fly ash/plastic synthetic aggregate for construction material

fly ash/plastic synthetic aggregate for construction material

fly ash/plastic synthetic aggregate for construction material

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The samples were w<strong>ash</strong>ed and then oven dried to a constant mass at 110 ± 5°C. The test<br />

sample was then placed into the Los Angeles testing machine along with the six steel<br />

charges, as shown in Figure 13. The machine was then rotated at a speed of<br />

approximately 32 revolutions per minute <strong>for</strong> 500 revolutions. The <strong>material</strong> was then<br />

removed from the testing apparatus and preliminarily separated using a No. 8 sieve (2.36<br />

mm spacing). The finer portion was then sieved through a No. 12 (1.70 mm) sieve. The<br />

<strong>material</strong> coarser than the No. 12 sieve was then oven dried to a constant mass at 110 ±<br />

5°C. The mass of the oven-dried <strong>material</strong> was then measured and recorded, and the Los<br />

Angeles Abrasion Number was calculated using the following equation:<br />

⎛ M<br />

sample(<br />

original)<br />

sample(<br />

coarse)<br />

LA Abrasion Number = ⎜<br />

⎟( 100% )<br />

⎝<br />

M<br />

− M<br />

sample(<br />

coarse)<br />

⎞<br />

⎠<br />

where M sample(original) is the total mass of the original sample (g) and M sample(coarse) is the<br />

coarse portion of the <strong>aggregate</strong> larger than the No. 12 sieve (1.77 mm) after 500<br />

revolutions.<br />

The LA Abrasion Test was conducted on three coarse <strong>aggregate</strong>s; N 1 , E, and C 2 80H. LA<br />

Abrasion #’s were calculated using the above equation and the values are presented in<br />

Table 5.<br />

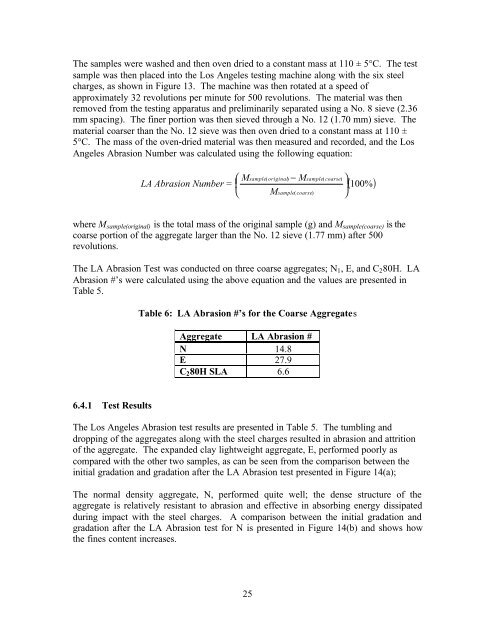

Table 6: LA Abrasion #’s <strong>for</strong> the Coarse Aggregates<br />

Aggregate LA Abrasion #<br />

N 14.8<br />

E 27.9<br />

C 2 80H SLA 6.6<br />

6.4.1 Test Results<br />

The Los Angeles Abrasion test results are presented in Table 5. The tumbling and<br />

dropping of the <strong>aggregate</strong>s along with the steel charges resulted in abrasion and attrition<br />

of the <strong>aggregate</strong>. The expanded clay lightweight <strong>aggregate</strong>, E, per<strong>for</strong>med poorly as<br />

compared with the other two samples, as can be seen from the comparison between the<br />

initial gradation and gradation after the LA Abrasion test presented in Figure 14(a);<br />

The normal density <strong>aggregate</strong>, N, per<strong>for</strong>med quite well; the dense structure of the<br />

<strong>aggregate</strong> is relatively resistant to abrasion and effective in absorbing energy dissipated<br />

during impact with the steel charges. A comparison between the initial gradation and<br />

gradation after the LA Abrasion test <strong>for</strong> N is presented in Figure 14(b) and shows how<br />

the fines content increases.<br />

25