Torque Power Meter System

Torque Power Meter System

Torque Power Meter System

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

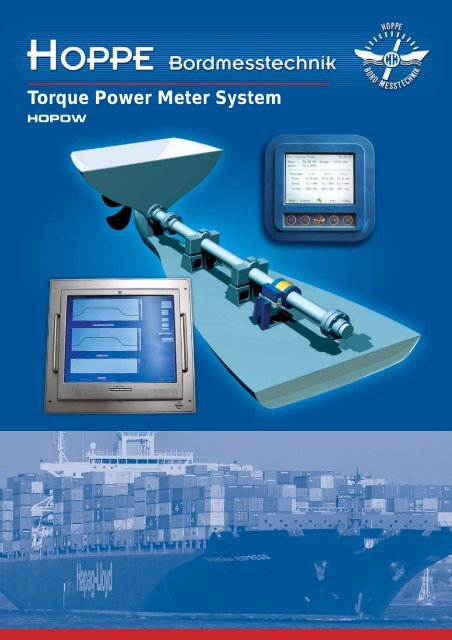

<strong>Torque</strong> <strong>Power</strong> <strong>Meter</strong> <strong>System</strong><br />

HOPOW

<strong>System</strong><br />

The <strong>Torque</strong> <strong>Power</strong> <strong>Meter</strong> <strong>System</strong><br />

enables engine protection against<br />

overload, optimise the maintenance<br />

and improve the fuel economy. The<br />

RELIABILITY<br />

More than 50 years experience in<br />

measurement technologies combined<br />

with the use of modern micro -<br />

processors are the solid base of<br />

Hoppe’s <strong>Torque</strong> <strong>Power</strong> <strong>Meter</strong><br />

<strong>System</strong>s. More than 1,000 installed<br />

systems for continuous duty on all<br />

kind of ships is proof of a high<br />

degree of reliability.<br />

EASY HANDLING<br />

The assembly and installation of<br />

the <strong>Torque</strong> <strong>Power</strong> <strong>Meter</strong> <strong>System</strong><br />

do not require any special knowledge<br />

and can be carried out with<br />

usual mechanical and electrical<br />

skills. Special adjustments during<br />

installation or operation are not<br />

necessary. After installation the<br />

system will be zero calibrated via its<br />

own internal functions.<br />

Telemetry<br />

receiver<br />

Strain gauge<br />

Pick up<br />

RPM<br />

Shaft<br />

generator<br />

system measures the propulsion<br />

shaft torsion. The effective power is<br />

calculated by torsion and RPM. The<br />

adapted performance monitoring<br />

FLEXIBILITY<br />

Via serial interface the <strong>Torque</strong><br />

<strong>Power</strong> <strong>Meter</strong> can communicate<br />

with the ship’s monitoring system.<br />

Analogue or digital remote display<br />

indicators can be connected. Additionally<br />

the signals of shaft generator<br />

power or fuel consumption meter<br />

can be processed.<br />

HOPOW<br />

Fuel<br />

consumption<br />

Ship´s<br />

speed<br />

Engine Control Room<br />

Indication<br />

system is developed for installation<br />

on a panel PC. It is also used as a<br />

form of indication panel for all<br />

relevant data.<br />

Bridge Indication<br />

Draught Seastate Wind

Components<br />

HOMIP<br />

The PLC core component HOMIP<br />

analyses the signals from the torsion<br />

and RPM transducers and calculates<br />

the torque and power. A touch screen<br />

is used for data and trend displays as<br />

well as for parameter inputs. Parameter<br />

and zero point adjustment can be<br />

arranged by a touch screen. Com -<br />

pact dimensions of 190x190 mm<br />

allow installation of the control unit<br />

in all kinds of control panels.<br />

SHAFT TRANSDUCER<br />

The torsion of the propulsion shaft is<br />

measured by strain gauges. The<br />

signals are transmitted wireless to the<br />

telemetric receiver where they are<br />

amplified and sent together with the<br />

speed signal for further analysing and<br />

data processing to the HOMIP.<br />

Shaft transducer system<br />

Shaft<br />

Telemetric receiver<br />

Pick up distance<br />

3-5mm<br />

285<br />

235

PERFORMANCE MONITORING<br />

The performance monitoring system shows the current<br />

parameters of the vessel’s performance data fuel<br />

consumption, ship speed, draught and wind. It displays<br />

different charts and informations on the monitor and also<br />

supports logging functions. All charts are designed as<br />

rolling diagrams and include zoom functions. Special<br />

views like “shaft view”, “current working point” and different<br />

statistical views are available.<br />

Data<br />

PROJECT DATA<br />

Shaft design<br />

Shaft diameter<br />

Motor Curve<br />

MEASURED DATA<br />

RPM<br />

Torsion<br />

Shaft Generator <strong>Power</strong>*<br />

Ship speed*<br />

Fuel Consumption*<br />

Cargo Handling <strong>System</strong>s<br />

Tank Content Measuring<br />

Draught Measuring<br />

Valve Remote Control<br />

Bunker Safety<br />

Overflow Safety<br />

Water Ingress Detection<br />

Dewatering <strong>System</strong><br />

Ballast Exchange<br />

Loading Computer<br />

shaft view<br />

<strong>Power</strong><br />

<strong>Torque</strong><br />

RPM<br />

RPM counter<br />

Fuel counter*<br />

Mean Values per hour / day<br />

- <strong>Power</strong><br />

- <strong>Torque</strong><br />

- RPM<br />

- Fuel consumption*<br />

Kieler Straße 318<br />

D-22525 Hamburg<br />

Tel. +49-40-561949-0<br />

Fax +49-40-561949-99<br />

www.hoppe-bmt.de<br />

info@hoppe-bmt.de<br />

Motion Control <strong>System</strong>s<br />

Anti Heeling<br />

Stability Test<br />

Anti Rolling<br />

Parametric Roll<br />

WWW.HOPPE-BMT.DE<br />

OUTPUT DATA<br />

Load – <strong>Power</strong> deviation from<br />

the theoretical Motor Curve*<br />

Specific Fuel Consumption<br />

- per hour*<br />

- per mile*<br />

* optional<br />

Monitoring <strong>System</strong>s<br />

<strong>Torque</strong> <strong>Power</strong> <strong>Meter</strong><br />

Ship Speed <strong>Meter</strong><br />

Performance Monitoring<br />

Hull Stress Monitoring<br />

Integrated Solutions<br />

www.envise.de