t h i c k - f i l m ceramic substrates design guide - CoorsTek

t h i c k - f i l m ceramic substrates design guide - CoorsTek

t h i c k - f i l m ceramic substrates design guide - CoorsTek

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

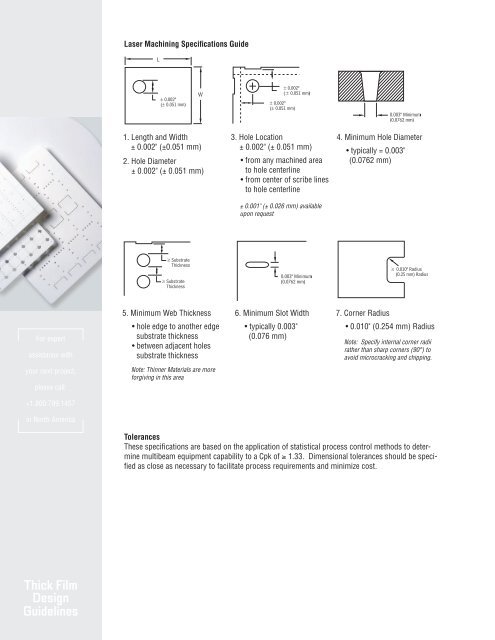

Laser Machining Specifi cations Guide<br />

1. Length and Width<br />

± 0.002" (±0.051 mm)<br />

2. Hole Diameter<br />

± 0.002" (± 0.051 mm)<br />

3. Hole Location<br />

± 0.002" (± 0.051 mm)<br />

• from any machined area<br />

to hole centerline<br />

• from center of scribe lines<br />

to hole centerline<br />

4. Minimum Hole Diameter<br />

• typically = 0.003"<br />

(0.0762 mm)<br />

± 0.001" (± 0.026 mm) available<br />

upon request<br />

5. Minimum Web Thickness<br />

6. Minimum Slot Width<br />

7. Corner Radius<br />

For expert<br />

assistance with<br />

• hole edge to another edge<br />

substrate thickness<br />

• between adjacent holes<br />

substrate thickness<br />

• typically 0.003"<br />

(0.076 mm)<br />

• 0.010" (0.254 mm) Radius<br />

Note: Specify internal corner radii<br />

rather than sharp corners (90°) to<br />

avoid microcracking and chipping.<br />

your next project,<br />

please call:<br />

Note: Thinner Materials are more<br />

forgiving in this area<br />

+1.800.799.1457<br />

in North America<br />

Tolerances<br />

These specifications are based on the application of statistical process control methods to determine<br />

multibeam equipment capability to a Cpk of ≥ 1.33. Dimensional tolerances should be specifi<br />

ed as close as necessary to facilitate process requirements and minimize cost.<br />

Thick Film