NMI/Signature Series: MC-Pro 1500 - Woodproductsonlineexpo.com

NMI/Signature Series: MC-Pro 1500 - Woodproductsonlineexpo.com

NMI/Signature Series: MC-Pro 1500 - Woodproductsonlineexpo.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>NMI</strong> <strong>Signature</strong> <strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

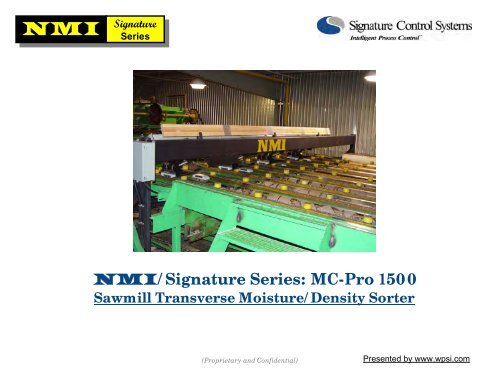

<strong>NMI</strong>/<strong>Signature</strong> <strong>Series</strong>: <strong>MC</strong>-<strong>Pro</strong> <strong>1500</strong><br />

Sawmill Transverse Moisture/Density Sorter<br />

(<strong>Pro</strong>prietary and Confidential)<br />

Presented by www.wpsi.<strong>com</strong>

<strong>NMI</strong><br />

<strong>Signature</strong><br />

<strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

Northern Milltech<br />

- Company Outline -<br />

NORTHERN MILLTECH INCORPORATED (<strong>NMI</strong>)<br />

is a World leader in the development and provision<br />

of moisture content verification and analysis<br />

products for sawmill applications. Market driven<br />

innovation, reliable products and a reputation for<br />

service has grown <strong>NMI</strong> to where it is the industry<br />

choice for sawmill, planermill and in-kiln moisture<br />

meter equipment and software.<br />

Digital pulse sensing, auto temperature<br />

<strong>com</strong>pensation and background noise suppression<br />

are three of many innovations that ensure the<br />

accuracy of our meters in all conditions.<br />

2

<strong>MC</strong> <strong>Pro</strong> <strong>1500</strong><br />

<strong>NMI</strong><br />

<strong>Signature</strong><br />

<strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

System Overview<br />

<strong>MC</strong>-<strong>Pro</strong> <strong>1500</strong><br />

Transverse Sawmill sorting system<br />

The <strong>MC</strong>-<strong>Pro</strong> <strong>1500</strong> moisture/density meter presorts<br />

green lumber for improved kiln drying. The result is less<br />

deviation going into the kiln which equates to less deviation<br />

<strong>com</strong>ing out, optimized drying times, improved grade<br />

recovery and a decrease in trim loss<br />

3

<strong>NMI</strong><br />

<strong>Signature</strong><br />

<strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

<strong>1500</strong> Theory of Operation<br />

The <strong>NMI</strong> moisture/density sorter is an electronic based sensing system which is used in the sawmill and planer<br />

to detect and sort lumber according to the moisture content and density of the piece. Moisture content of the<br />

lumber is the significant determining factor up to fiber saturation and density be<strong>com</strong>es more prevalent beyond<br />

this point. The system is extremely robust and virtually maintenance free.<br />

<strong>NMI</strong> Moisture Sensor<br />

Wood<br />

The heart of the <strong>NMI</strong> system is the moisture/density sensor head. This injects an electric field into the wood<br />

and monitors the response. The electronics in the sensor use a proprietary method to inject the electric field<br />

lines which give very consistent and repeatable readings. It does this with a consolidated sensor which is in<br />

full contact with the wood. As the above diagram illustrates, the electric field lines penetrate below the<br />

surface of the wood.<br />

A big advantage of the <strong>NMI</strong> system of sensing is that surface moisture does not significantly impact the<br />

readings. This is important in a mill where water or coolant is used on the saws which may have wet the<br />

lumber surface.<br />

4

<strong>NMI</strong><br />

Temperature Compensation<br />

• One of the first big hurdles that<br />

<strong>NMI</strong> had to over<strong>com</strong>e in<br />

developing the system was the<br />

effects of frozen wood. Frozen<br />

wood changes the MD reading due<br />

to the change in the structure of<br />

the water. The MD readings<br />

be<strong>com</strong>e lower and make it very<br />

difficult to distinguish the wet<br />

pieces. <strong>NMI</strong> has done extensive<br />

research and have developed a<br />

method using on-line temperature<br />

sensing which effectively<br />

<strong>com</strong>pensates for the effects of<br />

frozen wood. The system,<br />

therefore needs little or no<br />

adjustment between summer and<br />

winter conditions.<br />

<strong>Signature</strong><br />

<strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

Infra red Temperature Sensor<br />

5

<strong>NMI</strong><br />

The Sorter Hardware and Software<br />

• The sorter hardware consists of four (minimum) to eight (maximum) sensors on the<br />

line which ride on the lumber to take the readings. In order to get effective readings<br />

the sensors must be in full contact with the wood. The sensor heads are mounted on<br />

hardware which is spring loaded in order to apply consistent pressure to the wood.<br />

For a dimension line the eight sensors are configured with four sensors mounted<br />

above the line and four sensors mounted below in a transverse configuration (i.e. the<br />

lumber arrives at all eight sensors at the same time). The top and bottom mounting<br />

hardware are different due to the fact that the top mounting hardware must swing out<br />

of the way for jam-ups and larger pieces of wood. The hardware is designed to<br />

ac<strong>com</strong>modate multiple thickness' running together.<br />

• The rest of the system consists of the main control unit (<strong>MC</strong>U), distribution boxes,<br />

cabling, on-line photocells and IR temperature sensing. Sort parameters for each<br />

piece are passed to the <strong>NMI</strong> system from the sorter PLC and a moisture/density sort<br />

reading returned. The parameters may be any <strong>com</strong>bination of thickness, width,<br />

length, species and grade or, the user may simply select a fixed dimension as may be<br />

the case in a planer drop out application.<br />

• This is an embedded system at the <strong>MC</strong>U which handles all the <strong>com</strong>munication to and<br />

from the sensors, calculation of the moisture/density content of the lumber, interface<br />

to the line PLC and user interface. This is a user friendly, menu driven program<br />

which is easy to learn and difficult to program incorrectly. Through the nearest<br />

network hub the <strong>MC</strong>U is connected to a reporting <strong>com</strong>puter or, if this network is<br />

unavailable <strong>NMI</strong> can supply a stand alone system for this purpose.<br />

<strong>Signature</strong><br />

<strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

6

<strong>NMI</strong><br />

<strong>Signature</strong><br />

<strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

Sorting Advantage.<br />

•The premise behind the development of this system was “the less<br />

deviation you have going into the kiln the less you will have <strong>com</strong>ing out”<br />

and over 100 installations later, is industry recognized as an extremely<br />

cost effective way of increasing grade out turns and decreasing trim loss.<br />

You can see that even just pulling out the<br />

wettest 15% of the pieces will substantially<br />

reduce the deviation going out to the kiln.<br />

Reducing the drying time on the dryer sorts<br />

will reduce the losses due to over-drying<br />

these pieces.<br />

7

<strong>NMI</strong><br />

<strong>Signature</strong><br />

<strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

Data tracking system<br />

• The <strong>1500</strong> <strong>com</strong>bined with the power of our new “stack trak” database<br />

and bar coding system allows data for every package of lumber to be<br />

stored and <strong>com</strong>bined with dry kiln and Planer moisture information.<br />

This level of total moisture content management sets <strong>NMI</strong> <strong>Signature</strong><br />

systems apart from our <strong>com</strong>petitors.<br />

8

<strong>NMI</strong> Entered Into a Strategic Partnership<br />

with SCS<br />

<strong>NMI</strong> SCS Press Release – Dec 01, 2006<br />

<strong>NMI</strong><br />

<strong>Signature</strong><br />

<strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

Overview:<br />

Strategic alliance to optimize kiln drying<br />

and improve moisture control by<br />

integrating the moisture measurement<br />

systems in the sawmill, kilns and planer<br />

mill<br />

Benefit to Mills:<br />

<strong>NMI</strong> and SCS estimate that better moisture<br />

control can result in up to 4% improvement<br />

in grade out turns.<br />

<strong>Pro</strong>duct Release:<br />

<strong>NMI</strong> & SCS will release the <strong>NMI</strong>/<strong>Signature</strong><br />

<strong>Series</strong> family of interconnected systems in<br />

Q1-07.<br />

9

<strong>NMI</strong><br />

Bar coding and <strong>MC</strong> <strong>Pro</strong>-trac software<br />

integrates SCS and <strong>NMI</strong> products<br />

Sawmill Moisture Meter<br />

<strong>Signature</strong><br />

<strong>Signature</strong><br />

<strong>Series</strong><br />

<strong>Series</strong><br />

<strong>MC</strong> <strong>Pro</strong>-trac<br />

Planer Mill Moisture<br />

Meter<br />

<strong>MC</strong> <strong>Pro</strong> <strong>1500</strong> <strong>MC</strong> <strong>Pro</strong> 2500<br />

Data Link & Auto-Correlation<br />

Kiln Moisture<br />

Meter<br />

Data Link & Auto-Correlation<br />

MMS 2000<br />

10