSS HSS-E<br />

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

#d1#. 81040 81045 81013 81041 81061<br />

36 38 34 36 34<br />

R L R R R<br />

FN FN IS FN S<br />

2.65 57 30 <br />

2.70 61 33 ○ <br />

2.75 | | <br />

2.78 | | <br />

2.80 | | <br />

2.85 | | <br />

2.90 | | <br />

2.95 | | <br />

3.00 61 33 <br />

3.05 65 36 <br />

3.10 | | <br />

3.15 | | ○ <br />

3.17 | | <br />

3.20 | | <br />

3.25 | | ○ <br />

3.30 | | <br />

3.35 65 36 ○<br />

3.40 70 39 <br />

3.45 | | <br />

3.50 | | <br />

3.55 | | ○<br />

3.57 | | ○<br />

3.60 | | <br />

3.65 | | <br />

3.70 | | ○ <br />

3.75 70 39 ○<br />

3.80 75 43 <br />

3.90 | | <br />

4.00 | | <br />

4.05 | | <br />

4.10 | | <br />

4.20 | | <br />

4.25 75 43 ○<br />

4.30 80 47 <br />

4.40 | | <br />

4.50 | | <br />

4.60 | | <br />

4.65 | | ○<br />

4.70 | | ○ <br />

4.75 80 47 ○ <br />

4.80 86 52 ○ <br />

4.85 | | ○<br />

4.90 | | ○ <br />

5.00 | | <br />

5.10 | | <br />

5.20 | | <br />

5.30 86 52 ○ <br />

5.40 93 57 ○ <br />

5.50 | | ○ <br />

5.60 | | <br />

5.70 | | ○ ○ <br />

5.75 | | ○<br />

5.80 | | ○ <br />

5.85 | | ○<br />

5.90 | | ○ ○ <br />

6.00 93 57 <br />

6.10 101 63 ○ ○ <br />

* > Ø 2.36<br />

27

<strong>Jobber</strong> <strong>drills</strong> <strong>with</strong> <strong>straight</strong> <strong>shank</strong><br />

<strong>DIN</strong> <strong>338</strong><br />

6,80...12,50 HSS HSS-E<br />

#d1#. 81040 81045 81013 81041 81061<br />

36 38 34 36 34<br />

nom.-Ø<br />

mm<br />

total<br />

length<br />

mm<br />

flute<br />

length<br />

mm<br />

R L R R R<br />

FN FN IS FN S<br />

6.20 101 63 <br />

6.30 | | ○ <br />

6.40 | | ○ <br />

6.50 | | ○ <br />

6.60 | | ○ <br />

6.70 101 63 ○ <br />

6.75 109 69 ○ ○<br />

6.80 | | <br />

6.90 | | ○ ○ <br />

7.00 | | <br />

7.10 | | ○ ○ ○ <br />

7.20 | | ○ ○ ○ <br />

7.30 | | ○ ○ ○ <br />

7.40 | | ○ ○ <br />

7.50 109 69 ○ ○ <br />

7.60 117 75 ○ <br />

7.70 | | ○ <br />

7.80 | | ○ <br />

7.90 | | ○ ○ ○ <br />

8.00 | | ○ <br />

8.10 | | ○ ○ <br />

8.20 | | <br />

8.30 | | ○ ○ <br />

8.40 | | ○ ○ <br />

8.50 117 75 ○ <br />

8.60 125 81 ○ ○ <br />

8.70 | | ○ ○ <br />

8.80 | | ○ ○ <br />

8.90 | | ○ ○ ○ <br />

9.00 | | ○ <br />

9.10 | | ○ ○ <br />

9.20 | | ○ ○ ○ <br />

9.30 | | ○ ○ ○ <br />

9.40 | | ○ ○ <br />

9.50 125 81 ○ ○ <br />

9.60 133 87 ○ ○ ○ ○ ○<br />

9.70 | | ○ ○ ○ <br />

9.80 | | ○ ○ ○ <br />

9.90 | | ○ ○ ○ <br />

10.00 | | ○ <br />

10.10 | | ○ <br />

10.20 | | ○ ○ <br />

10.30 | | ○ ○ ○ <br />