fly ash/plastic synthetic aggregate for construction material

fly ash/plastic synthetic aggregate for construction material

fly ash/plastic synthetic aggregate for construction material

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

There are few, if any, <strong>plastic</strong> products that can be made using combination of multiple<br />

polymers together without using compatiblizing agents. However, this test was<br />

conducted in large part to show that the <strong>synthetic</strong> <strong>aggregate</strong> process is less critical than<br />

most conventional thermo<strong>plastic</strong> processes in terms of <strong>material</strong> viscosity and process<br />

stability and final product integrity. The <strong>aggregate</strong> properties are more dependent on <strong>fly</strong><br />

<strong>ash</strong> concentration than thermo<strong>plastic</strong> composition at such high <strong>fly</strong> <strong>ash</strong> concentrations<br />

(e.g. 80% <strong>fly</strong> <strong>ash</strong>)<br />

The <strong>synthetic</strong> lightweight <strong>aggregate</strong> was tested <strong>for</strong> physical and chemical properties.<br />

Several concrete cylinders made with the <strong>synthetic</strong> lightweight <strong>aggregate</strong> and their<br />

characteristics were comparable in properties with those of ordinary lightweight<br />

<strong>aggregate</strong> available in the market.<br />

Using a cement/<strong>aggregate</strong> mixture ratio suitable <strong>for</strong> concrete masonry blocks, several<br />

concrete masonry blocks were made in the lab using a plywood mold. Both lightweight<br />

<strong>aggregate</strong> and SLA were used in the mixes and several cylinders cast from these mixes<br />

were also tested <strong>for</strong> compressive strength at various ages. Test results (see CCFRED<br />

Technical Report # 35) indicated that the SLA is suitable to be used in concrete masonry<br />

units (CMU).<br />

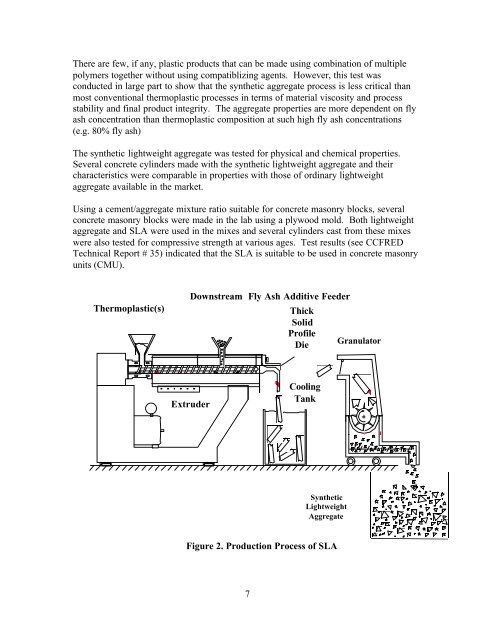

Thermo<strong>plastic</strong>(s)<br />

Downstream Fly Ash Additive Feeder<br />

Thick<br />

Solid<br />

Profile<br />

Die<br />

Granulator<br />

Extruder<br />

Cooling<br />

Tank<br />

Synthetic<br />

Lightweight<br />

Aggregate<br />

Figure 2. Production Process of SLA<br />

7