ProLine Manual Keg Filler - GW Kent

ProLine Manual Keg Filler - GW Kent

ProLine Manual Keg Filler - GW Kent

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

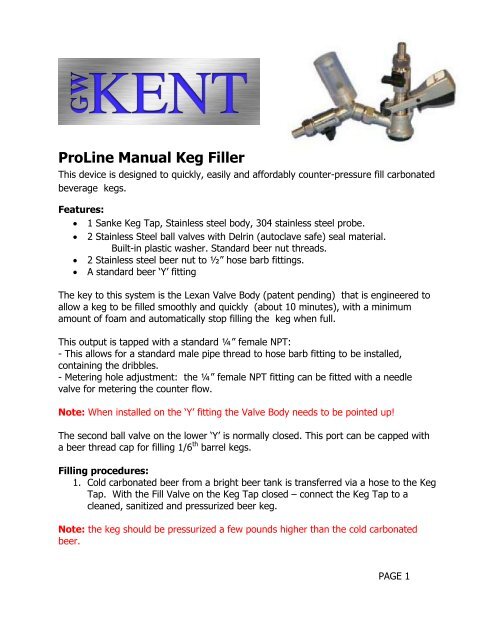

<strong>ProLine</strong> <strong>Manual</strong> <strong>Keg</strong> <strong>Filler</strong><br />

This device is designed to quickly, easily and affordably counter-pressure fill carbonated<br />

beverage kegs.<br />

Features:<br />

1 Sanke <strong>Keg</strong> Tap, Stainless steel body, 304 stainless steel probe.<br />

2 Stainless Steel ball valves with Delrin (autoclave safe) seal material.<br />

Built-in plastic washer. Standard beer nut threads.<br />

2 Stainless steel beer nut to ½” hose barb fittings.<br />

A standard beer ‘Y’ fitting<br />

The key to this system is the Lexan Valve Body (patent pending) that is engineered to<br />

allow a keg to be filled smoothly and quickly (about 10 minutes), with a minimum<br />

amount of foam and automatically stop filling the keg when full.<br />

This output is tapped with a standard ¼” female NPT:<br />

- This allows for a standard male pipe thread to hose barb fitting to be installed,<br />

containing the dribbles.<br />

- Metering hole adjustment: the ¼” female NPT fitting can be fitted with a needle<br />

valve for metering the counter flow.<br />

Note: When installed on the ‘Y’ fitting the Valve Body needs to be pointed up!<br />

The second ball valve on the lower ‘Y’ is normally closed. This port can be capped with<br />

a beer thread cap for filling 1/6 th barrel kegs.<br />

Filling procedures:<br />

1. Cold carbonated beer from a bright beer tank is transferred via a hose to the <strong>Keg</strong><br />

Tap. With the Fill Valve on the <strong>Keg</strong> Tap closed – connect the <strong>Keg</strong> Tap to a<br />

cleaned, sanitized and pressurized beer keg.<br />

Note: the keg should be pressurized a few pounds higher than the cold carbonated<br />

beer.<br />

PAGE 1

2. The counter pressure gas will begin to bleed out of the valve body immediately.<br />

Open the Fill Valve – when the pressure in the keg is lower than the beer in the<br />

bright tank - the keg will begin to fill.<br />

3. When the beer level gets to the top - beer flows into the Valve Body - this causes<br />

the ball to float and closes the relief port – stopping the flow of beer.<br />

4. When keg is full – close the Fill Valve and remove the <strong>Keg</strong> Tap.<br />

Beer should drain from the valve body – and you are ready to tap the next keg.<br />

Rinse – dry – cap the keg.<br />

Trouble Shooting:<br />

<strong>Keg</strong> not full: Too much foam – warm beer – over carbonated – out of beer?<br />

Metering hole gets plugged – use a sewing needle to open the hole.<br />

Beer may need to be run through a coarse filter to remove particulates.<br />

Be careful to not over size the hole – as this will change the fill rate.<br />

Parts:<br />

<strong>ProLine</strong> <strong>Manual</strong> <strong>Keg</strong> <strong>Filler</strong> SKU: 5925<br />

Stainless Steel Coupler Filling Head SKU: 2512<br />

Beer Line Shutoff Valve - stainless steel SKU: 2515<br />

‘Y’ for Beer Line - stainless steel SKU: 2513<br />

1/4" Hose Nipple NPT SKU: 109-14<br />

NEEDLE VALVE<br />

SKU: 5925A<br />

WASHER – NEOPRENE<br />

SKU: 5925B<br />

BALL CHECK<br />

SKU: 5925C<br />

RETAINER<br />

SKU: 5925D<br />

BEER THREAD CAP<br />

SKU: 5925E<br />

PAGE 2