cantilever reclaimers storage silo and bottom unloader systems

cantilever reclaimers storage silo and bottom unloader systems

cantilever reclaimers storage silo and bottom unloader systems

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

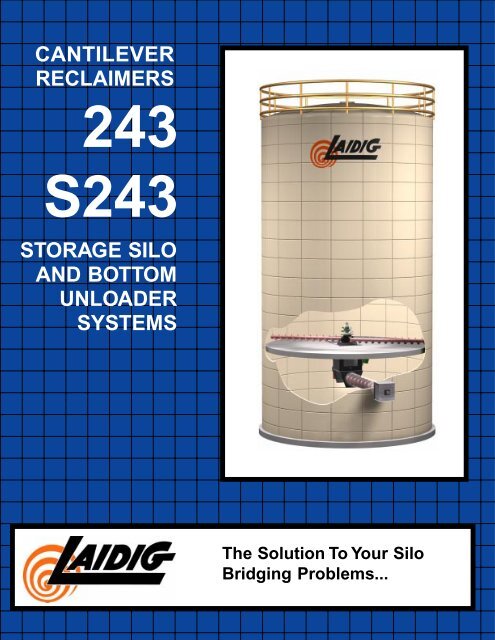

CANTILEVER<br />

RECLAIMERS<br />

243<br />

S243<br />

STORAGE SILO<br />

AND BOTTOM<br />

UNLOADER<br />

SYSTEMS<br />

The Solution To Your Silo<br />

Bridging Problems...

MODELS 243 AND S243 PROVIDE FLEXIBILITY<br />

The equipment for System 243 consists of a Model 243 or Model<br />

S243 Unloader <strong>and</strong> heavy duty Laidig Silo. The System 243 <strong>silo</strong><br />

<strong>and</strong> <strong>unloader</strong> packages are ruggedly designed to store <strong>and</strong> h<strong>and</strong>le<br />

a variety of materials including sawdust, wood chips, soybean meal,<br />

corn fiber, cotton seed meal, other meat <strong>and</strong> grain meals, along<br />

with other bulk products that typically present flow problems.<br />

Choose the Model 243-1 Motor System where simplicity is desired.<br />

The Model 243- 2 Motor System is ideal for applications requiring<br />

more flexibility for material delivery control. The Model S243 is<br />

the choice when more power <strong>and</strong> higher delivery rates are required.<br />

All three models are available for 6’ to 30’ diameter applications<br />

depending on material flow characteristics <strong>and</strong> delivery rates<br />

needed. They can either be installed into a new Laidig Silo or<br />

retrofit into existing structures.<br />

Model 243 <strong>unloader</strong> installed into a new <strong>silo</strong><br />

The System 243 consists of three elements:<br />

1. 243 Series Unloader<br />

2. The Steel Bolted Silo<br />

(Monolithic Concrete Silo also available)<br />

3. The Laidig Guarantee<br />

Side view of the Model 243 - 1 Motor<br />

Team up the Model 243 Series Unloader with the top<br />

quality a Steel Bolted Silo or a Monolithic Concrete<br />

Silo to create the unique System 243 from Laidig<br />

Industrial Systems.<br />

Dome<br />

Optional dome for flow control.<br />

Dome removed in maximum flow applications.<br />

Dual Sweep<br />

Augers<br />

SYSTEM BENEFITS<br />

INCLUDE:<br />

Motor<br />

Exit Auger<br />

Total cleanout<br />

Helps approach FIFO -<br />

First In First Out<br />

minimizing particle<br />

segregation.<br />

Some metering capabilities.<br />

Sweep Advancement Drive<br />

Solves material flow<br />

problems in <strong>silo</strong>s.<br />

Illustrated above is the Model 243 - 1 Motor

LAIDIG SILOS<br />

THE STEEL SILO STORAGE:<br />

Baked on acrylic enamel exterior coating (choice of five colors)<br />

Epoxy interior coating<br />

Heavy duty construction<br />

Designed for mass flow<br />

Ladder, safety cage, <strong>and</strong> deck rail meets OSHA st<strong>and</strong>ards<br />

Specially designed access openings for easy service<br />

Optional explosion relief deck or panels<br />

OPTIONAL CONCRETE SILO STORAGE:<br />

4000# concrete<br />

18 degree sloped roof option for some sizes<br />

Guardrail, ladder, safety cage, <strong>and</strong> rest platforms<br />

Framed tunnel openings<br />

Unloader access openings<br />

Special spiral staircase (Available as an option)<br />

BENEFITS:<br />

Attractive appearance<br />

Can be color coordinated with surrounding buildings<br />

Choice of protective coatings<br />

Easily repaired or modified<br />

Can be removed<br />

Can be extended<br />

BENEFITS:<br />

Rugged, tough <strong>and</strong> nearly indestructible<br />

Smooth, concentric walls to aid mass flow<br />

Virtually no maintenance<br />

Can accept heavy deck loading<br />

Economical <strong>storage</strong> for large <strong>systems</strong><br />

Optional Spindome<br />

for more fibrous<br />

materials<br />

CAPACITY:<br />

The capacity of the Model 243 Series Unloader is<br />

dependent on several factors of the material being<br />

h<strong>and</strong>led:<br />

Particle size<br />

Moisture content<br />

Stringiness<br />

Flowability<br />

Duty cycle<br />

Illustrated above is the Model 243 - 2 Motor<br />

STANDARD COMPARISONS<br />

Model 243<br />

Model S243<br />

Reclaim auger diameter 8.5” variable 11.5” variable<br />

Reclaim drive train Up to 15 HP Up to 30 HP<br />

Sweep advance Mechanical Hydraulic<br />

Optional exit auger 12” dia. 16”/18” dia.<br />

Control panel Optional Optional<br />

Dome-flow control Optional Optional<br />

Spindome Optional Optional<br />

Illustrated above is the Model S243.

THE TOTAL PACKAGE...<br />

from Laidig Industrial Systems<br />

The System 243 consists of more than a <strong>silo</strong> <strong>and</strong> <strong>unloader</strong>.<br />

Laidig Industrial Systems include a complete package in every<br />

System 243:<br />

LAYOUT AND SPECIFICATIONS<br />

Before recommending a specific system, Laidig considers the material to be stored,<br />

the <strong>storage</strong> period, the unloading rate, the expected usage, <strong>and</strong> other factors.<br />

Because the <strong>unloader</strong>s <strong>and</strong> <strong>silo</strong>s are designed for different materials <strong>and</strong> purposes,<br />

Laidig considers all factors before recommending a particular system.<br />

CONSTRUCTION<br />

At Laidig Industrial Systems, the crews which install the <strong>unloader</strong> <strong>and</strong> erect the<br />

structure are well aware of their responsibility to meet high construction st<strong>and</strong>ards.<br />

Well trained <strong>and</strong> equipped, the competent people at Laidig meet the highest<br />

st<strong>and</strong>ards in the construction industry.<br />

CUSTOMER SERVICE<br />

Laidig personnel consult with their customers regarding the proper filling <strong>and</strong><br />

operating procedures for each system. When the system is first started up, Laidig’s<br />

policy is to be there to demonstrate how to operate the system. Laidig Industrial<br />

System excels in customer service —our troubleshooters can solve problems over<br />

the phone or, if necessary, will come to your plant. In addition, Laidig inventories<br />

a complete line of parts to service their equipment.<br />

THE GUARANTEE FROM LAIDIG INDUSTRIAL SYSTEMS<br />

Laidig Industrial Systems is a company with unique characteristics: extensive<br />

experience in <strong>bottom</strong> unloading, a complete family of <strong>silo</strong>s <strong>and</strong> <strong>unloader</strong>s, qualified<br />

<strong>and</strong> trained personnel, <strong>and</strong> <strong>systems</strong> installed in all types of materials. These<br />

factors allow us to provide an exclusive guarantee: if Laidig Industrial Systems<br />

engineers, designs, <strong>and</strong> erects a <strong>storage</strong> system, WE GUARANTEE IT TO WORK.<br />

Laidig Industrial Systems:<br />

“Performance Makes<br />

the Difference”<br />

LAIDIG INDUSTRIAL SYSTEMS<br />

14535 DRAGOON TRAIL<br />

MISHAWAKA, IN 46544-6896 USA<br />

PHONE: (574) 256-0204<br />

FAX: (574) 256-5575<br />

www.laidig.com<br />

sales@laidig.com<br />

Laidig Industrial Systems, Inc. And Laidig Mfg. Reserve the right to change specifications <strong>and</strong> policies without notice.