Hammond Organ Service Manual - Early Models (A,B ... - Audiofanzine

Hammond Organ Service Manual - Early Models (A,B ... - Audiofanzine

Hammond Organ Service Manual - Early Models (A,B ... - Audiofanzine

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

It<br />

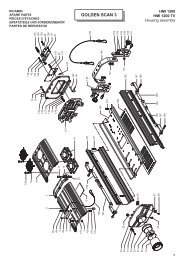

CONSOLE POWER WIRING<br />

{Main and Chorus Generators)<br />

0.<br />

Starting and Synchronous Motors<br />

A shaded pole induction motor is used for starting the generator and<br />

is located at the right end of the generator as viewed from the back.<br />

The rotor of this motor will slide endwise when current is supplied<br />

and engage a pinion on its shaft with a gear on the generator driving<br />

shaft, bringing the tone generator up to slightly greater than synchronous<br />

speed.<br />

When the organ is started, the starting switch is turned on and held<br />

for about 8 seconds while the starting motor brings the system up to<br />

speed. The "run" switch is then turned on. This switch simultaneously<br />

connects the synchronous motor and introduces a resistor in series<br />

with the starting motor (Figure l), thus reducing its driving power.<br />

With a braking action of the synchronous motor and a loss of power<br />

of the starting motor, the system slows to synchronous speed and<br />

the synchronous motor begins to carry the load. A period of about<br />

B seconds should be allowed for this to take place, after which the<br />

starting switch may be released. The starting switch springs back<br />

to the "off" position, and turns off the starting motor, which is<br />

disengaged from the rotating shaft by a spring-<br />

should be noted that the synchronous motor can supply power only<br />

at synchronous speed, Thereforei if for any reason the system fails<br />

to reach synchronous speed it will not continue to run after the starting<br />

switch is released. Failure to start properly is usually due to<br />

increased oil viscosity and may be overconne by an increase in starting<br />

time.<br />

As the schen-iatic diagram (Figure 1) indicates, the "run" switch in its<br />

"off" position shorts out the wirewound resistor attached -o the line<br />

panel. If the "run" switch is defective in its '"off*" position, the generator<br />

will not start because this resistor will be permanently in series with<br />

the starting motor. Before assuming that there is anything amiss with<br />

the motors, short out this resistor and start the generator in the norrnal<br />

manner. If the generator operates satisfactorily, replace the "run" switch<br />

The "run" switch on all consoles is a two-circuit switch, but types of<br />

switches having two different terminal arrangements have been used, as<br />

shown in Figure 2. When replacing a switch, observe the wiring of the<br />

old switch and check the connections of the new switch with an ohmmeter.<br />

Note that black and blue are connected in the "on" position, and yellow<br />

and brown are connected in the "off" position, no rnatter which type of<br />

switch is used.<br />

STARTING MOTORS<br />

CHORUS<br />

MAIN<br />

<<br />

I<br />

W<br />

m<br />

o<br />

Q<br />

Z<br />

< -J a<br />

<<br />

MAIN<br />

SYNCHRONOUS MOTORS<br />

CHORUS<br />

ON<br />

ON<br />

u<br />

<<br />

A A<br />

OFF<br />

OFF<br />

-START" rvVXAA*-<br />

SWITCH<br />

"RUN"<br />

SWITCH<br />

WIRE WOUND RESISTOR<br />

U5V, LINE, 1 GEN. - ISO OHMS<br />

115V. LINE, 2 GEN. - 125 OHMS<br />

230V. LINE, 1 GEN. - 1000 OHMS<br />

230V. LINE. 2 GEN. 500 OHMS<br />

FIGURE I<br />

SWITCH AND MOTOR CIRCUITS<br />

2-15