Aqueducts & Large Diameter Trunk Mains Clean & Maintain ...

Aqueducts & Large Diameter Trunk Mains Clean & Maintain ...

Aqueducts & Large Diameter Trunk Mains Clean & Maintain ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

APM Project Management Awards<br />

WINNER’S<br />

CASE STUDY<br />

Category<br />

Winner<br />

Programme of the Year 2010<br />

<strong>Aqueducts</strong> and <strong>Large</strong> <strong>Diameter</strong> <strong>Trunk</strong> <strong>Mains</strong> <strong>Clean</strong><br />

& <strong>Maintain</strong> Programme, United Utilities<br />

Sponsor<br />

Overview<br />

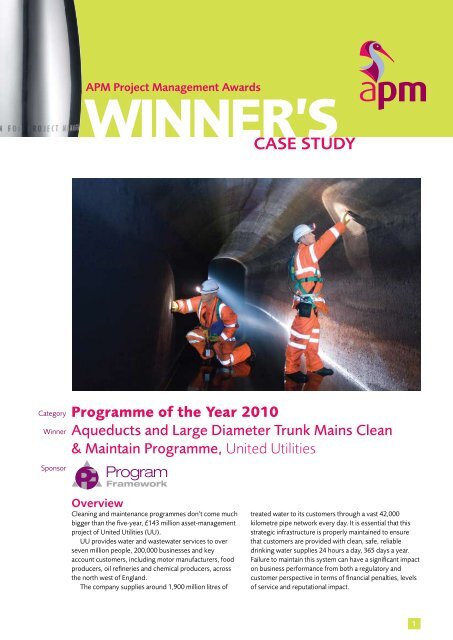

<strong>Clean</strong>ing and maintenance programmes don’t come much<br />

bigger than the five-year, £143 million asset-management<br />

project of United Utilities (UU).<br />

UU provides water and wastewater services to over<br />

seven million people, 200,000 businesses and key<br />

account customers, including motor manufacturers, food<br />

producers, oil refineries and chemical producers, across<br />

the north west of England.<br />

The company supplies around 1,900 million litres of<br />

treated water to its customers through a vast 42,000<br />

kilometre pipe network every day. It is essential that this<br />

strategic infrastructure is properly maintained to ensure<br />

that customers are provided with clean, safe, reliable<br />

drinking water supplies 24 hours a day, 365 days a year.<br />

Failure to maintain this system can have a significant impact<br />

on business performance from both a regulatory and<br />

customer perspective in terms of financial penalties, levels<br />

of service and reputational impact.<br />

1

APM Project Management Awards<br />

WINNER’S<br />

CASE STUDY<br />

Objectives<br />

As part of an asset management plan from 2005 – 2010,<br />

UU invested £3.1 billion in a wide range of asset and<br />

infrastructure improvements through a number of targeted<br />

capital investment programmes. The aqueducts and<br />

large diameter trunk mains (LDTM) clean and maintain<br />

programme was part of this and had two main objectives:<br />

1. To plan, design, develop and implement a major<br />

programme of inspection, maintenance and repairs on<br />

UU’s two main aqueducts, the Haweswater (HA) and<br />

the Thirlmere (TA), and associated infrastructure, which<br />

transfer water from the Lake District through to areas of<br />

Cumbria, Lancashire and Manchester.<br />

2. To clean and refurbish six LDTMs reducing levels of<br />

levels of iron and manganese, which are harmless but<br />

can discolour the water supplied to customers.<br />

Resources<br />

The project included the largest-scale cleaning work ever<br />

undertaken in the UK water industry. Over £143 million<br />

was invested across more than 30 co-related projects over<br />

a five-year period.<br />

Up to 100 people worked in the TA at any one time,<br />

presenting a huge exercise in logistics, resource and health<br />

and safety planning.<br />

The LDTM projects were delivered using project<br />

manager led project centric teams comprising members<br />

from three organisations, UU and strategic partners<br />

Balfour Beatty Utility Solutions and Montgomery Watson<br />

Harza. The team members were drawn from cross<br />

business resource pools of specialist skills, including<br />

co-located project management, co-ordination, control,<br />

design, health, safety and environmental teams to ensure<br />

efficiency and effectiveness through open communication.<br />

Due to the high risk, high profile nature of this programme<br />

a governance board was established. This provided an<br />

opportunity for reporting the programme and its co-related<br />

projects status, managing senior management expectations<br />

and allowed risks and issues to be escalated to the correct<br />

level within the organisation quickly and efficiently.<br />

Challenges<br />

The programme had one major constraint – the works<br />

could not affect supplies to customers. This meant a fresh<br />

approach to project prioritisation, resource planning, risk<br />

management, integration and scheduling.<br />

Other challenges were that the majority of these<br />

strategically important assets were over 50 years old (and<br />

in some cases over 100 years old) and had never been<br />

taken out of service for significant maintenance before, and<br />

the nature, scale and uncertainty of unforeseen events,<br />

such as extremes of weather, major bursts, and third party<br />

damage, and issues that required reactive maintenance put<br />

pressure on the overall annual budget and caused project<br />

priorities to be frequently re-assessed.<br />

2

APM Project Management Awards<br />

WINNER’S<br />

CASE STUDY<br />

Co-ordination<br />

Due to the scale of inspection and maintenance work<br />

required and the need to avoid disrupting customers’<br />

supplies, the aqueduct maintenance and LDTM cleaning<br />

projects were carried out in phases over a five-year period.<br />

Work on the two aqueducts – the Thirlmere one being<br />

more than 115 years old – included investigation, survey<br />

and structural repairs. Targeted repairs were carried out<br />

along the entire 134-kilometre length of the TA, but the<br />

aqueduct could only be taken out of service for one month<br />

each autumn.<br />

<strong>Clean</strong>ing of the LDTM’s also required complex planning<br />

and execution. For instance, the first mains - supplying<br />

more than 1.7 million customers – required two 25<br />

kilometre mains to be cleaned that were large enough<br />

for an adult to walk through. Access was necessary at<br />

more than 80 locations, requiring substantial third-party<br />

negotiations and more than 15 kilometres of access track.<br />

Only one main could be out of service at any one time and<br />

cleaning work was restricted to the autumn/winter period.<br />

It was also vital that nearby mains were not affected or<br />

damaged to ensure customer supplies were maintained.<br />

Comprehensive contingency plans were required for each<br />

scheme to ensure that assets could be repaired or returned<br />

to service quickly should an incident or emergency occur<br />

within the regional system.<br />

Innovative approaches and techniques also had to be<br />

developed to scale up existing technologies to meet the<br />

demands of the programme and generate cost efficiencies.<br />

Specialist equipment was developed, including a CCTV<br />

device that was floated through the live systems to identify<br />

areas of concern requiring further investigation and low<br />

ground pressure vehicles allowing jetting and removal of<br />

wash water from up to 1km of LDTM.<br />

Successes<br />

£8 million efficiency savings.<br />

Improved customer service standards.<br />

Better water quality.<br />

Reduced health and safety risk to employees and third<br />

parties by upgraded access.<br />

Improved structural integrity of the aqueducts.<br />

Improved regional network response to incidents such<br />

as bursts, with faster diversions, and altered flow rates<br />

to minimise water loss and maintain customer supplies<br />

without major discolouration.<br />

Delivered with no lost time accidents and no significant<br />

impact on customer levels of service.<br />

3

APM Project Management Awards<br />

WINNER’S<br />

CASE STUDY<br />

The APM Project Management Awards have been celebrating<br />

project management excellence since 1993 and the broad range<br />

of categories is designed to make entry possible for projects and<br />

companies of all sizes and complexity.<br />

The awards reflect the invaluable contribution project managers<br />

make in all sectors of society and the event provides an opportunity<br />

for industry professionals to meet with colleagues and entertain<br />

guests as well as celebrate at one of the year’s most exciting events.<br />

Highly regarded in the project management industry, the awards<br />

reflect the dedication and talent that helps to shape the project<br />

management community and the world around us. The finalists,<br />

winners and sponsors of the awards attract national publicity for<br />

their achievement and involvement. Winning an award provides<br />

invaluable recognition and kudos to the careers of winners.<br />

For more details on the awards and how to enter or attend, visit<br />

www.apm.org.uk/awards.asp or email awards@apm.org.uk<br />

4

Association for Project Management<br />

Ibis House, Regent Park<br />

Summerleys Road<br />

Princes Risborough<br />

Buckinghamshire, HP27 9LE<br />

Telephone 0845 458 1944<br />

International +44 (0)1844 271640<br />

Facsimile +44 (0)1844 274509<br />

Email<br />

Web<br />

info@apm.org.uk<br />

www.apm.org.uk