SRS Product Brochure - Evapco

SRS Product Brochure - Evapco

SRS Product Brochure - Evapco

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

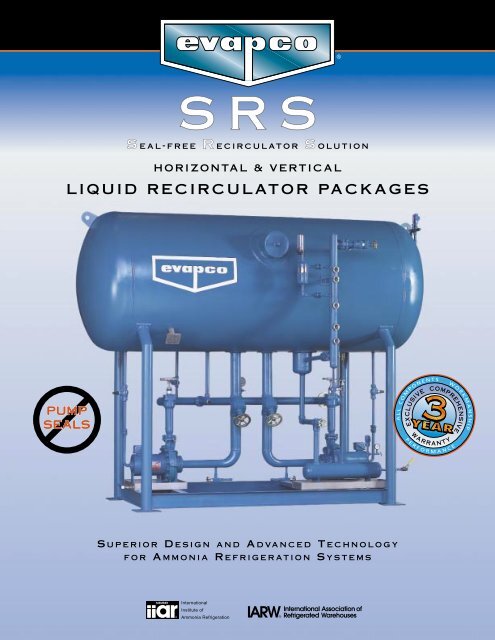

®<br />

S R S<br />

S EAL- FREE R ECIRCULATOR S OLUTION<br />

HORIZONTAL & VERTICAL<br />

LIQUID RECIRCULATOR PACKAGES<br />

PUMP<br />

SEALS<br />

S UPERIOR D ESIGN AND A DVANCED T ECHNOLOGY<br />

FOR A MMONIA R EFRIGERATION S YSTEMS<br />

International<br />

Institute of<br />

Ammonia Refrigeration

2<br />

Since its founding in 1983, Refrigeration<br />

Valves and Systems Corporation (RVS) has<br />

become the customer preferred supplier of<br />

innovative industrial refrigeration products<br />

including factory assembled, packaged<br />

recirculation systems and ASME pressure<br />

vessels of all types and sizes.<br />

RVS was acquired by EVAPCO, Inc. in 1994.<br />

EVAPCO is recognized as the leading supplier<br />

of quality heat transfer equipment to the<br />

Industrial Refrigeration, HVAC, and Process<br />

Cooling Industries. The success of<br />

EVAPCO/RVS has been the result of a<br />

continual commitment to product<br />

improvement, quality workmanship, and a<br />

dedication to providing unparalleled customer<br />

service and satisfaction.<br />

Pressure vessels and recirculator packages<br />

are manufactured to ASME requirements in<br />

two modern facilities located in Bryan, Texas<br />

and Taneytown, Maryland. With 90,000<br />

square feet of manufacturing area,<br />

EVAPCO/RVS has the capacity to handle all of<br />

your vessel and recirculator package<br />

requirements.<br />

From the smallest pressure vessel to the<br />

largest packages, EVAPCO/RVS is committed<br />

to providing superior technical support and<br />

the highest quality products with fast, on-time<br />

shipments to meet your construction<br />

schedule.<br />

© EVAPCO,INC. 2000<br />

The <strong>SRS</strong>: Seal-Free Recirculator Solution<br />

In today’s industrial refrigeration systems, a premium is placed on<br />

operational reliability, value-added features, and reduced maintenance<br />

requirements. As regulations governing refrigerant emissions increase,<br />

end-users are focusing more resources on reducing the potential for<br />

refrigerant leaks.<br />

The <strong>SRS</strong> Recirculator Package is engineered to solve these challenges<br />

with the ultimate in reliable, zero-leakage pump technology and troublefree<br />

maintenance. The <strong>SRS</strong> Recirculator Package takes factory-assembled<br />

recirculators to a higher level and reflects EVAPCO’s dedication to the<br />

continual pursuit of improving product quality and dependability.<br />

The <strong>SRS</strong> Advantage: EVAPCO extends an EXCLUSIVE 3-YEAR WARRANTY<br />

on each <strong>SRS</strong> Recirculator Package. Additionally, EVAPCO carries a<br />

complete inventory of pumps and parts to guarantee immediate availability<br />

of components in the unlikely event of a problem.<br />

All <strong>SRS</strong> Recirculator Packages are manufactured in accordance with ASME<br />

BPV Code Sec. VIII Div. 1, ANSI/ASME B31.5, ASHRAE-15, IIAR-2, and<br />

include the following features:<br />

Advanced Refrigerant Pump Technology<br />

• Featuring Buffalo ® refrigerant pumps, with over 40 years design and application<br />

experience.<br />

• Hermetically sealed, zero-leakage pump<br />

eliminates refrigerant emissions.<br />

• Absence of mechanical seals reduces<br />

maintenance requirements and costs.<br />

• No complicated protective electrical controls<br />

required to safeguard warranty coverage.<br />

• Very low NPSH requirements ensure reliable,<br />

cavitation-free operation.<br />

• Totally enclosed, liquid cooled motor with 316SS<br />

construction on all wetted parts.<br />

• Balanced, self-lubricating conical bearing design<br />

provides service life up to 50,000 hours.<br />

• Concentric axial wear pattern on bearings inhibits<br />

radial movement of shaft and prevents rotor from<br />

impacting stator.<br />

• Patented variable flow orifice imparts balanced<br />

axial thrust loads on bearings.<br />

• Self-venting, vertical centerline discharge simplifies piping and pump-downs.<br />

Finished Package Features<br />

• Standard stainless steel condensate drain pan<br />

for pumps reduces corrosion and improves<br />

equipment room cleanliness and safety.<br />

• Simplified refrigerant piping for easy access<br />

for insulation and maintenance functions.<br />

• Reduced height on horizontal units for lower<br />

shipping costs and one-piece rigging operations.<br />

• High quality surface preparation and primer application.<br />

• Dried, nitrogen blanket charged, and sealed before shipment.

ASME Accumulator<br />

• Designed and constructed for 150 psig, option for 250 psig.<br />

• National Board registered.<br />

• Increased shell length for maximum system surge volume.<br />

• Dual relief valve assembly with 3-way selector valve<br />

(shipped loose).<br />

• Sized for low refrigerant velocity to prevent liquid<br />

carryover to compressors.<br />

• Internal recirculation and vent lines reduce insulation<br />

cost and protect against shipping damage.<br />

• Stainless steel nameplate bracket and standoff.<br />

Liquid Level Control<br />

• Electronic level control with 3 easily adjustable set points.<br />

• High level float switch for positive compressor protection.<br />

• Low level shut down to prevent pump cavitation.<br />

• Five visual liquid level indicators with frost extensions.<br />

• Option available for factory mounting of liquid feed assembly.<br />

ASME Oil Pot with Relief<br />

• Low side oil recovery without<br />

system shutdown.<br />

• One common drain point for all<br />

low side oil recovery.<br />

• Standard stainless steel<br />

drain pan.<br />

Additional Options:<br />

NEMA-4, UL Listed Control Panel<br />

• Main circuit breaker<br />

disconnect.<br />

• Integral control power<br />

transformer.<br />

• Integral starter contactors.<br />

• Protection against pump<br />

motor overheating.<br />

• Factory mounting and<br />

wiring available.<br />

Factory Installed Insulation<br />

• High quality Styrofoam ® insulation.<br />

• ASJ vapor barrier.<br />

• 0.030” thick PVC jacketing.<br />

Galvanized Steel<br />

Base Available<br />

Custom Seismic<br />

Designs Available<br />

3

<strong>SRS</strong> Factory Assembled Advantages<br />

<strong>SRS</strong> Liquid Recirculator Packages are completely<br />

assembled by a factory-trained workforce dedicated to<br />

building quality refrigeration products. All packages begin<br />

with ASME code materials used for the vessel and its<br />

internals. The packages are assembled in a controlled<br />

factory environment with the industry’s highest quality<br />

components. The finished package is designed for longlife,<br />

to simplify installation, and to allow easy access for<br />

performing routine maintenance functions.<br />

The <strong>SRS</strong> reduces installation time and cost compared to the<br />

field fabricated units–the complete package is rigged into<br />

place. Extensive labor costs and coordination associated<br />

with building a package on site are reduced due to minimal<br />

refrigerant connections and welding requirements. Let<br />

EVAPCO be your single-point source for recirculator design<br />

and performance—EVAPCO personnel are dedicated to<br />

quick response time, insuring that the finished product<br />

leaves the factory according to your time requirements and<br />

project specifications.<br />

The benefits of zero-leakage hermetic pump technology are<br />

widely acknowledged. With the introduction of the new<br />

<strong>SRS</strong> Recirculator Package, EVAPCO becomes the only<br />

recirculator manufacturer willing to back up a seal-free<br />

refrigerant pump with an extended warranty to fully protect<br />

your investment. The Buffalo ® pump is a reliable, stable<br />

operating pump, requiring a simple control circuit for motor<br />

cooling protection only. Complex controls that frequently<br />

result in nuisance shutdowns and warranty disputes are not<br />

required. And in the unlikely event of a pump failure,<br />

EVAPCO maintains a stock of pumps and commits to ship<br />

out a replacement within 24 hours.<br />

<strong>SRS</strong> Recirculator Packages provide single point responsibility for recirculator<br />

pump and package performance. The combination of superior workmanship and<br />

quality materials, along with proven seal-free pump technology allows EVAPCO to<br />

offer an EXCLUSIVE 3-YEAR WARRANTY on each <strong>SRS</strong> Recirculator Package.<br />

This standard is unparralled in the refrigeration industry, and is the result of<br />

EVAPCO’s confidence and willingness to stand behind our package design,<br />

including the performance of the refrigerant pumps.<br />

4

DESCRIPTION OF OPERATION<br />

Liquid refrigerant is fed into the recirculator to maintain a<br />

controlled liquid level. The liquid is mechanically pumped<br />

to the evaporators at a rate exceeding the evaporation rate.<br />

The liquid and vapor leaving the evaporators return to the<br />

recirculator where they are separated. The liquid is<br />

recirculated through the pump to the evaporators and the<br />

dry suction gas passes to the compressors.<br />

SYSTEM ADVANTAGES OF THE <strong>SRS</strong> RECIRCULATOR<br />

• Excess feed rate optimizes evaporator performance by<br />

completely wetting the internal tube surface and<br />

maximizing heat transfer coefficients.<br />

• Recirculator vessel protects compressor(s) from liquid<br />

carryover and allows for hot gas defrosting into wet<br />

suction lines.<br />

• Excess feed rate and hot gas defrosting help to wash oil<br />

from evaporators. Oil flows with the refrigerant to the<br />

recirculator where it can be drained from one centralized<br />

location.<br />

• Pumps provide uniform flow of refrigerant to the plant<br />

regardless of condensing pressure.<br />

• Factory packaging reduces installation costs.<br />

• Vertical recirculator saves floor space in the equipment<br />

room.<br />

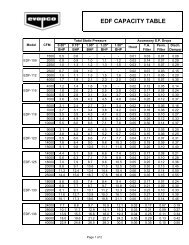

SELECTION PROCEDURE<br />

From TABLE 1, select a model with a capacity equal to or<br />

greater than the required capacity at the given saturated<br />

suction temperature.<br />

In TABLE 2, check available surge volume for model<br />

selected against required system surge volume. If<br />

available surge volume is inadequate, select next larger<br />

model with sufficient surge volume (or contact factory).<br />

Determine required pump capacity from TABLE 3.<br />

Select pump with sufficient capacity and head from<br />

TABLE 4.<br />

WHEN ORDERING PLEASE SPECIFY:<br />

Recirculator model number and pump. Please include<br />

required capacity in tons of refrigeration, saturated suction<br />

temperature, recirculation rate, surge volume, liquid feed<br />

temperature, and voltage/frequency. Also, please indicate<br />

right hand or left hand pumped liquid connection.<br />

Table 1a<br />

VERTICAL RECIRCULATOR CAPACITY - NH 3 TONS OF REFRIGERATION<br />

EVAPORATOR TEMPERATURE °F<br />

MODEL SINGLE STAGE* TWO STAGE**<br />

NO. 30°F 20°F 10°F 0°F -10°F -10°F -20°F -30°F -40°F -50°F<br />

<strong>SRS</strong>-24V 150 140 120 110 95 110 95 80 65 50<br />

<strong>SRS</strong>-30V 220 200 170 150 140 160 140 120 100 80<br />

<strong>SRS</strong>-36V 310 280 250 220 200 220 200 175 150 120<br />

<strong>SRS</strong>-42V 430 380 340 300 270 310 270 240 210 160<br />

<strong>SRS</strong>48V 560 500 450 400 350 400 350 320 270 210<br />

<strong>SRS</strong>-54V 740 660 600 520 470 540 470 420 360 280<br />

<strong>SRS</strong>-60V 920 820 730 650 580 660 580 510 450 345<br />

<strong>SRS</strong>-72V 1300 1200 1050 930 830 950 830 740 640 500<br />

<strong>SRS</strong>-84V 1800 1600 1400 1300 1100 1300 1100 1000 860 670<br />

<strong>SRS</strong>-96V 2400 2000 1900 1700 1400 1700 1500 1300 1100 880<br />

<strong>SRS</strong>-108V 3100 2600 2500 2200 1800 2100 1800 1600 1400 1100<br />

<strong>SRS</strong>-120V 3800 3200 3000 2700 2300 2600 2300 2000 1700 1400<br />

<strong>SRS</strong>-144V 5900 5300 4700 4500 3500 4600 3500 3000 2400 2000<br />

Table 1b<br />

HORIZONTAL RECIRCULATOR CAPACITY - NH 3 TONS OF REFRIGERATION<br />

EVAPORATOR TEMPERATURE °F<br />

MODEL SINGLE STAGE* TWO STAGE**<br />

NO. 30°F 20°F 10°F 0°F -10°F -10°F -20°F -30°F -40°F -50°F<br />

<strong>SRS</strong>-24H 115 110 95 85 70 80 70 60 50 40<br />

<strong>SRS</strong>-30H 195 175 160 135 120 130 120 100 80 65<br />

<strong>SRS</strong>-36H 295 265 235 195 175 200 175 150 120 100<br />

<strong>SRS</strong>-42H 410 370 310 280 250 280 250 210 170 140<br />

<strong>SRS</strong>-48H 540 490 430 365 320 365 320 270 220 180<br />

<strong>SRS</strong>-54H 790 710 630 530 470 530 470 395 325 265<br />

<strong>SRS</strong>-60H 970 875 785 655 585 650 585 485 400 320<br />

<strong>SRS</strong>-72H 1400 1270 1120 940 840 940 830 700 570 470<br />

<strong>SRS</strong>-84H 1990 1800 1600 1350 1190 1340 1190 1000 810 675<br />

<strong>SRS</strong>-96H 2620 2360 2110 1770 1570 1760 1570 1310 1080 885<br />

<strong>SRS</strong>-108H 3330 2990 2680 2250 1990 2240 1990 1670 1370 1120<br />

<strong>SRS</strong>-120H 4110 3700 3310 2780 2460 2760 2460 2060 1690 1390<br />

<strong>SRS</strong>-144H 5920 5330 4770 4000 3550 4000 3550 2980 2450 2010<br />

* Single stage assumes 96°F Max. liquid feed temperature. ** Two stage assumes 25°F Max. liquid feed temperature.<br />

5

Table 2a<br />

CAPACITY AND WEIGHTS<br />

MODEL SURGE VOLUME SHIPPING OPERATING<br />

NO. CUBIC FT. WEIGHT LBS. WEIGHT LBS.<br />

<strong>SRS</strong>-24V 17 2,800 4,450<br />

<strong>SRS</strong>-30V 25 3,120 4,740<br />

<strong>SRS</strong>-36V 35 3,530 5,310<br />

<strong>SRS</strong>-42V 48 4,590 8,160<br />

<strong>SRS</strong>-48V 70 5,960 10,490<br />

<strong>SRS</strong>-54V 86 6,690 13,050<br />

<strong>SRS</strong>-60V 110 7,070 14,530<br />

<strong>SRS</strong>-72V 140 8,210 18,270<br />

<strong>SRS</strong>-84V 190 9,980 25,580<br />

<strong>SRS</strong>-96V 250 13,300 37,300<br />

<strong>SRS</strong>-108V 320 16,680 45,220<br />

<strong>SRS</strong>-120V 390 19,380 48,980<br />

<strong>SRS</strong>-144V 510 32,300 90,300<br />

Table 2b<br />

CAPACITY AND WEIGHTS<br />

MODEL SURGE VOLUME SHIPPING OPERATING<br />

NO. CUBIC FT. WEIGHT LBS. WEIGHT LBS.<br />

<strong>SRS</strong>-24H 10 2,960 4,010<br />

<strong>SRS</strong>-30H 17 3,300 4,200<br />

<strong>SRS</strong>-36H 28 3,690 5,090<br />

<strong>SRS</strong>-42H 42 4,850 6,950<br />

<strong>SRS</strong>-48H 61 6,110 8,910<br />

<strong>SRS</strong>-54H 74 6,790 10,490<br />

<strong>SRS</strong>-60H 86 7,200 11,800<br />

<strong>SRS</strong>-72H 128 8,340 15,140<br />

<strong>SRS</strong>-84H 180 10,280 23,080<br />

<strong>SRS</strong>-96H 247 14,260 33,560<br />

<strong>SRS</strong>-108H 336 17,070 43,570<br />

<strong>SRS</strong>-120H 420 19,400 52,900<br />

<strong>SRS</strong>-144H 650 36,900 87,900<br />

Table 3<br />

PUMP CAPACITY REQUIREMENTS NH 3 FLOW GPM PER TON<br />

OVERFEED EVAPORATOR TEMPERATURE °F<br />

RATE 30°F 20°F 10°F 0°F -10°F -20°F -30°F -40°F -50°F<br />

3 : 1 .206 .201 .196 .191 .186 .182 .178 .174 .171<br />

4 : 1 .275 .268 .261 .254 .249 .243 .238 .232 .228<br />

6 : 1 .412 .401 .391 .382 .373 .364 .356 .349 .342<br />

Table 4<br />

PUMP SPECIFICATIONS<br />

PUMP MODEL MAX. GPM PSID PUMP HP<br />

E100M5 100 35 5<br />

E125L5 125 30 5<br />

E125H10 125 50 10<br />

E250L10 250 30 10<br />

*PSID based on .68 specific gravity. To correct pressure for other<br />

ammonia specific gravities, multiply PSID by SG .<br />

.68<br />

6

VERTICAL RECIRCULATOR ASSEMBLY<br />

G<br />

RETURN FROM<br />

EVAPORATORS<br />

F<br />

SUCTION TO<br />

COMPRESSORS<br />

F<br />

SUCTION TO<br />

COMPRESSORS<br />

(FRONT 90°)<br />

G<br />

RETURN FROM<br />

EVAPORATORS<br />

(BACK 90°)<br />

B<br />

C<br />

J<br />

LIQUID<br />

FEED<br />

J<br />

LIQUID<br />

FEED<br />

H<br />

PUMPED LIQUID<br />

TO EVAPORATORS<br />

H<br />

PUMPED LIQUID<br />

TO EVAPORATORS<br />

D<br />

E<br />

Diameter Length Total Ht. Base Width Base Length Dry Suct. Wet Suct. Pump Liq. Liq. Feed<br />

MODEL NO. A B C D E F G H J<br />

<strong>SRS</strong>-24V 24” 125” 193” 65” 69” 4” 5” 2” 1”<br />

<strong>SRS</strong>-30V 30” 127” 196” 65” 71” 5” 5” 2” 1-1/4”<br />

<strong>SRS</strong>-36V 36” 130” 198” 65” 72” 6” 6” 2” 1-1/4”<br />

<strong>SRS</strong>-42V 42” 133” 201” 65” 74” 6” 6” 2-1/2” 1-1/4”<br />

<strong>SRS</strong>-48V 48” 148” 216” 65” 75” 8” 8” 2-1/2” 1-1/2”<br />

<strong>SRS</strong>-54V 54” 151” 219” 65” 76” 8” 10” 3” 2”<br />

<strong>SRS</strong>-60V 60” 154” 222” 65” 78” 10” 10” 3” 2”<br />

<strong>SRS</strong>-72V 72” 160” 228” 74” 81” 10” 12” 3” 2-1/2”<br />

<strong>SRS</strong>-84V 84” 166” 234” 86” 89” 10” 12” 4” 2-1/2”<br />

<strong>SRS</strong>-96V 96” 172” 240” 98” 98” 12” 12” 4” 3”<br />

<strong>SRS</strong>-108V 108” 178” 246” 110” 107” 12” 14” 6” 4”<br />

<strong>SRS</strong>-120V 120” 184” 252” 122” 116” 14” 16” 6” 4”<br />

<strong>SRS</strong>-144V 144” 196” 264” 144” 134” 16” 18” 6” 4”<br />

Care must be taken to assure that wet suction return line is free draining to the recirculator.<br />

HORIZONTAL RECIRCULATOR ASSEMBLY<br />

RETURN FROM<br />

EVAPORATORS<br />

F<br />

B<br />

SUCTION TO LIQUID<br />

COMPRESSORS<br />

E<br />

FEED (BACK<br />

SIDE)<br />

H<br />

F<br />

RETURN FROM<br />

EVAPORATORS<br />

A<br />

E<br />

SUCTION TO<br />

COMPRESSORS<br />

C<br />

G<br />

PUMPED LIQUID<br />

TO EVAPORATORS<br />

PUMPED LIQUID<br />

TO EVAPORATORS<br />

G<br />

SPLIT<br />

PACKAGE<br />

FOR<br />

SHIPPING<br />

D 9' 0"<br />

Diameter Length Total Ht. Base Width Dry Suct. Wet Suct. Pump Liq. Liq. Feed<br />

MODEL NO. A B C D E F G H<br />

<strong>SRS</strong>-24H 24” 136-1/2” 102” 66” 4” 5” 2” 1”<br />

<strong>SRS</strong>-30H 30” 139” 102” 66” 5” 5” 2” 1-1/4”<br />

<strong>SRS</strong>-36H 36” 142” 102” 66” 6” 6” 2” 1-1/4”<br />

<strong>SRS</strong>-42H 42” 145” 108” 66” 6” 6” 2-1/2” 1-1/4”<br />

<strong>SRS</strong>-48H 48” 148” 112” 66” 8” 8” 2-1/2” 1-1/2”<br />

<strong>SRS</strong>-54H 54” 151” 121” 66” 8” 10” 3” 1-1/2”<br />

<strong>SRS</strong>-60H 60” 154” 126” 66” 10” 10” 3” 2”<br />

<strong>SRS</strong>-72H 72” 160” 138” 76” 10” 12” 3” 2-1/2”<br />

<strong>SRS</strong>-84H 84” 166” 150” 86” 10” 12” 4” 2-1/2”<br />

<strong>SRS</strong>-96H 96” 172” 177” 86” 12” 12” 4” 3”<br />

<strong>SRS</strong>-108H 108” 178” 189” 96” 12” 14” 6” 3”<br />

<strong>SRS</strong>-120H 120” 184” 201” 106” 14” 16” 6” 4”<br />

<strong>SRS</strong>-144H 144” 196” 225” 127” 16” 18” 6” 4”<br />

Care must be taken to assure that wet suction return line is free draining to the recirculator.<br />

7

EVAPCO–Your One Source<br />

for Quality Refrigeration System Components<br />

Evaporative Condensers<br />

Custom<br />

Recirculators &<br />

Vessels<br />

Induced Draft Models<br />

Forced Draft Models<br />

Cooling Towers & Closed Circuit Coolers<br />

Induced Draft Models<br />

Forced Draft Models<br />

Evaporators<br />

Horizontal & Vertical<br />

Recirculators<br />

Workroom Models Cooler and Freezer Models Custom Units<br />

EVAPCO...Taking Quality and Service to a Higher Level.<br />

World Headquarters<br />

Research/Development Center<br />

EVAPCO, Inc.<br />

P.O. Box 1300<br />

Westminster, MD 21158 USA<br />

Ph: 410-756-2600<br />

Fax: 410-756-6450<br />

E-mail: evapco@evapco.com<br />

Asia/Pacific Headquarters<br />

EVAPCO ASIA, LTD.<br />

Unit 1 G/F, Cloud Nine<br />

9 Plunkett’s Road<br />

The Peak, Hong Kong S.A.R.<br />

P.R. China<br />

Ph: (852) 2849-4100<br />

Fax: (852) 2849-5233<br />

E-mail: ktlonge@evapco.com<br />

European Sales Offices<br />

EVAPCO France S.A.R.L.<br />

5 Rue des Cerisiers<br />

Z.I. de I’Eglantier<br />

F-91090 Lisses, France<br />

Ph: (33) 1 6086-0506<br />

Fax: (33) 1 6086-3990<br />

EVAPCO Europe GmbH<br />

Bovert 22<br />

D-40670 Meerbusch, Germany<br />

Ph: (49) 2159-912367<br />

Fax: (49) 2159-912368<br />

E-mail: sturles@evapco.de<br />

EVAPCO Manufacturing Facilities<br />

Refrigeration Valves & Systems<br />

1520 Crosswind Dr.<br />

Bryan, TX 77808 USA<br />

Ph: 979-778-0095<br />

Fax: 979-778-0030<br />

E-mail: rvs@rvscorp.com<br />

EVAPCO East<br />

5151 Allendale Lane<br />

Taneytown, MD 21787 USA<br />

Ph: 410-756-2600<br />

Fax: 410-756-6450<br />

E-mail: evapco@evapco.com<br />

EVAPCO Midwest<br />

1723 York Road<br />

Greenup, IL 62428 USA<br />

Ph: 217-923-3431<br />

Fax: 217-923-3300<br />

E-mail: evapco@rr1.net<br />

EVAPCO Iowa<br />

Engineering & Sales Office<br />

285 18th St., S.E.<br />

Owatonna, MN 55060 USA<br />

Ph: 507-446-8005<br />

Fax: 507-446-8239<br />

E-mail: evapcomn@evapcomn.com<br />

Manufacturing Facility<br />

925 Quality Drive<br />

Lake View, IA 51450 USA<br />

Ph: 712-657-3223<br />

Fax: 712-657-3226<br />

E-mail: evapcoia@netins.net<br />

EVAPCO West<br />

1900 West Almond Avenue<br />

Madera, CA 93637 USA<br />

Ph: 559-673-2207<br />

Fax: 559-673-2378<br />

E-mail: evapco@lightspeed.net<br />

EVAPCO Europe, N.V.<br />

Heersterveldweg 19<br />

Industriezone, Tongeren-Oost<br />

3700 Tongeren, Belgium<br />

Ph: (32) 12-395029<br />

Fax: (32) 12-238527<br />

E-mail: evapco@pi.be<br />

EVAPCO Europe, S.R.L.<br />

Via Ciro Menotti 10,<br />

I-20017 Passirana di Rho<br />

Milano, Italy<br />

Ph: (39) 02-939-9041<br />

Fax: (39) 02-935-00840<br />

E-mail: evapco@tin.it<br />

EVAPCO Europe, S.R.L.<br />

Via Dosso, 2<br />

Piateda Sondrio, Italy 23020<br />

Air EVAPCO (Ltd.)<br />

92 Asma Fami Street, ARD El-Golf<br />

Heliopolis, Cairo, Egypt<br />

Ph: (202) 290-7483<br />

Fax: (202) 290-0892<br />

E-mail: manzlawi@egyponline.com<br />

Beijing–EVAPCO Refrigeration<br />

Equipment Co., Ltd.<br />

Yan Qi Industrial Development District<br />

Huai Rou County Beijing, P.R. China<br />

Code 101407<br />

Ph: (86) 10-6166-7238<br />

Fax: (86) 10-6166-7395<br />

E-mail: beijing@evapco.com<br />

Shanghai Hezhong–EVAPCO<br />

Refrigeration Co., Ltd.<br />

855 Yang Tai Road<br />

Bao Shan Area, Shanghai, P.R. China<br />

Code 201901<br />

Ph: (86) 21-5877-3980<br />

Fax: (86) 21-5877-2928<br />

E-mail: evapco@online.sh.cn<br />

EVAPCO S.A. (Pty.) Ltd.<br />

18 Quality Road<br />

Isando 1600<br />

Republic of South Africa<br />

Ph: (27) 11-392-6630<br />

Fax: (27) 11-392-6615<br />

E-mail: evapco@icon.ca.za<br />

Visit EVAPCO’s Website at:<br />

http://www.evapco.com<br />

Bulletin No. 505<br />

7.5M/9799/DGD