data sheet

data sheet

data sheet

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Desalination of Seawater<br />

Place of operation: Mainland Spain<br />

A decentralized water supply is currently<br />

and will in the future be one of the options<br />

in remote areas. When high-efficiency<br />

equipment is built together with the latest<br />

technology, low-power consumption can<br />

be obtained as proven with this 600 m 3 /d<br />

water maker with less than 2.2 kW/m 3<br />

power consumption. The pumps are vertically<br />

mounted onto the electric motors .<br />

Desalination of Seawater<br />

Place of operation: Canary Islands Spain<br />

The compact design of the APP pumps<br />

enables new thinking in the design of<br />

conventional water makers. Here the APP<br />

pumps are mounted on top of the membrane<br />

train providing new possibilities for OEMs<br />

to set new standards in system design. This<br />

300 m 3 /d ro-skid uses less than 2.3 kW/m 3<br />

permeate production.<br />

Danfoss A/S is one of the largest industrial<br />

companies in Denmark, with net sales of<br />

around DKK 15 billion.<br />

We employ more than 18,500 people, and<br />

6,500 of them work in Denmark in 15 different<br />

locations.<br />

Danfoss is an international group and a<br />

leader in research, development and production<br />

for a wide spectrum of different<br />

industries.<br />

Desalination of Seawater<br />

Place of operation: Oil Rigs North Sea<br />

Long service life combined with ATEX<br />

approved APP pumps mounted together<br />

with EX-Proof Zone II motors via stainless<br />

steel bell housings. The light weight and<br />

compact design of the APP pumps make it<br />

cost-effective to maintain and service the<br />

system, as the pumps can be transported<br />

between harbour and oil rig with helicopters<br />

and replaced without any lifting gear or<br />

special arrangements.<br />

We produce about 250,000 components<br />

each day at our 59 factories in 21 countries.<br />

The Group’s primary aim is to create quality<br />

of life for our stakeholders and to be a<br />

leader in refrigeration, heating and motion<br />

controls.<br />

Our work is based on our Core Values: Trust,<br />

Passion for Technology, Reliability, Global<br />

Perspective with Local Commitment and<br />

Environmental and Social Responsibility.<br />

Danfoss A/S<br />

DK-6430 Nordborg<br />

Denmark<br />

Phone: +45 7488 4325<br />

Telefax: +45 7445 3831<br />

E-mail: waterpumps@danfoss.com<br />

www.danfoss.com<br />

RO-Solutions<br />

.... setting new standards.<br />

DKCFN.PB.010.B1.02 / 521B0734<br />

Produced by Danfoss G1 Communication 04.09.MR.JN.na<br />

DANFOSS HIGH-PRESSURE<br />

WATER SOLUTIONS

The Natural Choice<br />

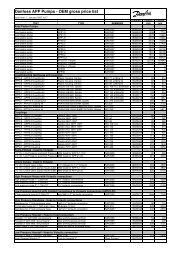

APP 0.6-1.0 specifications<br />

Metric measure US measure<br />

Flow APP 0.6 10 l/min 2.6 GPM<br />

APP 1.0 17 l/min 4.5 GPM<br />

Discharge pressure 10 to 80 bar 140-1150 psi<br />

Inlet pressure Flodded to 7 bar Flodded to 100 psi<br />

Pump rpm 1) 700-3000 rpm 700-3000 rpm<br />

Horse power APP 0.6 1.5 kW 2.0 HP<br />

At 80 bar APP 1.0 2.2 kW 3.2 HP<br />

Weight 4.4 kg 9.7 lbs<br />

Inlet port 1 ⁄ 2 ” BSP 1 ⁄ 2 ” BSP<br />

Outlet port 1 ⁄ 2 ” BSP 1 ⁄ 2 ” BSP<br />

APP 1.8-2.2 specification<br />

Metric measure US measure<br />

Flow APP 1.8 28 l/min 7.3 GPM<br />

APP 2.2 35 l/min 9.2 GPM<br />

Discharge pressure 10 to 80 bar 140-1150 psi<br />

Inlet pressure Flodded to 7 bar Flodded to 100 psi<br />

Pump rpm 1) 700-3000 rpm 700-3000 rpm<br />

Horse power APP 1.8 4.2 kW 5.7 HP<br />

At 80 bar APP 2.2 5.5 kW 7.0 HP<br />

Weight 7.7 kg 17 lbs<br />

Inlet port 3 ⁄ 4 ” BSP 3 ⁄ 4 ” BSP<br />

Outlet port 1 ⁄ 2 ” BSP 1 ⁄ 2 ” BSP<br />

APP 5.1-10.2 specifications:<br />

Metric measure US measure<br />

Flow APP 5.1 85 l/min 22.45 GPM<br />

APP 6.5 108 l/min 28.1 GPM<br />

APP 7.2 120 l/min 31.7 GPM<br />

APP 8.2 136 l/min 35.4 GPM<br />

APP 10.2 170 l/min 44.9 GPM<br />

Discharge pressure 10-80 bar 140-1150 psi<br />

Inlet pressure Flodded to 7 bar Flodded to 7 bar<br />

Pump rpm 700-1800 rpm 700-1800 rpm<br />

Horse power APP 5.1 13.3 kW 17.9 HP<br />

At 80 bar APP 6.5 15 kW 20 HP<br />

APP 7.2 18.6 kW 25 HP<br />

APP 8.2 19 kW 25.5 HP<br />

APP 10.2 26.7 kW 35.9 HP<br />

Weight 32 kg 70 lbs<br />

Inlet port 2) 1 1 ⁄ 2 ” VIC. 1 1 ⁄ 2 ” VIC.<br />

Outlet port 2) 1 1 ⁄ 2 ” VIC. 1 1 ⁄ 2 ” VIC.<br />

1) Higher speed available. Please contact the Sales Organisation.<br />

2) Other types of connections available on request.<br />

Common material specifications<br />

• All wetted parts : Superdublex, polymer, ceramic<br />

• All external parts: Superdublex, 316 SS, plastic<br />

The Axial Piston Pump (APP) is a positive displacement pump design<br />

originating from oil hydraulics and subsequently redesigned by<br />

Danfoss during the last 15 years, to pump tap and seawater. Tens of<br />

thousands of pumps are in operation worldwide proving the<br />

pumps to be among the most cost-effective and reliable pumps for<br />

membrane applications, both as main high-pressure pumps but<br />

also for recovering energy as reversing pumps (motors) in the reject<br />

line. The pumps are made in exotic materials incorporating Duplex<br />

and Superduplex materials as standard.<br />

Danfoss A/S RO-Solutions offers not only High-Pressure Pumps but<br />

also Frequency Inverters, Soft Starters, Valves, Pressure Transmitters<br />

and all kinds of “around-the-pump” accessories, since one of our<br />

goals is to facilitate supply chain optimisation for our customers.<br />

If your business is among the below mentioned applications:<br />

• Seawater Reverse Osmosis<br />

• Brackish Water Reverse Osmosis<br />

• Nanofiltration, ultrafiltration, microfiltration<br />

• Or even pump and measure low-viscosity corrosive fluids<br />

prefiltered down to 10 micron absolute<br />

... have a look on our homepage www.nessie.danfoss.com/rosolution<br />

With APP pumps from Danfoss you get the following<br />

benefits<br />

Low energy consumption<br />

Total efficiencies up to 95 percent – among the most efficient in the<br />

market.<br />

Long service life<br />

Danfoss guarantees service free operation for more than 8,000<br />

hours thanks to two design features:<br />

• No oil lubrication: the medium itself lubricates the pump.<br />

• No need for service on a regular basis:<br />

the mechanical shaft is the only seal in the pump.<br />

Corrosion resistance<br />

All wetted parts of the pump are designed in duplex, super duplex<br />

stainless steel and polymer, ensuring resistance to corrosive and<br />

low viscosity fluids, e.g. seawater and brackish water.<br />

High-pressure operation<br />

Continuous operation at a discharge pressure between 10 and 80<br />

bar (145-1160 psi). Higher discharge pressures are available on<br />

request.<br />

Wide flow range<br />

One pump size covers the same flow range as several centrifugal<br />

pumps, because the flow is a linear function of the speed (rpm). The<br />

pumps run at speeds between 700 and 3,000 rpm.<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

<br />

Flow (l/min)<br />

160<br />

140<br />

120<br />

100<br />

80<br />

60<br />

40<br />

20<br />

0<br />

700<br />

900<br />

Typical flow curves at 80 bar (1160 psi)<br />

2500<br />

2300<br />

2100<br />

1900<br />

1700<br />

1500<br />

1300<br />

1100<br />

Pump rpm<br />

APP 10.2<br />

APP 8.2<br />

APP 7.2<br />

APP 6.5<br />

APP 5.1<br />

APP 2.2<br />

APP 1.8<br />

APP 1.0<br />

APP 0.6<br />

2700<br />

3000<br />

2900<br />

40<br />

35<br />

30<br />

25<br />

20<br />

15<br />

10<br />

5<br />

0<br />

Flow (gal/min)<br />

Low pulsation<br />

A design featuring up to nine pistons reduces pressure pulsations<br />

in the discharge line down to 1.5 percent, rendering pulsation<br />

dampers superflous addition, and reduceing installing cost.<br />

Compact design<br />

The most compact pump on the market, giving system builders a<br />

free hand to design more compact systems. The pump may also be<br />

directly mounted onto an electrical motor via a bell housing with a<br />

flexible coupling.

DATA SHEET<br />

Water Pumps<br />

APP0.6 - 2.5<br />

1. General information<br />

APP0.6, APP1.0, APP1.5, APP1.8, APP2.2 and APP2.5 pumps are designed to supply low viscosity and corrosive fluids under high<br />

pressure, eg. in seawater reverse osmosis filtration applications and for high pressure salt water pumping.<br />

The pumps are based on the axial piston principle enabling a very light and compact design, and they are designed so that<br />

lubrication of the moving parts in the pumps is provided by the fluid itself. No oil lubrication is thus required.<br />

All parts included in the pumps are designed to provide long service life, i.e. long service life with a constantly high efficiency and<br />

minimum of service required.<br />

The pumps are fixed displacement pumps in which the flow is proportional to the number of revolutions of the input shaft and the<br />

pump displacement, regardless of any counter-pressure.<br />

1 2 11 3<br />

6 8<br />

7<br />

1: Shaft sealing<br />

2: Mounting flange<br />

3: Bleeding plugs<br />

4: Retaining ring<br />

5: Piston/shoe<br />

6: Valve plate<br />

7: Swash plate<br />

8: Cylinder barrel<br />

9: Spring<br />

10: Port plate<br />

11: Connecting flange<br />

12: Housing with bearing<br />

10 9<br />

5<br />

12<br />

4<br />

2. Benefits<br />

• One of the smallest and lightest pumps on the market.<br />

• Can be powered by a combustion engine provided that a special coupling is used.<br />

• Generates insignificant pulsations in the pressure line.<br />

• No preventive maintenance required (no periodic service like e.g. change of lubricant and wearing parts).<br />

• Long service life. Danfoss guarantees 8000 hours maintenance-free operation.<br />

• All parts of the pump are made of non corrosive materials eg. Duplex (SAF 2205/EN1.4462) and<br />

Super-duplex (SAF 2507/EN1.4410) stainless steel and carbon reinforced PEEK.<br />

• High efficiency.<br />

521B0850 DKCFN.PD.010.FA2.02 11-2006

3. Technical <strong>data</strong><br />

Code number 180B3001 180B3002 180B3026 180B3003 180B3004 180B3000<br />

APP pumps APP0.6 APP1.0 APP1.5 APP1.8 APP2.2 APP2.5<br />

Geometric displacement cm 3 /rpm (in 3 /rpm) 4 (0.24) 6.3 (0.38) 9.3 (0.56) 10 (0.61) 12.5 (0.76) 15.3 (0.93)<br />

Flow (3000 rpm) m 3 /h (gpm) 0.6 (2.6) 1.0 (4.4) 1.5 (6.6) 1.7 (7.5) 2.1 (9.2) 2.6 (11.4)<br />

Min. pressure 1) bar (psi) 20 290 20 290 20 290 20 290 20 290 20 290<br />

Max. pressure, cont. 2) bar (psi) 80 (1160) 80 (1160) 80 (1160) 80 (1160) 80 (1160) 80 (1160)<br />

Max. pressure, intermittent 3) bar (psi) 100 (1450) 100 (1450) 100 (1450) 100 (1450) 100 (1450) 100 (1450)<br />

Max. speed cont. 4) rpm 3450 3450 3450 3450 3450 5) 3000<br />

Min. speed cont. rpm 700 700 700 700 700 700<br />

Power requirement at<br />

80 bar and 3000 rpm:<br />

kW (hp) 1.9 (2.5) 2.9 (3.9) 4.5 (6) 4.8 (6.3) 6.0 (7.9) 7.2 (9.6)<br />

Weight kg (lb) 5.2 (9.7) 5.2 (9.7) 8,6 (17) 8.6 (17.0) 8.6 (17.0) 8.6 (17)<br />

1) For lower pressure, please contact Danfoss RO Sales Organization. 4) For speeds above 3000 rpm the pump must be<br />

2) For higher pressure, please contact Danfoss RO Sales Organzation. boosted at a pressure of 2-5 bar (29.0 - 72.5 psi).<br />

3) Intermittent pressure is acceptable for less than 10 seconds per minute. 5) For speeds above 3000 rpm, inspect the pump<br />

after every 4000 hours of operation.<br />

4. Flow at different rpm<br />

Using the diagram shown below, it is easy to select the pump which fits the application best if the flow required and the rotation<br />

speed (rpm) of the pump are known.<br />

3<br />

2,5<br />

APP2.5<br />

APP2.2<br />

m 3 /h<br />

2<br />

1,5<br />

1<br />

0,5<br />

APP1.8<br />

APP1.5<br />

APP1.0<br />

APP0.6<br />

0<br />

500 1000 1500 2000 2500 3000 3500<br />

Furthermore, this diagram shows that the flow can be changed by changing the rotation speed of the pump. The flow/rpm ratio is<br />

constant, and the “desired “ flow can be obtained by changing the rotation speed to a corresponding value. Thus, the required rpm<br />

can be determined as:<br />

Desired flow × Rated rpm<br />

Required rpm =<br />

Rated flow<br />

5. Power requirements<br />

Pump model Flow Pressure rpm Calc. factor<br />

60 bar 70 bar 80 bar<br />

l/min m 3 /h gpm 870 psi 1015 psi 1160 psi<br />

rp m<br />

APP0.6 10.2 0.61 2.69 1.38 kW 1.61 kW 1.84 kW 2840 475.8<br />

APP0.6 12.3 0.74 3.25 1.66 kW 1.94 kW 2.21 kW 3400 475.8<br />

APP1.0 16.53 0.99 4.37 2.14 kW 2.49 kW 2.85 kW 2840 474.6<br />

APP1.0 19.83 1.19 5.24 2.57 kW 2.99 kW 3.42 kW 3400 474.6<br />

APP1.5 25.11 1.51 6.63 3.21 kW 3.75 kW 4.29 kW 2890 468.6<br />

APP1.5 30.17 1.81 7.97 3.86 kW 4.51 kW 5.15 kW 3470 468.6<br />

APP1.8 26.78 1.61 7.07 3.43 kW 4.00 kW 4.57 kW 2890 463.2<br />

APP1.8 32.18 1.93 8.50 4.12 kW 4.81 kW 5.49 kW 3470 463.2<br />

APP2.2 33.48 2.01 8.84 4.29 kW 5.00 kW 5.71 kW 2900 468.6<br />

APP2.2 40.22 2.41 10.63 5.15 kW 6.01 kW 6.87 kW 3480 468.6<br />

APP2.5 41.94 2.52 11.08 5.07 kW 5.92 kW 6.77 kW 2900 484.8<br />

The power requirements can be determined using one of the following guiding equations:<br />

l/min × bar 16.7 × m 3 /h × bar 0.26 × gpm × psi<br />

Required power = [kW] or [kW] or [kW]<br />

Calc. factor Calc. factor Calc. factor<br />

1 hp = 0.75 kW<br />

1 kW = 1.34 hp<br />

1 gpm = 3.79 l/min<br />

1 l/min = 0.26 gpm<br />

1 m 3 /h = 4.40 gpm<br />

1 gpm = 0.23 m 3 /h<br />

DKCFN.PD.010.FA2.02 521B0850

6. Inlet pressure<br />

Water supply to the pump is either made from a tank placed above the pump or directly from a feed pump. The pressure at the<br />

pump inlet (I) must be in the range: 0.5 - 5 bar (7.3 - 72.5 psi).<br />

7. Temperature and corrosion<br />

7.1 Operation:<br />

• Fluid temperature: +3°C to +50°C (+37.4°F to 122°F) - dependent on the NaCl concentration<br />

• Ambient temperature: +3°C to +50°C (+37.4°F to 122°F)<br />

The chart below illustrates the corrosive resistance of different types of stainless steel related to NaCl concentration and<br />

temperature.<br />

All critical parts of the APP water pump is made of SAF 2507.<br />

If the water pump is operated at high salinity, always flush the water pump with fresh water at operation stop in order to minimise<br />

the risk of crevice corrosion.<br />

904L / SAF 2205<br />

NaCl vs. temperature<br />

7.2 Storage:<br />

• Storage temperature: -40°C to +70°C (+37.4°F to 122°F) – provided that the pump is drained of fluid and stored<br />

”plugged”.<br />

Antefreeze protection is required at temperatures below 2°C. Danfoss recommends using Dowcal N from Dow Chemical<br />

Company or Chillsafe mono propylene glycol from Arco Chemical Company.<br />

8. Noise level<br />

The chart indicates the noise level in dB(A) measured at a distance of 1 m from the pump in a reverberation room.<br />

Type<br />

60 bar (870 psi)<br />

1500 rpm<br />

60 bar (870 psi)<br />

3000 rpm<br />

80 bar (1160 psi)<br />

1500 rpm<br />

80 bar (1160 psi)<br />

3000 rpm<br />

APP0.6 70 73 74 77<br />

APP1.0 73 75 74 77<br />

APP1.5 75 76 73 77<br />

APP1.8 75 76 73 77<br />

APP2.2 75 76 73 77<br />

APP2.5 76 77 74 78<br />

Generally, noise will be reduced if speed is reduced and vice versa. Use flexible hoses in order to minimize vibrations and noise.<br />

Since the pump is typically mounted on a bell housing or frame, the noise level can only be determined for the complete unit<br />

(system).<br />

It is therefore very important that the pump is mounted correctly on a frame with dampers to minimize vibrations and noise.<br />

The noise level is influenced by:<br />

• The speed of the pump, high rpm create more noise than low rpm<br />

• Rigid mounting of the pump generates more noise than flexible mounting<br />

• Pipe mounting direct to the pump increases the noise level compared to a flexible hose<br />

9. Filtration<br />

As water has very low viscosity, the APP pumps have been designed with very narrow clearance in order to control internal leakage<br />

rates and improve component performance. Therefore it is important that the inlet water is filtered properly to minimize the wear of<br />

the pump.<br />

The main filter must have a filtration efficiency of 99.98% at 10 µm. We recommend that you use precision depth filter cartridges<br />

rated 10µm abs. ß10>5000 (equivalent to a filtration efficiency of 99.98%). Bag filters and string wound filter cartridges typically<br />

have only 90% filtration efficiency. This means that for each 100,000 particles reaching the filter, 10,000 particles pass through it<br />

compared to only 20 particles in a filter with an efficiency of 99.98%.<br />

For more information on the importance of proper filtration, please consult our publication “Filtration” (code number 521B0861),<br />

which also will provide you with an explanation of filtration definitions and a guidance on how to select the right filter.<br />

521B0850 DKCFN.PD.010.FA2.02 3

10. Dimensions<br />

10.1 Pump<br />

Description APP0.6 and APP1.0 APP1.5, APP1.8, APP2.2 and APP2.5<br />

A Port position, mm (in) 15.9 (0.63) 18.8 (0.74)<br />

B Port position, mm (in) 15.9 (0.63) 21.0 (0.83)<br />

C mm (in) Ø 88 (3.5) Ø 105 (4.1)<br />

D mm (in) 131 (5.2) 166 (6.5)<br />

E<br />

Parallel key, DIN 6885, mm (in)<br />

5 × 5 × 20<br />

(0.20 × 0.20 × 0.78)<br />

5 × 5 × 20<br />

(0.20 × 0.20 × 0.78)<br />

F Bleeding M6, Hexagon AF = 5 mm M6, Hexagon AF = 5 mm<br />

I Inlet connection BSP G½”; 15 (0.59) deep BSP G¾”; 15 (0.59) deep<br />

O Outlet connection BSP G½”; 15 (0.59) deep BSP G½”; 17 (0.67) deep<br />

Pump mounting flange SAE A 2 SAE A 2<br />

10.2 Complete unit<br />

Pump A (mm) B (mm) C (mm) D (mm) E (mm) F (mm) G (mm) H (mm) IEC Electric motor<br />

APP0.6 200 245 90 140 100 265 100 131 1.5 kW, FPA 90S-2<br />

APP1.0 200 245 90 140 125 290 100 131 2.2 kW, FPA 90L-2<br />

APP1.5 250 280 100 160 140 325 120 166 3.0 kW, FPA 100L-2<br />

APP1.8 250 302 112 190 140 340 120 166 4.0 kW, FPA 112M-2<br />

APP2.2 300 342 132 216 140 390 144 166 5.5 kW, FPA 132S1-2<br />

APP2.5 300 342 132 216 178 430 144 166 7.5 kW, FPA 132S2-2<br />

DKCFN.PD.010.FA2.02 521B0850

11. Installation<br />

11.1 Mounting<br />

The figure below illustrates how to mount the pump and connect it to electric motor/combustion engine.<br />

A: Flexible coupling<br />

B: Bell housing<br />

C: Motor shaft<br />

If alternative mounting is required, please contact Danfoss Sales Organization for further information.<br />

To ensure easy mounting of the flexible coupling without using tools, the tolerances must be dimensioned accordingly.<br />

Note: Any axial and/or radial loads on the shaft must be avoided, see “User guide” (521B0888).<br />

Min. 3 mm<br />

A<br />

B<br />

C<br />

The pump should be connected to the rest of the plant with a flexible hoses.<br />

11.2 Open-ended systems with water supply from tank<br />

In order to eliminate the risk of cavitation, a positive inlet pressure should always be maintained by observing the following<br />

guidelines:<br />

1. Place the tank (1) above pump inlet (water level in tank should always be above the pump).<br />

2. Place a filter (2) in the water supply line in front of the tank.<br />

3. Dimension the inlet line (3) with minimum pressure drop (large internal diameter, minimum length of pipe, avoid bends and<br />

fittings with small internal diameter).<br />

11.3 Open-ended system with direct water supply<br />

In order to eliminate the risk of cavitation, a positive inlet pressure is always to be maintained at min. 0.5 bar (7.3 psi) and max. 5 bar<br />

(72.5 psi).<br />

1. Place the filter (1) in the water supply line in front of the pump.<br />

2. Place a monitoring pressure switch (2) set at min. 1 bar (14.5 psi) between filter and pump inlet. The monitoring switch must<br />

stop the pump at pressures lower than 1 bar. (14.5 psi) At speeds above 3000 rpm - use 2 bar (29 psi) as set point.<br />

521B0850 DKCFN.PD.010.FA2.02 5

11.4 RO system with APP pump<br />

1. For easy system bleeding and flushing, apply a bypass non-return valve (1) in parallel with the APP pump.<br />

2. Place an inlet filter (2) in front of the APP pump (3). Please consult section 9, “Filtration” for guidance on how to select the<br />

right filter. Throughly clean pipes and flush system prior to start-up.<br />

3. Place a monitoring pressure switch (6) set at min. 1 bar between filter and pump inlet. The monitoring switch must stop the<br />

pump at pressures lower than 1 bar (14.5 psi). At 3000 rpm - use 2 bar (29 psi) as set point.<br />

4. Dimension the inlet line to obtain minimum pressure loss (large flow, minimum pipe length, minimum number of bends/<br />

connections, and fittings with small pressure losses).<br />

5. In order to eliminate the risk of damage and cavitation, a positive pressure at the inlet (4) is always to be maintained at min.<br />

0.5 bar (7.3 psi) and max. 5 bar (72.5 psi). At speeds above 3000 rpm the pressure at the inlet of the water pump must be min.<br />

2 bar (29 psi).<br />

6. Use flexible hoses (5) to minimize vibrations and noise.<br />

7. Install a safety valve (7) in order to avoid system damage as the Danfoss APP pump creates pressure and flow immediately<br />

after start-up, regardless of any counter-pressure.<br />

Feed<br />

2<br />

5 4<br />

1<br />

3<br />

APP<br />

5<br />

7<br />

Permeate<br />

6<br />

M<br />

Brine<br />

12. Service<br />

Provided that the pump has been running according to the Danfoss specifications on pre-filtration, pressure, and rotation speed,<br />

Danfoss guarantees minimum 8000 hours operation, however max. 18 months from date of sale.<br />

To prevent a total and disastrous breakdown, Danfoss recommends a pump inspection after max. 8000 hours – at which any worn<br />

parts must be replaced.<br />

Note: It is always recommended to replace pistons and shaft sealing if another service-free period is to be obtained.<br />

If the pistons are not replaced, more frequent inspection is recommended.<br />

The APP pump is made of duplex/super duplex materials with fine corrosion properties. However, it is always recommended to<br />

flush the pump when the system is shut down.<br />

The shaft sealing in the APP pump is made of AISI 316. At high TDS and high water temperature, the service life of the shaft sealing<br />

will be reduced. For these applications it is recommended to replace the shaft sealing after approx. 4000 hours operation.<br />

12.1 Periodic maintenance<br />

Water acts as lubricant in the APP. Thus there is no oil in the pump.<br />

By operation below the curve for SAF 2507 in the figure in section 7.1, no parts are expected to be replaced within the first 8000<br />

hours of operation.<br />

12.2 Repair<br />

In case of irregular function of the APP, please contact the Danfoss RO Solutions Sales Organisation.<br />

DKCFN.PD.010.FA2.02 521B0850

DATA SHEET<br />

Water Pumps<br />

APP5.1 - 10.2<br />

1. General information<br />

APP5.1, APP6.5, APP7.2, APP8.2 and APP10.2 pumps are designed to supply low viscosity and corrosive fluids under high pressure,<br />

eg. in seawater reverse osmosis filtration applications and for high pressure salt water pumping.<br />

The APP pumps are based on the axial piston principle enabling a very light and compact design, and they are designed so that<br />

lubrication of the moving parts in the pumps is provided by the fluid itself. No oil lubrication is thus required.<br />

All parts included in the APP pumps are designed to provide long service life, i.e. long service life with a constantly high efficiency<br />

and minimum of service required.<br />

The pumps are fixed displacement pumps in which the flow is proportional to the number of revolutions of the input shaft and the<br />

pump displacement, regardless of any counter-pressure.<br />

1 2 3 4 5<br />

6<br />

1: Shaft sealing<br />

2: Mounting flange<br />

3: Bleeding plugs<br />

4: Retaining ring<br />

5: Piston/shoe<br />

6: Valve plate<br />

7: Swash plate<br />

8: Cylinder barrel<br />

9: Spring<br />

10: Port plate<br />

11: Connecting flange<br />

12: Housing with bearing<br />

7<br />

8 9 10<br />

12<br />

11<br />

2. Benefits<br />

• One of the smallest and lightest pumps on the market.<br />

• Can be powered by a combustion engine provided that a special coupling is used.<br />

• Generates insignificant pulsations in the pressure line.<br />

• No preventive maintenance required (no periodic service like e.g. change of lubricant and wearing parts).<br />

• Long service life. Danfoss guarantees 8000 hours maintenance-free operation.<br />

• All parts of the pump are made of non-corrosive materials eg. duplex (SAF 2205/EN1.4462) and<br />

superduplex (SAF 2507/EN1.4410) stainless steel and carbon reinforced PEEK.<br />

• High efficiency.<br />

521B0851 DKCFN.PD.010.FB1.02 11-2006

3. Technical <strong>data</strong><br />

Code number 180B3005 180B3006 180B3007 180B3008 180B3010<br />

APP pumps APP5.1 APP6.5 APP7.2 APP8.2 APP10.2<br />

Geometric displacement cm 3 /rpm (in 3 /rpm) 50 (3.05) 63 (3.84) 70 (4.27) 80 (4.88) 100 (6.10)<br />

Flow (1800 rpm) m 3 /h (gpm) 5.1 (22.5) 6.5 (28.6) 7.2 (31.7) 8.2 (36.1) 10.2 (44.9)<br />

Min. pressure 1) bar (psi) 20 (290) 20 (290) 20 (290) 20 (290) 20 (290)<br />

Max. pressure, cont. 2) bar (psi) 80 (1160) 80 (1160) 80 (1160) 80 (1160) 80 (1160)<br />

Max. pressure, intermittent 3) bar (psi) 100 (1450) 100 (1450) 100 (1450) 100 (1450) 100 (1450)<br />

Max. speed cont. 4) rpm 1800 1800 1800 1800 1800<br />

Min. speed cont. rpm 700 700 700 700 700<br />

Power requirement at<br />

80 bar and 1800 rpm:<br />

kW (hp) 13.7 (18.4) 17.3 (23.2) 19.2 (25.7) 21.7 (29.1) 27.4 (36.7)<br />

Weight kg (lb) 30 (66) 30 (66) 30 (66) 30 (66) 30 (66)<br />

1) For lower pressure, please contact Danfoss RO Solutions Sales Organization.<br />

2) For higher pressure, please contact Danfoss RO Solutions Sales Organzation.<br />

3) Intermittent pressure is acceptable for less than 10 seconds per minute.<br />

4) For speeds above 1500 rpm the APP pump must be boosted at a pressure of 2-5 bar (29-72.5 psi).<br />

4. Flow at different rpm<br />

Using the diagram shown below, it is easy to select the APP pump which fits the application best if the flow required and the<br />

rotation speed (rpm) of the pump are known.<br />

m 3 /h<br />

12,00<br />

10,00<br />

8,00<br />

6,00<br />

4,00<br />

APP10.2<br />

APP8.2<br />

APP7.2<br />

APP6.5<br />

APP5.1<br />

2,00<br />

0,00<br />

600 800 1000 1200 1400 1600 1800 2000<br />

rp m<br />

Furthermore, this diagram shows that the flow can be changed by changing the rotation speed of the pump. The flow/rpm ratio is<br />

constant, and the “desired “ flow can be obtained by changing the rotation speed to a corresponding value. Thus, the required rpm<br />

can be determined as:<br />

Desired flow × Rated rpm<br />

Required rpm =<br />

Rated flow<br />

5. Power requirements<br />

Pump model Flow Pressure rpm Calc. factor<br />

60 bar 70 bar 80 bar<br />

l/min m 3 /h gpm 870 psi 1015 psi 1160 psi<br />

APP5.1 66 4.0 17.4 8.3 kW 9.7 kW 11.1 kW 1460 475.2<br />

APP5.1 79 4.7 20.9 10.0 kW 11.7 kW 14.3 kW 1752 475.2<br />

APP6.5 83 5.0 22.0 10.5 kW 12.3 kW 14.0 kW 1460 475.2<br />

APP6.5 100 6.0 26.4 12.6 kW 14.7 kW 16.8 kW 1752 475.2<br />

APP7.2 93 5.6 24.6 11.6 kW 13.5 kW 15.5 kW 1470 480.6<br />

APP7.2 112 6.7 29.5 13.9 kW 16.3 kW 18.6 kW 1764 480.6<br />

APP8.2 106 6.4 28.1 12.7 kW 14.8 kW 16.9 kW 1470 502.2<br />

APP8.2 128 7.7 33.7 15.3 kW 17.8 kW 20.3 kW 1764 502.2<br />

APP10.2 133 8.0 35.1 16.0 kW 18.7 kW 21.4 kW 1470 496.2<br />

APP10.2 159 9.6 42.1 19.3 kW 22.5 kW 25.7 kW 1764 496.2<br />

The power requirements can be determined using one of the following guiding equations:<br />

l/min × bar 16.7 × m 3 /h × bar 0.26 × gpm × psi<br />

Required power = [kW] or [kW] or [kW]<br />

Calc. factor Calc. factor Calc. factor<br />

1 hp = 0.75 kW<br />

1 kW = 1.34 hp<br />

1 gpm = 3.79 l/min<br />

1 l/min = 0.26 gpm<br />

1 m 3 /h = 4.40 gpm<br />

1 gpm = 0.23 m 3 /h<br />

DKCFN.PD.010.FB1.02 521B0851

6. Inlet pressure<br />

Water supply to the APP pump is either made from a tank placed above the pump or directly from a feed pump. The pressure at the<br />

pump inlet (I) must be in the range: 0.5 - 5 bar (7.3 - 72.5 psi).<br />

7. Temperature and corrosion<br />

7.1 Operation:<br />

• Fluid temperature: +3°C to +50°C (+37.4°F to 122°F) - dependent on the NaCl concentration<br />

• Ambient temperature: +3°C to +50°C (+37.4°F to 122°F)<br />

The chart below illustrates the corrosive resistance of different types of stainless steel related to NaCl concentration and<br />

temperature.<br />

All critical parts of the APP pump are made of SAF 2507.<br />

If the APP pump is operated at high salinity, always flush the pump with fresh water at operation stop in order to minimise the risk<br />

of crevice corrosion.<br />

904L / SAF 2205<br />

NaCl vs. temperature<br />

7.2 Storage:<br />

• Storage temperature: -40°C to +70°C (+37.4°F to 122°F) – provided that the APP pump is drained of fluid and stored<br />

”plugged”.<br />

Antefreeze protection is required at temperatures below 2°C. Danfoss recommends using Dowcal N from Dow Chemical<br />

Company or Chillsafe mono propylene glycol from Arco Chemical Company.<br />

8. Noise level<br />

The chart indicates the noise level in dB(A) measured at a distance of 1 m from the APP pump in a reverberation room.<br />

Type<br />

60 bar (580 psi)<br />

1500 rpm<br />

60 bar (580 psi)<br />

1800 rpm<br />

80 bar (2000 psi)<br />

1500 rpm<br />

80 bar (2000 psi)<br />

1800 rpm<br />

APP5.1 74 79 73 78<br />

APP6.5 74 79 73 78<br />

APP7.2 74 79 73 78<br />

APP8.2 74 79 73 78<br />

APP10.2 74 79 73 78<br />

Generally, noise will be reduced if speed is reduced and vice versa. Use flexible hoses in order to minimize vibrations and noise.<br />

Since the APP pump is typically mounted on a bell housing or frame, the noise level can only be determined for the complete unit<br />

(system).<br />

It is therefore very important that the APP pump is mounted correctly on a frame with dampers to minimize vibrations and noise.<br />

The noise level is influenced by:<br />

• The speed of the pump, high rpm create more noise than low rpm<br />

• Rigid mounting of the pump generates more noise than flexible mounting<br />

• Pipe mounting direct to the pump increases the noise level compared to a flexible hose<br />

9. Filtration<br />

As water has very low viscosity, the APP pumps have been designed with very narrow clearance in order to control internal leakage<br />

rates and improve component performance. Therefore it is important that the inlet water is filtered properly to minimize the wear of<br />

the pump.<br />

The main filter must have a filtration efficiency of 99.98% at 10 µm. We recommend that you use precision depth filter cartridges<br />

rated 10µm abs. ß10>5000 (equivalent to a filtration efficiency of 99.98%). Bag filters and string wound filter cartridges typically<br />

have only 90% filtration efficiency. This means that for each 100,000 particles reaching the filter, 10,000 particles pass through it<br />

compared to only 20 particles in a filter with an efficiency of 99.98%.<br />

For more information on the importance of proper filtration, please consult our publication “Filtration” (code number 521B0861),<br />

which also will provide you with an explanation of filtration definitions and a guidance on how to select the right filter.<br />

521B0851 DKCFN.PD.010.FB1.02 3

10. Dimensions<br />

10.1 APP pump<br />

Description<br />

APP5.1 and APP10.2<br />

C Bleeding M6, Hexagon AF = 5 mm<br />

D<br />

Parallel key, DIN 6885, mm (in)<br />

12 × 8 × 70<br />

(0.44 × 0.31 × 2.76)<br />

I Inlet connection M42 x 1½ mm; 13 mm (0.51 in) deep<br />

O Outlet connection M42 x 1½ mm; 13 mm (0.51 in) deep<br />

Pump mounting flange<br />

125 A2<br />

10.2 Complete unit<br />

Pump A (mm) B (mm) C (mm) D (mm) E (mm) F (mm) IEC Electric motor<br />

APP5.1 350 415 160 254 210 505 11 kW, FPC 160 M-4<br />

APP6.5 350 415 160 254 254 560 15 kW, FPC 160 L-4<br />

APP7.2 350 415 160 254 254 560 15 kW, FPC 160 L-4<br />

APP8.2 350 460 180 279 241 590 18.5 kW, FPC 180 M-4<br />

APP10.2 350 460 180 279 279 630 22 kW, FPC 180 L-4<br />

APP10.2 400 505 200 318 305 660 30 kW, FPC 200 L-4<br />

For inlet and outlet connections <strong>data</strong>, see “Accessories catalogue” (521B0903).<br />

DKCFN.PD.010.FB1.02 521B0851

11. Installation<br />

11.1 Mounting<br />

The figure below illustrates how to mount the APP pump and connect it to an electric motor/combustion engine.<br />

A: Flexible coupling<br />

B: Bell housing<br />

C: Motor shaft<br />

If alternative mounting is required, please contact Danfoss Sales Organization for further information.<br />

To ensure easy mounting of the flexible coupling without using tools, the tolerances must be dimensioned accordingly.<br />

Note: Any axial and/or radial loads on the shaft must be avoided, see “User guide” (521B0888).<br />

Min. 3 mm<br />

A<br />

B<br />

C<br />

The APP pump should be connected to the rest of the plant with a flexible hoses.<br />

11.2 Open-ended systems with water supply from tank<br />

In order to eliminate the risk of cavitation, a positive inlet pressure should always be maintained by observing the following<br />

guidelines:<br />

1. Place the tank (1) above the APP pump inlet (water level in tank should always be above the pump).<br />

2. Place a filter (2) in the water supply line in front of the tank.<br />

3. Dimension the inlet line (3) with minimum pressure drop (large internal diameter, minimum length of pipe, avoid bends and<br />

fittings with small internal diameter).<br />

11.3 Open-ended system with direct water supply<br />

In order to eliminate the risk of cavitation, a positive inlet pressure is always to be maintained at min. 0.5 bar (7.3 psi) and max. 5 bar<br />

(72.5 psi).<br />

1. Place the filter (1) in the water supply line in front of the APP pump.<br />

2. Place a monitoring pressure switch (2) set at min. 1 bar (14.5 psi) between filter and pump inlet. The monitoring switch must<br />

stop the pump at pressures lower than 1 bar (14.5 psi) At speeds above 1500 rpm - use 2 bar (29 psi) as set point.<br />

521B0851 DKCFN.PD.010.FB1.02 5

11.4 RO system with APP pump<br />

1. For easy system bleeding and flushing, apply a bypass non-return valve (1) in parallel with the APP pump.<br />

2. Place an inlet filter (2) in front of the APP pump (3). Please consult section 9, “Filtration” for guidance on how to select the<br />

right filter. Throughly clean pipes and flush system prior to start-up.<br />

3. Place a monitoring pressure switch (6) set at min. 1 bar between filter and pump inlet. The monitoring switch must stop the<br />

pump at pressures lower than 1 bar (14.5 psi). Above 1500 rpm - use 2 bar (29 psi) as set point.<br />

4. Dimension the inlet line to obtain minimum pressure loss (large flow, minimum pipe length, minimum number of bends/<br />

connections, and fittings with small pressure losses).<br />

5. In order to eliminate the risk of damage and cavitation, a positive pressure at the inlet (4) is always to be maintained at min.<br />

0.5 bar (7.3 psi) and max. 5 bar (72.5 psi). At speeds above 1500 rpm the pressure at the inlet of the APP pump must be min.<br />

2 bar (29 psi).<br />

6. Use flexible hoses (5) to minimize vibrations and noise.<br />

7. Install a safety valve (7) in order to avoid system damage as the APP pump creates pressure and flow immediately after startup,<br />

regardless of any counter-pressure.<br />

Feed<br />

2<br />

5 4<br />

1<br />

3<br />

APP<br />

5<br />

7<br />

Permeate<br />

6<br />

M<br />

Brine<br />

12. Service<br />

Provided that the APP pump has been running according to the Danfoss specifications on pre-filtration, pressure, and rotation<br />

speed, Danfoss guarantees minimum 8000 hours operation, however max. 18 months from date of sale.<br />

To prevent a total and disastrous breakdown, Danfoss recommends a pump inspection after max. 8000 hours – at which any worn<br />

parts must be replaced.<br />

Note: It is always recommended to replace pistons and shaft sealing if another service-free period is to be obtained.<br />

If the pistons are not replaced, more frequent inspection is recommended.<br />

The APP pump is made of duplex/super duplex materials with fine corrosion properties. However, it is always recommended to<br />

flush the APP pump when the system is shut down.<br />

The shaft sealing in the APP pump is made of Hasteloy C. At high TDS and high water temperature, the service life of the shaft<br />

sealing will be reduced. For these applications it is recommended to replace the shaft sealing after approx. 4000 hours operation.<br />

12.1 Periodic maintenance<br />

Water acts as lubricant in the APP pump. Thus there is no oil in the pump.<br />

By operation below the curve for SAF 2507 in the figure in section 7.1, no parts are expected to be replaced within the first 8000<br />

hours of operation.<br />

12.2 Repair<br />

In case of irregular function of the APP pump, please contact the Danfoss RO Solutions Sales Organisation.<br />

DKCFN.PD.010.FB1.02 521B0851

DATA SHEET<br />

Water Pumps<br />

APP24 - 26<br />

1. General information<br />

APP24 - APP26 pumps are designed to supply low viscosity and corrosive fluids under high pressure, eg. in seawater reverse osmosis<br />

filtration applications and for high pressure salt water pumping.<br />

The pumps are based on the axial piston principle enabling a very light and compact design, and they are designed so that the<br />

lubrication of the moving parts in the pumps is provided by the fluid itself. No oil lubrication is thus required.<br />

All parts included in the pumps are designed to provide long service life, i.e. long service life with a constantly high efficiency and<br />

minimum service required.<br />

The pumps are fixed displacement pumps in which the flow is proportional to the number of revolutions of the input shaft and the<br />

pump displacement.<br />

2. Benefits<br />

• One of the smallest and lightest pumps on the market.<br />

• Can be powered by a combustion engine provided that a special coupling is used.<br />

• Generates insignificant pulsations in the pressure line.<br />

• No preventive maintenance required (no periodic service like e.g. change of lubricant and wearing parts).<br />

• Long service life (Danfoss guarantees 8000 hours maintenance-free operation)<br />

• All parts of the pump are made of non corrosive materials eg. Duplex (SAF 2205/EN1.4462) and<br />

Super-duplex (SAF 2507/EN1.4410) stainless steel and carbon reinforced PEEK<br />

• High efficiency<br />

3. Technical <strong>data</strong><br />

1: Shaft sealing<br />

2: Mounting flange<br />

3: Bleeding plugs<br />

4: Retaining ring<br />

5: Piston/shoe<br />

6: Valve/thrust plate<br />

7: Swash plate<br />

8: Cylinder barrel<br />

9: Spring<br />

10: Port plate<br />

11: Connecting flange<br />

12: Housing with bearing<br />

PRELIMINARY<br />

Frequency 50 Hz 60 Hz<br />

APP pumps APP24-50 APP26-50 APP24-60 APP26-60<br />

Rated speed rpm 1200 1200 1200 1200<br />

Maximum speed rpm 1200 1200 1200 1200<br />

Minimum speed rpm 700 700 700 700<br />

Geometric displacement<br />

cm 3 /rpm 352 380 352 380<br />

in 3 /rpm 21.5 23.2 21.5 23.2<br />

Flow (1200 rpm) m 3 /h 24 26 24 26<br />

gpm 105.7 114.5 105.6 114.5<br />

Max. pressure<br />

bar 80 80 80 80<br />

psi 1160 1160 1160 1160<br />

Min. pressure<br />

bar 40 40 40 40<br />

psi 580 580 580 580<br />

Power requirement at<br />

kW 64 69 64 69<br />

max. speed and 80 bar (1160 psi):<br />

hp 86 92 86 92<br />

Weight<br />

kg 125 125 125 125<br />

lb 275.6 275.6 275.6 275.6<br />

521B0852 DKCFN.PD.010.FC1.02 09-2006

4. Flow at different rpm<br />

When using the diagram shown below, it is easy to select the pump which fits the application best if the flow required and the<br />

rotation speed (rpm) of the pump are known.<br />

30<br />

25<br />

20<br />

m3/h<br />

15<br />

10<br />

APP26-50Hz<br />

APP24-50Hz<br />

APP26-60Hz<br />

APP24-60Hz<br />

5<br />

0<br />

900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900<br />

rp m<br />

Furthermore, this diagram shows that the flow can be changed by changing the rotation speed of the pump. The flow/rpm ratio is<br />

constant, and the “desired “ flow can be obtained by changing the rotation speed to a corresponding value. Thus, the required rpm<br />

can be determined as:<br />

Required rpm =<br />

5. Dimensions<br />

Desired flow × Rated rpm<br />

Rated flow<br />

PRELIMINARY<br />

Description<br />

E<br />

Parallel key, DIN 6885, mm (in)<br />

APP24 - APP26<br />

12 × 8 × 70<br />

(0.47 × 0.31 × 2.76)<br />

F Bleeding G ¼”, Hexagon AF = 8 mm<br />

I Inlet connection 3” hose pipe<br />

O Outlet connection 2½ Victaulic<br />

Pump mounting flange 180 B 4<br />

6. Inlet pressure<br />

Water supply to the pump is either made from a tank placed above the pump or directly from the mains. The pressure at the pump<br />

inlet (I) must be in the range: 2 - 5 bar (29 - 72.5 psi)<br />

DKCFN.PI.010.FC1.02 521B0852

7. Temperature and corrosion<br />

7.1 Operation:<br />

• Fluid temperature: +3°C to +50°C (dependent on the NaCl concentration)<br />

• Ambient temperature: +3°C to +50°C<br />

The chart below illustrates the corrosive resistance of different types of stainless steel related to NaCl concentration and<br />

temperature.<br />

All critical parts of the APP water pump is made of SAF 2507.<br />

If the water pump is operated at high salinity, always flush the the water pump with fresh water at operation stop in order to<br />

minimise the risk of crevice corrosion.<br />

NaCl vs. temperature<br />

7.2 Storage:<br />

• Storage temperature: -40°C to +70°C – provided that the pump is drained of fluid and stored ”plugged”.<br />

Antefreeze protection is required at temperatures below 2°C. Danfoss recommends using Dowcal N from Dow Chemical<br />

Company or Chillsafe mono propylene glycol from Arco Chemical Company.<br />

8. Filtration<br />

As water has very low viscosity, the APP pumps have been designed with very narrow clearance in order to control internal leakage<br />

rates and improve component performance. Therefore it is important that the inlet water is filtered properly to minimize the wear of<br />

the pump.<br />

The main filter must have a filtration efficiency of 99.98% at 10 µm. We recommend that you use precision depth filter cartridges<br />

rated 10µm abs. ß10>5000 (equivalent to a filtration efficiency of 99.98%). Bag filters and string wound filter cartridges typically<br />

have only 33% filtration efficiency.<br />

For more information on the importance of proper filtration, please consult our publication “Filtration” (code number 521B0861),<br />

which also will provide you with an explanation of filtration definitions and a guidance on how to select the right filter.<br />

9. Installation<br />

9.1 Mounting<br />

PRELIMINARY<br />

The figure below illustrates how to mount the pump and connect it to the electric motor/combustion engine.<br />

A: Flexible coupling<br />

B: Bell housing<br />

C: Motor shaft<br />

If alternative mounting is required, please contact Danfoss RO Sales Organization for further information.<br />

To ensure easy mounting of the flexible coupling without using tools, the tolerances must be dimensioned accordingly.<br />

Note: Any axial and radial loads on the shaft must be avoided.<br />

A<br />

B<br />

C<br />

521B0852 DKCFN.PI.010.FC1.02 3

10. Dimensions, complete unit<br />

11. Service<br />

Pump A (mm) B (mm) C (mm) D (mm) E (mm) F (mm) IEC Electric motor<br />

APP24 550 620 250 406 349 770 55 kW, FPC 250 M-4<br />

APP26 550 920 280 457 368 845 75 kW, FPC 280 S-4<br />

Provided that the pump has been running according to the Danfoss specifications on pre-filtration, pressure, and rotation speed,<br />

Danfoss guarantees minimum 8000 hours operation, however max. 18 months from date of sale.<br />

To prevent a total and disastrous breakdown, Danfoss recommends a pump inspection after max. 8000 hours – at which any worn<br />

parts must be replaced.<br />

Note: It is always recommended to replace pistons and shaft sealing if another service-free period is to be obtained.<br />

If the pistons are not replaced, more frequent inspection is recommended.<br />

E<br />

The APP pump is made of duplex/super duplex materials with fine corrosion properties. However, it is always recommended to<br />

flush the pump when the system is shut down.<br />

PRELIMINARY<br />

The shaft sealing in the APP pump is made of Hasteloy C. At high TDS and high water temperature, the service life of the shaft<br />

sealing will be reduced. For these applications it is recommended to replace the shaft sealing after approx. 4000 hours operation.<br />

11.1 Periodic maintenance<br />

Water acts as lubricant in the APP. Thus there is no oil in the the pump.<br />

By operation below the curve for SAF 2507 in the figure in section 8.1, no parts are expected to be replaced within the first 8000<br />

hours of operation.<br />

11.2 Repair<br />

In case of irregular function of the APP, please contact the Danfoss RO Solutions Sales Organisation.<br />

D<br />

DKCFN.PI.010.FC1.02 521B0852

The Danfoss APP pumps<br />

The Danfoss Axial Piston Pump (APP) is a positive<br />

displacement pump with an almost constant flow (+/- 1%)<br />

to speed ratio.<br />

The design originating from oil hydraulics and<br />

subsequently redesigned by Danfoss, during the last 15<br />

years, to pump tap and seawater. Tens of thousands of<br />

pumps are in operation worldwide proving the pumps to<br />

be among the most cost-effective and reliable pumps for<br />

membrane applications, both as main high-pressure<br />

pumps but also for recovering energy as reversing<br />

pumps (motors) in the reject line.<br />

The pumps are made in materials incorporating Duplex<br />

and Super-duplex materials as standard.<br />

With Danfoss APP pumps you get the following benefits:<br />

• Low energy consumption<br />

Total efficiencies up to 95 percent – among the most efficient in the market.<br />

• Long service life<br />

Danfoss guarantees service free operation for more than 8,000 hours thanks to two design features:<br />

• No oil lubrication: the medium itself lubricates the pump -no risk for contamination of the permeate.<br />

• No need for service on a regular basis: the mechanical shaft is the only seal in the pump.<br />

• Easy service<br />

• Its easy and quick to assemble and dissemble the pump - less 1 / 2 then hour.<br />

• Corrosion resistance<br />

All wetted parts of the pump are designed in duplex, super duplex stainless steel and polymer, ensuring<br />

resistance to corrosive and low viscosity fluids, e.g. seawater and brackish water.<br />

• High-pressure operation<br />

Continuous operation at a discharge pressure between 10 and 80 bar (145-1160 psi). Higher discharge<br />

pressures are available on request.<br />

• Wide flow range<br />

One pump size covers the same flow range as several centrifugal pumps, because the flow is a linear<br />

function of the speed (rpm). The pumps run at speeds between 700 and 3,450 rpm with the same<br />

efficiency.<br />

• Low pulsation<br />

A design featuring up to nine pistons reduces pressure pulsations in the discharge line down to 1.5<br />

percent, rendering pulsation dampers superfluous addition, and reducing installing cost.<br />

• Compact design<br />

The most compact pump on the market. Giving system builders a free hand to design more compact<br />

systems. The pump may also be directly mounted onto an electrical motor via a bell housing with a<br />

flexible coupling. No need for frames, belt drive or gearbox.

Since one of our goals is to facilitate supply chain optimization for our customers we offer:<br />

• High-Pressure Pumps<br />

• Electrical Motors<br />

• Frequency Inverters<br />

• Soft Starters<br />

• Valves<br />

• Pressure Transmitters<br />

• ….and all kinds of "around-the-pump" accessories<br />

I would especially like to introduce our new line of check<br />

valves, standpipes and high pressure hoses with victaulic<br />

connections in duplex.<br />

Danfoss A/S RO-Solution can supply all APP pumps with ATEX approval mounted with EX-proof Zone II motors<br />

via stainless steel housing.<br />

Cost-effective operation and service due to light weight<br />

and compact design:<br />

• Flexibility in design of desalination units.<br />

• Mounted on motor frame – only one frame<br />

needed e.g. no alignment.<br />

• No belt-drive or gearbox<br />

• Replacement without lifting gear<br />

• Easy and quick replacement.<br />

Emergency stock for all pumps for overnight shipment for urgent service situations…..setting new standards<br />

For Further information please visit our website : www.danfoss.com/nessie/rosolution<br />

Or contact us at Danfoss RO-Solutions:<br />

Torben Østerby<br />

Anders Grum Kjærgaard<br />

Sales Manager, Asia<br />

Sales Manager<br />

Direct tel.: +45 7488 5272 Direct tel.: +45 7488 7320<br />

Cell Phone.: +45 2343 5272 Cell Phone.: +45 5133 7320<br />

E-mail: toe@danfoss.com<br />

E-mail: kjaergaard@danfoss.com<br />

Fax.: +45 7445 3831 Fax.: +45 7445 3831