Thiess News September 2002

Thiess News September 2002

Thiess News September 2002

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

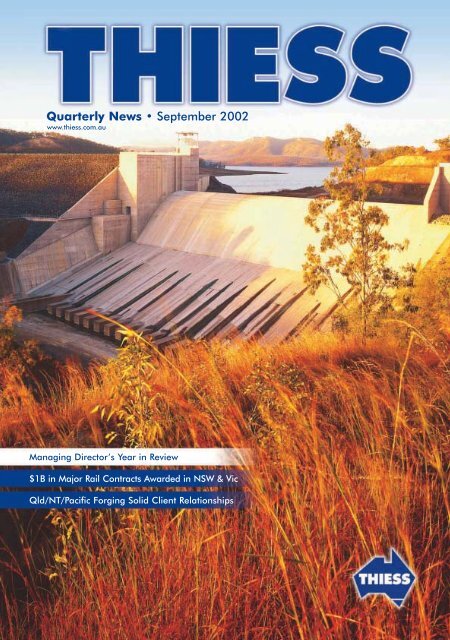

Quarterly <strong>News</strong> • <strong>September</strong> <strong>2002</strong><br />

www.thiess.com.au<br />

FRONT<br />

COVER<br />

Managing Director’s Year in Review<br />

$1B in Major Rail Contracts Awarded in NSW & Vic<br />

Qld/NT/Pacific Forging Solid Client Relationships

Contents<br />

2 Managing Director’s Year in<br />

Review<br />

6 Major Rail Projects<br />

$1B in major rail contracts awarded<br />

in NSW and Vic<br />

8 Qld/NT/Pacific Overview<br />

The Qld/NT/Pacific Business Unit<br />

continued its solid performance during<br />

2001/02 financial year, securing nine<br />

new contracts.<br />

• Building<br />

• Civil Engineering<br />

• Mining<br />

• Process Engineering<br />

• Community Partnerships<br />

• Safety<br />

• Engineering Awards<br />

22<br />

23<br />

24<br />

Chullora Recycling<br />

<strong>Thiess</strong> Services’ Chullora Materials<br />

Recycling facility has passed the<br />

300 million mark in PET bottles<br />

Recycled.<br />

<strong>News</strong> in Brief<br />

Sustainable Water Supply<br />

The continued prosperity of the<br />

Gladstone Region has been<br />

reinforced following the completion<br />

of Awoonga Dam Raising and<br />

Infrastructure Relocation Project.<br />

FRONT COVER: Awoonga Dam Raising<br />

and Infrastructure Relocation Project,<br />

Gladstone, Qld.<br />

> THIESS Quarterly <strong>News</strong> is published by<br />

<strong>Thiess</strong> Pty Ltd, ABN 87 010 221 486<br />

Marketing Services Section of the<br />

Technical Services Department.<br />

>Editor: Rebecca McDonald<br />

> Phone, fax or email your comments<br />

and feedback to:<br />

Ph: (07) 3002 9661 Fax: (07) 3002 9690<br />

Email: rdmcdonald@thiess.com.au<br />

Visit our homepage @<br />

http://www.thiess.com.au<br />

Managing<br />

Director’s<br />

Year in Review<br />

2001/<strong>2002</strong> saw <strong>Thiess</strong><br />

continue to strengthen the<br />

quality of work in hand,<br />

with our business well<br />

served by the strategy of<br />

market and geographic<br />

diversity.<br />

Our turnover of $2.2B and<br />

▲ Managing Director, Roger Trundle<br />

the value of work in hand<br />

of over $5B reflect record workloads in Australia and<br />

overseas in mining and resources, infrastructure and<br />

engineering and services.<br />

Alliances and joint ventures form a significant and rapidly<br />

increasing proportion of the work in which we are involved.<br />

Featured in this edition of <strong>Thiess</strong><br />

<strong>News</strong>, the Awoonga Dam Raising and<br />

Infrastructure Relocation project is<br />

typical of our flexible, outcomes<br />

focused approach.<br />

The Awoonga Dam was completed<br />

in June this year, five months ahead<br />

of schedule and well under budget<br />

through an innovative alliance<br />

between the client (Gladstone Area<br />

Water Board), the infrastructure<br />

Performance<br />

1150<br />

1531<br />

1815<br />

1808<br />

1852<br />

97 98 99 00 01 02 97 98 99 00 01 02<br />

Total Revenue $ Million<br />

2254<br />

designer (PPK), the dam designer<br />

(SunWater) and <strong>Thiess</strong> as Project<br />

Manager.<br />

In addition, a number of strategic<br />

partnerships were initiated with<br />

local training organisations to<br />

deliver training and career<br />

development opportunities for<br />

employees.<br />

Significant work in partnerships<br />

was won in June when the <strong>Thiess</strong><br />

2625<br />

3193<br />

2817<br />

3698<br />

4866<br />

Work in Hand $ Million<br />

5218<br />

THIESS 2

Year in Review<br />

Hochtief Alstom Group was<br />

awarded Australia’s largest publicly<br />

funded infrastructure contract – the<br />

Epping to Chatswood section of the<br />

Parramatta Rail Link in New South<br />

Wales, valued at $862M.<br />

The work incorporates the design<br />

and construction of tunnels,<br />

stations, track, signal and<br />

communications work to deliver a<br />

fully operational rail system to the<br />

NSW Government.<br />

Also awarded in June, a <strong>Thiess</strong><br />

Alstom Joint Venture will design,<br />

construct and commission track,<br />

signal and communications for the<br />

Ballarat and Geelong corridors of<br />

the Regional Fast Rail Project in<br />

Victoria, with a project value of<br />

$200M.<br />

The award of these two<br />

significant rail infrastructure<br />

projects is the result of the<br />

commitment and hard work by our<br />

teams, demonstrating the<br />

company’s technical expertise and<br />

strong project management<br />

capability.<br />

The Year’s Highlights<br />

Mining and resources activities<br />

contributed strongly to revenue<br />

during the year. In Australia, we<br />

progressed operations at 12 mine<br />

sites in New South Wales and<br />

Queensland and we were recently<br />

awarded, with Joint Venture partner<br />

Sedgman Pty Ltd, the construction<br />

of new coal handling facilities at<br />

the Hail Creek Coal Mine in<br />

Queensland’s Bowen Basin.<br />

In Gladstone, Queensland, we are<br />

constructing new calciners at QAL’s<br />

▲ Swing Bridge Project, Victoria<br />

alumina refinery and undertaking<br />

major civil works at Comalco’s<br />

alumina refinery.<br />

At year end, work was ongoing at<br />

the Goro Nickel project in New<br />

Caledonia and the LNG4 project at<br />

the North West Shelf in Western<br />

Australia.<br />

In Indonesia, we performed well<br />

on our $1B contract for PT Arutmin<br />

at the Satui and Senakin coal mines<br />

and also the Kideco and the KPC<br />

mines.<br />

Building work undertaken during<br />

the year included the Royal Prince<br />

Alfred Hospital and Shoal Bay Resort<br />

in New South Wales, the<br />

commencement of Stage 3 of the<br />

Lavarack Barracks in Queensland<br />

and a number of commercial and<br />

residential projects in Victoria.<br />

The Services business contributed<br />

with ongoing work across the<br />

environmental, telecommunications<br />

and utilities sectors. Facilities<br />

operations and maintenance<br />

continues to grow with good levels<br />

of new work won. Silcar, our Joint<br />

Venture with Siemans Pty Ltd, has a<br />

strong order book for maintenance<br />

and asset management in the<br />

industrial and utilities areas.<br />

Safety in the work place remains<br />

an absolute priority. A highlight to<br />

note was the achievement of the<br />

<strong>Thiess</strong> Services team operating the<br />

BHP Port Kembla coke ovens water<br />

recycling plant. In February this<br />

year they passed the ten year mark<br />

of continuous operation since<br />

project inception without a lost<br />

time injury.<br />

In the course of the year, we<br />

were recognised with sixteen<br />

▲ <strong>Thiess</strong> Infraco, maintenance and<br />

management for M>Train and M>Tram<br />

Network, Victoria<br />

industry awards for innovation,<br />

environmental management, waste<br />

management, training and project<br />

excellence.<br />

Increased awareness of<br />

environmental issues is important<br />

together with responsible<br />

management decisions. To that<br />

end we completed our third annual<br />

greenhouse gas audit and<br />

established operational key<br />

performance measures.<br />

We won the National Case Earth<br />

Award for the second time for our<br />

rehabilitation work in relation to<br />

the construction of the Kwinana<br />

Freeway in Perth. More than a<br />

tonne of native seed was collected<br />

from the works area, cleaned,<br />

stored and then replanted upon<br />

completion of the works.<br />

<strong>Thiess</strong> Services continues as the<br />

sole corporate supporter of the<br />

prestigious annual international<br />

and national Riverprizes, which<br />

recognises the vital work of those<br />

responsible for river and waterway<br />

management in Australia and<br />

around the world and helps to<br />

communicate the importance of<br />

this work to the broader<br />

community.<br />

<strong>Thiess</strong> believes that the<br />

communities in which we work are<br />

important stakeholders in our<br />

business and we commit each year<br />

to support vital community services<br />

at a national, regional and local<br />

level.<br />

Research to seek feedback from<br />

our clients was undertaken during<br />

3 THIESS

Projects secured in the year to 30<br />

June <strong>2002</strong>:<br />

THIESS<br />

• Epping to Chatswood section of<br />

the Parramatta Rail Link in NSW<br />

(<strong>Thiess</strong> share is $421M)<br />

• Ballarat and Geelong corridors<br />

of the Regional Fast Rail Project<br />

in Victoria (<strong>Thiess</strong> share is<br />

$100M).<br />

• Management contract for<br />

construction of Lavarack Barracks<br />

Stage 3, Townsville, QLD, for<br />

Department of Defence (value<br />

$154M).<br />

• Contracts for design and<br />

construction of three calciners,<br />

Gladstone, QLD, for Queensland<br />

Alumina Limited ($108M).<br />

• Alliance contract to construct a<br />

river diversion aqueduct,<br />

including three conveyor tunnels<br />

for the Morwell River, Yallourn,<br />

VIC, for Yallourn Energy (<strong>Thiess</strong><br />

share $44M).<br />

• Contract to design, construct and<br />

maintain the Karuah bypass for<br />

NSW Roads and Traffic Authority<br />

($82M).<br />

• Joint venture contract for site<br />

and civil works at the Comalco<br />

Alumina Refinery, Gladstone,<br />

QLD, for Bechtel Australia<br />

(<strong>Thiess</strong> share $36M).<br />

• Management contract for<br />

redevelopment of the Cairns<br />

waterfront and central business<br />

district areas, QLD, for Cairns<br />

Port Authority ($42M).<br />

• Contract to design, construct and<br />

commission the Hail Creek coal<br />

handling plant, Nebo, QLD, for<br />

Hail Creek Coal (<strong>Thiess</strong> share<br />

$41M).<br />

• Contract to construct two<br />

wharves at the Darwin East Arm<br />

Port Stage 2A, Darwin, NT, for<br />

Northern Territory of Australia<br />

($38M).<br />

• Contract to design and construct<br />

a rail car maintenance facility,<br />

Nowergup, WA, for EDI<br />

Rail/Bombardier Transportation<br />

($33M).<br />

• Management contract for<br />

construction of nine health<br />

facilities, in rural NSW, for NSW<br />

Department of Public Works and<br />

Services ($33M).<br />

• Contract to construct civil works<br />

for the North West Shelf Phase IV<br />

project, Karratha, WA, for<br />

Woodside Energy Limited ($32M).<br />

• Contract to construct pavements<br />

and associated roadworks at the<br />

West Charlestown bypass,<br />

Charlestown, NSW Roads and<br />

Traffic Authority ($22M).<br />

• Contract to design and construct<br />

civil works at the Springwood bus<br />

station, Logan, for Queensland<br />

Transport ($15M).<br />

PT THIESS CONTRACTORS<br />

INDONESIA<br />

• Contract to install a pipeline and<br />

associated works at the PGN<br />

Sakernan pipeline pump station,<br />

Jambi, Indonesia, for PT<br />

Perusahaan Gas Negara ($13M).<br />

• Contract to construct drainage<br />

structures and hire equipment,<br />

Batu Hijau copper-gold mine,<br />

West Nusa Tenggara, Indonesia,<br />

for PT Newmont Nusa Tenggara<br />

($13M).<br />

• Contract to supply mine support<br />

services at the Minahasa Messel<br />

coal mine, North Sulawesi,<br />

Indonesia, for Newmont Minahasa<br />

Raya ($11M).<br />

THIESS SERVICES<br />

• Contract for domestic waste<br />

collection and recycling for the<br />

City of Casey, Victoria ($41M).<br />

• Contract to design, construct and<br />

operate the pretreat facility in<br />

South Windsor, NSW, for Resource<br />

NSW ($29M).<br />

• Contract to remediate the<br />

Homebush Bay site, Sydney, NSW,<br />

for Waterways Authority ($20M).<br />

• Contract to collect and recycle<br />

domestic waste for Cardinia<br />

Shire, Victoria ($11M).<br />

THIESS SOUTH AMERICA<br />

• Contract for construction of a<br />

tailings dam and associated<br />

facilities, Tintaya, Peru, for BHP<br />

Billiton Tintaya SA ($30M).<br />

• Contract to build new leach pad<br />

as part of the Yanacocha<br />

Carachugo Stage 9 expansion<br />

for Minera Yanacocha, Peru<br />

($30M).<br />

the year, to help us to better<br />

understand their requirements and<br />

priorities, including:<br />

• The qualities they regard as<br />

important when using service<br />

providers such as <strong>Thiess</strong><br />

• Our performance on a range of<br />

service aspects<br />

• The challenges our clients expect<br />

to face in the next three years.<br />

Representatives of fifty of our<br />

client organisations from across<br />

Australia were interviewed,<br />

providing information that will be<br />

important in helping us to<br />

continually improve the quality of<br />

our services.<br />

Results show that while clients<br />

continue to place a strong emphasis<br />

on value, quality and timely<br />

▲ <strong>Thiess</strong> Services waste management<br />

services<br />

delivery, there is an increasing<br />

emphasis on the importance of a<br />

good, responsive working<br />

relationship between clients and<br />

service providers.<br />

When responses from all<br />

participants were collated, we were<br />

given a rating of 4.2 out of 5 for<br />

overall performance.<br />

The challenge for us is to turn<br />

this valuable feedback into actions<br />

that will further enhance our service<br />

and performance.<br />

Outlook<br />

The outlook for our business is<br />

positive. The <strong>2002</strong>/03 year will be<br />

characterized by consolidation of<br />

our strong market position with<br />

particular focus on quality<br />

opportunities and the delivery of<br />

quality outcomes.<br />

Continuing to foster strong<br />

stakeholder relationships is key to<br />

THIESS 4

Year in Review<br />

▲ Satui Coal Mine, Indonesia<br />

maintaining high levels of repeat<br />

business and to enhancing our<br />

reputation as a provider of quality<br />

services.<br />

There are good opportunities in<br />

civil and process engineering and in<br />

large-scale transport infrastructure<br />

projects. We expect an upturn in<br />

the building and property market<br />

in Australia and our services<br />

business is expected to perform<br />

well in a steadily growing market.<br />

An increasing demand worldwide<br />

for minerals should provide good<br />

levels of activity in the minerals and<br />

resources sector, both in Australia<br />

and internationally.<br />

Our ongoing success depends on<br />

our people who are encouraged to<br />

undertake training and development<br />

programs to enhance their skills and<br />

to achieve their full potential.<br />

A new Group Health, Safety and<br />

Environment Plan is being<br />

implemented as we constantly strive<br />

for improvements in our safety and<br />

environmental performance.<br />

We will also be focusing on<br />

business efficiencies through the<br />

implementation of the JD Edwards<br />

enterprise system, due for<br />

completion by late 2003.<br />

In closing I would like to say a<br />

most sincere thank you to our<br />

valued clients and business<br />

partners for your continuing<br />

support of <strong>Thiess</strong> and your<br />

confidence that in working<br />

together we are able to achieve<br />

common goals and objectives.<br />

I would also like to thank all<br />

<strong>Thiess</strong> Group employees for your<br />

valuable contribution over the<br />

course of 2001/02 and I look<br />

forward to another strong<br />

performance in the year ahead.<br />

▲ Shoal Bay Country Club, NSW<br />

Roger Trundle<br />

Managing Director ■<br />

5 THIESS

Major Rail Projects<br />

$1B in Major Rail<br />

Contracts<br />

The recent award of more than $1 billion in major rail contracts in NSW and Victoria has<br />

placed <strong>Thiess</strong> at the forefront in the push to rejuvenate and expand Australia's transport<br />

infrastructure.<br />

Works Commence on $880M Rail<br />

Contract in NSW<br />

The <strong>Thiess</strong> Hochtief Joint Venture<br />

has commenced work on the largest<br />

single infrastructure contract ever to<br />

be awarded by the NSW Government<br />

– the $880M Parramatta Rail Link in<br />

Sydney.<br />

Selected from a strong Australian<br />

and international field, the <strong>Thiess</strong><br />

Hochtief Joint Venture will be<br />

responsible for all tunneling and<br />

station excavation work and<br />

installation of track, and through our<br />

partnership with Alstom, the signaling<br />

and communication systems for the<br />

14 kilometre section between<br />

Chatswood and Epping.<br />

The contract signing in July<br />

signaled a major investment in public<br />

transport by the NSW Government<br />

aimed at increasing the long-term<br />

capacity of the Sydney metropolitan<br />

rail system and providing rail access<br />

to areas not previously served by rail.<br />

NSW Minister for Transport Mr Carl<br />

Scully said, once operational, the<br />

project would add 12,000 new rail<br />

passengers to the City Rail network<br />

each working day.<br />

"It will also create the capacity for<br />

an extra 18,000 passengers to travel<br />

by train from Western Sydney each<br />

morning peak by diverting current<br />

Northern services via Epping rather<br />

than Strathfield," Mr Scully said.<br />

<strong>Thiess</strong> Executive General Manager<br />

NSW/ACT & VIC said "Our success<br />

was due to mobilising the best<br />

available tunneling expertise world<br />

wide combined with strong<br />

THIESS 6

management of design, construction,<br />

safety and environmental and<br />

community issues".<br />

"The <strong>Thiess</strong> Hochtief Alstom group<br />

are leading edge in their respective<br />

fields and together will respond to<br />

the challenge of constructing a world<br />

class operating rail system" he said.<br />

The main component of the works<br />

involve 12km of twin tunnels<br />

stretching from Epping in Sydney’s<br />

north west to Chatswood on Sydney’s<br />

North Shore. The rail tunnels will be<br />

seven metres in diameter and run<br />

mostly in parallel. They will vary in<br />

depth from 15 metres to 60 metres<br />

underground. The works will also add<br />

three new stations to the rail<br />

network and enable the upgrading of<br />

two existing stations.<br />

A number of construction methods<br />

will be used, including bored<br />

tunneling, road header and cut and<br />

cover tunneling techniques. Two<br />

Tunnel Boring Machines will excavate<br />

approximately 1.2M bcm of spoil.<br />

These machines will arrive in mid-<br />

2003 and undertake tunneling<br />

activities for two years - traveling<br />

approximately 120 to 180 metres per<br />

week through Sydney sandstone.<br />

Following excavation of tunnels and<br />

station, lining of the tunnel (using<br />

concrete and membrane) and<br />

installation of rail components will<br />

commence.<br />

Hochtief’s International Tunnel<br />

Manager Ulrich Wadepohl said "We<br />

are delighted the strength of our<br />

local and international based Joint<br />

Venture has been recognised by the<br />

NSW Government."<br />

The environmental management<br />

requirements on this project are<br />

understandably stringent given the<br />

urban environment, and management<br />

plans and procedures are being<br />

developed and systematically<br />

implemented to ensure the impacts<br />

of construction are kept to an<br />

absolute minimum and in line with<br />

government and stakeholder<br />

expectations. To minimize the<br />

impact of noise and vibration during<br />

operation of the rail network, a<br />

number of acoustic treatments will<br />

be applied to the rail tracks along<br />

the route.<br />

Construction, commissioning and<br />

handover of the Epping to Chatswood<br />

section of the Parramatta Rail Link is<br />

expected to be completed in 2008. ■<br />

▲ Sandy Eliot (ALSTOM), Peter Batchelor (Minister for Transport), Premier Steve Bracks,<br />

Don Johnson and Robert Rust (ALSTOM).<br />

<strong>Thiess</strong> Wins Major Rail<br />

Project in Victoria<br />

<strong>Thiess</strong> and joint venture partner,<br />

ALSTOM Australia Ltd, have been<br />

awarded two contracts on Victoria’s<br />

$550M Regional Fast Rail Project.<br />

The contracts have a combined<br />

value of $200M, and involve rail<br />

infrastructure upgrade works<br />

between Melbourne and Ballarat<br />

(107km), and Melbourne and<br />

Geelong (41km).<br />

As one of the biggest upgrades of<br />

the Victorian regional rail system in<br />

120 years, the project will see a<br />

reduction in traveling times with<br />

trains operating at speeds up to<br />

160km/h and the delivery of more<br />

frequent services.<br />

The <strong>Thiess</strong> ALSTOM Joint Venture<br />

will be responsible for the design,<br />

construction and commissioning of<br />

track, civil, signal and<br />

communication works to achieve<br />

the Department of Infrastructure’s<br />

(DOI) specified times for each<br />

corridor.<br />

<strong>Thiess</strong> General Manager<br />

Vic/SA/Tas/NZ, Don Johnson said he<br />

was delighted that <strong>Thiess</strong>, and its<br />

joint venture partner, ALSTOM, had<br />

been chosen to play a significant<br />

role in this historic transport<br />

project which will drive economic<br />

growth across Victoria by providing<br />

greater accessibility to these<br />

regional communities, and linking<br />

them more closely to Melbourne.<br />

"<strong>Thiess</strong> and ALSTOM formed a<br />

strategic relationship, which has<br />

proven to be successful and for this<br />

project we have established a team<br />

with extensive rail and project<br />

management expertise to ensure the<br />

delivery of the project to the State’s<br />

requirements," said Don.<br />

"Our team is looking forward to<br />

managing the challenges on this<br />

complex project, and is committed<br />

to maximising the involvement of the<br />

local community.<br />

"We intend to implement<br />

strategies that promote local<br />

employment, providing opportunities<br />

to local contractors, suppliers and<br />

subcontractors to be involved in this<br />

major infrastructure project."<br />

Detailed design has commenced<br />

for both the Ballarat and Geelong<br />

corridors, along with community<br />

consultation in the form of public<br />

meetings and workshops. Work on<br />

site is scheduled to commence in<br />

November <strong>2002</strong> and will be<br />

completed by mid 2005.<br />

The award of these contracts<br />

strengthens <strong>Thiess</strong>’ rail portfolio in<br />

Melbourne which includes <strong>Thiess</strong><br />

Infraco’s ongoing contract for the<br />

infrastructure maintenance of the<br />

M>Train and M>Tram networks and<br />

the St Albans to Sydenham Rail<br />

Electrification project completed<br />

earlier this year. ■<br />

7 THIESS

Qld/NT/Pacific Overview<br />

Forging solid client<br />

relationships<br />

for win-win results<br />

▲ Murray Fox, Executive General<br />

Manager (Qld/NT/Pacific)<br />

The Qld/NT/Pacific Business Unit continued its solid performance during the 2001/02<br />

financial year, securing nine new contracts.<br />

Driving our success has been the<br />

positive relationships we have<br />

forged with our clients, supported<br />

through a team dedicated to<br />

maintaining high standards in client<br />

service.<br />

With 18 projects throughout the<br />

region, the Business Unit continues<br />

to deliver a full spectrum of civil,<br />

building, mining and process<br />

engineering services.<br />

Some key achievements:<br />

• Our appointment to undertake<br />

the $171M Lavarack Barracks<br />

Stage 3 project is a continuation<br />

of our strong relationship with<br />

the Department of Defence.<br />

Working in consultation with our<br />

client, we are confident the<br />

delivery of Stage 3 will reflect<br />

the excellent results achieved on<br />

the award-winning Stage 2<br />

Redevelopment.<br />

• We are proud to be working with<br />

Bechtel to assist in delivering the<br />

Comalco Alumina Refinery Project,<br />

with the Queensland Department of<br />

Transport in constructing the<br />

Springwood Bus Station, with QAL<br />

in delivering the QAL Calciners<br />

Project and with Hatch and our<br />

Joint Venture partner Sedgman in<br />

delivering the Hail Creek Coal<br />

Handling and Preparation Plant.<br />

With $1.6B worth of work in<br />

hand and a firm commitment to<br />

supporting our clients’ business<br />

objectives, we are confident that<br />

the Qld/NT/Pacific Business Unit is<br />

well positioned to continue its<br />

strong performance during the next<br />

12 months and beyond.<br />

Health and Safety<br />

Health and safety remains a priority.<br />

We are committed to achieving an<br />

incident and injury free workplace,<br />

and we continue to identify better<br />

ways to improve safety performance.<br />

Initiatives such as Job Safety and<br />

Environmental Observations, the JMJ<br />

Behavioural Change Program and the<br />

Remember Charlie video have proved<br />

to be invaluable in encouraging people<br />

to be responsible for work safety, as<br />

well as empowering them to take the<br />

initiative to correct or improve<br />

potentially hazardous situations.<br />

By providing a balanced mix of<br />

behavioural programs and health and<br />

safety procedures, we are creating a<br />

work culture focused on responsibility,<br />

commitment and consideration.<br />

▼ Geoff MacKenzie - Environmental Officer, monitors water quality at the Burton Coal Project<br />

• Under an alliancing agreement,<br />

we are pleased to be working in<br />

partnership with Queensland<br />

Transport and Sinclair Knight Merz<br />

to deliver Stage 3 of the $34M<br />

Inner Northern Busway Project in<br />

Brisbane.<br />

• In early <strong>2002</strong>, we re-entered the<br />

Pacific region with the<br />

opportunity to again work with<br />

our client, Inco, and provide<br />

civil engineering services to the<br />

$2.7B Goro Nickel project in New<br />

Caledonia. We look forward to<br />

developing our business in<br />

the region and to continuing our<br />

relationship with Inco.<br />

THIESS 8

▲ Kerry Weller (left) and Cassandra Pickard, Equipment Operators, at the Foxleigh Coal Project<br />

Highlighting the success of our<br />

approach is the performance of<br />

projects such as the QAL Calciners<br />

Project in Gladstone, which has not<br />

recorded an incident on site since<br />

the project started in July 2001. In<br />

addition, the Comalco Alumina<br />

Refinery Project in Gladstone has<br />

worked almost 650,000 employee<br />

hours without a lost time incident.<br />

Our People<br />

We employ some 1,600 employees<br />

and 1,400 subcontractors in the<br />

Qld/NT/Pacific Business Unit, and<br />

we understand that business<br />

excellence is achieved through our<br />

people.<br />

<strong>Thiess</strong> was recently announced<br />

"Large Employer of the Year" for the<br />

Brisbane district at the Queensland<br />

Department of Employment, Training<br />

and Youth <strong>2002</strong> Awards, as well as<br />

the "Mining Industry Training Provider<br />

for <strong>2002</strong>" at the annual Queensland<br />

Mining Industry Training Awards.<br />

Environmental Management<br />

Despite tightening regulations, our<br />

projects continue to achieve<br />

excellent environmental<br />

performance that can be measured<br />

through our due diligence and<br />

awards received.<br />

Each of our projects has passed<br />

all environmental inspections and<br />

reviews without a fine or penalty. In<br />

addition, our environmental<br />

performance on projects such as<br />

Lavarack Barracks Stage 2 has been<br />

recognised through the<br />

achievement of the “2001 Arbor<br />

Day Award”.<br />

Community Relations<br />

Our long association with the<br />

Queensland Arts Council continues<br />

this year through our sponsorship<br />

of the Ontour Inschools program –<br />

providing arts access statewide and<br />

therefore positively contributing to<br />

the cultural spirit of communities<br />

throughout regional Queensland.<br />

We continue to proactively raise<br />

funds for local groups through<br />

activities such as the <strong>Thiess</strong>/CQ<br />

RESQ Charity Ball and the<br />

Christmas Coal Dash in Mackay, the<br />

<strong>Thiess</strong>/Suncorp Hear and Say<br />

Charity Ball in Brisbane, and<br />

charity movie nights in Gladstone.<br />

Community groups we support<br />

include the Queensland Biennial<br />

Festival of Music, Gladstone Tutorial<br />

Centre, Variety Club of Queensland,<br />

Hear and Say Centre for Deaf<br />

Children and Central Queensland<br />

Rescue Helicopter Service. ■<br />

9 THIESS

Building<br />

Hospital’s<br />

New Building<br />

on Schedule<br />

Despite a technically challenging working environment,<br />

construction of the West Block Building within the Royal<br />

Brisbane Hospital’s Herston Complex in Brisbane is well on<br />

schedule to be completed by October <strong>2002</strong>.<br />

With responsibility for<br />

documentation, construction and<br />

commissioning, <strong>Thiess</strong> commenced<br />

work on the $35.5M project in May<br />

last year.<br />

Project Manager Brad Anderson<br />

said the challenge was to deliver a<br />

modern medical facility within a<br />

busy, operational hospital campus,<br />

while allowing for efficient,<br />

functional relationships between<br />

new and existing buildings to<br />

continue.<br />

"The small and restricted project<br />

site is located in close proximity to<br />

other hospital operations, as well as<br />

next to an access road for<br />

pedestrian traffic and emergency<br />

vehicles.<br />

"This meant that careful and<br />

detailed planning of all construction<br />

activities and continual<br />

communication with our client,<br />

Queensland Health, was vital in<br />

effectively managing all project<br />

outcomes," Brad said.<br />

Upon completion, the new<br />

12,700m 2 building will provide<br />

facilities for infectious diseases,<br />

medical and radiation oncology,<br />

including bone marrow transplant<br />

and haematology inpatient services,<br />

and administration areas.<br />

A major project success has been<br />

the installation of five linear<br />

accelerator bunkers for the<br />

Oncology Department, consisting of<br />

1.5 metre thick, high density<br />

concrete walls and roof slabs.<br />

According to Brad, the concrete<br />

mix design was an innovation that<br />

had never before been implemented.<br />

"As the linear accelerators use subatomic<br />

charged particles to treat<br />

various forms of cancer, it was<br />

necessary to use high density<br />

concrete to contain the therapeutic<br />

radiation and maintain radiation<br />

protection," he said.<br />

“Working in close consultation<br />

with our client, medical staff and<br />

structural engineers, we undertook<br />

extensive laboratory testing to<br />

determine the correct concrete mix<br />

and identify the best solution to<br />

control the core temperature of the<br />

concrete to ensure it set properly.” ■<br />

Cityport North...<br />

Maintaining Environmental Excellence<br />

Operating within a sensitive<br />

marine and natural environment, the<br />

Cairns Cityport Project has employed<br />

stringent management practices to<br />

ensure the highest standard of<br />

environmental excellence.<br />

Commencing in August 2001, the<br />

project team has worked closely with<br />

the Cairns Port Authority to ensure<br />

construction activities on the new<br />

waterfront do not impact existing<br />

flora and fauna.<br />

To date, a number of large fig<br />

trees have been preserved with other<br />

rare species of trees identified and<br />

relocated as part of the<br />

environmental management<br />

program.<br />

Project Manager Ken Spain said<br />

that retaining as much of the natural<br />

environment was a key focus for the<br />

project team, particularly with the<br />

close proximity of fish habitat areas,<br />

sea grass beds and the Great Barrier<br />

Reef Marine Park.<br />

"Cairns boasts a beautiful natural<br />

marine and land environment, with a<br />

solid reputation as the pre-eminent<br />

gateway to the Great Barrier Reef.<br />

This project is designed to enhance<br />

the existing port area and develop it<br />

into a world-class tourism precinct,"<br />

Ken said.<br />

The project includes the upgrade<br />

of the existing Marlin Jetty, land<br />

reclamation, expansion of the<br />

existing marina, roads and<br />

carparking, construction of a Reef<br />

Fleet Terminal Building and<br />

development of new boardwalks,<br />

street furniture and landscaping.<br />

"To ensure environmental issues<br />

are promptly identified, <strong>Thiess</strong><br />

actively participates in a Scientific<br />

Advisory Group that consists of<br />

representatives from the Cairns Port<br />

Authority, Environmental Protection<br />

Agency, Queensland Parks and<br />

Wildlife Services and the Great<br />

Barrier Reef Marine Park Authority,"<br />

Ken said.<br />

Work on the $41M project is<br />

scheduled for completion by May<br />

2003. ■<br />

THIESS 10

Performance Excellence<br />

Wins $171M Redevelopment Project<br />

<strong>Thiess</strong>’ success on the award-winning $140M Lavarack Barracks Stage 2 project resulted in the<br />

company being chosen on a ‘sole-select’ basis by the Department of Defence to undertake the<br />

$171M Lavarack Barracks Stage 3 Redevelopment.<br />

As Managing Contractor, <strong>Thiess</strong> is<br />

responsible for the briefing,<br />

planning, design, construction and<br />

commissioning of Stage 3, which will<br />

include office accommodation,<br />

training, warehousing and<br />

communications facilities,<br />

workshops, vehicle shelters,<br />

transport compounds and service<br />

infrastructure.<br />

Project Manager Murray Frame said<br />

the successful delivery of Stage 2,<br />

within a cost-capped budget, was<br />

achieved through <strong>Thiess</strong>’ proactive<br />

project management approach that<br />

involved open, two-way<br />

communication with the client and<br />

end users.<br />

"A key Stage 2 challenge was to<br />

address an increasing trend towards<br />

Army personnel having a preference<br />

for better accommodation off base.<br />

A further challenge was that mess<br />

membership and patronage was<br />

declining, resulting in less social<br />

interaction between Army<br />

personnel," Murray said.<br />

"Early and ongoing<br />

communication with our client and<br />

project personnel helped us to<br />

clearly identify the users’ functional<br />

requirements to be accommodated<br />

by the design, while ensuring that<br />

all issues were being effectively<br />

addressed.<br />

"To facilitate this process we<br />

developed a prototype of a single<br />

accommodation unit, which enabled<br />

stakeholder groups to see firsthand<br />

what the finished units would<br />

look like. This gave Defence the<br />

confidence to sign-off on key<br />

building design features prior to<br />

construction, reducing the<br />

likelihood of any future design<br />

changes.<br />

"By delivering a project that<br />

fulfilled all client and user<br />

requirements, there is now a<br />

waiting-list for Army personnel to<br />

move from rental accommodation<br />

in Townsville back to the Barracks."<br />

Brigadier Garry Kelly, who was<br />

Director General Capital<br />

Infrastructure for Defence during<br />

Redevelopment Stage 2, said the<br />

success of the project highlighted<br />

the benefits gained through a true<br />

partnership approach.<br />

"I appreciated the way in which<br />

<strong>Thiess</strong> embraced the Managing<br />

Contractor delivery method, in all<br />

senses of the term ‘partnering’.<br />

All outcomes were achieved in a<br />

friendly, cooperative manner<br />

through a philosophy of open<br />

communication and working<br />

together," he said.<br />

"Defence’s decision to negotiate<br />

the Stage 3 project with <strong>Thiess</strong> on<br />

a sole select basis is testimony to<br />

the value <strong>Thiess</strong> has added during<br />

Stage 2."<br />

Lavarack Barracks Stage 3 is<br />

scheduled for completion by<br />

mid-2005. ■<br />

11 THIESS

Civil Engineering<br />

Major Work Starts<br />

on Inner Northern Busway<br />

The first sod on the Inner Northern Busway Project in Brisbane was turned recently by<br />

Queensland Transport and Main Roads Minister Hon. Steve Bredhauer, marking the official<br />

start of construction on Stage 2 of the busway.<br />

According to Mr Bredhauer, the<br />

Inner Northern Busway will provide<br />

passengers with a fast, congestionfree<br />

run between the Queen Street<br />

bus station in the city and the<br />

Royal Brisbane Hospital at Herston.<br />

"The new busway forms part of<br />

the State Government’s<br />

commitment to reducing car<br />

dependency in Brisbane by<br />

providing improved public<br />

transport opportunities. This<br />

project will give buses various<br />

options to access local routes and<br />

communities along the way,<br />

providing people with a faster,<br />

safer and more comfortable<br />

journey," he said.<br />

Alliance partners Queensland<br />

Transport, <strong>Thiess</strong> and Sinclair<br />

Knight Merz will be responsible for<br />

the design and construction of<br />

Section 3, which will include a<br />

dedicated two-way busway from<br />

Roma Street to the Normanby<br />

Fiveways, as well as extensive civil<br />

and tunneling works.<br />

<strong>Thiess</strong> Alliance Manager Andrew<br />

Large said the alliance method was<br />

an effective way to minimise risk<br />

and ensure the successful delivery<br />

of the project through a collective<br />

approach to project challenges.<br />

"Unlike many contract methods<br />

where risks are normally borne by<br />

one party, an alliance focuses on a<br />

joint-approach that sees both<br />

benefits and risks equally shared,"<br />

Andrew said.<br />

"As Alliance partners, our focus<br />

is on achieving shared objectives<br />

and identifying solutions that will<br />

ensure the efficient delivery of all<br />

project aspects, including health<br />

and safety, environmental<br />

management, community relations<br />

and quality.<br />

"Furthermore, by drawing on the<br />

diverse skills and expertise of the<br />

partners, we are confident in<br />

delivering smart solutions that will<br />

achieve maximum results."<br />

The Inner Northern Busway<br />

Project is a joint effort by the<br />

State Government and the Brisbane<br />

City Council in providing attractive<br />

alternatives to the car when<br />

traveling into the inner city.<br />

The busway is expected to be<br />

completed by December 2003.■<br />

▲ Hon. Steve Bredhauer turns the first sod<br />

marking the start of construction<br />

▲ Alliance Manager - Andrew Large (left)<br />

and Marc Danckert review plans for INB3<br />

THIESS 12

Comalco Project<br />

Targets Local Employment<br />

With approximately 90 per cent of the existing workforce recruited locally, the<br />

Comalco Alumina Refinery Project in Gladstone continues its valuable contribution<br />

to the growth of the local economy.<br />

In mid-December 2001, the <strong>Thiess</strong><br />

Golding Joint Venture was appointed<br />

to undertake initial civil works in<br />

preparation for the construction of<br />

the first stage of the refinery, which<br />

is expected to produce approximately<br />

1.4 million tonnes of alumina<br />

annually.<br />

According to Project Manager Hugh<br />

Morrison, more than 200 locals are<br />

currently employed on the project,<br />

with further local recruitment to take<br />

place for the wharf development.<br />

"Local employees are carrying out<br />

a range of civil engineering activities,<br />

from general earthworks through to<br />

extensive concrete works. In addition,<br />

eight trainees are completing formal<br />

apprenticeships and TAFE-accredited<br />

courses on site," Hugh said.<br />

"Due to the significant size of the<br />

project and the extent of works to<br />

be undertaken, the construction<br />

workforce is expected to peak at<br />

2,300 people during mid 2003."<br />

Commencing site preparation<br />

work in December 2001, the Joint<br />

Venture is carrying out 1,000,000m 3<br />

of bulk and detailed earthworks,<br />

storm and sewerage services<br />

installation, some 50,000m 3 of<br />

structural concrete foundations,<br />

construction of wharf and jetty for<br />

inloading and outloading, building<br />

work, as well as the upgrading of<br />

existing road infrastructure to<br />

allow safe site access.<br />

Hugh said the overall project<br />

was being delivered via an<br />

innovative process where a group<br />

of five contractors, including the<br />

<strong>Thiess</strong> Golding Joint Venture,<br />

shared a common budget and<br />

program.<br />

"Contractors are rewarded<br />

through enhanced fees if they are<br />

able to collectively meet or<br />

achieve budget and time savings<br />

that result in early and most cost<br />

effective commencement of<br />

alumina production," he said.<br />

"We believe this type of<br />

incentive program has not been<br />

previously implemented on a<br />

project of this size and<br />

complexity. The program is an<br />

effective method to ensure that<br />

everyone is collectively delivering<br />

the best possible outcomes for the<br />

project.” ■<br />

<strong>Thiess</strong> Contract Extended<br />

on $2.7B Nickel Project in New Caledonia<br />

Successfully undertaking initial<br />

civil works on the $2.7B Goro Nickel<br />

project in New Caledonia, <strong>Thiess</strong>’<br />

work scope has been extended to<br />

include a further $30M worth of work<br />

by the world’s second largest nickel<br />

producer, Inco Limited.<br />

<strong>Thiess</strong>, in partnership with local<br />

earthmoving subcontractor COLAS,<br />

will be carrying out additional civil<br />

earthworks and management of<br />

geotechnical investigations and<br />

drilling, as well as development of<br />

substantial drainage structures and<br />

laydown areas.<br />

Construction Manager Duncan<br />

Gibb said <strong>Thiess</strong>’ contribution to the<br />

project was a positive step into a<br />

new market, with the extended<br />

contract strengthening the<br />

company’s re-entry into the Pacific<br />

region.<br />

"The Goro Nickel project is one of<br />

a number of billion dollar<br />

developments forecast for the New<br />

Caledonia region in the next 10<br />

years," he said.<br />

"We look forward to developing<br />

and strengthening our presence in<br />

New Caledonia by forging close<br />

working partnerships with local<br />

industry and community in<br />

supporting the economic growth of<br />

region." ■<br />

13 THIESS

Mining<br />

Collinsville<br />

Maintains Solid Position in Coal Market<br />

Commencing at Collinsville Coal Mine in 1996, <strong>Thiess</strong> continues to work in close consultation<br />

with our client, NCA Joint Venture, in all aspects of mine management to ensure that<br />

Collinsville maintains its solid position in the coal market.<br />

As Managing Contractor, <strong>Thiess</strong> is<br />

responsible for the overall<br />

operations of the mine, including<br />

mine planning, operation and<br />

maintenance of existing mine<br />

infrastructure, workplace health,<br />

and safety and community relations,<br />

as well as providing assistance to<br />

the client in the area of<br />

environmental management.<br />

Project Manager Steve Rodgers<br />

said the success of Collinsville could<br />

be attributed to the positive<br />

relationship established with the<br />

client, which had ensured the<br />

efficient implementation of<br />

initiatives to support mine<br />

expansion.<br />

"Collinsville produces up to nine<br />

product coal types for export and<br />

domestic customers. The mine has<br />

gradually expanded during the past<br />

three years, which has been<br />

supported through a steady rise in<br />

coal sales," Steve said.<br />

"To accommodate this increase,<br />

we recently recommissioned a<br />

BE1300 dragline and purchased a<br />

new higher capacity bucket that will<br />

assist to increase production.<br />

"Furthermore, we have undertaken<br />

two wash plant upgrades that have<br />

improved throughput by 30 per cent,<br />

which has allowed an increase in<br />

washed coking coal sales.<br />

"As the newly appointed Project<br />

Manager, my challenge is to maintain<br />

the excellent progress that has been<br />

achieved to date.<br />

"I plan to do this by continuing to<br />

work closely with our client and the<br />

project team to maximise the value<br />

of the Collinsville resource and<br />

therefore further strengthen the<br />

mine’s position in the competitive<br />

coal market."<br />

Steve Rodgers joined <strong>Thiess</strong> at<br />

Collinsville in July this year. He<br />

brings to the project more than 20<br />

years experience in the mining<br />

industry, covering open cut coal,<br />

large-scale iron ore mining,<br />

metalliferous mining, dry mining and<br />

large scale dredging of mineral sands.<br />

Steve has held the position of<br />

Site Senior Executive at a number of<br />

mine sites throughout Queensland,<br />

and is qualified as a Metalliferous<br />

Mine Manager in Queensland and<br />

Western Australia. ■<br />

Training Awards<br />

▲ (Lt-Rt) Mick Nash - Human Resources<br />

Manager (Qld/NT/Pacific) and Adam Chapple<br />

- Training and Development Manager<br />

(Qld/NT/Pacific) receive training award.<br />

<strong>Thiess</strong>’ outstanding efforts in<br />

training and development were<br />

recognised at the Queensland<br />

Mining Industry Training Awards<br />

with the company named the "<strong>2002</strong><br />

Mining Industry Training Provider of<br />

the Year". <strong>Thiess</strong> was also<br />

announced the "Large Employer of<br />

the Year" by the Queensland<br />

Government at the recent <strong>2002</strong><br />

Queensland Training Awards.<br />

THIESS 14

Burton Coal<br />

Completes Record Year<br />

Development of the new Ellensfield opencut pit has seen the<br />

Burton Coal project move more than 35 million BCM of<br />

overburden during the past 12 months – setting a new record<br />

for the mine.<br />

Located immediately south of<br />

the original Burton boxcut<br />

operation, Ellensfield commenced<br />

in January this year and required<br />

overburden removal of more than<br />

7.3 million BCM to develop the pit<br />

to a stage ready for steady state<br />

mining of coal.<br />

Project Manager Geoff Caton said<br />

the responsiveness of the project<br />

team in mobilising equipment and<br />

resources ensured the development<br />

of Ellensfield and extraction of first<br />

coal from the pit was undertaken<br />

within the scheduled timeframe.<br />

"As part of the mine plan to<br />

maintain Burton’s high quality<br />

coking product, our client required<br />

us to fast track the expansion,"<br />

Geoff said.<br />

"To ensure timeframes were<br />

efficiently met, upon approval of<br />

the Ellensfield scope, existing<br />

plant from the Burton Pit –<br />

including a 580 tonne Liebherr 966<br />

hydraulic excavator – was<br />

immediately relocated to<br />

Ellensfield. Additional equipment<br />

was then hired and purchased to<br />

augment the original fleet.<br />

"Also purchased was a new<br />

generation Liebherr R994B hydraulic<br />

excavator, which is a 290 tonne ‘big<br />

brother’ to the existing R994-200<br />

series of excavators operated by<br />

<strong>Thiess</strong>. As the first R994B to go into<br />

production in the world, Burton<br />

continues to break new ground in<br />

equipment selection," he said.<br />

"This resulted in Ellensfield being<br />

successfully established within six<br />

months of the initial proposal,<br />

allowing the first coal to be<br />

extracted in June this year. The<br />

timely delivery of the pit has<br />

contributed to overall production<br />

levels during the past 12 months."<br />

Located in Central Queensland<br />

and owned by RAG Australia Coal,<br />

the Burton project has more than<br />

doubled its yearly production rates<br />

since its establishment in 1996, with<br />

annual production currently at 5.2<br />

million tonnes. ■<br />

New Digging Method<br />

Increases Productivity<br />

The introduction of an innovative digging method at<br />

Newlands Coal Mine in Central Queensland has assisted in<br />

minimising operating delays and increasing productivity.<br />

According to Project Manager<br />

Scott Winter, the new digging method<br />

has increased the rate that coal is<br />

uncovered through improving<br />

efficiency in removing overburden<br />

and reducing operational delays.<br />

"The Jensen and Curtis digging<br />

technique has significantly increased<br />

production levels by reducing the<br />

cycle phase through shorter swing<br />

angles and improved fill times,"<br />

Scott said.<br />

"Unlike the conventional method<br />

where the dragline cuts a key along<br />

the highwall and removes<br />

overburden, this method relies on a<br />

dozer to cut the highwall, enabling<br />

the dragline to operate more<br />

efficiently and remove larger<br />

quantities of overburden from the<br />

highwall at a faster rate."<br />

The effectiveness of the Jensen<br />

and Curtis method in improving<br />

productivity has been reinforced<br />

through Newlands’ consistent<br />

production performance, since the<br />

digging method was introduced in<br />

March this year.<br />

"The success of the initiative can<br />

be attributed both to our operators<br />

and planners who have embraced the<br />

new technique. The productivity<br />

gains achieved and maintained over<br />

the past six months are testimony to<br />

their commitment and continued<br />

focus on innovation," Scott said.<br />

"The Jensen and Curtis method<br />

has proved to be beneficial for both<br />

<strong>Thiess</strong> and our client, NCA Joint<br />

Venture, in assisting Newlands to<br />

maintain its competitiveness as a low<br />

cost steaming coal producer." ■<br />

15 THIESS

Process Engineering<br />

Joint Venture<br />

Meets Growing Demands of Coal Industry<br />

The strength of the <strong>Thiess</strong> Sedgman Joint Venture in providing a ‘one stop’ solution for coal<br />

mine processing design and development has secured an $82M Coal Handling and<br />

Preparation Plant (CHPP) contract in the Bowen Basin.<br />

With construction commencing in<br />

July this year, the Joint Venture is<br />

responsible for designing,<br />

constructing, commissioning and<br />

testing a new, state-of-the-art CHPP<br />

at Hail Creek Mine, near Nebo in<br />

central Queensland.<br />

Construction Manager Kevin Vallino<br />

said the Joint Venture was a key<br />

factor in the Hail Creek success,<br />

providing the client, Pacific Coal<br />

subsidiary Hail Creek Developments,<br />

with greater flexibility of service and<br />

guaranteed project delivery.<br />

"Sedgman already had a long-term<br />

role in the Hail Creek development,<br />

which put us in a solid position to<br />

offer a complete service for the<br />

design and construction of the new<br />

CHPP," Kevin said.<br />

"Sedgman are arguably the<br />

industry’s leading technology provider<br />

in relation to coal handling and<br />

processing. This, coupled with <strong>Thiess</strong>’<br />

financial strength and proven total<br />

project management capability,<br />

ensures competitive solutions that can<br />

be tailored to suit the requirements<br />

of our clients in terms of cost, time,<br />

quality and risk management.<br />

"In addition, the Joint Venture<br />

offers clients the security to choose<br />

the type and extent of service they<br />

may require through all stages of<br />

project development.<br />

"Having immediate access to a<br />

complete range of services and<br />

capability to deliver on all phases of a<br />

project will generally provide clients<br />

with increased efficiency, as well as<br />

reduced administration and costs,<br />

while also providing consistency in<br />

quality," he said.<br />

According to Kevin, the ‘merger’<br />

between <strong>Thiess</strong> and Sedgman was an<br />

obvious move due to the<br />

complementary skills and capabilities<br />

of the respective companies in<br />

relation to the development of coal<br />

projects and the provision of<br />

innovative mining, handling and<br />

processing solutions.<br />

"<strong>Thiess</strong> and Sedgman have worked<br />

closely together on numerous<br />

projects in Australia and Indonesia,<br />

making the Joint Venture a strategic<br />

investment for both companies to<br />

provide a strong basis for meeting<br />

the growing demands of the coal<br />

industry." ■<br />

▼ (Lt-Rt) Mark Pietzner, Mark Ringiao, Brett Woodley and Rouru Tuaine, undertaking preparation work for the construction of a new CHPP at<br />

Hail Creek Mine<br />

THIESS 16

▲ (Lt-Rt) Michelle Garland - Student Engineer, Ross Greenhalgh – QAL Chief Consultant/Projects and Dave Fraser - Superintendent, discuss<br />

safety planning at QAL Stationary Calciner Project<br />

Safety Driving Success<br />

at QAL<br />

Focused on collective responsibility for safe work practices, the QAL Calciners Project team in<br />

Gladstone has achieved more than 100,000 employee hours of work, incident free.<br />

<strong>Thiess</strong> QAL Project Manager Brad<br />

Fackender said a new approach to<br />

workplace health and safety had<br />

enhanced employee morale,<br />

increased productivity and created a<br />

better working environment.<br />

"All actions undertaken on site are<br />

driven by a shared personal and<br />

project value that safety is not<br />

negotiable. This has been vital in<br />

building a work culture focused on<br />

individual responsibility and<br />

commitment, as well as care and<br />

concern for others," Brad said.<br />

"Our strong safety performance to<br />

date, coupled with the achievement<br />

of key milestones since project<br />

inception in July last year,<br />

strengthens the notion that a safe<br />

and responsible work environment<br />

translates to improved productivity<br />

and ultimately, better outcomes for<br />

our client."<br />

According to Brad, the<br />

introduction of the JMJ Associates<br />

High Performance Safety Program has<br />

been instrumental in facilitating a<br />

behavioural and attitudinal change<br />

towards workplace safety.<br />

"All actions undertaken<br />

on site are driven by a<br />

shared personal and<br />

project value that safety<br />

is not negotiable.”<br />

"In our industry there tends to be<br />

a focus on maintaining workplace<br />

safety through the implementation<br />

of management systems. Although<br />

this is important, we have found<br />

that a balanced mix of behaviourfocused<br />

programs and management<br />

procedures is more effective," he<br />

said.<br />

"JMJ is an excellent program to<br />

educate and stimulate proactive<br />

thinking regarding work safety,<br />

while motivating people to act<br />

safely by highlighting potential<br />

personal outcomes of unsafe work<br />

practices. This, in turn, positively<br />

influences people’s attitudes<br />

towards risk-taking at work and<br />

home.<br />

"The program’s effectiveness is<br />

further strengthened by ensuring<br />

that all individuals from the<br />

workforce through to project and<br />

Business Unit management, the<br />

client and sub-contractor personnel<br />

are involved in the development<br />

and implementation of initiatives,"<br />

Brad said.<br />

"Our solid safety performance is an<br />

indication that a balanced approach<br />

achieves good results. Given the QAL<br />

project team’s current level of<br />

commitment to safety, I am positive<br />

we can achieve our commitment to<br />

being a workplace free from injuries<br />

and incidents." ■<br />

17 THIESS

Vic/SA/Tas/NA Community Partnerships<br />

Operations<br />

Creative Partnership<br />

Provides Arts Access to Regional<br />

Communities<br />

Despite a downward trend in corporate sponsorship of the arts, <strong>Thiess</strong> and the<br />

Queensland Arts Council (QAC) continue to forge a creative business partnership that<br />

contributes to the cultural spirit of regional Queensland communities.<br />

Research conducted in 2001 by<br />

the Australia Council for the Arts<br />

showed that, although corporate<br />

sponsorship grew in real terms, the<br />

share going to the arts had dropped<br />

by more than 250 per cent.<br />

QAC Marketing and Corporate<br />

Development Manager Lenny Vance<br />

said a committed focus on forming a<br />

true partnership with <strong>Thiess</strong> had<br />

been integral in establishing a<br />

successful corporate sponsorship.<br />

"In the past, many arts<br />

organisations subscribed to the<br />

sponsorship model of accepting<br />

financial support and then keeping<br />

the sponsor at arm’s length. This<br />

often led to a dissatisfied sponsor<br />

who was then reluctant to<br />

participate in a long-term<br />

relationship," he said.<br />

"A true partnership approach<br />

based on regular communication<br />

and knowledge sharing has allowed<br />

a solid relationship to develop<br />

between <strong>Thiess</strong> and QAC that is<br />

providing significant benefits for<br />

both parties."<br />

<strong>Thiess</strong> Executive General<br />

Manager Murray Fox said mutual<br />

respect and understanding of each<br />

other’s business requirements and<br />

activities had lead to good<br />

community outcomes for both<br />

<strong>Thiess</strong> and QAC.<br />

"<strong>Thiess</strong>’ involvement with QAC<br />

and other arts sponsorships such as<br />

the Queensland Biennial Festival of<br />

Music, results from our desire to<br />

give back something tangible to<br />

the communities within which we<br />

operate," Murray said.<br />

"We have numerous operations<br />

throughout Queensland and with<br />

▲ “Poised for success” - Brian Clarke and Ciaran McKenna from the RBH West Block Project<br />

with QAC Ballerina<br />

QAC’s focus on providing arts<br />

access statewide, the partnership<br />

is an obvious one and has enabled<br />

both parties to contribute to the<br />

cultural spirit of Queensland’s<br />

regional communities."<br />

With a network of 63 regional<br />

arts councils and some 9,000<br />

members, QAC is Queensland’s<br />

peak regional arts organisation.<br />

The <strong>Thiess</strong> QAC partnership was<br />

established in 2000, when <strong>Thiess</strong><br />

became a major sponsor of QAC’s<br />

Ontour Inschools program. ■<br />

THIESS 18

Hear and Say<br />

Celebrates 10 Years<br />

This year the Hear and Say Centre<br />

celebrates both its 10th anniversary and its<br />

long-term partnership with companies such<br />

as <strong>Thiess</strong>, which have raised millions of<br />

dollars to help give more than 300 deaf and<br />

hearing-impaired children the gift of sound.<br />

From modest beginnings with a<br />

total enrolment of six children, the<br />

Hear and Say Centre is today<br />

recognised as one of Australia’s<br />

leading auditory-verbal early<br />

intervention centres.<br />

Qld/NT/Pacific Building Manager<br />

Peter Sheehy said the Hear and Say<br />

Centre’s vision to enhance the lives of<br />

young children was strong motivation<br />

for <strong>Thiess</strong> employees to actively<br />

contribute to the goodwill provided<br />

through the Centre.<br />

"The Kings Row Project team’s<br />

initiative to engender team spirit and<br />

contribute to the local community<br />

saw the start of our partnership with<br />

the Centre in 1996, which aimed to<br />

raise funds to upgrade and expand its<br />

leased premises and purchase<br />

equipment including a Hearing<br />

Assessment Booth.<br />

"Teams across a number of our<br />

project sites and Milton Office have<br />

since embraced the partnership,<br />

actively undertaking annual events<br />

and on-site fundraising initiatives.<br />

Seven years later, it is great to see<br />

that we have raised an estimated one<br />

million dollars, which has helped to<br />

directly change the lives of more than<br />

111 children," Peter said.<br />

Funds raised by <strong>Thiess</strong> have<br />

contributed to the Centre’s success<br />

through:<br />

• Support of hearing impaired and<br />

deaf children<br />

• Renovation and refurbishment of<br />

the Centre’s audiological and<br />

teaching facility in Brisbane<br />

• Renovation and fit-out of the<br />

Centre’s teaching facility in Cairns<br />

• Support in establishing an<br />

Outreach Program for deaf and<br />

hearing impaired children in rural<br />

and regional areas of Queensland.<br />

<strong>Thiess</strong> also provided management<br />

supervision for the renovation of<br />

the Centre’s Brisbane premises,<br />

utilising subcontractor and supplier<br />

contacts that helped to achieve<br />

savings of approximately $200,000.<br />

Hear and Say Development Officer<br />

Jim Fagan said <strong>Thiess</strong>’ enthusiasm and<br />

drive from top level managers through<br />

to site workers had been integral to<br />

the Centre’s success.<br />

"<strong>Thiess</strong> came on board when we<br />

were struggling and gave us<br />

encouragement when we needed it.<br />

Their support over the years has<br />

allowed us to treble our numbers and<br />

create a public awareness, which we<br />

previously did not have.<br />

"The Centre thanks <strong>Thiess</strong> for its<br />

support over the years and looks<br />

forward to a continued successful<br />

working relationship in helping<br />

Queensland’s deaf children," Jim<br />

said.<br />

In July this year, <strong>Thiess</strong>, in<br />

conjunction with Suncorp, again<br />

hosted the Hear and Say Charity Ball,<br />

which attracted more than 240<br />

guests and raised a further $30,000<br />

for the Centre.<br />

The next major fundraiser will be<br />

the <strong>Thiess</strong>/Suncorp Annual Charity<br />

Golf Day to be held at the Royal<br />

Queensland Golf Club on 1<br />

November <strong>2002</strong>. ■<br />

Mining Murals<br />

With paint brushes in hand, more<br />

than 55 children from Andergrove<br />

State School recently visited the<br />

North Goonyella Coal Project to<br />

paint underground mining murals on<br />

the office walls. As part of <strong>Thiess</strong>’<br />

ongoing involvement with the Bowen<br />

Basin community, the Year Seven students<br />

spent the day designing and<br />

painting images that reflect underground<br />

mining operations. As part of<br />

the exercise, students also received<br />

a tour of the preparation plant, lamp<br />

room and site office. ■<br />

19 THIESS

Safety<br />

Working Safely<br />

With Cultural and Behavioural Change Programs<br />

Working towards an incident and injury free workplace, the Qld/NT/Pacific Business Unit<br />

has strengthened its approach to safety management through the implementation of a<br />

range of cultural and behavioural change programs.<br />

Facilitating this approach has<br />

been the introduction of<br />

specialised safety initiatives, such<br />

as the Remember Charlie video and<br />

training program, as well as the<br />

Job Fit system.<br />

<strong>Thiess</strong> Qld/NT/Pacific Safety<br />

Manager Ken Esson said it was<br />

programs such as these that had<br />

provided the catalyst needed to<br />

motivate people to proactively<br />

think about workplace health and<br />

safety.<br />

"The Remember Charlie program<br />

highlights the potential ‘human’<br />

impact of workplace incidents. In<br />

the video, Charlie shares with<br />

viewers a personal account of an<br />

horrific work incident, which he<br />

could have avoided through due<br />

care and responsible work<br />

practices," Ken said.<br />

"The reality of Charlie’s story<br />

has strongly influenced people’s<br />

emotions and proven to be<br />

effective in encouraging individuals<br />

to take responsibility for their own<br />

safety."<br />

Ken said the health and wellbeing<br />

of employees, as well as<br />

their ability to undertake required<br />

tasks, were equally important in<br />

reducing workplace incidences and<br />

ensuring a safer work environment.<br />

"We were recently involved in<br />

developing the Job Fit system,<br />

which provides a database of<br />

information about the physical<br />

demands of work-related tasks and<br />

the physical capabilities of<br />

workers. This information helps to<br />

match a work task with a suitable<br />

employee," he said.<br />

"Job Fit is also an excellent<br />

program to facilitate the<br />

rehabilitation of employees by<br />

▲ Darin Thomson - Mining Supervisor at the Foxleigh Coal Project<br />

helping to identify suitable tasks<br />

for the individual to undertake, as<br />

well as to assist in goal setting for<br />

the employee’s graduated return to<br />

work."<br />

The Job Fit system has been<br />

endorsed by WorkCover, nominated<br />

medical advisers and the Mines<br />

Inspectorate as being a system that<br />

would benefit the mining industry.<br />

"Safety is a priority focus and by<br />

ensuring the health and safety of<br />

our people, we are able to create a<br />

work environment that guarantees<br />

better results for our people, and<br />

ultimately our clients," Ken said. ■<br />

THIESS 20

Engineering Awards<br />

Building Projects<br />

Scoop Awards<br />

<strong>Thiess</strong>’ strong project management skills were recently recognised at the <strong>2002</strong> Engineering<br />

Excellence Awards, with the $51M Holy Spirit Northside (HSN) Hospital and $140M<br />

Lavarack Barracks Redevelopment Stage 2 projects scooping the top two awards.<br />

HSN was announced the overall<br />

winner in the project management<br />

category, with Lavarack Barracks<br />

picking up the highly commended<br />

award.<br />

The completion of HSN in June<br />

2001 saw the delivery of the first<br />

co-location project of its size in<br />

Queensland, with the new facility<br />

providing 162 private hospital beds,<br />

in addition to a range of acute, subacute<br />

and general health services.<br />

As Design and Construction<br />

Manager, <strong>Thiess</strong> was responsible for<br />

the complete design and<br />

construction of the hospital facility.<br />

Project Manager Brad Anderson<br />

said HSN was the second hospital<br />

project undertaken by <strong>Thiess</strong> for the<br />

Sisters of Charity and Holy Spirit<br />

Health Service.<br />

"Following our successful delivery<br />

of the St Vincent’s Hospital and<br />

Health Service at Robina, the Sisters<br />

of Charity Health Service and Sisters<br />

of the Holy Spirit formed a joint<br />

venture with <strong>Thiess</strong> to build HSN,"<br />

Brad said.<br />

"Our partnership involved a<br />

seamless approach to all aspects of<br />

hospital development – combining<br />