Nozzle classification system in Japan based on the relative spray ...

Nozzle classification system in Japan based on the relative spray ...

Nozzle classification system in Japan based on the relative spray ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Drift Potential Index<br />

Reducti<strong>on</strong> Percentage, %<br />

Drift Potential Index<br />

Reducti<strong>on</strong> Percentage, %<br />

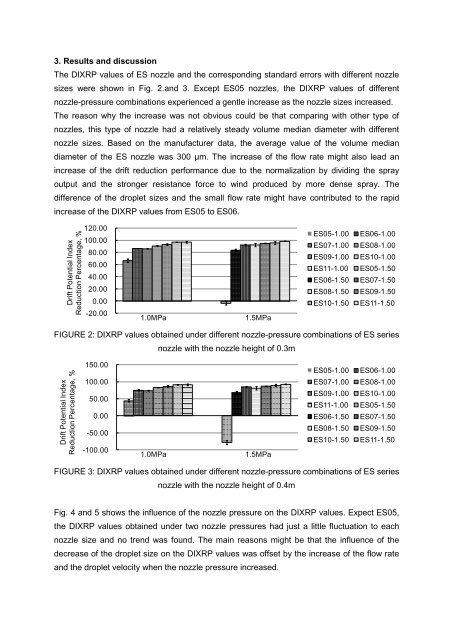

3. Results and discussi<strong>on</strong><br />

The DIXRP values of ES nozzle and <strong>the</strong> corresp<strong>on</strong>d<str<strong>on</strong>g>in</str<strong>on</strong>g>g standard errors with different nozzle<br />

sizes were shown <str<strong>on</strong>g>in</str<strong>on</strong>g> Fig. 2.and 3. Except ES05 nozzles, <strong>the</strong> DIXRP values of different<br />

nozzle-pressure comb<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong>s experienced a gentle <str<strong>on</strong>g>in</str<strong>on</strong>g>crease as <strong>the</strong> nozzle sizes <str<strong>on</strong>g>in</str<strong>on</strong>g>creased.<br />

The reas<strong>on</strong> why <strong>the</strong> <str<strong>on</strong>g>in</str<strong>on</strong>g>crease was not obvious could be that compar<str<strong>on</strong>g>in</str<strong>on</strong>g>g with o<strong>the</strong>r type of<br />

nozzles, this type of nozzle had a <strong>relative</strong>ly steady volume median diameter with different<br />

nozzle sizes. Based <strong>on</strong> <strong>the</strong> manufacturer data, <strong>the</strong> average value of <strong>the</strong> volume median<br />

diameter of <strong>the</strong> ES nozzle was 300 μm. The <str<strong>on</strong>g>in</str<strong>on</strong>g>crease of <strong>the</strong> flow rate might also lead an<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>crease of <strong>the</strong> drift reducti<strong>on</strong> performance due to <strong>the</strong> normalizati<strong>on</strong> by divid<str<strong>on</strong>g>in</str<strong>on</strong>g>g <strong>the</strong> <strong>spray</strong><br />

output and <strong>the</strong> str<strong>on</strong>ger resistance force to w<str<strong>on</strong>g>in</str<strong>on</strong>g>d produced by more dense <strong>spray</strong>. The<br />

difference of <strong>the</strong> droplet sizes and <strong>the</strong> small flow rate might have c<strong>on</strong>tributed to <strong>the</strong> rapid<br />

<str<strong>on</strong>g>in</str<strong>on</strong>g>crease of <strong>the</strong> DIXRP values from ES05 to ES06.<br />

120.00<br />

100.00<br />

80.00<br />

60.00<br />

40.00<br />

20.00<br />

0.00<br />

-20.00<br />

1.0MPa<br />

1.5MPa<br />

ES05-1.00<br />

ES07-1.00<br />

ES09-1.00<br />

ES11-1.00<br />

ES06-1.50<br />

ES08-1.50<br />

ES10-1.50<br />

ES06-1.00<br />

ES08-1.00<br />

ES10-1.00<br />

ES05-1.50<br />

ES07-1.50<br />

ES09-1.50<br />

ES11-1.50<br />

FIGURE 2: DIXRP values obta<str<strong>on</strong>g>in</str<strong>on</strong>g>ed under different nozzle-pressure comb<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong>s of ES series<br />

nozzle with <strong>the</strong> nozzle height of 0.3m<br />

150.00<br />

100.00<br />

50.00<br />

0.00<br />

-50.00<br />

-100.00<br />

1.0MPa<br />

1.5MPa<br />

ES05-1.00<br />

ES07-1.00<br />

ES09-1.00<br />

ES11-1.00<br />

ES06-1.50<br />

ES08-1.50<br />

ES10-1.50<br />

ES06-1.00<br />

ES08-1.00<br />

ES10-1.00<br />

ES05-1.50<br />

ES07-1.50<br />

ES09-1.50<br />

ES11-1.50<br />

FIGURE 3: DIXRP values obta<str<strong>on</strong>g>in</str<strong>on</strong>g>ed under different nozzle-pressure comb<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong>s of ES series<br />

nozzle with <strong>the</strong> nozzle height of 0.4m<br />

Fig. 4 and 5 shows <strong>the</strong> <str<strong>on</strong>g>in</str<strong>on</strong>g>fluence of <strong>the</strong> nozzle pressure <strong>on</strong> <strong>the</strong> DIXRP values. Expect ES05,<br />

<strong>the</strong> DIXRP values obta<str<strong>on</strong>g>in</str<strong>on</strong>g>ed under two nozzle pressures had just a little fluctuati<strong>on</strong> to each<br />

nozzle size and no trend was found. The ma<str<strong>on</strong>g>in</str<strong>on</strong>g> reas<strong>on</strong>s might be that <strong>the</strong> <str<strong>on</strong>g>in</str<strong>on</strong>g>fluence of <strong>the</strong><br />

decrease of <strong>the</strong> droplet size <strong>on</strong> <strong>the</strong> DIXRP values was offset by <strong>the</strong> <str<strong>on</strong>g>in</str<strong>on</strong>g>crease of <strong>the</strong> flow rate<br />

and <strong>the</strong> droplet velocity when <strong>the</strong> nozzle pressure <str<strong>on</strong>g>in</str<strong>on</strong>g>creased.