Technical data of JSL Aus grades - Gual Steel

Technical data of JSL Aus grades - Gual Steel

Technical data of JSL Aus grades - Gual Steel

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

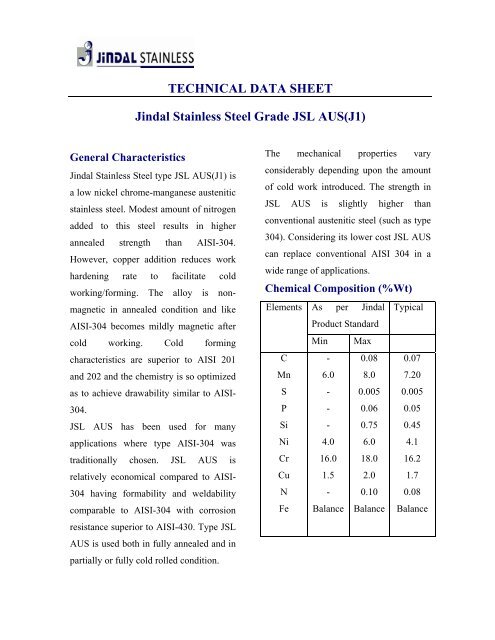

TECHNICAL DATA SHEET<br />

Jindal Stainless <strong>Steel</strong> Grade <strong>JSL</strong> AUS(J1)<br />

General Characteristics<br />

Jindal Stainless <strong>Steel</strong> type <strong>JSL</strong> AUS(J1) is<br />

a low nickel chrome-manganese austenitic<br />

stainless steel. Modest amount <strong>of</strong> nitrogen<br />

added to this steel results in higher<br />

annealed strength than AISI-304.<br />

However, copper addition reduces work<br />

hardening rate to facilitate cold<br />

working/forming. The alloy is nonmagnetic<br />

in annealed condition and like<br />

AISI-304 becomes mildly magnetic after<br />

cold working. Cold forming<br />

characteristics are superior to AISI 201<br />

and 202 and the chemistry is so optimized<br />

as to achieve drawability similar to AISI-<br />

304.<br />

<strong>JSL</strong> AUS has been used for many<br />

applications where type AISI-304 was<br />

traditionally chosen. <strong>JSL</strong> AUS is<br />

relatively economical compared to AISI-<br />

304 having formability and weldability<br />

comparable to AISI-304 with corrosion<br />

resistance superior to AISI-430. Type <strong>JSL</strong><br />

AUS is used both in fully annealed and in<br />

partially or fully cold rolled condition.<br />

The mechanical properties vary<br />

considerably depending upon the amount<br />

<strong>of</strong> cold work introduced. The strength in<br />

<strong>JSL</strong> AUS is slightly higher than<br />

conventional austenitic steel (such as type<br />

304). Considering its lower cost <strong>JSL</strong> AUS<br />

can replace conventional AISI 304 in a<br />

wide range <strong>of</strong> applications.<br />

Chemical Composition (%Wt)<br />

Elements As per Jindal Typical<br />

Product Standard<br />

Min Max<br />

C<br />

Mn<br />

S<br />

P<br />

Si<br />

Ni<br />

Cr<br />

Cu<br />

N<br />

Fe<br />

-<br />

6.0<br />

-<br />

-<br />

-<br />

4.0<br />

16.0<br />

1.5<br />

-<br />

Balance<br />

0.08<br />

8.0<br />

0.005<br />

0.06<br />

0.75<br />

6.0<br />

18.0<br />

2.0<br />

0.10<br />

Balance<br />

0.07<br />

7.20<br />

0.005<br />

0.05<br />

0.45<br />

4.1<br />

16.2<br />

1.7<br />

0.08<br />

Balance

Mechanical Properties<br />

UTS (MPa)<br />

YS (MPa)<br />

% Elongation<br />

Hardness<br />

(HRB)<br />

Ericcson<br />

Cupping Value<br />

Type<br />

<strong>JSL</strong> AUS<br />

550 min.<br />

205 min<br />

40 min.<br />

95 max.<br />

12-14<br />

Type 304<br />

515 min.<br />

205 min.<br />

40 min.<br />

92 max.<br />

12-13.5<br />

Test as per<br />

ASTM A262<br />

Practice B<br />

(Boiling Ferric<br />

Sulfate<br />

50% Sulphuric<br />

Acid)<br />

Practice C<br />

(65% Nitric Acid,<br />

Boiling)<br />

Corrosion Rate<br />

(mmpy)<br />

<strong>JSL</strong> Type<br />

AUS 304<br />

2.46 1.05<br />

0.93 0.32<br />

Typical Values<br />

UTS (MPa)<br />

YS<br />

(0.2%)(MPa)<br />

% Elongation<br />

Hardness(HRB)<br />

Ericcson<br />

Cupping Value<br />

665<br />

310<br />

55<br />

87<br />

12.9<br />

560<br />

262<br />

55<br />

83<br />

13.1<br />

Practice E<br />

(Copper/16%<br />

Copper<br />

Sulfate/Sulfuric<br />

Acid, Boiling)<br />

Practice A<br />

(Oxalic Acid etch<br />

Test)<br />

No<br />

cracks<br />

Step<br />

Structure<br />

No<br />

cracks<br />

Step<br />

Structure<br />

Corrosion Properties<br />

Intergranular Corrosion<br />

General atmospheric corrosion <strong>of</strong><br />

<strong>JSL</strong>-AUS in non-coastal atmosphere is<br />

comparable with Type 304. In<br />

intergranular corrosion test as per<br />

ASTM 262, <strong>JSL</strong> AUS and Type 304<br />

behave similarly in practice A and<br />

practice E tests. However, in boiling ferric<br />

sulphate and nitric acid, <strong>JSL</strong> AUS exhibits<br />

slightly inferior performance to Type 304.<br />

Corrosion in various food<br />

application media<br />

A series <strong>of</strong> corrosion tests in salt and<br />

organic acids, generally encountered in<br />

food processing and food packaging<br />

industries, clearly indicates that <strong>JSL</strong> AUS<br />

is a good cost effective substitute to Type<br />

304 in many applications. Acetic acid is<br />

present in vinegar. When milk<br />

deteriorates, lactic acid is produced. Citric<br />

acid is commonly present in fruit juices<br />

and tartaric acid is an ingredient in

tamarind extracts commonly used in<br />

Indian households. <strong>JSL</strong> AUS has been<br />

tested in individual acids and in<br />

combination with varying concentration to<br />

asses its corrosion resistance properties.<br />

The salt spray test in 5% NaCl<br />

environment shows <strong>JSL</strong> AUS has similar<br />

or even better resistance to common salt<br />

in comparison with Type 304.<br />

Test media<br />

3% NaCl for 720<br />

hrs<br />

at RT(25 o C)<br />

3% NaCl for 100<br />

hrs<br />

at Boiling Temp.<br />

(0.5%Citric+0.5<br />

%Tartaric)<br />

for 720 hrs at RT<br />

(0.5%Citric+0.5<br />

%Tartaric)<br />

for 100 hrs<br />

boiling<br />

(0.5%Acetic<br />

+0.5%Lactic) for<br />

720 hrs at RT<br />

(0.5%Acetic<br />

+0.5%Lactic) for<br />

120 hrs at<br />

Boiling Temp.<br />

Corr rate<br />

(mmpy)<br />

<strong>JSL</strong> AUS<br />

Corr rate<br />

(mmpy)<br />

304<br />

0.0004 0.00132<br />

0.0114834 0.001066<br />

0.0005525 0.0000034<br />

0.006721 0.000018<br />

0.0018 0.00051<br />

0.0101 0.001669<br />

Note: The corrosion rate less than<br />

0.02mm per year (mmpy) is considered<br />

excellent (Ref: Mars. G. Fontanna,<br />

Corrosion Engineering, Table 4-5, P 172)<br />

Salt Spray Test<br />

5% NaCl environment (for 120 hrs)<br />

Grade Corrosion rate (mmpy)<br />

<strong>JSL</strong> AUS 0.0003729<br />

304 0.00044<br />

Heat Treatment<br />

Type <strong>JSL</strong> AUS is annealed between<br />

1050–1100 o C. The annealing temperature<br />

should not exceed 1100 o C to avoid<br />

excessive oxidation and grain coarsening.<br />

The primary purpose <strong>of</strong> annealing is to<br />

relieve strain, recrystallize the material if<br />

it has been cold worked and to take<br />

carbides into solution. For <strong>JSL</strong> AUS,<br />

rapid cooling through the carbide<br />

precipitation range (500–800 o C) is<br />

necessary to avoid the precipitation <strong>of</strong><br />

carbides at grain-boundaries.<br />

Fabrication<br />

Welding<br />

Type <strong>JSL</strong> AUS can be welded by all<br />

conventional methods applied to 18/8<br />

type <strong>of</strong> austenitic stainless steel. Filler<br />

wires or electrodes <strong>of</strong> the conventional<br />

chromium-nickel 300 series can be used.<br />

Its susceptibility to intergranular<br />

corrosion in weld heat-affected zone is<br />

analogous to AISI 304.<br />

Hot Working<br />

<strong>JSL</strong> AUS can be readily rolled or forged,<br />

and required similar power for a given<br />

reduction as in case <strong>of</strong> AISI 304 stainless<br />

steel.

Cold Working<br />

<strong>JSL</strong> AUS is very tough and ductile and<br />

readily amenable to deep drawing,<br />

bending, stretch forming and spinning.<br />

After heavy cold working, it is only<br />

mildly magnetic like 304.<br />

Typical Applications<br />

Catering & Food Processing<br />

Deep drawn utensils, Pressure cookers,<br />

Water filters, Storage vessels, Milk cans.<br />

Consumer Durables<br />

Spin driers <strong>of</strong> Washing machine,<br />

Microwave ovens, Decorative trim, Dish<br />

washers, Thermo ware.<br />

Architecture, Building & Construction<br />

Doors and window frames, Column<br />

claddings, Furniture, Bus shelters,<br />

Telephone booths, Pipes and Tubes, Hand<br />

rails, Ornamental tubes, Tree guards, and<br />

Kitchen sinks.<br />

Transport (Automotive)<br />

Automotive trim, Wheel caps, Wiper<br />

arms, Rims, Auto accessories.<br />

Industry<br />

Beer, Wine, Beverage, Dairy equipment,<br />

Food processing and packing equipment<br />

Product and Surface Finish *<br />

Product<br />

Size (mm)<br />

Surface<br />

Process<br />

Edge Condition<br />

t x w x l<br />

Quality<br />

HR Coil<br />

2.8-6.0 X 1050<br />

Black<br />

HR<br />

Mill<br />

No.1<br />

HRAP<br />

Trim / Mill<br />

HR Plate and<br />

4.0-50.0 X 1250 max X<br />

No.1<br />

HRAP<br />

Trim / Mill<br />

Sheet<br />

7000 max<br />

2D<br />

CRAP<br />

Trim / Mill<br />

CR Coil and<br />

0.4-4.0 X 1250 max<br />

2B<br />

CRAP+SP<br />

Trim / Mill<br />

Sheets<br />

No.3<br />

CRAP+SP+G<br />

Trim / Mill<br />

No.4<br />

CRAP+SP+G<br />

Trim / Mill<br />

* For details, refer to <strong>Technical</strong> Brochure <strong>of</strong> Jindal Stainless.<br />

HR- Hot Rolled, CR- Cold Rolled, HRAP- Hot Rolled Annealed and Pickled,<br />

CRAP-Cold Rolled Annealed and Pickled, SP- Skin Pass, G- Ground.

Notice:<br />

• Information in this document is<br />

only for the explanation <strong>of</strong> general<br />

characteristics and properties <strong>of</strong><br />

<strong>JSL</strong> products, not for the guarantee<br />

for the material.<br />

• <strong>Technical</strong> information in this<br />

document is subject to change by<br />

environment condition and the<br />

purpose <strong>of</strong> use.<br />

Contact for information:<br />

Marketing Division,<br />

Corporate Office,<br />

Jindal Center,<br />

12-Bhikaiji Cama Place,<br />

New Delhi- 110066<br />

Tel- +91(011)26188340-50<br />

Fax- 91(011)26161271<br />

E mail: info@jindalsteel.com