Tractor Attachment Sales Manual - JS Woodhouse

Tractor Attachment Sales Manual - JS Woodhouse

Tractor Attachment Sales Manual - JS Woodhouse

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

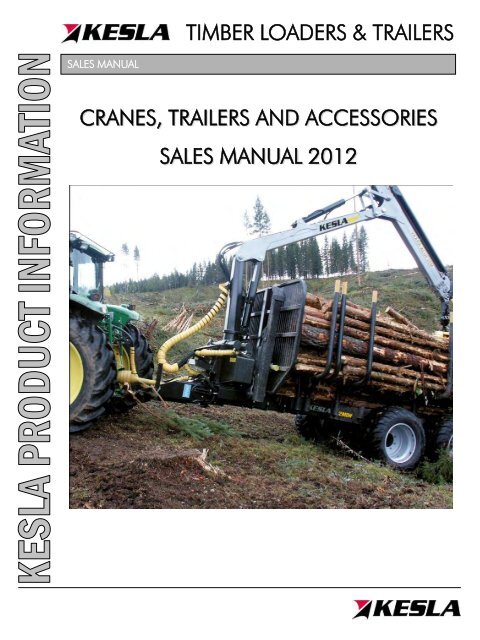

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL<br />

CRANES, TRAILERS AND ACCESSORIES<br />

SALES MANUAL 2012

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 2<br />

CONTACTS<br />

KESLA OYJ Tel. +358 20 7862 841<br />

P.O.BOX 282 Fax. +358 13 6100 523<br />

FIN-80101 JOENSUU<br />

www.kesla.com<br />

Managing Director<br />

Mr. Jari Nevalainen<br />

Tel. +358 40 8307 750<br />

jari.nevalainen@kesla.com<br />

Marketing Director<br />

Mr. Eero Lukkarinen<br />

Tel. +358 40 5609 310<br />

eero.lukkarinen@kesla.com<br />

Export Assistants:<br />

Mrs. Kirsi Soininen<br />

Mrs. Tarja Tykkyläinen<br />

Tel. +358 13 6828 303 Tel. +358 13 6828 326<br />

kirsi.soininen@kesla.com tarja.tykkylainen@kesla.com<br />

R&D Manager<br />

Mr. Kari Kokko<br />

Tel. +358 40 5868 843<br />

kari.kokko@kesla.com<br />

Service Manager<br />

Mr. Asko Leppänen<br />

after.sales@kesla.com Tel. +358 40 5752 095<br />

asko.leppanen@kesla.com<br />

Spare parts<br />

Mr. Sami Ropponen<br />

spare.parts@kesla.com Tel. +358 40 7084 481<br />

sami.ropponen@kesla.com<br />

More information:<br />

www.kesla.com<br />

www.ekesla.com

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 3<br />

INDEX<br />

KESLA CONTACT INFORMATION 2<br />

INDEX 3<br />

KESLA GRAPPLE LOADERS, GENERAL 5<br />

KESLA 200 - SERIES CRANES<br />

- technical specifications, dimensions, outreach diagrams<br />

- lifting capacity diagrams, mounting options, sales arguments<br />

KESLA 300 – SERIES GRAPPLE LOADERS 12<br />

- technical specifications, dimensions, outreach diagrams<br />

- lifting capacity diagrams, mounting options, sales arguments<br />

KESLA 500Z 18<br />

- technical specifications, dimensions, lifting capacity diagram<br />

- outreach diagram<br />

CONTROL VALVE ALTERNATIVES 21<br />

KESLA CRANE ACCESSORIES 25<br />

KESLA 8T, 9T, 9HD TRAILERS 32<br />

- ACCESSORIES<br />

KESLA 10T, 10H, 10HD, 10ND,12T, 12HD, 12ND,12MD/MDH TRAILERS 40<br />

- ACCESSORIES<br />

KESLA 19GX FELLING HEAD 61<br />

KESLA LF40 STROKE DELIMBER 62<br />

KESLA 60 ADDITIONAL HYDRAULIC PUMP KIT 64

FIELD OF APLICATION<br />

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 4<br />

The KESLA 200 and 300 -series cranes cover the needs in farming and forestry and<br />

they are especially useful for loading and lifting round timber, forage, manure,<br />

sand, loose fertilizer, fertilizer sacks etc. In forestry use the grapple loaders are<br />

suited for the farmer's own harvesting in thinning stands and also for professional<br />

work.<br />

OPERATING PRINCIPLE<br />

The operator guides the loader movements with a control valve. The valve transfers<br />

the hydraulic pressure, generated by the tractor, to the hydraulic cylinders of the<br />

loader, thus bringing about the wanted functions; slewing of booms, lifting of main<br />

lifting boom, compression of grapple etc. The loader valve is fitted with relief valves<br />

to prevent overloading of the grapple loader.<br />

Parts of a loader<br />

A-frame #21047104

200 –SERIE LOADERS<br />

Technical specifications<br />

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 5<br />

MODEL 201 202 202T 203 203T 204T<br />

Lifting capacity net kNm 19.0 19.8 19.2 30.5 27.5 37,0<br />

Max load @ 4m /<br />

outreach<br />

kg 400 525 490 770 700 800<br />

Max. outreach m 4.16 m 5.00 m 6.15 m 5.30 m 6.70 m 6.80 m<br />

Boom extension m - - 1.20 m - 1.40 m 1.65 m<br />

Slewing torque kNm 4.9 7.1 7.1 8.0 8.0 8.0<br />

Slewing angle º 400 400 400 380 380 380<br />

Rotator<br />

(torque/angle)<br />

Grapple max.<br />

opening<br />

750 Nm / continuous<br />

Finn-Rotor FR7<br />

(KESLA 18 grapple) 1240 mm (Kesla 19<br />

grapple)<br />

Weight * kg 670 700 785 965 1095 1095<br />

- Oil pressure Bar 175 190<br />

Recommended oil<br />

flow<br />

L/min 20 –30 25-40 25-40 30-50 30-50 30-60<br />

* Weight includes the grapple, rotator, rotator link and mechanical valve

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 6<br />

Dimensions<br />

I<br />

J<br />

H<br />

E<br />

F G<br />

D<br />

A<br />

L<br />

B<br />

C<br />

K<br />

MODEL 201 202 202T 203 203T 204T<br />

A mm 995 1324 1324 1375 1375 1375<br />

B mm 318 318 330 330 330<br />

C mm 652 652 652 635 635 635<br />

D mm 1105 1434 1434 1512 1512 1512<br />

E mm 35 35 35 100 100 100<br />

F mm 2465 2950 2950 3100 3100 3100<br />

G mm 1700 2050 2000 2155 2155 2155<br />

H mm - - 1200 - 1400 1650<br />

I mm 4165 5000 4950 5300 5300 5150<br />

J mm - - 6150 - 6700 6800<br />

K mm 1700-2300 1700-2300 1700-2300 1880-2680 1880-2680 1880-2680<br />

L mm 980 1150 1150 1250 1250 1250

Allowed loads<br />

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 7

Outreach diagrams<br />

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 8

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 9<br />

MOUNTING ALTERNATIVES<br />

You can either mount KESLA 200 series grapple loaders on the tractor's 3-point<br />

hitch, on the tractor's rear axle with special attachment kit or on the beam of a<br />

KESLA timber trailer. When mounting on trailer you may need attachment parts like<br />

a loader mounting plate or a loader mounting column, which you can get as<br />

accessories in a trailer price list.<br />

KESLA 201/202/202T

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 10<br />

MOUNTING ALTERNATIVES<br />

KESLA 203/203T/204T<br />

Recommendations:<br />

KESLA 201, 202, 202T, 203, 203T, 204T cranes and KESLA 8T/9T/9HD timber trailer<br />

KESLA 300 cranes / KESLA 10T, 10H/HD/ND, 12T, 12HD/ND, 12MD/MDH timber trailers<br />

Never connect a crane to the beam of a lighter class trailer. This means<br />

that e.g. the machine unit of KESLA 304 / KESLA 9T is forbidden!!!

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 11<br />

SALES ARGUMENTS FOR 201/202/203/204 –SERIES:<br />

• Practical transport position (204 different position)<br />

• Strong stabilizers, cylinders inside<br />

• One piece casted slew mechanism in oil bath ensures long life<br />

• Slewing angle 380-400 degrees<br />

• 2 –lever control valve system as standard<br />

• 0,18 m 2 or 0,19 m 2 grapple with bushings and continuous rotator<br />

• Main functions of loader protected with anti-cavitation shock relief valve for longer life<br />

• High quality steel, excellent strength in constructions<br />

• Very good retail value<br />

• Wide selection of control valves<br />

• Reliable after sales and spare parts

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 12<br />

300 –SERIE LOADERS<br />

Technical specifications<br />

MODEL 303 304 304T 305 305T<br />

Lifting capacity net kNm 37 44 40 51,6 46<br />

Max load @ 4m /<br />

outreach<br />

kg 810 1100 1000 1 290 1 150<br />

Max. outreach m 6.8 m 6.9 m 8.5 m 6.9 m 8.5 m<br />

Boom extension m 1.65 m 1.8 m 3.4 m 1.8 m 3.4 m<br />

Slewing torque kNm 13.5 13.5 13.5 16.0 16.0<br />

Slewing angle º 380 380 380 380 380<br />

Rotator<br />

(torque/angle)<br />

820 Nm<br />

/continuous<br />

Finn-Rotor<br />

FR7<br />

900 Nm / continuous<br />

Finn-Rotor FR10<br />

1100 Nm / continuous<br />

Finn-Rotor FR15<br />

Grapple max.<br />

opening<br />

(KESLA 19<br />

grapple)<br />

1 240 mm<br />

(KESLA 24 grapple) 1 260 mm<br />

Weight * kg 885 975 1070 1 260 1 370<br />

- Oil pressure Bar 190<br />

Recommended oil<br />

flow<br />

L/min 35 - 50 35 – 60 35 - 60 40 - 70 40 - 70<br />

* Weight includes the grapple, rotator, rotator link and mechanical valve

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 13<br />

DIMENSIONS<br />

J<br />

I<br />

H<br />

E<br />

F<br />

G<br />

D<br />

A<br />

L<br />

B<br />

MODEL 303 304 304T 305 305T<br />

A mm 1375 1454 1454 1570 1570<br />

B<br />

D<br />

E<br />

F<br />

G<br />

H<br />

I<br />

J<br />

L<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

mm<br />

334 334 334 356 356<br />

1515 1625 1625 1778 1778<br />

90 90 90 90 90<br />

2900 2900 2900 2900 2900<br />

2200 2200 2200 2200 2200<br />

1650 1800 3400 1800 3400<br />

5150 5100 5100 5100 5100<br />

6800 6900 8500 6900 8500<br />

1156 1156 1156 1168 1168

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 14<br />

OUTREACH DIAGRAMS AND ALLOWED LOADS

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 15<br />

MOUNTING ALTERNATIVES:<br />

Recommendations:<br />

KESLA 200 -series loaders and KESLA 8T/9T/ 9HD<br />

trailers.<br />

KESLA 300 -series loaders and KESLA<br />

10T/H/HD/ND, 12T/HD/ND and 12MD/MDH<br />

trailers.<br />

Never connect a crane to the beam of a lighter<br />

class trailer. This means that e.g. the machine<br />

unit of KESLA 305 / KESLA 9T is forbidden!<br />

To KESLA trailer (loader with A-frame) fig.1<br />

1 Mounting bolts of a loader<br />

2 A-frame with stabilizers<br />

3 Mounting bolts of mounting plate<br />

4 KESLA trailer<br />

To KESLA trailer (loader without A-frame)<br />

fig.2<br />

1 Mounting bolts of a loader<br />

2 Loader mounting column #21117158<br />

3 Mounting bolts of mounting column<br />

4 KESLA trailer<br />

5 Flap-down stabilizers for KESLA 10T-12T<br />

To rear axle of a tractor (with a special<br />

mounting kit) fig.3<br />

1 Mounting bolts of a loader<br />

2 Mounting console, specific for each tractor<br />

model

KESLA 300 -series A-frame<br />

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 16<br />

Mounting to 3-point hitch:<br />

The loader A-frame includes lugs that allow it to be attached to a tractor’s threepoint<br />

hitch. Only use the lugs to transfer the loader.<br />

Never use the loader to lift anything when it is attached to the hitch, as this may<br />

damage the hitch or the loader frame and tilt the loader!

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 17<br />

SALES ARGUMENTS FOR 300 -SERIES<br />

• Outer boom linkage system gives excellent loading geometry and constant power through out<br />

the full range of movement<br />

• Wide working area, excellent outreach<br />

• Short main boom makes loader easy to use at a close range, excellent ability to load near the<br />

base of the loader<br />

• Strong slewing mechanism:<br />

• One piece casted slew housing in oil bath with 4 slew cylinders<br />

• Slewing angle of 380 degrees<br />

• Bearing with sturdy bushing and spherical roller bearing<br />

• Dampers in slewing cylinders<br />

• One piece casted slew housing in oil bath with 4 slew cylinders. Slewing angle of 380 degrees<br />

• 2 –lever control valve system as a standard<br />

• 0,24 m ² grapple with bushings (303 0,19m ² grapple)<br />

• Continuous rotator and link with swing damper as standard<br />

• High quality steel, excellent strength in constructions<br />

• Very good retail value<br />

• Wide selection of control valves<br />

• Reliable after sales and spare parts

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 18<br />

KESLA 500Z LOADER<br />

KESLA 500Z is a Z-type loader for loading cut-to-length timber in light professional use. It’s<br />

also suitable for loading scrap, sand, fertilizers etc., when equipped with suitable grapple.<br />

The loader can be installed on the main beam of KESLA trailer with flap-down stabilizers.<br />

Control valves can be installed either in tractor cabin or at the pillar of the loader with<br />

operator’s seat.<br />

Technical specifications<br />

MODEL<br />

500Z<br />

Lifting capacity<br />

net<br />

Max load @ 4m /<br />

outreach<br />

kNm 37<br />

kg 705<br />

Max. outreach m 5.7<br />

Boom extension m 1.2<br />

Slewing torque kNm 7.1<br />

Slewing angle º 420<br />

Rotator<br />

(torque/angle)<br />

Grapple max.<br />

opening<br />

750 Nm / continuous<br />

Finn-Rotor FR7<br />

(KESLA 18 grapple) 1240 mm<br />

Weight * kg 960<br />

- Oil pressure Bar 175<br />

Recommended oil<br />

flow<br />

L/min 25 – 50<br />

* Weight includes the grapple, rotator, rotator link and mechanical valve

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 19<br />

Dimensions

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 20<br />

Outreach diagrams and allowed loads

THE MULTI-TALENT IN FOREST TECHNOLOGY<br />

OPTIONS – CONTROL VALVES<br />

SALES MANUAL – LOADERS<br />

DATE 1.1.2012 PAGE 21<br />

Finnhydraulic RS valves<br />

-4 mechanic levers<br />

-This RS- control valve is easy to operate, the operator always can keep his hands on the control levers (only the<br />

stabilizers are operated with separate levers). The extension and grapple are controlled by the ear shaped levers.<br />

The main levers are on the standard loader pattern. Main lift and slew have a floating position that permits loader<br />

movement during transportation. When in presence of closed center hydraulics this valve can be converted by<br />

adding a simple power beyond plug. A shock relief valve protects the whole system and some shock relief valves<br />

protect vital functions.<br />

Finn-Rotor FRV60/72<br />

-7 functions<br />

- 5 mechanic levers<br />

For KESLA 201<br />

#21053181<br />

RS 217 with 7 functions<br />

For KESLA 201 / 202 / 203<br />

#21037130<br />

RS 218 with 8 functions<br />

For KESLA 202T / 203T / 204T<br />

#21037141<br />

Walvoil SDS 100/8/CR<br />

-8 functions<br />

- 4 mechanic levers + 2 electric on/off switches<br />

(for grapple and telescope)<br />

For KESLA 202T / 203T / 204T<br />

#21047123

THE MULTI-TALENT IN FOREST TECHNOLOGY<br />

SERVOHYDRAULIC SYSTEMS<br />

Hydraulic pilot control (servo hydraulic<br />

system) is available for new KESLA loaders.<br />

Main advantages from hydraulic pilot control<br />

are:<br />

• light and ergonomic operating<br />

• no need to lift heavy control valve block<br />

when mounting loader<br />

• only light handles in the cabin of tractor<br />

• the valve block is located to the A-frame<br />

of the loader, well-protected<br />

SALES MANUAL – LOADERS<br />

DATE 1.1.2012 PAGE 22<br />

System includes hydraulic pilot control for<br />

main functions (slewing, main boom, outer<br />

boom, rotator). Grapple, boom extension<br />

and stabilizers are controlled electrohydraulically<br />

with electric switches.<br />

Finn-rotor FRV60 servohydraulic<br />

- for 200 and 300 series<br />

#21050460<br />

Walvoil SD8 servohydraulic<br />

#21050110 for 200-series<br />

#21050107 for 300-series

THE MULTI-TALENT IN FOREST TECHNOLOGY<br />

ELECTRO-HYDRAULIC SYSTEMS<br />

Electro-hydraulic control (electric pilot control) is available for new<br />

KESLA 200 and 300 –series loaders. Main advantages from electrohydraulic<br />

control system are:<br />

• light and ergonomic operating<br />

• no need to lift heavy control valve block when mounting loader<br />

• only light joysticks in the cabin of tractor<br />

• the valve block is located to the A-frame of the loader, wellprotected<br />

• smooth and accurate control<br />

• adjustable (depending on the model)<br />

System includes electric joysticks for main functions.<br />

The stabilizers are controlled with electric switches<br />

SALES MANUAL – LOADERS<br />

DATE 1.1.2012 PAGE 23<br />

WALVOIL SDM 100/ 8 #21050484<br />

• Basic electric control valve<br />

• 4 proportional + 4 on/off -valves<br />

DANFOSS PVG 32<br />

Hydraulic load-sensing valve designed to give maximum<br />

flexibility. Main advantages for PVG 32 are:<br />

-Load independent flow control and accurate flow<br />

controllability:<br />

•Oil flow to an individual function is<br />

independent of the load pressure of this function<br />

•Oil flow to one function is independent of the<br />

load pressure of the other functions.<br />

-Good regulation characteristics<br />

-Energy saving<br />

-Low weight<br />

-Max flow per section 129 l/min, max pressure per<br />

section 350 bar (5075 psi)<br />

Options:<br />

PVRE- joystick<br />

21050108 PVG32/6 (4 proportional + 2 on/off functions), PVRE -<br />

joysticks<br />

21050112 PVG32/8 (4 proportional + 4 on/off functions), PVRE -<br />

extended- joysticks<br />

21050126 PVG32/6 (6 proportional functions), Prof1 extendedjoysticks<br />

21050128 PVG32/8 (6 proportional + 2 on/off functions), Prof1<br />

extended- joysticks<br />

Prof1- joystick

THE MULTI-TALENT IN FOREST TECHNOLOGY<br />

SALES MANUAL – LOADERS<br />

PARKER – the best you can get -<br />

P70 / IQAN electric control system is available for new KESLA loaders (for variable pump #21050115<br />

and for fixed pump #21050116, both 8 spools).<br />

Main advantages for P70 electric control system are:<br />

• Low lever forces: smooth and comfortable actuation characteristics reduce fatigue, increase<br />

precision and raise productivity<br />

• Pressure compensated spools, which are particularly advantageous in lifting and lowering<br />

movements<br />

• Separate load-hold check valves, which prevent interference in load lowering functions when other<br />

functions are operated simultaneously<br />

• Small dimensions and low weight of equipment<br />

• High grade materials and precision manufacturing: give quality product with low internal leakage<br />

and long service life<br />

• Recommended oil flow for P70 is 25-75l/min, for working pressures up to 320 bar<br />

LS90 / IQAN electric control system is available for new KESLA loaders (6 spools #21050113 and 8<br />

spools #21050114).<br />

Main advantages for LS90 electric control system are:<br />

• Stackable, multi-section, load-sensing, pressure-compensated directional valve for cranes and<br />

harvesters<br />

• Recommended maximum oil flow for LS90 is 5-130l/min, for working pressures up to 320 bar<br />

Both Parker IQAN systems are controlled with LM-3D mini-joysticks #21051121 (Frameco armrestpair<br />

included) for in-cab use. The combination of a mini lever and armrest provide a substantial<br />

ergonomic benefits.<br />

LM-3D mini-joystick<br />

and Frameco armrest

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 25<br />

KESLA operator seats<br />

#21038134 for KESLA 201, 202, 202T<br />

#21038652 for KESLA 203, 203T, 204T<br />

#21038133 for KESLA 304, 304T, 305, 305T<br />

Measurements in millimeters

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 26<br />

Flap-down stabilizers (#11180001 / #11929004 stronger)<br />

Hydraulic flap-down stabilizers for KESLA 10T, 10H, 10HD, 10ND and<br />

12T, 12H, 12HD, 12ND, 12MD/MDH trailers available as option.

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 27<br />

KESLA GRAPPLES<br />

KESLA 18<br />

KESLA 24

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 28<br />

KESLA GRAPPLES<br />

Timber grapples<br />

Technical<br />

specifications<br />

Gripping area tip<br />

to tip<br />

Working pressure<br />

max<br />

Gripping force tip<br />

to tip<br />

Opening time @<br />

50 l/min flow<br />

m²<br />

bar<br />

kN<br />

s<br />

KESLA 18<br />

#11307001<br />

KESLA 19<br />

#11307003<br />

KESLA 24<br />

#11314001<br />

0.18 0.19 0.24<br />

175 190 190<br />

6.4 6.6 8.5<br />

0.6 0.6 1.0<br />

Closing time s 0.9 1.0 1.3<br />

Weight kg 67 80 115<br />

Energy grapples<br />

KESLA 15E energy grapple 0,15 m² #11314002<br />

KESLA 20E energy grapple 0,20 m² #90018671<br />

Working light set #29010647<br />

- Cranes 303-305T<br />

- 2 pcs. H-3 lights on outer boom

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 29<br />

ACCESSORIES<br />

Gravel clamshell bucket (attachment on grapple)<br />

#11917000 for Kesla 18 grapple (201-203T)<br />

#11917001 for Kesla 19 grapple (204T-303)<br />

#11914001 for Kesla 24 grapple (304 – 305T)<br />

- For loading soil, gravel etc.<br />

- Easy installation on timber grapple<br />

- Good penetration into material, thanks to narrow design<br />

For grapple: KESLA 18 KESLA 24<br />

Width min 350 mm 370 mm<br />

Width max 750 mm 800 mm<br />

Volume / pair 120 l<br />

150 l<br />

Weight 56 kg 71 kg<br />

KESLA manure/forage grab (attachment on grapple)<br />

#11916000 for Kesla 18 timber grapple (201 – 203T)<br />

#11915001 for Kesla 19 & 24 timber grapple (204T – 305T)<br />

- Suited for loading silage and hay as well as manure. Useful also when lifting<br />

unwrapped round bales<br />

- Easy mounting on timber grapple<br />

For grapple: KESLA 18 KESLA 24<br />

Number of tines 4<br />

Width 675 mm 710 mm<br />

Weight 38 kg 43 kg

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 30<br />

Accessories<br />

KESLA digging device<br />

(#11920002 for 201/202/202T, #11920004 for 203/203T)<br />

Makes a KESLA loader to efficient backhoe digger.<br />

2 ton breaking force at the bucket tip<br />

Easy and quick installation with hydraulic quick couplings (provided)<br />

2 bucket alternatives, ditch forming bucket & drain bucket<br />

drain bucket<br />

#11927000<br />

Technical specifications<br />

Bucket volume - ditch forming bucket<br />

ditch forming<br />

bucket<br />

#21920102<br />

KESLA digging device<br />

120 l<br />

- drain bucket 60 l<br />

Bucket width - ditch forming bucket 1100 / 180 mm<br />

Breaking force at bucket tip<br />

- drain bucket 330 mm<br />

2 ton @ 175 bar pressure<br />

-boom and cylinder<br />

-ditch forming bucket<br />

-drain bucket<br />

63 kg<br />

86 kg<br />

64 kg

KESLA remote controlled winch<br />

Kesla We1400P winch # 3301296 is remote controlled version for Kesla 200- and<br />

300-series loaders.<br />

Technical data:<br />

-Pulling force 1400 kg/175 bar<br />

-Speed 27 m/min<br />

-Wire rope Ø 6 mm / 40 m<br />

-Weight 45 kg<br />

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 31<br />

The Kesla We1400P remote controlled hydraulic winch is driven by cog-wheel to get the best<br />

effect. An enclosed valve regulates the winding-up process, the middle position is a motor<br />

brake position and off position of the drum enables to draw out the wire. The valve is mounted<br />

with enclosed tubes in a series with the crane’s hydraulic system.<br />

Wireless managing<br />

A transmitter regulates the winding-up process, when transmitting breaks, the cog-wheel<br />

comes to the off position and the wire can be drawn out. The valve is mounted and well<br />

protected near the engine of the winch. The little receiver is placed inside the cabin for best<br />

protection and the electric cable is connected to the tractor’s trailer contact. The system is<br />

developed for the forest industry to manage a demanding environment.

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 32<br />

8T, 9T/9HD TRAILERS<br />

Field of application<br />

KESLA 8T, 9T/9HD trailers<br />

are designed to be used<br />

together with loaders KESLA<br />

200 – series loaders<br />

especially for timber<br />

forwarding in thinning<br />

stands, but are also well<br />

suited for professional timber<br />

hauling. All kinds of timber,<br />

from firewood stems and<br />

pulpwood to logs, can be<br />

transported with the trailers.<br />

In addition the trailer lends<br />

itself to transport of round<br />

bales, if fitted with suitable<br />

round bale equipment.<br />

Optional hydraulic drawbar articulation – with 2-cylinders (8T – 1-cylinder)<br />

The use of the drawbar articulation makes the trailer follow the tractor, thus diminishing the<br />

damage caused to the growing trees alongside the skid road. Stability of the trailer in slope<br />

can be increased by turning the bar uphill. Using the drawbar to steer the bogie to run beside<br />

stones and stumps prevents the trailer from useless inclination. The closer the bogie is, the<br />

more nimble and more stable in turns is the trailer. Thanks to the drawbar, the loader<br />

mounted to the trailer will get an extra reach of about 80 cm.

MAIN PARTS OF A TRAILER<br />

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 33<br />

1. Drawbar – optional drawbars in the price list<br />

2. Parking leg<br />

3. Hydraulic hoses<br />

4. Towing eye<br />

5. Drawbar articulation cylinder – optional<br />

6. Head rack – optional<br />

7. Crossbeam<br />

8. Stake<br />

9. Crossbeam<br />

10. Drive motor, driving motor, cyliders of drive rollers<br />

(KESLA 9HD, 10HD, 12HD)<br />

The maximum permitted loads (without crane) for KESLA trailers:<br />

• 8T<br />

8 000 kg<br />

• 9T/HD<br />

9 000 kg<br />

• 10T/H/HD/ND<br />

10 000 kg<br />

• 12T/HD/ND/MD/MDH 12 000 kg<br />

Always also check the capacity of the draw hook of the tractor in the tractor manual.

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 34<br />

DRAWBAR OPTIONS 9T/HD:<br />

#21103161<br />

#21124152 #21124154<br />

#29011573 #21103513 – straight drawbar with fork hitch-<br />

BRAKES:<br />

• 2-wheel and 4-wheel hydraulic drum brakes<br />

• 4-wheel pneumatic brakes – requires pneumatic system in tractor<br />

• Eurosafe ES-V hydraulic parking brake<br />

WHEELS:<br />

8T trailer<br />

11,5/80x15,3<br />

9T/HD trailer 400/60 x 15.5<br />

- Optional Alliance tire # 3300027

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 35<br />

SALES ARGUMENTS 8T,9T/HD:<br />

All KESLA trailers feature robust frame with single main beam. This means several advantages:<br />

• Sturdy central beam tube 150x150 mm, 10 mm thick<br />

• Frame with single beam makes trailer easy to unload the last logs<br />

• Trailer doesn’t stuck to stones and stumps as easy as a trailer with double beams frame<br />

• There is no weak, welded corners in the trailer frame<br />

• It’s easy to put grapple around the beam during transporting of empty trailer<br />

• Solution makes trailer lighter than trailers with double beams<br />

• The bunks are movable, rear axle can be locked in 4 positions<br />

• Pivot joint pin diameter of 80 mm, with large bushings<br />

• Rocking beam joints with sturdy bushings<br />

• Robust, movable head rack height of 126 cm<br />

ACCESSORIES:<br />

• Head rack #11196000<br />

• Head rack support – between stake and head rack #21110675<br />

• Tool box to be installed on head rack #21196103<br />

• Hydraulic drawbar articulation kit – with two cylinders (8T one cylinder) #21103160<br />

• Locking valve for hydraulic drawbar #21110417<br />

• Mounting plate for 203/203T/204T cranes #11190002<br />

• Movable extra crossbeam with stakes #21103001<br />

• Frame extension #29010614<br />

• Rear light set 12V #21110200<br />

• Bioenergy transportation set #29011438

DIMENSIONS:<br />

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 36<br />

MODEL 8T 9T 9HD<br />

A mm 5420 5420 5420<br />

B mm 2080 2080 2080<br />

C mm 1910 1910 1910<br />

D mm 1780 1780 1780<br />

E mm 530 530 530<br />

F mm 3500 3500 3500<br />

G mm 1660 1660 1660<br />

H mm 1260 1260 1260<br />

I mm 4035 -4750 4035 -4750 3935-4335<br />

J m² 1.80 1.80 1.80<br />

K mm 1260 1260 1260

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 37<br />

Technical specifications<br />

MODEL 8T 9T 9HD<br />

Max. load Tons 8 9 9<br />

Total length mm 5420 5420 5420<br />

Total width Mm 2080 2080 2080<br />

Load Area m² 1,80 1,80 1,80<br />

Length of<br />

load space<br />

mm 3500 3500 3500<br />

Ground<br />

clearance<br />

mm 530 530 530<br />

# of bunks pcs 2 2 2<br />

Weight basic<br />

trailer<br />

Steering<br />

angle<br />

Kg 950 1020 1050<br />

º +38 +38 +38<br />

Wheel size 11,5/80x15,3 400/60x15,5 400/60x15,5<br />

# of ply pcs 10 14 14<br />

Drive power ton - - 1,2<br />

Max pressure bar - - 175<br />

Max speed Km/h - - 5,0<br />

Maximum drawbar load ( 25 km/h) for KESLA 8T/9T/9HD trailers is 1500 kg!

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 38<br />

HYDRAULIC DRIVE (9 HD)<br />

•When engaging the pressure from the valve to the trailer traction, the pressure in the dividing<br />

block (inside the trailer frame) will be divided to the hydraulic motors (to the drive roller) on<br />

both sides. The working pressure is also directed to the arm cylinders, which effects the settling<br />

of the rollers between the tyres.<br />

•When centering the control valve spool (stopping the trailer traction) the hoses will get<br />

connected with the tank through the control valve spool. Now also the pressure in the arm<br />

cylinder (which presses down the drive rollers) will drop to tank pressure and the recoil spring<br />

inside the cylinder will raise the arm (the drive roller).<br />

•The control valve shall be fitted with a pressure-relief valve for the working pressure. The max<br />

pressure of the drive hydraulics is 175 bar.<br />

When the work pressure hoses are connected to the tractor hydraulics, the pressure-relief is<br />

usually attended to (in newer tractors about 180 bar.)<br />

The pressure-relief valve is included in the control valve available as an accessory for the<br />

KESLA 9HD trailer.<br />

Drive roller, driving motor<br />

and cylinder of the roller

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 39<br />

COUPLING EXAMPLES<br />

Loader valve<br />

TRACTOR HYDRAULICS<br />

P<br />

T<br />

KESLA<br />

8T/9T/HD<br />

Single acting outlet<br />

Double acting outlet<br />

Brake hose<br />

(option)<br />

Double acting outlet<br />

Drawbar<br />

hoses<br />

KESLA 9HD<br />

TRACTOR HYDRAULICS<br />

Single acting outlet<br />

From auxiliary hydraulics<br />

Loader valve<br />

P<br />

Brakes<br />

(option)<br />

T<br />

Option 1:<br />

<strong>Tractor</strong> with one<br />

single acting and<br />

two double acting<br />

outlets.<br />

Double acting outlet,<br />

spool with a floating<br />

position<br />

Trailer power drive<br />

Double acting outlet<br />

Drawbar<br />

articulation<br />

Control valve<br />

TRACTOR HYDRAULICS<br />

To the reservoil r<br />

Double acting outlet<br />

Double acting outlet<br />

P<br />

T<br />

Loader valve<br />

Power beyond<br />

Trailer power<br />

drive<br />

Brake hose<br />

(option)<br />

T<br />

Drawbar hoses<br />

Option 2:<br />

<strong>Tractor</strong> with two<br />

double acting outlets<br />

- One action of the<br />

tractor’s double acting<br />

valve to the control<br />

valve (#21110314),<br />

the other to the brake.<br />

- Return hoses of<br />

loader and drive<br />

control valve directly<br />

to the tank.

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 40<br />

10T/H/HD/ND & 12T/HD/ND AND 12MD/MDH TRAILERS<br />

Field of application<br />

KESLA 10T, 10H, 10HD, 10ND and 12T, 12HD, 12MD/MDH trailers are designed to professional<br />

timber forwarding together with KESLA 300 – series loaders. Hydraulic drive of KESLA 10HD/ND<br />

and 12HD/ND improves significantly propagation of tractor/trailer- combination. Mechanical<br />

bogie drive of KESLA 12MD and hydrostatic-mechanical bogie drive of KESLA 12MDH enables full<br />

transportation capacity also in the hardest terrain conditions.<br />

All KESLA trailers have robust frame with single main beam. This means several advantages:<br />

Thanks to single beam, unloading the last logs of the load is easy.<br />

Trailer doesn’t stuck to stones and stumps as easy as a trailer with double beams frame<br />

There is no weak, welded corners in the trailer frame<br />

It’s easy to put grapple around the beam during transporting of empty trailer<br />

Solution makes trailer lighter than trailers with double beam tubes.<br />

10T<br />

<strong>Sales</strong> arguments:<br />

• Sturdy single main beam of 200x200x10 mm<br />

• Drawbar articulation with double cylinders<br />

• Robust, movable head rack height of 132 cm<br />

• Movable crossbeams and rear axle<br />

(rear axle can be locked in 4 positions)<br />

• Pivot joint pin as well as rocking beam joints with<br />

large bushings<br />

•Wheel spindles with high quality conical bearings<br />

• Wheel options<br />

• Optional brakes<br />

• Very good retail value<br />

• Reliable after sales and spare parts

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 41<br />

Technical specifications<br />

MODEL 10T 10H/HD 10ND 12T/HD/ND 12MD 12MDH<br />

Max. load Ton 10 10 10 12 12 12<br />

Total<br />

length<br />

mm 6050 6050 6050 6050 6210 6210<br />

Total<br />

width<br />

Load<br />

Area<br />

Mm 2260 2260 2500 2500<br />

2550 (12T)<br />

2250 2250<br />

m² 2,7 2,7 2,7 3,15 3,15 3,15<br />

Length of<br />

load<br />

space<br />

Ground<br />

clearance<br />

# of<br />

bunks<br />

Weight<br />

basic<br />

trailer<br />

Steering<br />

angle<br />

Wheel<br />

size<br />

mm 3900 3900 3900 3900 4050 4050<br />

mm 550 530-600 530-580 550-580 550-580 550-580<br />

pcs 3 3 3 3 4 4<br />

Kg 1490 2030<br />

2180 (HD)<br />

2250 2250 (12T)<br />

2930 (12HD)<br />

3000 (12ND)<br />

3220 3700<br />

º +40 +40 +40 +40 +40 +40<br />

400/60x15,5<br />

15,0/70x18<br />

500/55x17<br />

400/60x15,5<br />

400/55x22,5<br />

500/55x17<br />

550/45x22,5 (HD)<br />

400/55x22,5<br />

550/45x22,5<br />

550/45x22,5<br />

550/45x22,5<br />

550/50x22,5<br />

550/45x22,5<br />

550/50x22,5<br />

600/50x22,5<br />

# of ply pcs 12-14 12-14 12-14 12-14 12-14 12-16<br />

Drive<br />

power<br />

ton - 1,4t (HD)<br />

Opt. (H)<br />

1,5-3,0t*<br />

1,4 t (12HD)<br />

1,5-3,0(12ND)<br />

5,3 t 4,8 t<br />

Max<br />

pressure<br />

Max<br />

speed<br />

bar - 175 175 175 - -<br />

Km/<br />

h<br />

4,0 4,0<br />

(2-WD)<br />

2,5<br />

(4-WD)<br />

4,0<br />

(2-WD, 12HD)<br />

2,5<br />

(4-WD)<br />

15,0 5,0<br />

* Theoretical values

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 42<br />

10 T

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 43<br />

10H, 10HD<br />

<strong>Sales</strong> arguments:<br />

• Sturdy single main beam of 200x200x10 mm<br />

• Hydraulic drive with 1.4 ton traction force (optional in H)<br />

• Drawbar articulation with two cylinders<br />

• Strong, movable head rack height of 132 cm<br />

• Movable bunks<br />

• Strong rear axle<br />

• Pivot joint pin as well as rocking beam joint with durable bushings,<br />

robust pivot joint is made to last<br />

• High quality conical bearings in wheel spindles<br />

• Wheel options<br />

• Optional brakes<br />

• Very good retail value<br />

• Reliable after sales and spare parts

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 44<br />

Hydraulic drive (10 HD)<br />

•When engaging the pressure to the trailer traction, the pressure in the dividing block (inside<br />

the trailer frame) will be divided to the hydraulic motors (to the drive rollers) on both sides. The<br />

working pressure is also directed to the arm cylinders, which press the rollers between the<br />

tyres.<br />

•When centering the control valve spool (stopping the trailer traction) the hoses will get<br />

connected to the tank through the control valve spool. Now also the pressure in the arm<br />

cylinders (which presses down the drive rollers) will drop to tank pressure and the recoil<br />

springs inside the cylinders will raise the arms (the drive roller).<br />

•The control valve shall be fitted with a max. pressure-relief valve for the working pressure.<br />

The max. pressure of the drive hydraulics is 175 bar. When the working pressure hoses are<br />

connected to the tractor’s own hydraulics, the max. pressure-relief is usually attended to (in<br />

new tractors usually 175 bar). The pressure-relief valve is included in the control valve<br />

available as an accessory (#21110314)<br />

Drive roller, driving motor<br />

and cylinder of the roller

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 45<br />

10 H, 10 HD

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 46<br />

Hydraulic nave drive (10 ND)

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 47<br />

Hydraulic drive with wheel motor (10 ND)<br />

The hydraulic motor is equipped with a hydraulic one-way clutch. When motors are used,<br />

pressure is connected to the control line, and the spool inside the motor allows normal oil flow in<br />

the motor. When control pressure is removed, the spool prevents oil from getting under the<br />

pistons, the springs keep the pistons inside the cylinder block and the motors go into free rotation<br />

mode. In a KESLA 10ND trailer, switching pressure is taken through change valves and a<br />

pressure reducer from the working line, so a separate control line from the tractor is not<br />

required. Therefore switching into free rotation takes place automatically when pressure<br />

disappears from the working line. When driving on the road, the drive hydraulics must be<br />

switched off, unless required in a specific situation. This is because when the trailer brakes<br />

(accessory) are used, pressure in the working line increases and motors are switched on causing<br />

a decrease in braking power and premature wear of the brakes.

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 48<br />

Coupling examples<br />

10T, 10H<br />

10HD, 10ND

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 49<br />

Coupling examples<br />

10HD, 10ND

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 50<br />

DRAWBAR OPTIONS 10T-10ND:<br />

#21110421<br />

#21110443 #21110444<br />

#21110620 #21110643<br />

WHEELS:<br />

15,0/70x18<br />

400/60 x 15.5 -Basic/Alliance-<br />

500/55 x 17 Alliance<br />

400/55 x 22,5 (10H/HD)<br />

550/45 x 22,5 (10HD/ND)

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 51<br />

ACCESSORIES 10T -10ND:<br />

• Drive control valve #21110314<br />

• Mounting plate for 203/203T/204T cranes #11190003<br />

• Mounting plate for 304-305T cranes – with flap-down stabilizers #11184001<br />

• Mounting column for 304-305T cranes #21117158<br />

• Flap-down stabilizers #11180001 and #11929004 (stronger)<br />

• Head rack support – between stake and head rack #21110675<br />

• Movable extra crossbeam with stakes #21120001<br />

• Frame extension #21110503<br />

• Tool box #21196103<br />

• Rear light set 12V #21110200<br />

• Bioenergy transportation set #29011571<br />

• Hydraulic parking brake #3301378

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 52<br />

12T, 12HD, 12ND<br />

<strong>Sales</strong> arguments:<br />

• Sturdy single main beam of 200x200x12,5 mm<br />

• Hydraulic drive with 1.4 ton traction force (12HD)<br />

• Hydraulic drive with 1,5 – 3,0 ton traction force (12ND)<br />

• Drawbar articulation with two cylinders<br />

• Strong, movable head rack height of 132 cm<br />

• Movable bunks<br />

• Strong rear axle<br />

• Pivot joint pin as well as rocking beam joint with durable bushings,<br />

robust pivot joint is made to last<br />

• High quality conical bearings in wheel spindles<br />

• Many different wheel options<br />

• Optional brakes<br />

• Very good retail value<br />

• Reliable after sales and spare parts

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 53<br />

12MD / 12MDH<br />

KESLA 12MD is equipped with sturdy mechanical drive with huge 5.3 tons traction force.<br />

Transmission is fully mechanical with oil-bathed chain transmission in bogies. Power<br />

transmission is to be connected to ground-speed PTO of tractor (type and tire size of tractor<br />

has to be informed so that right gear ratio can be adjusted).<br />

KESLA 12MDH has hydrostatic-mechanical power transmission to be used with tractors<br />

without ground-speed PTO (to be connected to 540rpm PTO). It gives 4.8 tons traction<br />

force. Hydraulic system of the trailer is equipped with 71cm3 variable-displacement pump<br />

(Rexroth) and driving motor Danfoss OMV 400. Oil flow and driving direction are controlled<br />

by electrical valve. Oil tank of 120 liters (31.7 gal US) with return filter is in inside the loader<br />

mounting column. The hydraulic system of trailer can be used also for loader.<br />

Trailers are featured with a unique traction release clutch, witch means that trailer doesn’t<br />

restrict the driving speed on roads.<br />

<strong>Sales</strong> arguments:<br />

• Robust single main beam tube of 250x250x10 mm<br />

• Drawbar articulation with two cylinders<br />

• Sturdy, movable head rack height of 162 cm<br />

• Large load capacity<br />

• Movable front & rear crossbeams<br />

• Robust pivot joint with large pin and bushings<br />

• Rocking beam joints with durable bushings<br />

• Wheel spindles with high quality conical bearings<br />

• Wheel options<br />

• Very good retail value<br />

• Reliable after sales and spare parts

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 54<br />

Power transmission of 12MD<br />

2<br />

3<br />

The transmission mechanism of KESLA 12 MD<br />

can only be connected to a tractor with<br />

ground-speed PTO, and the transmission ratio<br />

of the trailer must be suited for the tractor in<br />

question.<br />

1: Reduction gear<br />

2: Drive gear<br />

3: Chain gear in oil<br />

bath<br />

4: Traction release<br />

clutch<br />

4<br />

1<br />

When driving with ground-speed PTO<br />

engaged, the torque from the tractor is<br />

transmitted through the transmission line to<br />

the reduction gear of the trailer, and through<br />

an overload switch to the release clutch and<br />

the drive gear. The transmission ratio is to be<br />

made suitable for the tractor in the reduction<br />

gear. A disc coupling with the torque adjusted<br />

to be equal to the maximum traction power<br />

operates as an overload switch. The release<br />

clutch can be used to disengage the<br />

transmission when faster speed is needed<br />

(driving on road). The drive gear is equipped<br />

with a differential gear.<br />

From the drive gear the torque is transferred<br />

to both bogies with drive shafts that drive the<br />

wheels through the chain gear. The roller<br />

chains are oil immersed and equipped with<br />

tighteners.

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 55<br />

Power transmission of 12MDH<br />

6<br />

4<br />

7<br />

5<br />

2<br />

While the power transmission<br />

mechanism of KESLA 12 MD is fully<br />

mechanical, KESLA 12 MDH<br />

features a hydrostatic-mechanical<br />

power transmission. Components<br />

are similar but instead of drive shaft<br />

from ground-speed PTO there is a<br />

variable displacement hydraulic<br />

pump (Rexroth 71cc) and drive<br />

motor (Danfoss OMV 400). This<br />

systems features adjustable gear<br />

ratio and is to be fitted to any<br />

tractor with 540rpm PTO.<br />

1<br />

KESLA 12 MDH is equipped with<br />

integral oil tank placed inside the<br />

loader mounting column. Hydraulic<br />

system can be used also to use the<br />

loader.<br />

3<br />

1: Pump Rexroth 71<br />

2: Drive motor Danfoss OMV-400<br />

3: Electrically controlled valve<br />

4: Oil tank<br />

5: Pressure filter<br />

6: Return filter<br />

7: Oil cooler

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 56<br />

12MD<br />

Coupling examples<br />

12MD

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 57<br />

12MDH<br />

Coupling examples

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 58<br />

12 MD, 12 MDH dimensions

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 59<br />

DRAWBAR OPTIONS 12T-12ND:<br />

#21110700<br />

#21110727 #21110951<br />

DRAWBAR OPTIONS 12MD/MDH:<br />

#21122153<br />

#21122764<br />

#21122154<br />

#29011400<br />

#21122765

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 60<br />

ACCESSORIES 12T -12MDH:<br />

• Drive control valve #21110314 (12HD)<br />

• Mounting column for 304-305T cranes #21117158<br />

• Mounting plate for flap-down stabilizer #11184001<br />

• Flap-down stabilizers #11180001, #11929004 (stronger)<br />

• Head rack support – between stake and head rack #21110675<br />

• Movable extra crossbeam with stakes #21121161<br />

• Frame extension #21110633<br />

• Tool box #21196103<br />

• Rear light set 12V #21110200, #21110192 (12HD-MDH)<br />

• Bioenergy transportation set #29011689 (12T-12ND)<br />

• Bioenergy transportation set #29011705 (12MD/MDH)<br />

• Hydraulic parking brake #3301378

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 61<br />

KESLA 19 GX – Energy Grapple<br />

19GX – Energy grapple with guillotine cutting blade<br />

- Easy turnable blade, possible to load with same grapple<br />

- Cutting diameter approx. 150mm (max. 190mm)<br />

- Grapple opening 700mm<br />

- Coupling to the rotator without separate wires and hoses<br />

- Tilting functions by using simultaneously grapple closed/open and rotator<br />

- Weight approx.190kg, fits also in small cranes

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 62<br />

KESLA LF40 stroke delimber # 11504000<br />

KESLA LF40 stroke delimber is well-suited for self-employed forest owners or light<br />

contracting use. KESLA LF40 delimbs, cross-cuts and piles the timber along the<br />

skidroad ready for forwarding. Work is conducted on the skidroad and the stems<br />

are fed in from both sides of the skidroad.<br />

Chainsaw<br />

Chain oil<br />

tank<br />

Jaws<br />

Knives<br />

LF40 is to be fitted<br />

to A-frame<br />

#21047104<br />

(standard for<br />

KESLA 203/203T,<br />

204T available<br />

also for KESLA<br />

202/202T) with<br />

mounting kit<br />

#21504182<br />

KESLA 60 pump kit<br />

(#21504165) is<br />

available if<br />

external hydraulics<br />

are needed.

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 63<br />

KESLA LF40 stroke delimber<br />

Technical specifications<br />

KESLA LF40<br />

Length Min 2440mm (8’), max 3690mm (12’1”)<br />

Width 840 mm (2’5”)<br />

Height 1350 mm (4’5”)<br />

1700 mm (5’7”) with parking legs<br />

Weight<br />

Working pressure<br />

Oil flow required<br />

540 kg (1190 lbs)<br />

175 – 210 bar (2500 – 3000 PSI)<br />

50 – 60 l/min (13 – 15 gal imp.)<br />

Stroke of delimbing cylinder 1000 / 1220 / 1250 mm (3’3” / 4’ / 4’1”)<br />

Slewing angle 260<br />

Slewing torque<br />

Tilting angle - knife end<br />

- saw end<br />

1100 – 2200 Nm (800 – 1600 lbft)<br />

15<br />

5<br />

Cutting diameter max 400 mm (16”)<br />

Delimbing diameter max 350 mm (14”)<br />

Chain saw<br />

16” bar, .404” chain<br />

The following values @ 175 bar (2500 PSI) pressure and 50l/min (13 gpm US) flow:<br />

-delimbing force<br />

- delimbing speed -stroke out<br />

-stroke in<br />

21.5 kN (4800 lbs)<br />

0.66 m/s (26”/s)<br />

1.20 m/s (47”/s)<br />

- saw power 12 kW (16 hp)<br />

- chain speed 38 m/s (125’/s)

TIMBER LOADERS & TRAILERS<br />

SALES MANUAL Date: 01/01/2012 PAGE 64<br />

KESLA 60 ADDITIONAL HYDRAULIC PUMP KIT<br />

- mounted on A-frame #21504165 or on trailer #21110909<br />

- oil flow 60 l/min (540 r.p.m)<br />

- max. oil pressure 210 bar<br />

- oil tank 80 l<br />

- weight 70 kg (without oil)<br />

- additional oil cooler #3300838 for hard conditions