You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>Stacking</strong> <strong>Corners</strong><br />

XK605<br />

Made in Sweden.<br />

These unique stackable hinges enable you to make stacking frames for<br />

a host of purposes. Just screw boards onto hinges to form a square or<br />

rectangular frame, and then stack as many frames as you want, until you<br />

reach the desired height. When not in use, each frame collapses nearly<br />

flat for compact storage. Useful for making raised-bed grow-boxes,<br />

composters, or stackable and removable sides for wagons or utility trailers.<br />

To unload whatever is being held or carted, you can remove one layer at a<br />

time and then the contents, working your way downward.<br />

Safety Note: These stacking corners are made by the manufacturer in the<br />

millions, primarily for use in the shipping industry as pallet hinges. As<br />

such, they are not as fi nely fi nished as we would like and may have sharp<br />

or rusty edges. Depending where you locate your stacking frame(s), and<br />

whether children (or even adults) could come in contact with these edges,<br />

we suggest that you lightly fi le these (edges) before assembly.<br />

Making Stacked Frames without Gaps<br />

(e.g., Grow-Boxes)<br />

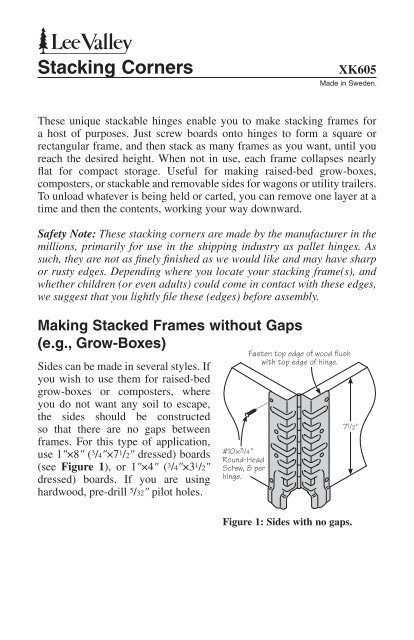

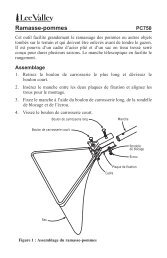

Sides can be made in several styles. If<br />

you wish to use them for raised-bed<br />

grow-boxes or composters, where<br />

you do not want any soil to escape,<br />

the sides should be constructed<br />

so that there are no gaps between<br />

frames. For this type of application,<br />

use 1"×8" ( 3 /4"×7 1 /2" dressed) boards<br />

(see Figure 1), or 1"×4" ( 3 /4"×3 1 /2"<br />

dressed) boards. If you are using<br />

hardwood, pre-drill 5 /32" pilot holes.<br />

#10× 3 /4"<br />

Round-Head<br />

Screw, 8 per<br />

hinge.<br />

Fasten top edge of wood flush<br />

with top edge of hinge.<br />

7 1 /2"<br />

Figure 1: Sides with no gaps.

In order to hold the heavy load exerted by the soil inside the frames,<br />

braces are recommended when boards longer than 4 feet are used<br />

(see Figure 2).<br />

21/4"<br />

4' Max. Unsupported Span<br />

3" to 6" wide × 7 1 /4"<br />

long × 3 /4" thick braces<br />

screwed onto boards.<br />

2"<br />

Place extension of bottom<br />

brace into ground. Successive<br />

braces/boards are restrained<br />

by adjoining board.<br />

Figure 2: Brace supports for spans greater than 4'.<br />

Boxes should be no longer than 12' to prevent excessive bowing and<br />

no wider than 5' so you can reach across them comfortably. Most<br />

raised-bed grow-boxes are made 4' wide and 8' long.<br />

Note: It is possible to build the frames using 2"×8" (1 1 /2"×7 1 /2" dressed) or<br />

2"×4" (1 1 /2"×3 1 /2" dressed) material, but this will require a small chamfer<br />

on the inside corner edge of the boards to allow the two pieces to sit at 90°<br />

to each other. If 2" material is used, it will not be possible for the frame to<br />

collapse fl at for storage unless it is partially dismantled.<br />

Filling Raised-Bed Grow-Boxes: Although you may fill a grow-box with<br />

plain soil, a soilless mix is a better choice. We had great results with a 1:1<br />

mix of sand and compost. (Although we tested only mushroom compost,<br />

yard waste compost and composted animal manure should also work.)<br />

This mix makes a light aerated growing medium, ideal for root growth and<br />

virtually free from any weeds. Make sure you adjust the pH to about 6.5 by<br />

adding sufficient lime. Once every 2 weeks, depending on the needs of the<br />

crops, add a water-soluble complete fertilizer to your waterings.<br />

Soil in boxes tends to dry out faster than on the ground. Make sure you<br />

keep an eye on the moisture levels during dry periods. Test the dryness of<br />

the soil 4 to 5 inches below the surface before adding water. It should be<br />

moist, not dry or soggy.<br />

You may also notice that the raised beds drain better in wet weather and<br />

warm up sooner in the spring, allowing for early plantings.<br />

2

Making Stacked Frames with Gaps<br />

(e.g., Wagon Frame)<br />

The extensions on the bottom end of<br />

each hinge not only allow you to stack<br />

the frames on top of one another, but<br />

also serve as locators for fitting the<br />

lower frame onto a flat-bed wagon<br />

or utility trailer. To fit properly, the<br />

planks should be cut 2" shorter than<br />

the dimensions of the flat-bed on<br />

which the frame(s) will rest.<br />

3 1 /2"<br />

3 1 /2"<br />

1/2"<br />

Gap<br />

When these hinges are used to make<br />

wagon or trailer sides for hauling<br />

material, the sides may be constructed<br />

so that there are gaps between the<br />

boards. In this case, you may use<br />

1"×4" ( 3 /4"×3 1 /2" dressed) boards to<br />

obtain a gap of approximately 1 /2" (see<br />

Figure 3). If you are using hardwood,<br />

pre-drill 5 /32" pilot holes.<br />

You may wish to increase the gap<br />

between boards by using 1"×3"<br />

( 3 /4"×2 1 /2" dressed) boards. This will<br />

yield a gap of approximately 1 3 /8"<br />

(see Figure 4).<br />

The screws will be quite close to<br />

the edge of these narrow boards. To<br />

prevent splitting, drill 5 /32" pilot holes<br />

for the mounting screws.<br />

1"<br />

Figure 3: Sides with 1 /2" gaps.<br />

2 1 /2"<br />

2 1 /2"<br />

Pre-drill 5 /32" pilot holes.<br />

Position 2 1 /2" sides so these<br />

distances are roughly the same.<br />

Repeat for lower sides.<br />

Figure 4: Sides with 1 3 /8" gaps.<br />

13/8"<br />

Gap<br />

Safety Note: If you will be making frames for utility trailer sides, it is<br />

essential that the frames are fastened to each other, and that the bottom<br />

frame is fastened to the trailer, in order to ensure that the frames do not<br />

bounce off the trailer! There are many ways of securing a frame to a<br />

fl at-bed; here are two suggestions:<br />

a) Place four screws into the sides of the fl at-bed, near each corner<br />

(see Figure 5). Hook a bungee cord over each hinge on the uppermost<br />

frame, with the opposite end hooked over the corner screws.<br />

3

) Drill 7 /32" screw clearance holes in the lower extensions of each hinge<br />

(see Figure 6). The lower frame can then be fastened by driving a<br />

screw through each of these holes into the edge of the fl at-bed.<br />

Successive frames can have this hole transferred into the upper end of<br />

the adjoining hinge, with a screw going through both holes and into<br />

the side boards.<br />

Trailer<br />

Flat-Bed<br />

Hook bungee<br />

cord over screw,<br />

one at each<br />

corner of trailer.<br />

Figure 5: Trailer sides secured<br />

with bungee cords.<br />

Drill 7 /32" holes through steel<br />

hinge only, then fasten with<br />

#10× 3 /4" round-head screws.<br />

Figure 6: Trailer sides secured<br />

with screws.<br />

152<br />

© <strong>Lee</strong> <strong>Valley</strong> <strong>Tools</strong> Ltd. 2009<br />

www.leevalley.com<br />

1090 Morrison Drive 814 Proctor Avenue<br />

Ottawa, Ontario Ogdensburg, New York<br />

K2H 1C2 Canada 13669-2205 USA<br />

1-800-267-8761 1-800-267-8735<br />

customerservice@leevalley.com<br />

INS-380 Rev. C<br />

Printed in Canada.