STIHL 020 T - Arbtalk

STIHL 020 T - Arbtalk

STIHL 020 T - Arbtalk

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

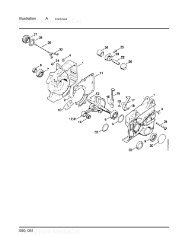

4. ENGINE<br />

4.1 Exhaust Muffler<br />

4.2 Leakage Test<br />

Troubleshooting chart - see 2.2.<br />

• Remove sprocket cover –<br />

see 3.1.<br />

• Take out the screw (1).<br />

• Remove the cover (2).<br />

• Take out the screws.<br />

• Lift lower casing away from<br />

upper casing.<br />

Defective oil seals and gaskets or<br />

cracks in castings are the usual<br />

causes of leaks. Such faults allow<br />

supplementary air to enter the<br />

engine and thus upset the fuel-air<br />

mixture.<br />

This makes adjustment of the<br />

prescribed idle speed difficult, if<br />

not impossible.<br />

Moreover, the transition from idle<br />

speed to part or full throttle is not<br />

smooth.<br />

The crankcase can be checked<br />

thoroughly for leaks with the .<br />

carburetor and crankcase tester<br />

and the vacuum pump.<br />

• Remove mounting screws from<br />

underside of machine.<br />

• Take out the screw.<br />

• Remove baffle from guide in<br />

upper casing.<br />

• Clean baffle or fit a new one.<br />

Note: If baffle is equipped with<br />

spark arresting screen, make sure<br />

the spark arresting screen is refitted.<br />

Reassemble in the reverse<br />

sequence.<br />

Note: Install a new gasket.<br />

Tighten screws of upper casing to<br />

4 Nm (3 Ibf.ft) and muffler mounting<br />

screws to 11.5 Nm (8.5 Ibf.ft).<br />

• Pull out the muffler.<br />

• Remove the gasket.<br />

<strong>STIHL</strong> <strong>020</strong> T 16