750-303 - Binar Elektronik

750-303 - Binar Elektronik

750-303 - Binar Elektronik

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

0123456789<br />

0123456789<br />

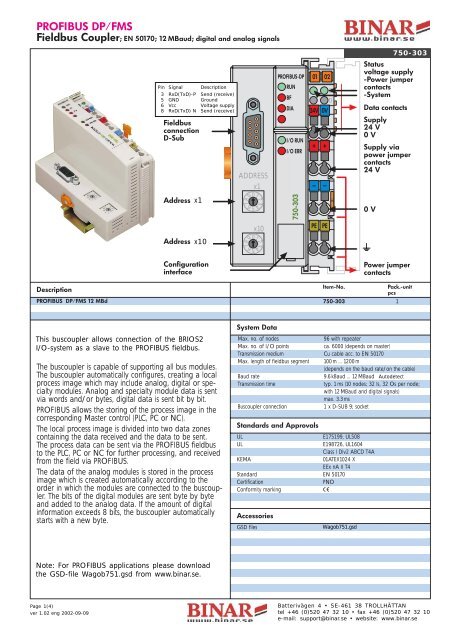

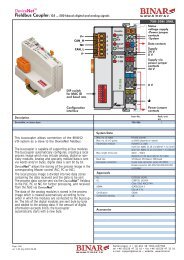

PROFIBUS DP/FMS<br />

Fieldbus Coupler; EN 50170; 12 MBaud; digital and analog signals<br />

<strong>750</strong>-<strong>303</strong><br />

Pin Signal Description<br />

3 RxD(TxD)-P Send (receive)<br />

5 GND Ground<br />

6 Vcc Voltage supply<br />

8 RxD(TxD) N Send (receive)<br />

Fieldbus<br />

connection<br />

D-Sub<br />

ADDRESS<br />

x1<br />

PROFIBUS-DP<br />

RUN<br />

BF<br />

DIA<br />

I/O RUN<br />

I/O ERR<br />

A<br />

B<br />

01 02<br />

C<br />

D<br />

24V 0V<br />

+ +<br />

— —<br />

Status<br />

voltage supply<br />

-Power jumper<br />

contacts<br />

-System<br />

Data contacts<br />

Supply<br />

24 V<br />

0 V<br />

Supply via<br />

power jumper<br />

contacts<br />

24 V<br />

Address<br />

x1<br />

<strong>750</strong>-<strong>303</strong><br />

0 V<br />

x10<br />

PE<br />

PE<br />

Address<br />

x10<br />

Configuration<br />

interface<br />

Power jumper<br />

contacts<br />

Description<br />

PROFIBUS DP/FMS 12 MBd<br />

Item-No.<br />

<strong>750</strong>-<strong>303</strong> 1<br />

Pack.-unit<br />

pcs<br />

This buscoupler allows connection of the of the BRIOS2<br />

I/O-system WAGO ➟I/O➟SYSTEM as a slave to as the a slave PROFIBUS to the PROFIBUS fieldbus. fieldbus.<br />

The buscoupler is capable of supporting all bus modules.<br />

The buscoupler automatically configures, creating a local<br />

process image which may include analog, digital or specialty<br />

modules. Analog and specialty module data is sent<br />

via words and/or bytes, digital data is sent bit by bit.<br />

PROFIBUS allows the storing of the process image in the<br />

corresponding Master control (PLC, PC or NC).<br />

The local process image is divided into two data zones<br />

containing the data received and the data to be sent.<br />

The process data can be sent via the PROFIBUS fieldbus<br />

to the PLC, PC or NC for further processing, and received<br />

from the field via PROFIBUS.<br />

The data of the analog modules is stored in the process<br />

image which is created automatically according to the<br />

order in which the modules are connected to the buscoupler.<br />

The bits of the digital modules are sent byte by byte<br />

and added to the analog data. If the amount of digital<br />

information exceeds 8 bits, the buscoupler automatically<br />

starts with a new byte.<br />

When implementing new installations with<br />

PROFIBUS DP, please consider fieldbus coupler<br />

<strong>750</strong>-333 with extended functions (page 1.016).<br />

Note: For PROFIBUS applications please also order<br />

Note: For PROFIBUS applications please download<br />

GSD files.<br />

the<br />

Item-No.<br />

GSD-file<br />

<strong>750</strong>-910.<br />

Wagob751.gsd from www.binar.se.<br />

or<br />

download it from: www.wago.com<br />

Page Subject 1(4) to design changes<br />

ver 08.10.2001 1.02 eng 2002-09-09<br />

System Data<br />

Max. no. of nodes<br />

96 with repeater<br />

Max. no. of I/O points<br />

ca. 6000 (depends on master)<br />

Transmission medium Cu cable acc. to EN 50170<br />

Max. length of fieldbus segment 100 m ... 1200 m<br />

(depends on the baud rate/on the cable)<br />

Baud rate<br />

9.6 kBaud ... 12 MBaud Autodetect<br />

Transmission time<br />

typ. 1 ms (10 nodes; 32 Is, 32 Os per node;<br />

with 12 MBaud and digital signals)<br />

max. 3.3 ms<br />

Buscoupler connection<br />

1 x D-SUB 9; socket<br />

Standards and Approvals<br />

UL<br />

E175199, UL508<br />

UL<br />

E198726, UL1604<br />

Class I Div2 ABCD T4A<br />

KEMA<br />

01ATEX1024 X<br />

EEx nA II T4<br />

Standard EN 50170<br />

Certification<br />

PNO<br />

Conformity marking 1<br />

Accessories<br />

GSD files Wagob751.gsd<br />

<strong>750</strong>-910<br />

Miniature WSB quick marking system pages 1.166 /167<br />

WAGO Kontakttechnik GmbH Postfach 2880 • D-32385 Batterivägen Minden Tel.: 405 • 71/887-0 SE-461 38 E-Mail: TROLLHÄTTAN info@wago.com<br />

Hansastr. 27 • D-32423 tel Minden +46 (0)520 Fax.: 05 4771/887-169 32 10 • fax Web: +46 http://www.wago.com<br />

(0)520 47 32 10<br />

e-mail: support@binar.se • website: www.binar.se

<strong>750</strong>-<strong>303</strong><br />

24 V<br />

1<br />

5<br />

24 V/0 V<br />

10nF<br />

DC<br />

DC<br />

Bus<br />

modules<br />

0V<br />

2<br />

6<br />

24 V<br />

24 V<br />

FIELDBUS INTERFACE<br />

ELECTRONICS<br />

3<br />

4<br />

7<br />

8<br />

0V<br />

0V<br />

10nF<br />

ELECTRONICS<br />

FIELDBUS<br />

INTERFACE<br />

<strong>750</strong>-<strong>303</strong><br />

Technical Data<br />

Max. no. of I/O modules 64<br />

Fieldbus<br />

Input process image<br />

max. 64 bytes<br />

Output process image<br />

max. 64 bytes<br />

Configuration<br />

via PC or PLC<br />

Voltage supply DC 24 V (-15 % ... +20 %)<br />

Input current max.<br />

500 mA at 24 V<br />

Efficiency of the power supply 87 %<br />

Internal current consumption 350 mA at 5 V<br />

Total current for I/O modules 1650 mA at 5 V<br />

Isolation<br />

500 V system /supply<br />

Voltage via power jumper contacts max. DC 24 V (-15 % ... +20 %)<br />

Current via power jumper contacts max. DC 10 A<br />

Operating temperature 0 °C ... +55 °C<br />

Wire connection CAGE CLAMP ®<br />

0.08 mm 2 ... 2.5 mm 2<br />

AWG 28 ... 14<br />

8 ... 9 mm /0.33 in stripped length<br />

Dimensions (mm) W x H x L 51 x 65* x 100<br />

* from upper edge of DIN 35 rail<br />

Weight<br />

ca. 195 g<br />

Storage temperature -25 °C ... +85 °C<br />

Relative air humidity<br />

95 % no condensation<br />

Vibration and acc. to IEC 60068-2-6<br />

shock resistance acc. to IEC 60068-2-27<br />

Degree of protection IP 20<br />

EMC<br />

Immunity to interference acc. to EN 50082-2 (96)<br />

Emission of interference acc. to EN 50081-2 (94)<br />

Item-No.<br />

Pack.-unit<br />

Variations<br />

pcs<br />

PROFIBUS DP 12 MBaud <strong>750</strong>-<strong>303</strong>/000-013 1<br />

Fieldbus<br />

Input process image<br />

max. 128 bytes<br />

Output process image<br />

max. 128 bytes<br />

Page Subject 2(4) to design changes<br />

ver 08.10.2001 1.02 eng 2002-09-09<br />

Batterivägen 4 • SE-461 38 TROLLHÄTTAN<br />

tel +46 (0)520 47 32 10 • fax +46 (0)520 47 32 10<br />

e-mail: support@binar.se • website: www.binar.se

Buscoupler PROFIBUS-DP – <strong>750</strong>-<strong>303</strong> BRIOS2<br />

2. Node address<br />

The desired node address is set by<br />

means of the two encoding switches<br />

located on the buscoupler. The address<br />

is adjustable in the range of 0<br />

to 99.<br />

Address<br />

Ones<br />

x1<br />

9<br />

0<br />

1<br />

8 2<br />

Off 7 3<br />

6<br />

5<br />

4<br />

x1<br />

9 0 1<br />

8 2<br />

Off 7 3<br />

6 5 4<br />

x1<br />

x1<br />

9 0 1<br />

9 0 1<br />

8 2<br />

8 2<br />

7 3 Off 7 3<br />

6 5 4<br />

6 5 4<br />

The value of the switch at the bottom<br />

must be multiplied with 10, the value<br />

of the switch at the top must be<br />

added and this number is the value of<br />

the address.<br />

Address<br />

Tens<br />

x10<br />

9<br />

0<br />

1<br />

8 2<br />

7 3<br />

6<br />

5<br />

4<br />

<strong>750</strong>-<strong>303</strong><br />

x10<br />

9<br />

0<br />

1<br />

8 2<br />

7 3<br />

6<br />

5<br />

4<br />

x10<br />

9<br />

0<br />

1<br />

8 2<br />

7 3<br />

6<br />

5<br />

4<br />

x10<br />

9<br />

0<br />

1<br />

8 2<br />

7 3<br />

6<br />

5<br />

4<br />

The address should be set before<br />

switching on the buscoupler. Changing<br />

the address switches during operation<br />

does not affect the buscoupler<br />

address since it is read only during<br />

the power up sequence.<br />

Address 3 Address 17 Address 40<br />

3 Diagnostic LEDs - fieldbus<br />

The fieldbus LEDs show the operating condition of the fieldbus. The functions of PROFIBUS are<br />

indicated by the LEDs “RUN”, “BF”, and “DIA”. The fourth LED available has no significance.<br />

LEDs Meaning Remedy<br />

RUN BF I/O RUN<br />

No function<br />

Test the voltage supply.<br />

OFF OFF OFF<br />

Power LED ON: Coupler defective<br />

Exchange coupler.<br />

Power LED OFF: No supply<br />

ON ON OFF<br />

ON OFF ON<br />

ON OFF OFF<br />

1. Coupler has left initialization and is ready for<br />

parameterization and configuration.<br />

2. Error in parameterization and/or configuration.<br />

3. Wrong station address.<br />

4. Break in the connection to the master (short<br />

circuit, wire break)<br />

RUN:<br />

Inputs are read, outputs are written.<br />

CLEAR:<br />

Inputs are read and outputs set.<br />

Start PROFIBUS-Master.<br />

Look for the projecting.<br />

Check the decimal switch.<br />

Check the bus cable.<br />

PLC stopped, another station<br />

does not work.<br />

RUN<br />

BF<br />

DIA<br />

I/O RUN<br />

I/O ERR<br />

4 Buscoupler startup and troubleshooting<br />

After configuration of the master connection and electrical installation of the fieldbus<br />

node/station, operation of the system can begin.<br />

After power to the Buscoupler and I/O modules has been applied, the Buscoupler verifies<br />

all internal functions, components and the communication interface by an internal diagnostic<br />

routine. Then the function modules and the existing configuration is determined.<br />

During the power up phase the ‘I/O ERR’ LED flashes with a high frequency. After a<br />

faultless power up the buscoupler enters the state ‘fieldbus start’. The green LED ‘RUN’<br />

indicates that the internal bus is operating normally.<br />

I/O RUN<br />

I/O ERR<br />

Page 3(4)<br />

ver 1.02 eng 2002-09-09<br />

ver 1.01 eng 2001-04-18<br />

Batterivägen 4 • SE-461 38 TROLLHÄTTAN<br />

tel +46 (0)520 47 32 10 • fax +46 (0)520 47 32 10<br />

e-mail: support@binar.se • website: www.binar.se

Buscoupler PROFIBUS-DP – <strong>750</strong>-<strong>303</strong> BRIOS2<br />

In case of a fault, the red ‘I/O ERR’ LED will continue flashing.<br />

By counting the number and frequency of flashes the fault can be easily identified quickly and accurately. A varying<br />

number of flashes and frequencies defines the fault. The table below describes the fault condition based on the<br />

counted number of ‘I/O ERR’ LED flashes.<br />

Sequence 1<br />

High frequency Pause<br />

Sequence 2<br />

Low frequency Pause<br />

Sequence 3<br />

Low frequency Pause<br />

I/O ERR<br />

Hardware and<br />

configuration error<br />

Error code Error argument<br />

No. of blinks No. of blinks Error description<br />

1<br />

0 EEPROM check sum error / check sum fault in parameter<br />

area of the flash memory.<br />

1 Overflow of the internal buffer memory for the inline code.<br />

2 Unknown data type.<br />

3 Module type of the flash program memory could not be determined<br />

/ is incorrect.<br />

4 Error during writing the flash memory.<br />

5 Error when deleting the flash memory.<br />

6 Changed I/O module configuration found after Autoreset.<br />

7 Invalid firmware.<br />

8 Timeout error serial EPROM.<br />

Additional<br />

configuration error<br />

2<br />

1 Process image is inactive at the switching operation Control<br />

or Monitor mode.<br />

2 Process image is bigger than the available cache.<br />

3 Error by the process image compilation.<br />

Internal bus<br />

command error<br />

3 0 Bus module(s) has (have) identified errors in the internal bus<br />

communication.<br />

Internal bus<br />

data error<br />

4<br />

0 Data error on internal bus or internal bus break at the bus<br />

coupler<br />

n* (n>0) internal bus break after module N, passive modules like supply<br />

terminal blocks do not count.<br />

Register<br />

communication error<br />

Fieldbus specific<br />

error<br />

I/O module<br />

not supported<br />

5 n* Internal bus error during register communication with the I/O<br />

module n.<br />

6 0 Number of I/O modules exceeded. The process image is<br />

bigger than the available cache.<br />

7 n* I/O module not supported at position n.<br />

Not used 8 - Not used<br />

CPU-TRAP-error 9 - Not used<br />

Blink code example:<br />

* The number of blink pulses (n) indicates the position of the I/O module.<br />

I/O modules without data are not counted (i.e. supply module without diagnostics).<br />

Assume that the 13th I/O module is removed. This will generate the following cyclically displayed blink sequence:<br />

1. The ‘I/O’ LED generates a fault display with the first blink sequence (red, approx. 10 Hz) and then pause.<br />

2. The first pause is followed by the second blink sequence (approx. 1 Hz). The ‘I/O’ LED blinks red four times<br />

and then pause. This indicates the error code 4 meaning an Internal bus data error.<br />

3. The second pause is followed by the third blink sequence (approx. 1 Hz). The ‘I/O’ LED blinks red twelve<br />

times and then pause. The error argument 12 means that the internal bus is interrupted after the 12th I/O<br />

module.<br />

After elimination of the fault, the buscoupler can only be set to the normal working condition by another POWER ON<br />

sequence.<br />

The green I/O RUN LED flashes when accessing the I/O modules internal data channels. After being switched on, the<br />

Buscoupler queries the configuration of the bus modules but does not carry out a data exchange with the I/O modules.<br />

This means that the red I/O ERR LED will extinguish after a faultless startup. The green I/O RUN LED indicates that<br />

data is being exchanged via the internal bus.<br />

Page 4(4)<br />

ver 1.02 eng 2002-09-09<br />

ver 1.01 eng 2001-04-18<br />

Batterivägen 4 • SE-461 38 TROLLHÄTTAN<br />

tel +46 (0)520 47 32 10 • fax +46 (0)520 47 32 10<br />

e-mail: support@binar.se • website: www.binar.se