Nozzle classification system in Japan based on the relative spray ...

Nozzle classification system in Japan based on the relative spray ...

Nozzle classification system in Japan based on the relative spray ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Drift Potential Index<br />

Reducti<strong>on</strong> Percentage, %<br />

Drift Potential Index<br />

Reducti<strong>on</strong> Percentage, %<br />

Drift Potential Index<br />

Reducti<strong>on</strong> Percentage, %<br />

120.00<br />

ES05-1.00 ES05-1.50<br />

100.00<br />

ES06-1.00 ES06-1.50<br />

80.00<br />

ES07-1.00 ES07-1.50<br />

60.00<br />

ES08-1.00 ES08-1.50<br />

40.00<br />

ES09-1.00 ES09-1.50<br />

20.00<br />

ES10-1.00 ES10-1.50<br />

0.00<br />

ES11-1.00 ES11-1.50<br />

-20.00<br />

05 06 07 08 09 10 11<br />

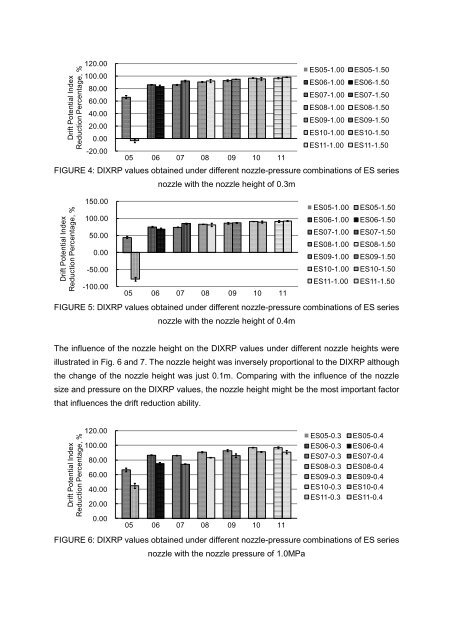

FIGURE 4: DIXRP values obta<str<strong>on</strong>g>in</str<strong>on</strong>g>ed under different nozzle-pressure comb<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong>s of ES series<br />

nozzle with <strong>the</strong> nozzle height of 0.3m<br />

150.00<br />

100.00<br />

ES05-1.00<br />

ES06-1.00<br />

ES05-1.50<br />

ES06-1.50<br />

50.00<br />

ES07-1.00<br />

ES07-1.50<br />

0.00<br />

ES08-1.00<br />

ES09-1.00<br />

ES08-1.50<br />

ES09-1.50<br />

-50.00<br />

ES10-1.00<br />

ES10-1.50<br />

-100.00<br />

05 06 07 08 09 10 11<br />

ES11-1.00<br />

ES11-1.50<br />

FIGURE 5: DIXRP values obta<str<strong>on</strong>g>in</str<strong>on</strong>g>ed under different nozzle-pressure comb<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong>s of ES series<br />

nozzle with <strong>the</strong> nozzle height of 0.4m<br />

The <str<strong>on</strong>g>in</str<strong>on</strong>g>fluence of <strong>the</strong> nozzle height <strong>on</strong> <strong>the</strong> DIXRP values under different nozzle heights were<br />

illustrated <str<strong>on</strong>g>in</str<strong>on</strong>g> Fig. 6 and 7. The nozzle height was <str<strong>on</strong>g>in</str<strong>on</strong>g>versely proporti<strong>on</strong>al to <strong>the</strong> DIXRP although<br />

<strong>the</strong> change of <strong>the</strong> nozzle height was just 0.1m. Compar<str<strong>on</strong>g>in</str<strong>on</strong>g>g with <strong>the</strong> <str<strong>on</strong>g>in</str<strong>on</strong>g>fluence of <strong>the</strong> nozzle<br />

size and pressure <strong>on</strong> <strong>the</strong> DIXRP values, <strong>the</strong> nozzle height might be <strong>the</strong> most important factor<br />

that <str<strong>on</strong>g>in</str<strong>on</strong>g>fluences <strong>the</strong> drift reducti<strong>on</strong> ability.<br />

120.00<br />

100.00<br />

80.00<br />

60.00<br />

40.00<br />

20.00<br />

ES05-0.3<br />

ES06-0.3<br />

ES07-0.3<br />

ES08-0.3<br />

ES09-0.3<br />

ES10-0.3<br />

ES11-0.3<br />

ES05-0.4<br />

ES06-0.4<br />

ES07-0.4<br />

ES08-0.4<br />

ES09-0.4<br />

ES10-0.4<br />

ES11-0.4<br />

0.00<br />

05 06 07 08 09 10 11<br />

FIGURE 6: DIXRP values obta<str<strong>on</strong>g>in</str<strong>on</strong>g>ed under different nozzle-pressure comb<str<strong>on</strong>g>in</str<strong>on</strong>g>ati<strong>on</strong>s of ES series<br />

nozzle with <strong>the</strong> nozzle pressure of 1.0MPa