Specifications - Maersk Drilling

Specifications - Maersk Drilling

Specifications - Maersk Drilling

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

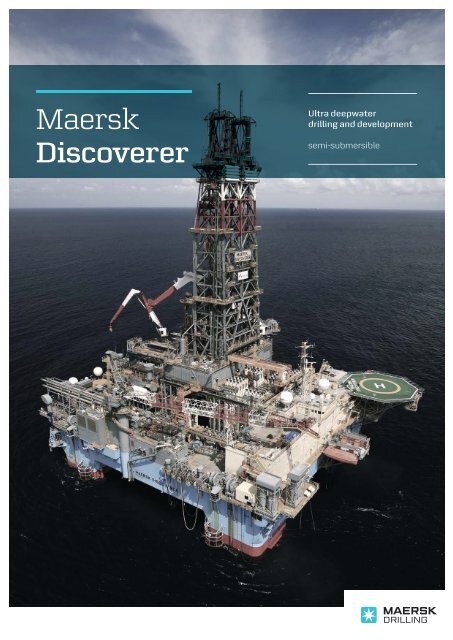

<strong>Maersk</strong><br />

Discoverer<br />

Ultra deepwater<br />

drilling and development<br />

semi-submersible

<strong>Maersk</strong> <strong>Drilling</strong><br />

<strong>Maersk</strong> Discoverer<br />

<strong>Maersk</strong><br />

Discoverer<br />

TYPE<br />

DPS2/M, Column stabilised dynamically positioned semisubmersible<br />

drilling rig with capability to attach to an 8-point<br />

pre-installed mooring system; provisions to attach to a<br />

12-point pre-installed mooring system<br />

BUILT<br />

KeppelFELS, Singapore , 2009<br />

<strong>Maersk</strong> <strong>Drilling</strong> is a considerable player in the ultra deepwater<br />

market with four newly built drillships and three Ultra<br />

Deepwater Development semi-submersibles.<br />

The three semi-subs are DP rigs designed for year-round<br />

operation in areas such as Brazil, the Gulf of Mexico, West<br />

Africa and Asia pacific at water depths up to 3,000 m<br />

(10,000 ft).<br />

CLASS<br />

American Bureau of Shipping<br />

FLAG<br />

Singapore<br />

Main advantages<br />

• Exploratory, appraisal and development drilling<br />

• Batch drilling and completion of multiple well clusters<br />

• Installation of subsea facility components<br />

• Derrick – 1,361 t (3,000,000 lbs) combined load rating<br />

Max. 2,500,000 lbs single load rating<br />

• Main hoisting system – 910 t (2,000,000 lbs) capacity<br />

• Auxiliary hoisting system – 680 t (1,500,000 lbs) capacity<br />

• Large 5-chair driller’s cabin with automated sequenced<br />

pipe handling operations<br />

• Automated and dust-free bulk, mud and chemical transfer<br />

and mixing systems<br />

• Hydraulic work baskets and service platforms providing<br />

safe access for servicing of major drilling equipment<br />

• Deck drainage, containment and treatment systems for<br />

controlled discharge<br />

• Large heave compensated knuckle-boom crane (165 t lift<br />

capacity from deck to deck) with winch for deployment of<br />

subsea trees and other components up to 100 t over the<br />

side of the rig to 3,000 m water depth

<strong>Maersk</strong> <strong>Drilling</strong><br />

<strong>Maersk</strong> Discoverer<br />

Main particulars<br />

DIMENSIONS IMPERIAL METRIC<br />

Length overall 384 ft 117 m<br />

Width overall 256 ft 78 m<br />

Length of pontoons 376 ft 115 m<br />

Pontoon (width / height) 57 ft / 33 ft 18 m / 10 m<br />

Columns 55 ft x 57 ft 17 m x 18 m<br />

Upper hull (length / width) 259 ft / 258 ft 78.5 m / 78 m<br />

Moonpool opening 108.3 ft x 29.5 ft 33 m x 9 m<br />

Draft operational (max / min) 67.3 ft / 60.7 ft 20.5 m / 18.5 m<br />

Draft transit 31.8 ft 9.7 m<br />

PARTICULARS IMPERIAL METRIC<br />

Rated drilling depth 40,000 ft 12,000 m<br />

Hook load static (main) 2,500,000 lbs 1,134 t<br />

Hook load static (aux) 1,500,000 lbs 680 t<br />

Rotary load static (main) 2,756,000 lbs 1,250 t<br />

Rotary load static (aux) 2,000,000 lbs 907 t<br />

Setback load 2,646,000 lbs 1,200 t<br />

Variable deck load (max / transit) 15,400,000 lbs / 10,120,000 lbs 7,000 t / 4,600 t<br />

Variable column load (max / transit) 3,300,000 lbs / 880,000 lbs 1,500 / 400 t<br />

Variable pontoon load (max / transit) 11,000,000 lbs / 4,400,000 lbs 5,000 t / 2,000 t<br />

Total payload (max / transit) 29,900,000 lbs / 15,400,000 lbs 13,500 t / 7,000 t<br />

Riser tensioner load 4,200,000 lbs 1,906 t<br />

Pipe rack area 10,765 f t2 1,000 m2<br />

WEATHER/DESIGN CRITERIA (SURVIVAL) IMPERIAL METRIC<br />

Water depth (moored in less than 1,640 ft / 500 m) 328 ft – 10,000 ft 100 m – 3,000 m<br />

Wind speed 56 knots 29 m/sec<br />

Wave height (Hs) 26.2 ft 8 m<br />

Wave period 12.3 s 12.3 s<br />

Current (surface) 1.7 knots 0.9 m/sec<br />

CAPACITIES IMPERIAL METRIC<br />

Drill water 12,580 bbl 2,000 m³<br />

Potable water 5,032 bbl 800 m³<br />

Fuel oil 25,160 bbl 4,000 m³<br />

Brine 4,718 bbl 750 m³<br />

Base oil 4,718 bbl 750 m³<br />

Liquid mud (surface pits) 9,435 bbl 1,500 m³<br />

Liquid mud (pontoons) 9,435 bbl 1,500 m³<br />

Bulk mud 24,000 ft³ 680 m³<br />

Bulk cement 24,000 ft³ 680 m³<br />

Sack material 2,160 f t³ 200 m³<br />

Accommodation 180 people 180 people<br />

Derrick rated for US GOM category 4 hurricane

<strong>Maersk</strong> <strong>Drilling</strong><br />

<strong>Maersk</strong> Discoverer<br />

Key features<br />

CROWN MOUNTED COMPENSATION<br />

Main rotary: static / compensating load 2,500,000 lbs /<br />

1,000,000 lbs (1,134 t / 454 t). Hydraulic locking with<br />

25 ft stroke. Auxiliary rotary: static / compensating load<br />

1,500,000 lbs / 750,000 lbs (680 t / 340 t). Hydraulic locking<br />

with 25 ft stroke. Active heave compensation mode<br />

available.<br />

DERRICK AND HOISTING SYSTEMS<br />

Rated drilling depth capacity 30, 000 ft. MAIN side equipped<br />

with hoisting System capable of 2,500,000 lbs static hook<br />

load. Drawworks: 6,000 hp. Top drive: 2,000,000 lbs capacity.<br />

Rotary: 60 ½”. AUX side equipped with hoisting System<br />

capable of 1,500,000 lbs hook load. Drawworks: 4,500 hp<br />

Top Drive: 1,500,000 lbs capacity. Rotary: 60 ½”.<br />

TUBULAR HANDLING SYSTEMS<br />

Primary mover is one pipehandling knuckle-boom crane<br />

feeding two horizontal pipe conveyor / skate systems. Two<br />

V-door stand-building and tripping machines. Two column<br />

rackers for pipe handling and two iron roughnecks. Offline<br />

casing make-up capability drill string / casing vertical<br />

setback designed for 3” – 16”. Tubulars racked in nominal<br />

135 ft stand lengths. Marine riser vertical storage for 126 ea.<br />

75 ft of riser joints. Total 9,450 ft plus two telescoping joints;<br />

additional storage area for drilling riser on deck.<br />

DRILL STRING AND TUBULARS<br />

In excess of 50,000 ft setback capability for drill pipe, work<br />

string and casing running string, capable of racking 25,000 ft<br />

of 6 ⅝” drill pipe. Approximately 15,000 ft of 9 ⅝” casing<br />

racking capacity in addition to drill string.<br />

MARINE RISER AND TENSIONING SYSTEMS<br />

Clip riser with two 15,000 psi choke & kill lines, one 7,500 psi<br />

booster line, two hydraulic conduit lines total 10,000 ft of<br />

riser, 75 ft length joints and 21” OD Riser tensioning system<br />

consisting of 6 x 700,000 lbs N-line cylinder riser tensioners.<br />

Tripsaver system to allow movement of BOP and riser to wet<br />

storage position.<br />

BOP AND SUBSEA TREE HANDLING SYSTEMS<br />

At port side of the main deck: BOP overhead (gantry type)<br />

crane: 2 x 125 t. In the moonpool: BOP transporter: 400 t.<br />

Subsea tree overhead crane installed underneath drill floor +<br />

subsea tree staging and skidding system. Subsea tree cart<br />

underhull guide systems each rotary.<br />

WELL CONTROL EQUIPMENT<br />

18 ¾” BOP – 15,000 psi equipped with two annular + six ram<br />

preventers. The lower ram can be configured as a test ram.<br />

Multiplex BOP control system; redundancy to allow both<br />

pods to operate with one MUX cable. 60 ½” diverter system<br />

and riser gas handler, choke & kill manifold, 15,000 psi and<br />

mud gas separator, 12 MMscfd.<br />

HP MUD SYSTEM<br />

Four 2,200 hp mud pumps rated for 7,500 psi.<br />

MUD RETURN SYSTEM<br />

System design to minimise time displacing mud system /<br />

completion fluids and capable of handling more than one<br />

mud system. Provisions for centrifuge and cuttings dryer<br />

installation. Completion fluid capability. Eight shale shakers.<br />

Cuttings blower system.<br />

MUD AND BULK SYSTEM<br />

Fitted with two automatic sack cutting machines in sack<br />

store and one bigbag machine: One dual liquid additive<br />

pump unit. Four surge tank outlet feeders, four automatic<br />

mud mixing hoppers, one caustic mixing unit. Two HP mud<br />

shearing devices.<br />

PROVISIONS FOR 3 RD PARTY EQUIPMENT<br />

Designed for two large work class ROV systems<br />

(Oceaneering Millenium +) port forward and starboard aft for<br />

flexibility of operation. Diesel cementing unit (Schlumberger).<br />

Staging area for subsea completion equipment, including<br />

subsea tree transport system. Completion equipment,<br />

including well test equipment and coil tubing. Dedicated<br />

control rooms, store rooms and offices for 3 rd party system<br />

operators.<br />

POWER SYSTEMS<br />

8 generators x 4,800 kw(e), 11 kVAC, 60 Hz, divided into two<br />

self-contained power plants. Power Distribution System:<br />

690 VAC, 60 Hz IT. One emergency generator: 1,500 kW(e).<br />

POSITIONING SYSTEMS<br />

DP Class 2: power management system and position,<br />

reference systems to DP Class 3. Azimuthing thrusters<br />

8 x 4,000 kW(e) of min. 700 kN static thrust each. Optional<br />

moored operation: four double drum windlasses for 3.”<br />

K4 chains, 8 x 600 m K-4 chain for attachment to a preinstalled.<br />

Space for additional windlasses and chain for<br />

12-point mooring system.

<strong>Maersk</strong> <strong>Drilling</strong><br />

<strong>Maersk</strong> Discoverer<br />

CRANES<br />

Port deck crane: Knuckle-boom crane with 3,000 m, 3” wire<br />

for deployment of subsea trees and other modules up to<br />

100 t heave compensated over the side of the rig. 165 t lift<br />

capability from supply boat. Auxiliary whipline hoist 15 t SWL<br />

@ 50 m. Starboard deck crane: 50 m max. reach, SWL 60 t @<br />

20 m dynamic. One pipehandling knuckle-boom crane: 30 m<br />

max. reach, SWL 12 t @ 10 m.<br />

HELICOPTER DECK<br />

Helicopter deck suitable for an EH101 helicopter or Sikorsky<br />

S61.<br />

SAFETY EQUIPMENT<br />

Lifesaving and firefighting equipment in accordance with<br />

Singapore flag state requirements and the IMO MODU code<br />

2001. The rig holds a vessel specific safety case which has<br />

been approved by HSE UK.<br />

ACCOMMODATION<br />

Accommodation for 180 people in 10 one-man rooms and 85<br />

two-men rooms. Ample office spaces and conference rooms<br />

for clients and 3rd party service contractors. Recreation<br />

rooms, total area of 270 m2.

<strong>Maersk</strong> <strong>Drilling</strong><br />

<strong>Maersk</strong> Discoverer<br />

<strong>Drilling</strong> features<br />

The rig includes a number of innovative features, which enhance the capacity and flexibility for<br />

multiple concurrent activities and improve the drilling efficiency. Back-up facilities and solutions<br />

are generally provided to reduce the impact of equipment failures.<br />

Rig Floor<br />

FLEXIBILITY FOR MULTIPLE ACTIVITIES<br />

• Two hoisting / rotary systems<br />

• Large setback area for drill pipe, casing and completion<br />

riser outside of derrick / drillfloor<br />

• Offline pipe handling capability : standbuilding, casing<br />

make-up and rack back<br />

• Transfer of drill string, casing and riser from outside of<br />

derrick / drillfloor<br />

Moonpool<br />

LARGE MOONPOOL;<br />

FLEXIBILITY FOR MULTIPLE ACTIVITIES<br />

• N-Line riser tensioner system with tripsaver<br />

• Transfer of equipment across the moonpool<br />

• Dedicated off-line ‘wet parking’ position for BOP / drilling<br />

riser<br />

• BOP handling area (starboard side)<br />

• Subsea tree staging area (port side)<br />

OPTIMUM LAYOUT FOR SUBSEA COMPLETION<br />

• Capability for large umbilical and services (tubing hanger<br />

running tool or subsurface test tree)<br />

• Additional space for small umbilicals for completion<br />

accessories<br />

Optimised layout<br />

The hull design and layout are based on the operational experience of various deepwater operators<br />

and third party system suppliers and incorporate a number of innovative ideas from our potential<br />

customers. Great emphasis has been made on optimising the rig’s layout to facilitate flexibili ty in<br />

installation and operation of third party equipment.<br />

Subsea completions<br />

FLEXIBLE SYSTEM FOR<br />

MULTIPLE WELL SUBSEA DEVELOPMENTS<br />

• Option to deploy equipment through the main well centre<br />

or over the side by large knuckle-boom crane<br />

• Large staging area for multiple subsea trees and<br />

accessories<br />

• Flexibility in subsea tree handling area for various subsea<br />

system designs<br />

• High load capacity for flatbed transporter and tree cart<br />

• High vertical clearance in moonpool for subsea system<br />

stack-up and transport<br />

Logistics<br />

MAXIMUM USUABLE DECK SPACE FOR OPTIMUM<br />

LAYOUT OF DRILLING AND COMPLETION EQUIPMENT<br />

• 9,600 ft (2,926 m) vertical riser storage<br />

• Large vertical drill pipe and casing setback area<br />

• Large pipe rack area (aft) for deepwater completion<br />

equipment layout<br />

• Well test equipment<br />

• Tubing / downhole tools<br />

• Completion riser accessories<br />

• Completion fluids / filtration<br />

• Stimulation<br />

• Coil tubing<br />

• Primary ROV within upper hull ; 2 nd ROV location on aft deck

<strong>Maersk</strong> <strong>Drilling</strong><br />

<strong>Maersk</strong> Discoverer<br />

<strong>Drilling</strong> features<br />

TOP VIEW AND DRILL FLOOR<br />

TANK TOP

<strong>Maersk</strong> <strong>Drilling</strong><br />

<strong>Maersk</strong> Discoverer<br />

SIDE VIEW

October 2014<br />

Head office:<br />

<strong>Maersk</strong> <strong>Drilling</strong><br />

50, Esplanaden<br />

1098 Copenhagen K<br />

Denmark<br />

Telephone: +45 3363 3363<br />

Telefax: +45 3363 3182<br />

E-mail: copenhagen@maerskdrilling.com<br />

www.maerskdrilling.com<br />

Follow us to learn more<br />

www.maerskdrilling.com<br />

www.facebook.com/<strong>Maersk</strong><strong>Drilling</strong><br />

www.linkedin.com/company/maerskdrilling<br />

www.twitter.com/maerskdrilling<br />

www.vimeo.com/maerskdrilling<br />

www.youtube.com/user/<strong>Maersk</strong>com<br />

www.instagram.com/maerskdrilling<br />

“DISCLAIMER: This brochure is for promotional purposes only. All descriptions, specifications and other information contained in this brochure and/or in any accompanying material is: (i) intended to give only a general indication of the sorts<br />

of service or equipment or performance that might be available (ii) intended to be no more than an invitation to treat (iii) subject to contract and possible change or alteration at our discretion and without notice to you (iv) not to be relied<br />

upon by you for any purposes whatsoever when entering into any legally binding agreement with us.”