TECHNICAL DATA SHEETS - Gual Steel

TECHNICAL DATA SHEETS - Gual Steel

TECHNICAL DATA SHEETS - Gual Steel

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

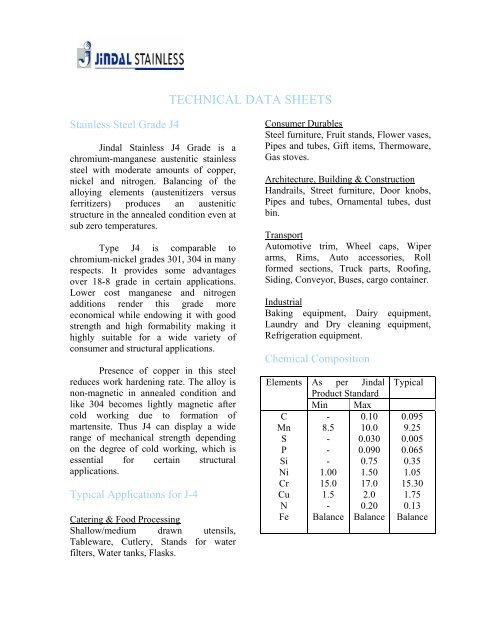

<strong>TECHNICAL</strong> <strong>DATA</strong> <strong>SHEETS</strong>Stainless <strong>Steel</strong> Grade J4Jindal Stainless J4 Grade is achromium-manganese austenitic stainlesssteel with moderate amounts of copper,nickel and nitrogen. Balancing of thealloying elements (austenitizers versusferritizers) produces an austeniticstructure in the annealed condition even atsub zero temperatures.Type J4 is comparable tochromium-nickel grades 301, 304 in manyrespects. It provides some advantagesover 18-8 grade in certain applications.Lower cost manganese and nitrogenadditions render this grade moreeconomical while endowing it with goodstrength and high formability making ithighly suitable for a wide variety ofconsumer and structural applications.Presence of copper in this steelreduces work hardening rate. The alloy isnon-magnetic in annealed condition andlike 304 becomes lightly magnetic aftercold working due to formation ofmartensite. Thus J4 can display a widerange of mechanical strength dependingon the degree of cold working, which isessential for certain structuralapplications.Typical Applications for J-4Catering & Food ProcessingShallow/medium drawn utensils,Tableware, Cutlery, Stands for waterfilters, Water tanks, Flasks.Consumer Durables<strong>Steel</strong> furniture, Fruit stands, Flower vases,Pipes and tubes, Gift items, Thermoware,Gas stoves.Architecture, Building & ConstructionHandrails, Street furniture, Door knobs,Pipes and tubes, Ornamental tubes, dustbin.TransportAutomotive trim, Wheel caps, Wiperarms, Rims, Auto accessories, Rollformed sections, Truck parts, Roofing,Siding, Conveyor, Buses, cargo container.IndustrialBaking equipment, Dairy equipment,Laundry and Dry cleaning equipment,Refrigeration equipment.Chemical CompositionElementsCMnSPSiNiCrCuNFeAs per JindalProduct StandardMin Max- 0.108.5 10.0- 0.030- 0.090- 0.751.00 1.5015.0 17.01.5 2.0- 0.20Balance BalanceTypical0.0959.250.0050.0650.351.0515.301.750.13Balance

Corrosion PropertiesIntergranular CorrosionTest as perASTMA262Practice BPractice CPractice EPractice ACorrosion Rate Mils Peryear (MPY)Boiling Ferric Sulfate50% Sulphuric AcidType J4 Type 304250 5065% Nitric Acid, BoilingType J4 Type 30435 10Copper/16% CopperSulfate/Sulfuric Acid,BoilingType J4 Type 304No cracks No cracksOxalic Acid etch TestType J4 Type 304Step StepStructure StructurePitting and Crevice CorrosionType J4 is susceptible to pitting & crevicecorrosion attack in chloride containingmedia. Although the alloy cansuccessfully be used in fresh water wherechloride ion concentration is very low.Stress Corrosion TestThe stress corrosion resistance of the alloyis comparable to 18/8 types of alloys. Theresults of the test conducted on thesolution-annealed samples as per ASTMG36 (MgCl 2 .6H 2 O) are shown in thefollowing table and comparison is madewith type 304.Standard Type J4 Type 304ASTM G38(MgCl 2 .6H 2 OU-bend stressedsamples)Crackedin 18-16hoursCracked in2-4 hours.Mechanical PropertiesRoomTemperatureUTS (Mpa)YS (Mpa)% ElongationHardness (HRB)EriccsonCupping ValueAt 350 o CUTS (Mpa)YS(0.2%)(Mpa)% ElongationAt 550 o CUTS (Mpa)YS(0.2%)(Mpa)% ElongationType J4 Type 304700-750375-40050-5594-9610-125772223845217433550-580270-30050-5584-8712-14.54631664140414235Type J4 is mainly used both infully annealed condition and in temperrolled as well as cold rolled condition.The mechanical properties varyconsiderably depending upon the amountof cold work introduced. The strength ofJ4 is higher than conventional austeniticsteel (such as type 304) and for this reasonhave found a wide field of application instructural assemblies.Heat TreatmentType J4 is annealed between 1050 –1100 o C. The annealing temperatureshould not exceed 1100 o C to avoidexcessive oxidation and grain coarsening.The primary purposes of annealing is torelieve strain, recrystallize the material ifit has been cold worked and take carbidesinto solution. For J4, rapid coolingthrough the carbide precipitation range(500 – 800 o C) is necessary to avoid theprecipitation of the carbide at grainboundaries.

FabricationWeldingType J4 can be welded by all conventionalmethods applied to 18/8 type of austeniticstainless steel. Filler wire or electrodes ofthe conventional chromium-nickel 300series stainless steel can be used. Type J4is sensitive to Intergranular corrosion inweld heat affected zone.Hot WorkingCan be readily rolled or forged. Becauseof the presence of nitrogen, more powerfor a given reduction is required than withAISI 304 stainless steel but lessercompared to AISI 316.Cold WorkingVery tough and ductile and readilyemanable to deep drawing, bending,stretch forming and spinning. After heavycold working, it is only mildly magneticlike 304.